Professional Documents

Culture Documents

Vacuum Collection

Uploaded by

LoganBohannonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vacuum Collection

Uploaded by

LoganBohannonCopyright:

Available Formats

VACUUM COLLECTION SYSTEM

The powerful system that configures to your rig requirements

D

R

I

L

L

I

N

G

W

A

S

T

E

M

A

N

A

G

E

M

E

N

T

Features and Benefits

Field-Proven

Operated successfully for major

producers around the world

since 1993

Versatile

Suitable for most applications:

cuttings collection and trans-

portation; slurrification and

re-injection; rig, pit and tank

cleaning; vessel cleaning; and

fluid recovery

Safe

No hazardous moving parts

Fill sensors for automatic shut-off

Vacuum power skid is completely

contained

Customized, non-sparking blower

design with hazardous-duty class

electric motors

Explosion-proof (Class I, Zone I)

30- or 100-hp electric motor

Efficient

Maximizes filling of cuttings-

collection modules

Cuttings collection and disposal

does not interrupt drilling

Conveys fluids and cuttings

horizontally and vertically,

saving valuable rig-floor space

Skid-mounted diaphragm pump

for recycling and fluid transfer

Environmental Compliance

Designed to meet or exceed future

discharge regulations

Total Containment

Contains all drilling-waste streams

Minimizes potential

contamination during drilling

Modular Design

Flexible design allows central rig

location with remote on/off

Suitable for all rig configurations

Simple Installation

Minimal or no welding required

Makes hook-up faster and safer

Pre-installed collection pipe serves

multiple collection locations

Equipment tool box with spare

parts includes connections, pipe,

wands and hoses

Thefield-proven, cost-efficient and

safesystemthat helps youachieve

total containment for zerodischarge

The VCS unit conveys fluids and cuttings

both horizontally and vertically, saving

vital rig-floor space.

A P P L I C A T I O N S

Rigs and/or other installations requiring

an enclosed system for: cuttings collec-

tion and transportation; slurrification

and re-injection; rig, pit and tank clean-

ing; vessel cleaning; and fluid recovery.

P R O B L E M S

With growing concerns for personnel

safety, environmental issues and an

increased emphasis on saving costly

rig time, the industry has required a

totally enclosed system for collecting

and storing drilled cuttings.

S O L U T I O N S

The VACUUMCOLLECTION SYSTEM

*

(VCS*)

fromM-I SWACO* collects, moves and

stores drilled cuttings within a totally

enclosed environment that minimizes

spills and contamination.

E C O N O M I C S

In addition to preventing many safety

and environmental problems, the VCS

is easy to configure to any rig, requires

little or no welding, and sets up quickly

and easily. These same features allow

it to be moved from one location to

another in a minimal amount of time.

E N V I R O N M E N T A L

The totally enclosed system minimizes

spills and containment problems, vapor

escape or safety issues that can arise

with open systems.

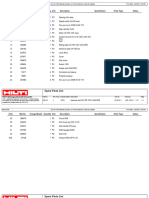

System components

Cuttings Collection Box

Patented

1

design offers safety and versatility in cuttings

handling. Features include double marine lightweight

(only 65 lb [29.5 kg]) self-sealing hatches at each end

for easy unloading, safe, one-way rupture disk valve,

square tubing to eliminate inadvertent and hazardous

gravel/cuttings pickup, and stacking frame interlocks

enabling three-high, space-saving storage. Also meets

air/hydrostatic inspection, USCG, MMS.

