Professional Documents

Culture Documents

VLE Unit (Complete)

Uploaded by

hishamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VLE Unit (Complete)

Uploaded by

hishamCopyright:

Available Formats

1

ABSTRACT

The Vapor Liquid Equilibrium Unit experiment was conducted to identify the

relationship between the vapor and liquid at equilibrium. In this experiment also, the main

aim is to construct an equilibrium curve for the methanol-water system at atmospheric

pressure. Besides that, the experiment was conducted to study the effect of initial mixture

composition upon the boiling temperature and vapor liquid phase compositions. A mixture of

methanol and water with known composition is fed into the evaporator through the valve and

the mixture will start to boil when the heater is switched on. Next, the mixture vapor will rise

up and will be cooled down by the condenser at the top of the evaporator. The liquid will fall

back into the evaporator as the vapor starts to condense. After a few minutes, the system will

stabilize and finally achieve an equilibrium state when temperature remains constant. After

that, the sample of vapor of methanol and the sample of liquid that contains methanol and

water are collected. Based on the composition of the samples, the refractive index was

determined by using refractometer. Then, we determined the relationship between the vapor

and liquid at equilibrium by drawing a graph of mole fraction of vapor against mole fraction

of liquid and a graph of temperature against mole fraction of liquid and vapor. It can be said

that from the graphs, due to high volatility of methanol than water, the composition of

methanol in vapor is higher than liquid. The experiment was successfully conducted as all the

aims were achieved.

2

INTRODUCTION

Vapor Liquid Equilibrium can be defined as a condition where a liquid and its vapor

are in equilibrium with each other. This is a condition where the rate of evaporation equals

the rate of condensation. The experiment is conducted by using Vapor Liquid Equilibrium

(VLE) unit. Pressure and temperature are very important in this experiment because they will

influence the equilibrium of vapor and liquid. In order to set and adjust the temperature to

achieve equilibrium, a temperature controller is used. There is an insulator for this unit to

minimize heat losses.

In the VLE unit experiment, two main substances used are methanol and water. Both

of them have different characteristics, therefore we need to characterize the fluids based on

their refractive index by using refractometer. Refractive index is the ratio of the velocity of

light in a vacuum to its velocity in a specified medium. The refraction occurs in the

refractometer due to the change in the speed of light as it travels through a material of one

density to one of different density.

One of the properties of methanol is the volatility of methanol is higher than water.

This is because methanol is less polar than water. Higher polarity of water means a water

molecule sticks to other water molecules more tightly, thus it tends to stay in the liquid phase.

Therefore, lots of energy and higher boiling point needed to break these attractions.

Meanwhile, methanol is less sticky and easy to enter the gaseous phase, thus it is more

volatile than water.

There are several equipments that applied the vapor liquid equilibrium concept in

industrial process such as vapor-liquid separator and distillation. Vapor-liquid separator is a

vessel which a liquid and vapor mixture is fed where the liquid is separated by gravity and

falls to the bottom of the vessel while the vapor travels upward as it exits the top of the vessel.

For distillation, a reboiler is used to provide the necessary vaporization for the distillation

process while a condenser is used to cool and condense the vapor leaving the top of the

column.

3

AIM

The objectives of the experiment are:

- To investigate the relationship between vapor and liquid at equilibrium

- To construct an equilibrium curve for the methanol and water system at

atmospheric pressure.

- To study the effect of initial mixture composition upon boiling temperature and

vapor-liquid phase compositions.

4

THEORY

Vapour-liquid equilibrium is a condition of where the liquid and vapour are in equilibrium

with each other, by means it is a condition of where the rate of evaporation is equals to the

rate of condensation.

There are theories or laws that are related to Vapor Liquid Equilibrium which are Raoults

law, Daltons law and Antoines law.

According to Gavhane, Raoults law is commonly used for predicting the vapor liquid

equilibrium for an ideal solution in equilibrium with an ideal gas mixture from the pure

component vapor pressure. Raoults law states that the equilibrium partial pressure of a

constituent or component in a solution at a given temperature is equal to the product of its

vapor pressure in the pure state and its mole fraction in the liquid phase.

For a binary system which means, a system consist of two components, if p

A

is the

equilibrium partial pressure of A, p

A

is the vapor pressure of A in the pure state and x

A

is the

mole fraction of A in the liquid phase, so we have

p

A

= p

A

x

A

p

B

= p

B

x

B

=p

B

(1-x

A

), as x

A

+ x

B

= 1

Where p

B

= equilibrium partial pressure of B

x

B

= mole fraction of B in liquid phase

= vapour pressure of pure B

Daltons law states that the total pressures exerted by a gas or vapor mixture is equal to the

sum of the partial pressure of the components present in the gas or vapor mixture. Therefore,

mathematically for binary system which is :

P = P

A

+ P

B

Where P is the total pressure.