Cuttings Box Specifications

Cleaning of

drill floor

Cleaning of

shaker room

Cleaning of

mud pits

Reclamation

tank

Return to

mud system

Rig

vacuum

tank

Vacuum

power skid

Cleaning of

separators

Modular design allows for versatility in applications

The VCS modular components enable usage

in a wide variety of rig operations including:

Total cuttings containment

Secondary recovery where total cuttings

containment is not required

Secondary mud-recovery systems

Cuttings slurrification and

re-injection systems

Tank and vessel cleaning

Shipping cuttings to shore

Mud-spill cleanup on rig floor

Pit cleaning for mud-system change out

Liquid-waste-stream transfer

Non-hazardous oilfield-waste

minimization, recycling and cleanup

Rig shakers

Cuttings

collection boxes

Rig

vacuum

tank Vacuum

power skid

Cuttings

trough

Artificial

trough

Outlet valved

and locked

Cuttings collection and transportation

Rig- and tank-cleaning operations

Vessel transports cuttings containers

to Snorre TLP for re-injection

Vacuum lines

for rig cleanup

Rig floor

Pit room

Other

Rig shakers

Cuttings trough

Vacuum cuttings

container

RVT drop tank

Vacuum unit

Vacuumcuttings container storage

1

2

3

4

5

6

3

4

6

5

1

1

1

1

2

7

8

9

Satellite

drilling rigs

7

8

9

Interfield vacuum transport

Rig shakers

Cuttings ditch

Slurrification

unit

Fines

tank

Batch

holding

tank

Fines tank

circulating

pumps

Coarse tank

(sealed)

Coarse tank

circulating

pumps

Transfer

pump

High-pressure

injection pump

Wellhead

Vacuum units

RVT

drop tanks

Classifying

shaker

Drainwater

and slops

Seaw

ater supply

R

ig flo

o

r

O

th

er P

it

ro

o

m

Slurrification and re-injection

15-bbl Unit

Length Width Height Weight

in. (mm) in. (mm) in. (mm) lb (kg)

80 53 60 3,000

(2,032) (1,346) (1,524) (1,361)

25-bbl Unit

Length Width Height Weight

in. (mm) in. (mm) in. (mm) lb (kg)

106 70 59 5,000

(2,692) (1,778) (1,499) (2,268)

2004 M-I L.L.C. All rights reserved.*Mark of M-I L.L.C.

1

Protected by one or more of the following: U.S. Patent Nos. 5,402,857; 5,564,509;

Des. 296,027; Des. 337,809; UK Patent No. GB 2 286 615.

Other domestic and foreign patents pending.

Order No. MS-03356 2M 12/04 Litho in U.S.A.

This information is supplied solely for informational purposes and M-I SWACO

makes no guarantees or warranties, either expressed or implied, with respect to the

accuracy and use of this data. All product warranties and guarantees shall be

governed by the Standard Terms of Sale.

P.O. Box 42842

Houston, Texas 77242-2842

Tel: 2819881866

18006540660

Fax: 2819881888

www.miswaco.com

E-mail: questions@miswaco.com

Rig Vacuum Tank (RVT)

As its name implies, the RVT functions as the rigs central

vacuum-cleaner canister. Remote controlled from the rig

floor, it features strategically placed connections for vac-

uum attachments to clean critical areas . . . i.e., rig floor,

cuttings ditch, shaker house, deck areas, pit room and

loading stations. It can also function as temporary storage

during high-volume removal or as a drop tank.

Continuous Vacuum Rotary Hopper

Versatile vacuum-fed rotary hopper is an ideal solution

for operations where vacuumed materials need to be dis-

charged into separate non-vacuum-rated receptacles. The

hopper allows continuous vacuum collection along with

continuous discharge of materials into open-top slurrifica-

tion units, standard open-top cuttings containers, sturdy

lined bags or feeding of materials to cuttings dryers.

Length Width Height Weight

in. (mm) in. (mm) in. (mm) lb (kg)

60 50 65 2,000

(1,524) (1,270) (1,651) (907)

Length Width Height Weight

in. (mm) in. (mm) in. (mm) lb (kg)

56 59 72 3,200

(1,422) (1,499) (1,829) (1,451)

Holding Tanks: (2) capacity 5 bbl each

Motor (2 hp): 480 volts, 3-phase 10 Amp.

Air Flow: 100 ton/hr

RVT Tank Specifications

Rotary Hopper Specifications

To find out more about the VACUUMCOLLECTION SYSTEM

and how its performing for our customers, contact your

local M-I SWACO representative.

Vacuum Power Skid

The VACUUMCOLLECTION SYSTEMis a powerful drill

cuttings collection system designed specifically for

the oil industry. Easy to install with little or no welding

required, it minimizes costly rig time for preparation

and installation. At the heart of the system is the

Vacuum Power Skid. Patented,

1

the Quiet Vac Power

Skid features insulated noise-depression enclosure,

explosion-proof (Class I, Zone I) motors in 30 and 100 hp.

30 hp

Length Width Height Weight

in. (mm) in. (mm) in. (mm) lb (kg)

84 48 66 1,800

(2,134) (1,219) (1,676) (816)

Motor: 480 volts, 3-phase 60 amp.

Air Flow: 550 ft

3

/min (934.4 m

3

/hr)

100 hp (enclosed)

Length Width Height Weight

in. (mm) in. (mm) in. (mm) lb (kg)

109 74.5 72 12,000

(2,762) (1,892) (1,828) (5,443)

Motor: 480 volts, 3-phase 200 amp.

Air Flow: 1,541 ft

3

/min (2,618.1 m

3

/hr)

Vacuum Unit Specifications

System components

You might also like

- Method Statement For Steel Structure & Erection PDFDocument16 pagesMethod Statement For Steel Structure & Erection PDFDomie Neil Bucag Salas83% (24)

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Washing Brochure TerexDocument21 pagesWashing Brochure TerexWashington HuallpaNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Caterpillar Cat M316C WHEELED Excavator (Prefix BDX) Service Repair Manual (BDX02001 and Up) PDFDocument26 pagesCaterpillar Cat M316C WHEELED Excavator (Prefix BDX) Service Repair Manual (BDX02001 and Up) PDFfkdmmaNo ratings yet

- Cams and LociDocument15 pagesCams and LociAnonymous hlRLVcMNo ratings yet

- Kids Playhouse Plans AmazingDocument11 pagesKids Playhouse Plans Amazingnedland12No ratings yet

- Unique Drum Assembly - Sheet 1 of 2: B - 22 SD-100D TFDocument2 pagesUnique Drum Assembly - Sheet 1 of 2: B - 22 SD-100D TFRICHARD BURBANONo ratings yet

- OVIVO EWT TracVac Sludge CollectorDocument4 pagesOVIVO EWT TracVac Sludge Collectormiguel_vera6592No ratings yet

- RH Series Coiled Tubing Hangers - Wellhead Control ProductsDocument29 pagesRH Series Coiled Tubing Hangers - Wellhead Control Productsclaudio godinezNo ratings yet

- Guzzler CLDocument2 pagesGuzzler CLgshdavidNo ratings yet

- Product Catalogue PC7 Web PDFDocument15 pagesProduct Catalogue PC7 Web PDFjohnNo ratings yet

- Subsea Chokes BrochureDocument12 pagesSubsea Chokes Brochureprihartono_diasNo ratings yet

- VERTI-G Cuttings DryerDocument4 pagesVERTI-G Cuttings DryerLoganBohannon100% (1)

- Catalogues Au MyDocument28 pagesCatalogues Au MyChu Hữu LạcNo ratings yet

- Completion Tools CatalogDocument118 pagesCompletion Tools CatalogPavaniimc Mc100% (1)

- Wellhead Brochure - DP PDFDocument12 pagesWellhead Brochure - DP PDFmaso0140100% (1)

- High Efficiency Phase Separation Internals BrochureDocument8 pagesHigh Efficiency Phase Separation Internals BrochurePoncho RmzNo ratings yet

- SPT High Efficiency Phase Separation Internals BrochureDocument8 pagesSPT High Efficiency Phase Separation Internals BrochurefunctionlakeNo ratings yet