5

Another law that is related to vapour liquid equilibrium is Antoines Law. The Antoine

equation is a vapor pressure equation. It describes the relation between vapor pressure and

temperature for pure components. The Antoine equation is derived from the Clausius

Clapeyron relation.

P

A

where P is the vapor pressure, T is temperature and A, B and C are component-specific

constants.

There are two types of diagram curve that represents the binary system, which Txy and xy

curve. Txy curve is a diagram of temperature against x and y composition, while xy curve is

x against y. X represents the liquid composition where in this experiment we use their mole

fraction, while Y is the vapour composition.

6

The above diagram shows Txy diagrams. Saturated liquid is the lower curve that gives the

mole fraction of benzene in liquid phase, x. The upper curve is the saturated vapour, that

gives the mole fraction of benzene in the vapor phase y.

The curved line is called the equilibrium line. It is defined as the compositions of the liquid

and vapor in equilibrium at a fixed pressure. For the straight line according to the figure

above, Y is equals to X.

X = Y

Where

x = mole fraction of more volatile component in liquid

y = mole fraction of more volatile component in vapour

7

APPARATUS AND MATERIALS

1) Methanol.

2) Distilled water.

3) SOLTEQ Vapour Liquid Equilibrium Unit.

4) Refractometer.

5) Sample collectors.

6) Dropper.

7) 500mL, 1000 mL and 2000 mL beakers.

8) 50 mL and 500 mL measuring cylinders.

8

PROCEDURE

General start up procedures.

1. A calibration curve of refractive index vs composition plot for the binary system was

prepared.

2. The evaporator and condenser were checked to make sure the units are empty of liquid.

3. All valves were initially closed and the heater power switch was turned off.

4. The main power on the control panel was switched on.All sensors and indicators were

checked to ensure functioning properly.

General experiment procedures.

1. The general start-up as described was performed.

2. About 12-L methanol and 5-L deionized water were prepared.

3. Valve V8 was opened.

4. 0.1-L methanol and 3-L water were poured into the evaporator through valve V1.Then,

valve V1 was closed.

5. Valves V13 and valve V14 were opened at the level sight tube.It was ensured that the

liquid level was above the safety line on the level sight tube.Then,valves V13 and V14 were

closed.

6. Valve V10 was opened and adjusted to allow about 5 L/min of cooling water to flow

through the condenser.

7. The temperature controller TIC-01 was set to about 100C.The heater was switched on.

8.The temperature rise in TIC-01 was observed.The liquid in the evaporator had started to

boil when the temperature at TIC-02 started to increase sharply.The pressure at P1-01 was

observed.All temperatures and pressure were let to stabilized at a steady state value.

9. The evaporator pressure and liquid and vapour temperatures were recorded.

9

10. Liquid and vapour sample were collected from the unit according to the sampling

procedure.The samples were analyzed to determine their compositions.

11. The heater was switched off and valve V11 was opened to allow cooling water to flow

through the cooling coil in the evaporator.

12. The temperature at T1-02 was let to drop significantly to signify that the boiling had

stopped.Valve V11 was closed.

13. An additional 0.2-L methanol was poured into the evaporator through valve

V1.Then,valve V1 was closed.There was about 0.3-L methanol and 3-L water in the

evaporator.Steps 5 to 12 above were repeated.

14. An additional 0.2-L methanol was poured again into the evaporator through valve

V1.Then valve V1 was closed.There was about 0.5-L methanol and 3-L water in the

evaporator.Steps 5 to 12 were repeated again.

15. An additional 0.5-L methanol was poured into the evaporator through valve V1.Then

valve V1 was closed.There was about 1-L methanol and 3-L water in the evaporator.Steps 5

to 12 were repeated again.

16. An additional 1-L methanol was poured into the evaporator through valve V1.Then valve

V1 was closed.There was about 2-L methanol and 3-L water in the evaporator.Steps 5 to 12

were repeated again.

17. An additional 1-L methanol was poured into the evaporator through valve V1.Then valve

V1 was closed.There was about 3-L methanol and 3-L water in the evaporator.Steps 5 to 12

were repeated again.

18. Valve V2 and V3 were opened to drain all liquid from the evaporator.

19. 2-L methanol and 1-L water were poured into the evaporator through valve V1.Then

valve V1 was closed.Steps 5 to 12 were repeated.

20. An additional 1-L methanol was poured into the evaporator through valve V1.Then valve

V1 was closed.There was about 3-L methanol and 1-L water in the evaporator.Steps 5 to 12

were repeated.