- Completion Tools Catalog PDFDocument174 pagesCompletion Tools Catalog PDFjosephbenettonNo ratings yet

- Eurovac High Volume Collector PackageDocument15 pagesEurovac High Volume Collector PackageDaniel AustinNo ratings yet

- Ejector BrochureDocument8 pagesEjector Brochurebabis1980No ratings yet

- Hydraulic SnubberDocument4 pagesHydraulic Snubberamit_mishra_52100% (2)

- XHXDocument12 pagesXHXMatias MancillaNo ratings yet

- TOP LOADING ARMS: KEY ADVANTAGES AND APPLICATIONSDocument5 pagesTOP LOADING ARMS: KEY ADVANTAGES AND APPLICATIONSjacksunyotoNo ratings yet

- Vakuumbandfilter enDocument14 pagesVakuumbandfilter enFrank Vega OrtegaNo ratings yet

- Brochure t2wDocument4 pagesBrochure t2wAnonymous kjJfuvMMNo ratings yet

- CentrexDocument16 pagesCentrexLLNo ratings yet

- Parts Catalog 02 25 15 5 PDFDocument60 pagesParts Catalog 02 25 15 5 PDFprince_oriaku1389No ratings yet

- Drain CoilDocument12 pagesDrain CoilBerlinNo ratings yet

- VORTOIL Deoiling HydrocyclonesDocument2 pagesVORTOIL Deoiling HydrocyclonesRoyster CabralNo ratings yet

- DR460 2008 BrochureDocument8 pagesDR460 2008 Brochuredeath666dark100% (1)

- Liebherr LHM 420 Mobile Harbour Crane Data Sheet EN 10492-0 PDFDocument8 pagesLiebherr LHM 420 Mobile Harbour Crane Data Sheet EN 10492-0 PDFJuan David Cabrera CardonaNo ratings yet

- Sepro Equipment BrochuresDocument26 pagesSepro Equipment BrochuresIvan Zurita100% (1)

- Drilling Products Overview Catalog PDFDocument92 pagesDrilling Products Overview Catalog PDFgerrzen64100% (3)

- 14 Waste Water Management FinalDocument6 pages14 Waste Water Management FinalmutazsalihNo ratings yet

- Bucyrus Rotary Blast DrillsDocument12 pagesBucyrus Rotary Blast DrillsManu Rojas Escobar100% (1)

- Packed Bed Tower ScrubbersDocument8 pagesPacked Bed Tower Scrubberssumit_waghmareNo ratings yet

- Coiled Tubing Workover ApplicationsDocument60 pagesCoiled Tubing Workover Applicationsak_adamNo ratings yet

- AXON 001 Drilling & Marine Packages Catalog v2014.08.27Document128 pagesAXON 001 Drilling & Marine Packages Catalog v2014.08.27Juan Pablo Villazon Richter67% (3)

- MOZLEY Wellhead DesanderDocument2 pagesMOZLEY Wellhead DesanderYosmar GuzmanNo ratings yet

- Centrifugal Separators For Industrial UseDocument6 pagesCentrifugal Separators For Industrial Use2xelacnuocNo ratings yet

- Brochure Pit Viper SeriesDocument16 pagesBrochure Pit Viper Seriesmanuel eduardo pomahuali liñanNo ratings yet

- Leading Tray TechnologyDocument20 pagesLeading Tray TechnologyMatt Agonya100% (2)

- Keller VDN VenturiDocument8 pagesKeller VDN Venturijpdavila205No ratings yet

- Dal Am A TicDocument12 pagesDal Am A TicMiguelAngelDavilaNo ratings yet

- Pumping Stations AwarenessDocument31 pagesPumping Stations Awarenessalan toomeyNo ratings yet