10

21. An additional 2-L methanol was poured into the evaporator through valve V1.Then valve

V1 was closed.There was about 5-L methanol and 5-L water in the evaporator.Steps 5 to 12

were repeated.

22. The general shut-down procedures were performed.

General shut-down procedures.

1. The heater was switched off.

2. Valve V10 was opened to increase cooling water flow rate through the condenser.

3. Valve V11 was opened to allow cooling water to flow through the cooling coil in the

evaporator.

4. Valve V8 was opened slowly to depressurize the unit.

5. Wait for the temperature of the unit to drop below 50C.

6. Valves V2 and V3 were opened to drain all liquid from the evaporator.

7. Valves V5 and V7 were opened to drain all liquid accumulated at the condenser.

8. All valves were closed and the main power of the control panel was switched off.

11

RESULTS

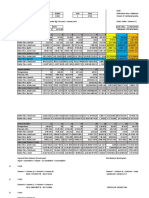

a) Vapor-Liquid Equilibrium Data

Component Temperature (C) Refractive Index (nD)

Water Methanol Vapor Liquid Vapor Liquid

3.0 0.1 86.0 96.0 1.34060 1.33470

3.0 0.3 85.4 92.9 1.33903 1.33412

3.0 0.5 84.5 90.1 1.34078 1.37506

3.0 1.0 80.5 84.6 1.34430 1.33564

3.0 2.0 76.3 78.2 1.34126 1.33581

3.0 3.0 74.7 76.0 1.34127 1.33590

Component Temperature (C) Refractive Index (nD)

Water Methanol Vapor Liquid Vapor Liquid

1.0 2.0 70.7 72.4 1.34081 1.34197

1.0 3.0 69.0 70.2 1.33997 1.34201

1.0 5.0 67.2 68.8 1.33924 1.34211

b) Calibration Table

Water

(ml)

Methanol

(ml)

Mol

Water

Mol

Methanol

Mol

Total

Methanol

Mol

Fraction

Methanol

wt%

Refractive

Index

10 0 0.556 0 0.556 0 0 1.33300

8 2 0.444 0.0494 0.4934 0.1001 16.49 1.33692

6 4 0.333 0.0986 0.4316 0.2285 34.50 1.34167

4 6 0.222 0.1481 0.3701 0.4002 54.23 1.34226

2 8 0.111 0.1975 0.3085 0.6409 75.96 1.33660

0 10 0 0.2466 0.2466 1.0000 100.00 1.33299

12

1.332

1.334

1.336

1.338

1.34

1.342

1.344

0 0.2 0.4 0.6 0.8 1 1.2

R

e

f

r

a

c

t

i

v

e

I

n

d

e

x

Mol Fraction

Graph of RI vs Mol Fraction

0

0.005

0.01

0.015

0.02

0.025

0.03

0 0.005 0.01 0.015 0.02 0.025 0.03 0.035

V

a

p

o

r

m

o

l

f

r

a

c

t

i

o

n

(

x

)

Liquid mol fraction (y)

X-Y Equilibrium Diagram

13

0

20

40

60

80

100

120

0 0.005 0.01 0.015 0.02 0.025 0.03 0.035

T

e

m

p

e

r

a

t

u

r

e

(

C

)

Vapor/Liquid mol fraction

T- xy Graph of Methanol-Water System

Vapor

Liquid

14

CALCULATIONS

*Note that the vapor pressure of methanol is 97.658 mmHg.

From Antoines Law: P

A

From Raolts Law: P

A

. P

A

where x (vapor mol fraction) can be

written as y (liquid mol fraction)

Therefore,

Antoines Constant:

Temperature

(C)

A B C Reference

80.5- 293.63

5.15853

1569.613

-34.846

Ambrose,

Sprake, et al.,

1975

15.1-103.83

5.20409 1581.341 -33.50

Ambrose and

Sprake, 1970

80-210

5.31301 1676.569 -21.728

Hirata and

Suda, 1967

15

Calculation of methanol mol fraction in vapor state.

When T = 86.0C (359 K)

0.0260

When T = 85.4C (358.4 K)

0.0222

When T = 84.5C (357.5 K)

0.0216

When T = 80.5C (353.5 K)

0.0187

16

When T = 76.3C (349.3 K)

0.0161

When T = 74.7C (347.7 K)

0.0152

When T = 70.7C (343.7 K)

0.0131

When T = 69.0C (342 K)

0.0123

When T = 67.2C (340.2 K)

0.0114

17

Calculation of methanol mol fraction in liquid state.

When T = 96.0C (369 K)

0.0317

When T = 92.9C (365.9 K)

0.0286

When T = 90.1C (363.1 K)

0.0246

When T = 84.6C (357.6 K)

0.0216

18

When T = 78.2C (351.2 K)

0.0173

When T = 76.0C (349 K)

0.0160

When T = 72.4C (345.4 K)

0.0139

When T = 70.2C (343.2 K)

0.0128

When T = 68.8C (341.8 K)

0.0122

19

Sample calculation of methanol mol fraction from calibration table.

Water : 2mL

Methanol : 8mL

Mole of water :

Mole of methanol :

Therefore,

0.6408

20

DISCUSSION

The VLE data of binary mixtures (methanol and water) of this experiment is

presented in the x-y equilibrium diagram. The y and x axis are represented by the vapor and

liquid mol fraction of the mixture respectively at different temperature. The VLE diagram

shows the bubble point and dew point of the binary mixture at constant pressure which is at 1

atmospheric pressure. Bubble point is the point at which the first drop of liquid of mixture

begins to vaporize whereas dew point is the point at which the first drop of gaseous mixture

begins to condense. The diagonal y=x serves for determination of azeotropic mixture. Based

on the plot,a curve is obtained. The curve also known as the equilibrium line represents the

compositions of vapor and liquid of the mixture at equilibrium.

By comparing the experiments equilibrium line with that of the ideal equilibrium line,

our group only managed to obtained a slightly curve equilibrium line. Human error might had

occurred, such as recording the non-steady temperature reading of the vapor and liquid unit

from TIC-01 and TIC-02 when we were supposed to get the steady temperature. These affect

the value of the vapor and liquid mol fraction calculated by using the obtained temperature

and also affect the x-y equilibrium diagram in which the ideal equilibrium line is not obtained.

An equilibrium diagram with ideal equilibrium line,using literature values of vapor

and liquid compositions(mol fractions).

21

Source: http://lorien.ncl.ac.uk/ming/distil/distilvle.htm

However, the obtained equilibrium curve from this experiment does not cross the

diagonal line to obtain azeotropic points where azeotropes occur. Azeotrope is a liquid

mixture which when vaporized, produces same composition as the liquid. Hence, the

methanol and water system is non azeotropic as the vapor does not produce same

composition as liquid when vaporized. The x-y equilibrium diagram follow Raoults

Law .Thus, we can say that the methanol-water mixture is an ideal solution.

Two VLE plots with two different azeotropic systems, one with a maximum boiling

point and one with a minimum boiling point. (non-ideal solutions)

Source: http://lorien.ncl.ac.uk/ming/distil/distilvle.htm

The graph of refractive index versus mol fraction is the calibration curve of this

experiment. The calibration curve is vital for the determination of the unknown mole

fractions of samples taken from the boiling mixtures. With the help of the curve, the T-xy

graph can be plot. However, Antoines Law can also be used to estimate the composition of

methanol in vapor and liquid state.

22

On the other hand, based on the T-xy graph of methanol- water system, the

composition (mol fraction) of liquid is higher than the composition of vapour at high

temperature. The extreme end of the graph represents the boiling point of the pure methanol

and boiling point of pure water water which is 86C and 96C respectively. Pure water has

lower vapour pressure than pure methanol. The vapour pressure of a pure substance is the

pressure exerted by the substance against the external pressure which is usually atmospheric

pressure. Vapour pressure is a measure of the tendency of a condensed substance to escape

the condensed phase. The larger the vapour pressure, the greater the tendency to escape.

When the vapour pressure of a liquid substance reaches the external pressure, the substance is

observed to boil.Hence,pure water has higher boiling point than that of methanol in the binary

system at 1 atm because it has lower vapor pressure.

23

CONCLUSION

In conclusion, the experiment is conducted successfully with some error occur. The

relationship between the vapor and liquid at equilibrium is determined where the graph of

equilibrium has been drawn. Effect of initial mixture composition upon the boiling

temperature and vapor-liquid phase compositions are also can be determine where the higher

the composition of methanol at initial, the higher will be its composition in the vapor and

liquid. As mentioned in discussion part, Antoines Law has been used to estimate the

composition of methanol in vapor and liquid state. From the result of this experiment, it can

be concluded that the composition of methanol in vapor is higher than liquid due to the

volatility of methanol which is more volatile than water. Besides, the pressure is kept

constant during the experiment which is at atmospheric pressure 1atm. Also, water has higher

boiling point than that of methanol in the binary system at 1atm because it has lower vapor

pressure.

24

RECOMMENDATION

Before and during the experiment, there are a few criteria that should be kept in mind

to ensure that the overall experiment will proceed smoothly.

First, any leftover liquid from the previous use of the VLE unit should be removed as

this can reduce a significant amount of experimental error. All the valves should be open

beforehand and collected in a waste container.

Second, the heater temperature should less than 50C when pouring in the liquids so

that rapid evaporation will not occur. This will affect the composition values of the sample.