- Centr CalDocument32 pagesCentr CalatenciajNo ratings yet

- 07 StraddlesDocument12 pages07 StraddlesyariyantoNo ratings yet

- Marley Underground Drainage Aug 08Document17 pagesMarley Underground Drainage Aug 08David Shanks 1No ratings yet

- KR En006Document5 pagesKR En006naconnetNo ratings yet

- Types of Completion PDFDocument45 pagesTypes of Completion PDFAbdullah IshaqNo ratings yet

- Brochure Conveying Systems en 001Document15 pagesBrochure Conveying Systems en 001jack-bc100% (1)

- PetroXtractor, Groundwater Remediation Oil Skimmer - Abanaki CorporationDocument4 pagesPetroXtractor, Groundwater Remediation Oil Skimmer - Abanaki CorporationKyle ChandlerNo ratings yet

- PR BW600Document8 pagesPR BW600tata_77No ratings yet

- Super Sucker Spec SheetDocument2 pagesSuper Sucker Spec SheetSuresh100% (1)

- Sewage Treatment Plant - Super Trident STA-C and ST-CDocument4 pagesSewage Treatment Plant - Super Trident STA-C and ST-CMohd ShajiNo ratings yet

- 1440152589KKI Series 73 BrochureDocument18 pages1440152589KKI Series 73 BrochurehaidinuNo ratings yet

- Bolting Products Brochure - rb04 0712 PDFDocument9 pagesBolting Products Brochure - rb04 0712 PDFEmilio Rodríguez VillarrealNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- DrilplexDocument6 pagesDrilplexLoganBohannonNo ratings yet

- Pipeline ServicesDocument6 pagesPipeline ServicesLoganBohannonNo ratings yet

- MegadrilDocument4 pagesMegadrilLoganBohannonNo ratings yet

- Scale ManagementDocument8 pagesScale ManagementLoganBohannonNo ratings yet

- SAGDrilDocument8 pagesSAGDrilLoganBohannonNo ratings yet

- Pressure & Fluid Management SystemDocument6 pagesPressure & Fluid Management SystemLoganBohannonNo ratings yet

- IFE Marketing BrochureDocument6 pagesIFE Marketing BrochureLoganBohannonNo ratings yet

- Carbon TrackerDocument4 pagesCarbon TrackerLoganBohannonNo ratings yet

- Faze ProDocument8 pagesFaze ProLoganBohannonNo ratings yet

- EPCONDocument4 pagesEPCONLoganBohannonNo ratings yet

- RHADIANTDocument8 pagesRHADIANTLoganBohannonNo ratings yet

- Process Control & System IntegrationDocument4 pagesProcess Control & System IntegrationLoganBohannonNo ratings yet

- Safe ThermDocument6 pagesSafe ThermLoganBohannonNo ratings yet

- FloPro CTDocument4 pagesFloPro CTLoganBohannonNo ratings yet

- Di ProDocument6 pagesDi ProLoganBohannonNo ratings yet

- Seal 'N PeelDocument6 pagesSeal 'N PeelLoganBohannonNo ratings yet

- Balanced Eliptical Motion Shale Shaker (BEM-650)Document8 pagesBalanced Eliptical Motion Shale Shaker (BEM-650)LoganBohannonNo ratings yet

- Corrosion ManagementDocument6 pagesCorrosion ManagementLoganBohannon100% (1)

- Optm IzerDocument6 pagesOptm IzerLoganBohannonNo ratings yet

- Aphron Invasion Control System (ICS)Document8 pagesAphron Invasion Control System (ICS)LoganBohannonNo ratings yet

- VERTI-G Cuttings DryerDocument4 pagesVERTI-G Cuttings DryerLoganBohannon100% (1)

- Balanced Eliptical Motion Shale Shaker (BEM-600)Document6 pagesBalanced Eliptical Motion Shale Shaker (BEM-600)LoganBohannonNo ratings yet

- Ne CADDDocument4 pagesNe CADDLoganBohannon100% (1)