Third, the eye level should be perpendicular to the reading on the beaker when

measuring liquid to prevent parallax error.

Lastly, the refractometer should be cleaned each time when taking a reading by

wiping its surface with a clean paper towel. This is to ensure that the refractive index of the

sample taken is obtained correctly.

25

REFERENCE

1. Wikipedia. (2014). Antoine equation. [online] Retrieved from

http://en.wikipedia.org/Antoine_equation [Accessed: 14 Apr 2014]

2. Webbook.nist.gov. (2014). Methyl Alcohol. [online] Retrieved from:

http://webbook.nist.gov/cgi/cbook.cgi?ID=C67561&Mask=4&Type=ANTOINE&Plo

t=on [Accessed: 14 Apr 2014]

3. Raoult's Law. (2008). Mass Transfer-II. [online] Available at:

http://books.google.com.my/books?id=p7FYpSuY0R8C&source=gbs_navlinks_s

[Accessed: 15 Apr 2014].

4. Wikibooks.org.(2014)Introduction to Chemical Engineering

Process.[online]Retrieved

from:http://en.wikibooks.org/wiki/Introduction_to_Chemical_Engineering_Processes/

Vapor-Liquid_equilibrium [Accessed: 14 Apr 2014]

5. Vapor Liquid Equilibrium in Binary System.[online]

Retrieved from:http://www.vscht.cz/fch/en/tools/VLE.pdf [Accessed: 14 Apr 2014]

6. Distillation.[online] Retrieved from:

http://www.umsl.edu/~orglab/documents/distillation/dist.htm [Accessed: 14 Apr

2014]

7. Boiling point Composition Diagram of a Binary System (Exp. 8.) [online] Retrieved

from:http://garfield.chem.elte.hu/Zsigy/oktatas/Pharmacy_PhysChemLab/Handouts/H

out08TL.pdf[Accessed: 14 Apr 2014]

8. Schmidt-haensch.com. 2014. What is refractometry? - Schmidt+Haensch. [online]

Available at: http://www.schmidt-haensch.com/en/knowledge/what-is-refractometry/

[Accessed: 15 Apr 2014].

9. Thermopedia.com. 2014. VAPOR-LIQUID SEPARATION. [online] Available at:

http://www.thermopedia.com/content/1236/?tid=110&sn=26 [Accessed: 15 Apr

2014].

26

APPENDIX

SOLTEQ VLE UNIT

Refractometer

You might also like

- Vle UnitDocument26 pagesVle UnitAhmad Ifwat50% (2)

- Methanol-Water VLE StudyDocument4 pagesMethanol-Water VLE StudyAmeerul AhwazNo ratings yet

- Vle (Discussion and Conclusion)Document5 pagesVle (Discussion and Conclusion)Afiqah Anuwar100% (1)

- Exp 3-Vapor-Liquid Equilibrium UnitDocument18 pagesExp 3-Vapor-Liquid Equilibrium UnitKhairulAzwanizam100% (2)

- Report VLEDocument10 pagesReport VLEaizaqsyazwan0% (1)

- Distillation Column Experiments: Pressure Drop & Composition AnalysisDocument14 pagesDistillation Column Experiments: Pressure Drop & Composition AnalysisWahida Shukori67% (3)

- Osbourne ReynoldDocument13 pagesOsbourne ReynoldN Afiqah Razak0% (1)

- Vapor-Liquid Equilibria of CCl4-Toluene MixtureDocument5 pagesVapor-Liquid Equilibria of CCl4-Toluene MixtureAakash Sharma100% (1)

- Files 2-Experiments Homogenuous Batch ReactorDocument6 pagesFiles 2-Experiments Homogenuous Batch ReactorS M AseemNo ratings yet

- Experiment 1 CSTR DynamicsDocument24 pagesExperiment 1 CSTR DynamicsFarhan Hazeeq50% (2)

- Energy BalanceDocument16 pagesEnergy BalancewizlanNo ratings yet

- Exp. 8 Diffusion of Sodium Chloride in WaterDocument6 pagesExp. 8 Diffusion of Sodium Chloride in WaterElaine Pui100% (1)

- Oil Distillation ReportDocument10 pagesOil Distillation ReportnisasoberiNo ratings yet

- Exp 2 Bubble Cap DistillationDocument7 pagesExp 2 Bubble Cap DistillationFaris HamirNo ratings yet

- Introduction For Batch Reactor ExperimentDocument5 pagesIntroduction For Batch Reactor ExperimentSaints Burner Christopher25% (4)

- Lab Report TPP Experiment 3Document10 pagesLab Report TPP Experiment 3Nurul Najwa100% (1)

- Isothermal Batch ReactorDocument10 pagesIsothermal Batch ReactorSaswiny Ritchie0% (2)