- PressPro RTDocument4 pagesPressPro RTLoganBohannonNo ratings yet

- Eco Toxicology LabDocument4 pagesEco Toxicology LabLoganBohannonNo ratings yet

- VersaPro LSDocument4 pagesVersaPro LSLoganBohannonNo ratings yet

- Integrated Wellbore Assurance FlowchartDocument1 pageIntegrated Wellbore Assurance FlowchartLoganBohannonNo ratings yet

- Composite OEM & Replacement ScreensDocument6 pagesComposite OEM & Replacement ScreensLoganBohannonNo ratings yet

- SilDril PDFDocument6 pagesSilDril PDFLoganBohannonNo ratings yet

- Operating Manual for Self-Priming PumpDocument9 pagesOperating Manual for Self-Priming PumpANo ratings yet

- Estimate Mechanical WorksDocument9 pagesEstimate Mechanical WorksIsrael MuhiNo ratings yet

- Ring Spinning PDFDocument45 pagesRing Spinning PDFNazmul-HassanNo ratings yet

- Cryocooler Technical Instruction, RDK-205DDocument12 pagesCryocooler Technical Instruction, RDK-205DluwerNo ratings yet

- US To India Ring SizeDocument1 pageUS To India Ring Size9c296h7my6No ratings yet

- TM Cie 2Document1 pageTM Cie 2FOODIE USNo ratings yet

- Me8595 Te II Steam Turbines Unit III-2022 - 23Document175 pagesMe8595 Te II Steam Turbines Unit III-2022 - 23CAD With RaoNo ratings yet

- Wd10j6410aw-Ax V1 EvDocument20 pagesWd10j6410aw-Ax V1 Evkarla-castellanosNo ratings yet

- Prestartup Check List of HRSGDocument3 pagesPrestartup Check List of HRSGmd abNo ratings yet

- PTC Inspector Training Manual Spark MindaDocument20 pagesPTC Inspector Training Manual Spark MindaYogiNo ratings yet

- It Re 500-SDDocument40 pagesIt Re 500-SDmarighergutNo ratings yet

- M15-MFM-78PL Drawings PheDocument1 pageM15-MFM-78PL Drawings PhefrankNo ratings yet

- HDPE Testing ProcedureDocument4 pagesHDPE Testing ProcedureaneezmhdNo ratings yet

- Defect Inspection Form@apron and Perimeter DrainDocument1 pageDefect Inspection Form@apron and Perimeter DrainMuhd Hamizan Mohd SallehNo ratings yet

- Bill - AKIJDocument3 pagesBill - AKIJm.tanjil2005No ratings yet

- Uh - 700 Manual de Servicio Taladro HiltiDocument7 pagesUh - 700 Manual de Servicio Taladro HiltiBenya MinNo ratings yet

- Group 3 Disassembly and AssemblyDocument99 pagesGroup 3 Disassembly and AssemblyBaciu NicolaeNo ratings yet

- Empty BOQ For Pricing MEPDocument26 pagesEmpty BOQ For Pricing MEPabdullah sahibNo ratings yet

- Kumkang Aluminium Formwork System PresentationsDocument36 pagesKumkang Aluminium Formwork System PresentationsMadusha Tissera100% (8)

- Bleeder VentDocument3 pagesBleeder Ventragul100% (1)

- John Deere - HANDBRAKE - Frame 5Document2 pagesJohn Deere - HANDBRAKE - Frame 5johann66No ratings yet

- SDDocument9 pagesSDrudy pumacahuaNo ratings yet

- Powertrain CAT 2Document29 pagesPowertrain CAT 2Marius Lakshan ThamelNo ratings yet

- CES Emergency and Segment Stops by Room and MachineDocument2 pagesCES Emergency and Segment Stops by Room and MachineSaurabh YadavNo ratings yet

- Jis and Fixture NotesDocument60 pagesJis and Fixture NotesMohammed KhatibNo ratings yet