- Distillation Column Pressure Drop & Refractive IndexDocument18 pagesDistillation Column Pressure Drop & Refractive IndexAmir Al-AimanNo ratings yet

- Experiment 1B - Tubular ReactorDocument14 pagesExperiment 1B - Tubular ReactorNajmul Puda PappadamNo ratings yet

- L9-Tubular Flow ReactorDocument20 pagesL9-Tubular Flow ReactorCik Tiem Ngagiman82% (11)

- Effect of Temperature on Reaction Rate ConstantDocument22 pagesEffect of Temperature on Reaction Rate Constantnur athilahNo ratings yet

- Distillation Column EfficiencyDocument33 pagesDistillation Column EfficiencyAldi StefanusNo ratings yet

- CEV452 Lab 2 Distillation ColumnDocument22 pagesCEV452 Lab 2 Distillation ColumnAjlaa Rahim100% (1)

- Full Report Exp Batch CPPDocument18 pagesFull Report Exp Batch CPPAdiba HamidiNo ratings yet

- Discussion Tray DryerDocument3 pagesDiscussion Tray DryerIskandar ZulkarnainNo ratings yet

- Results and Discussion of CSTR in SeriesDocument3 pagesResults and Discussion of CSTR in SeriesleenzalalNo ratings yet

- Wetted Wall Column Experiment and Set UPDocument4 pagesWetted Wall Column Experiment and Set UPvarun kumarNo ratings yet

- Lab6-Tubular Flow ReactorDocument11 pagesLab6-Tubular Flow ReactorNurtasha Atikah100% (1)

- Laboratory-Scale Cooling Tower Performance AnalysisDocument17 pagesLaboratory-Scale Cooling Tower Performance AnalysisHazieqah100% (1)

- Full Report Fluid MixingDocument21 pagesFull Report Fluid Mixingsyafiq100% (1)

- Bubble Cap Distillation ColumnDocument3 pagesBubble Cap Distillation Columnnhalieza1067No ratings yet

- PFR Lab ReportDocument16 pagesPFR Lab Reportcog0812No ratings yet

- Unit Operation Laboratory 2 (CCB 3062)Document7 pagesUnit Operation Laboratory 2 (CCB 3062)Carl Erickson100% (1)

- Lab ManualDocument24 pagesLab ManualAasia FarrukhNo ratings yet

- FIXED AND FLUIDIZED BED EXPERIMENTDocument6 pagesFIXED AND FLUIDIZED BED EXPERIMENTTuğbaNo ratings yet

- Experiment: Packed Distillation ColumnDocument4 pagesExperiment: Packed Distillation Columnnhalieza1067No ratings yet

- Lab Report (Distillation)Document10 pagesLab Report (Distillation)najihahNo ratings yet

- Chapter 4Document43 pagesChapter 4aliNo ratings yet

- Heat Exchanger Lab ReportDocument15 pagesHeat Exchanger Lab ReportOmar Samir100% (1)

- Gas Absorption ReportDocument16 pagesGas Absorption ReportAlohaaSwezzNo ratings yet

- Experiment 2 - Study of Packed Column DistillationDocument7 pagesExperiment 2 - Study of Packed Column DistillationAdawiyah Az-zahra100% (1)

- CLB11003 - Exp 4Document6 pagesCLB11003 - Exp 4Nur DiyanahNo ratings yet

- Chemical Engineering Laboratory Ii: /DT Term Is Zero SinceDocument9 pagesChemical Engineering Laboratory Ii: /DT Term Is Zero SinceKayathre Raveendran100% (1)

- My Diffusion of A Gas ReportDocument22 pagesMy Diffusion of A Gas ReportEmonbeifo Efosasere100% (3)

- CONTINUOUS DistillationDocument5 pagesCONTINUOUS DistillationNaseer SattarNo ratings yet

- Climbing FilmDocument34 pagesClimbing FilmTunji Aminu100% (1)

- Experiment 1Document15 pagesExperiment 1Sarah HarunNo ratings yet

- Investigation of Liquid-Solid and Gas-Solid Fluidized BedDocument18 pagesInvestigation of Liquid-Solid and Gas-Solid Fluidized Bedmahbub1332100% (1)

- Sec01 - GroupE - (Unsteady State Heat Transfer)Document11 pagesSec01 - GroupE - (Unsteady State Heat Transfer)Dzulfadhly ShaariNo ratings yet

- Film Boiling CondensationDocument5 pagesFilm Boiling CondensationMohamad Fahmi Abd Rased100% (3)

- Q2015 Physical Chemistry Measurements Laboratory Chemistry Department, Campus Monterrey Practice # 8 Distribution CoefficientDocument4 pagesQ2015 Physical Chemistry Measurements Laboratory Chemistry Department, Campus Monterrey Practice # 8 Distribution Coefficientandres_guadiana_7362100% (1)

- Gas AbsorptionDocument24 pagesGas AbsorptionShalini Krishnan100% (1)

- Flow Patterns and Power Consumption of MixersDocument26 pagesFlow Patterns and Power Consumption of MixersNawal DaBomb100% (1)

- Sedimentation Studies Apparatus DesignDocument7 pagesSedimentation Studies Apparatus Designgrkhari1100% (2)

- Table of Content: Vapour Liquid Equilibrium Lab ReportDocument37 pagesTable of Content: Vapour Liquid Equilibrium Lab ReportLouie Shaolin Lungao0% (1)

- VLE of Methanol-Water MixtureDocument14 pagesVLE of Methanol-Water MixtureHafiniHambaliNo ratings yet

- Bachelor of Engineering (Hons) Chemical Che 465 Chemical Engineering Laboratory IDocument14 pagesBachelor of Engineering (Hons) Chemical Che 465 Chemical Engineering Laboratory IRobert HarrisNo ratings yet

- VLE Lab Report 2015ssdaDocument37 pagesVLE Lab Report 2015ssdaRafiHunJian0% (1)

- SEPARATION ProcessDocument9 pagesSEPARATION Processtalha rasoolNo ratings yet

- Midterm CaeDocument17 pagesMidterm CaeDianne AlarconNo ratings yet

- Profitibilty AnalysisDocument2 pagesProfitibilty AnalysishishamNo ratings yet

- Mass Balance and Mole BalanceDocument5 pagesMass Balance and Mole BalancehishamNo ratings yet

- E-102 LatestDocument13 pagesE-102 LatesthishamNo ratings yet

- CP For Pinch (E-101 and E-102) ..Document2 pagesCP For Pinch (E-101 and E-102) ..hishamNo ratings yet

- Faculty of Chemical Engineering: AssignmentDocument1 pageFaculty of Chemical Engineering: AssignmenthishamNo ratings yet

- Mass & Energy BalanceDocument4 pagesMass & Energy BalancehishamNo ratings yet

- E-101 LatestDocument12 pagesE-101 LatesthishamNo ratings yet

- Cash FlowDocument1 pageCash FlowhishamNo ratings yet

- Heuristics For Heat ExchangerDocument3 pagesHeuristics For Heat ExchangerhishamNo ratings yet

- Name of Lecturer: DR Jagan Group: EH 220 5B Case Study: Production of MethanolDocument7 pagesName of Lecturer: DR Jagan Group: EH 220 5B Case Study: Production of MethanolhishamNo ratings yet

- Cash FlowDocument4 pagesCash FlowhishamNo ratings yet

- Draft For Mini Project (Plant Design)Document1 pageDraft For Mini Project (Plant Design)hishamNo ratings yet

- Chapter 5 - Chemical DesignDocument104 pagesChapter 5 - Chemical DesignhishamNo ratings yet

- Full Report - Production - of - MethanolDocument67 pagesFull Report - Production - of - Methanolhisham100% (4)

- Cp composition hot stream counter flow heat exchangerDocument2 pagesCp composition hot stream counter flow heat exchangerhishamNo ratings yet

- CSTR Series Experiment Determines Concentration ResponseDocument2 pagesCSTR Series Experiment Determines Concentration ResponsehishamNo ratings yet

- Photo BioreactorDocument4 pagesPhoto BioreactorhishamNo ratings yet

- Full Report Ip Sem 4Document75 pagesFull Report Ip Sem 4hishamNo ratings yet

- List of Previous Internship PlacementsDocument78 pagesList of Previous Internship PlacementsZaidi ZakariaNo ratings yet

- Certificates SubDocument4 pagesCertificates SubhishamNo ratings yet

- Reactor Design Guide1Document27 pagesReactor Design Guide1Chau MaiNo ratings yet

- Kmspico Install EditionDocument2 pagesKmspico Install EditionYohanes BongNo ratings yet

- Energy Balance On SeparatorDocument8 pagesEnergy Balance On SeparatorhishamNo ratings yet

- CascadeDocument11 pagesCascadehishamNo ratings yet

- Assignment For EnvDocument3 pagesAssignment For EnvhishamNo ratings yet

- EXP6 TubularDocument19 pagesEXP6 TubularhishamNo ratings yet

- Final CHE625 Dec 2014Document4 pagesFinal CHE625 Dec 2014hishamNo ratings yet

- Flowmeter DemonstrationDocument21 pagesFlowmeter DemonstrationhishamNo ratings yet

- CSTRDocument2 pagesCSTRhishamNo ratings yet

- CSTR 40LDocument16 pagesCSTR 40LhishamNo ratings yet

- Assignment 1 Theoretical QuestionsDocument1 pageAssignment 1 Theoretical QuestionsNetra PujarNo ratings yet

- HSC Chemistry Notes Module 6 Acid - Base ReactionsDocument19 pagesHSC Chemistry Notes Module 6 Acid - Base Reactionsjennifergerges82No ratings yet

- Heat Transfer Solved Problems: Thermal Resistance of Composite WallDocument2 pagesHeat Transfer Solved Problems: Thermal Resistance of Composite WallKTINE08100% (2)

- Why Is Water Not Used in The Reactant KB Concentration - Google SearchDocument1 pageWhy Is Water Not Used in The Reactant KB Concentration - Google SearchNique ToniAnnNo ratings yet

- A2 Chemistry - Ionic EquilbriumDocument2 pagesA2 Chemistry - Ionic EquilbriumPaul MurrayNo ratings yet

- Rumus AntoineDocument7 pagesRumus AntoineGaluh ChynintyaNo ratings yet

- P.E.S. College of Engineering, Mandya - 571 401Document4 pagesP.E.S. College of Engineering, Mandya - 571 401KN GowdaNo ratings yet

- Thermal ExpansionDocument3 pagesThermal ExpansionSenang OrangNo ratings yet

- 15.docx 1 1Document21 pages15.docx 1 1Nathan EscobalNo ratings yet

- Lesson 13 - 2Document49 pagesLesson 13 - 2Ganesh SawhNo ratings yet

- Dew Point CalculationDocument3 pagesDew Point CalculationasdtwrNo ratings yet

- Co1 PS PDFDocument2 pagesCo1 PS PDFanon_476594787No ratings yet

- AIR CONDITIONING AND VENTILATION SYSTEM Prelim ExamDocument1 pageAIR CONDITIONING AND VENTILATION SYSTEM Prelim ExamJames Patrick TorresNo ratings yet

- NCHO Problems IIDocument1 pageNCHO Problems IIgraceNo ratings yet

- Course Code: MTPC13 Course Title: Metallurgical Thermodynamics Number of Credits 4 Prerequisites (Course Code) : Nil Course Type: PCDocument1 pageCourse Code: MTPC13 Course Title: Metallurgical Thermodynamics Number of Credits 4 Prerequisites (Course Code) : Nil Course Type: PCNags DevaNo ratings yet

- Bab Iv Hasil Dan Pembahasan A. Data Hasil PraktikumDocument4 pagesBab Iv Hasil Dan Pembahasan A. Data Hasil PraktikumGabriel MehaNo ratings yet

- All Tutorials ChE 313Document12 pagesAll Tutorials ChE 313Gio Albert BesaNo ratings yet

- Mind Map 9Document1 pageMind Map 9Ayu SuwarniNo ratings yet

- Heatsink DesignDocument15 pagesHeatsink DesignAbubakkar SiddiqNo ratings yet

- 21.4 Simple Kinetic Molecular Model of Matter CIE IGCSE Physics Practical QPDocument14 pages21.4 Simple Kinetic Molecular Model of Matter CIE IGCSE Physics Practical QPSam AliNo ratings yet

- Content: Active Site Edutech - 9844532971 (For Customized Printed Books With Logo & Name)Document38 pagesContent: Active Site Edutech - 9844532971 (For Customized Printed Books With Logo & Name)Mayuri chatpalliwarNo ratings yet

- Specific Heat LabDocument5 pagesSpecific Heat LabMuammer Yasin HacisalihoğluNo ratings yet

- Temperature and Heat - FDocument44 pagesTemperature and Heat - Fmostafa_m_ibrahim2444100% (1)

- Bubble Point and Dew Point CalculationsDocument15 pagesBubble Point and Dew Point CalculationsRawlinsonNo ratings yet

- Introduction to Heat Transfer FundamentalsDocument30 pagesIntroduction to Heat Transfer FundamentalsEdwin BatallanosNo ratings yet

- Latent Heat, Latent Heat of Vaporization - Physics@TutorVistaDocument4 pagesLatent Heat, Latent Heat of Vaporization - Physics@TutorVistaOyedotun TundeNo ratings yet

- Specific Heat Capacity StrucDocument4 pagesSpecific Heat Capacity Strucyokecheng20003826No ratings yet

- Vapour Compression SystemDocument24 pagesVapour Compression SystemAbdullahNo ratings yet

- Thermophysical properties of humid air 0-100°CDocument13 pagesThermophysical properties of humid air 0-100°CBoris Joshua Q. TeodoroNo ratings yet

- Tutorial 2 Che 433Document2 pagesTutorial 2 Che 433Mohammad AmmarNo ratings yet