Professional Documents

Culture Documents

Job Security Analysis Job Data

Uploaded by

Jeffrey Sanchez Rojas0 ratings0% found this document useful (0 votes)

33 views2 pagesHEIGHT WORK 4.1.1. Cuts, blows and hits. 4.2.1. Damage to ears. 4.3.1. Eye damage, as well as lung and throat damage. 4.4.1. Use a class a safety hat, safety boots and leather gloves. 4.2.1.1. Wear earplugs or noise cancelling headphones.

Original Description:

Original Title

Trabajo 1 (2)

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHEIGHT WORK 4.1.1. Cuts, blows and hits. 4.2.1. Damage to ears. 4.3.1. Eye damage, as well as lung and throat damage. 4.4.1. Use a class a safety hat, safety boots and leather gloves. 4.2.1.1. Wear earplugs or noise cancelling headphones.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

33 views2 pagesJob Security Analysis Job Data

Uploaded by

Jeffrey Sanchez RojasHEIGHT WORK 4.1.1. Cuts, blows and hits. 4.2.1. Damage to ears. 4.3.1. Eye damage, as well as lung and throat damage. 4.4.1. Use a class a safety hat, safety boots and leather gloves. 4.2.1.1. Wear earplugs or noise cancelling headphones.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 2

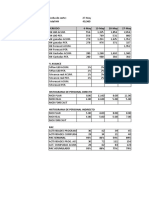

Building site: Date: Hour: Process:

Location: Supervisor work: Company:

YES/NO/N.A YES/NO/N.A

CONFINED WORK LOAD LIFTING

HEAT WORK ENERGY LOCK OTHERS

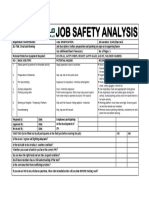

1. Prepare the surrounding

area

1.1.1.Fall at the same or different level.

1.1.2. Cuts and blows in general.

1.1.Obstacles

1.2. Sharp objects surrounding the area or on top

of the desired gathering spot.

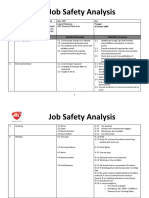

3.1.1. Fall from different level.

3.2.1. Hits, cuts and blows (essentially to the limbs).

HEIGHT WORK

4.1.1. Cuts, blows and hits.

4.2.1. Damage to ears.

4.3.1. Eye damage, as well as lung and throat

damage.

4.4.1. Hits and cuts.

2.1.1. Cuts and blows. 2.1 The hand tools themselves.

4.1.1.1. Use a class A safety hat, safety boots and leather gloves.

4.2.1.1. Wear earplugs or noise cancelling headphones.

4.3.1.1. Wear goggles and a face mask (a filter may be optional).

4.4.1.1. Wear a class A safety hat.

CONTROL MEASURES STEPS OF WORK RISKS HAZARDS

1.1.1.1. An established and properly signalized path.

1.1.1.2. Wear the proper PPE (class A safety hat, leather gloves, safety boots and overall).

4.1. Hand tools

4.2. The sound while hammering to close the

metallic form.

4.3. Concrete particles and dust

4.4. Objects above ditch

3. Enter the working area

4. Remove the form

2. Transport the hand tools

3.1. Work at height

3.2. The entrance (sharp edges) and the

workplaces walls (protruding objects of the metallic

form).

2.1.1.1. An small talk about the risks involved

2.1.1.2. Wear cotton or leather gloves.

3.1.1.1.Wear a harness with lifeline.

3.1.1.2. A supervisor to train the worker, if the work space is too reduced.

3.2.1.1.Wear leather gloves, overall, safety boots, class A safety hat, and goggles.

WORK SHEET

RISKS CONTROL MEASURES

Is there any existance of risk of falling some

material from uppers levels ?

Does exist chemical, explosive or flammable

substances in the work place can affect to people

or the environment

The routes of entry, promotion, traffic, escape and

or stairs for the personal are adequate?

Others risks?

RISKS

Does the personal can do contact with sources of

energy electric, mechanic, hydraulic, etc?

The hand tools of power and/or machines to be use

are in good conditions?

It required signalling /perimeter railings in the work

place to prevent entry or fall of people?

Does the personal have any experience about the

work?

REQUIRED WORK PERMITS

EXCAVATIONS & DITCHS

CONTROL MEASURES

JOB SECURITY ANALYSIS

EVALUATION, CONTROL & PERMITS REQUIRED

JOB DATA

REMOVAL OF A METALLIC FORM IN CONFINED SPACES

DATE & HOUR:

COMPLETE NAME : COMPLETE NAME :

SUPERVISOR WORK : PRODUCTION ENGINEER:

Cancellation

of AST

Reason:

AUTHORIZATION & CLOSURE

SIGNATURE: Leader signature of team work

in conformity of closing JSA

COMPLETE NAME & WORK POSITION SIGNATURE :

HOUR:

SIGNATURE : SIGNATURE : SIGNATURE :

SUPERVISOR WORK:

COMPLETE NAME :

5. 10.

4. 9.

8.

2.

3.

7.

1.

COMPLETE NAME DNI SIGN COMPLETE NAME DNI SIGN

6.

WORK PERSONAL

5.1.1. A collision of the falling object into the ditch

worker head.

5.2.1. Falls at same or different level.

5.3.1. Hits to others

5.3.2. Muscular damage.

5.1.1.1. A correct use of a safety helmet (Type A)

5.1.1.2. Cleaning up the work area can reduce the hazard of obstacles

5.2.1.1. Defining a safety route

5.3.1.1. Move the large form panels by 2 workers

5.3.2.1. Use back supports.

6.1.1.1. Wear a harness with lifeline.

6.1.1.2. A supervisor to train the worker, if the work space is too reduced.

6.2.1.1.Wear leather gloves, overall, safety boots, class A safety hat, and goggles.

6. Exit the work area

6.1. Work at height

6.2. The exit (sharp edges) and the workplaces

walls (protruding objects of the metallic form). 6.1.

Same as 3.1

6.1.1. Fall from different level.

6.2.1. Hits, cuts and blows (essentially to the limbs).

5.1. The ditch is considered a dangerous task.

5.2. Obstacles surrounding the workspace.

5.3. Overweight and size of the forms.

5. Transport the form

You might also like

- Jsa For Hotwork On DredgeDocument4 pagesJsa For Hotwork On DredgeOgunwa EmmanuelNo ratings yet

- Cutting, Grinding and Welding Safety ProceduresDocument3 pagesCutting, Grinding and Welding Safety ProceduresOgunwa Emmanuel100% (1)

- Gulfcon Jsa For Concreting ActivitiesDocument4 pagesGulfcon Jsa For Concreting ActivitiesOgunwa EmmanuelNo ratings yet

- Octopus Jsa For Fusion WeldingDocument2 pagesOctopus Jsa For Fusion WeldingOgunwa EmmanuelNo ratings yet

- SAND FILLING JSADocument5 pagesSAND FILLING JSAOgunwa Emmanuel0% (1)

- JSA for steel cuttingDocument1 pageJSA for steel cuttingKoneti JanardhanaraoNo ratings yet

- Jsa For Receiving and Loading of Aggregates Onto Material BargeDocument2 pagesJsa For Receiving and Loading of Aggregates Onto Material BargeOgunwa EmmanuelNo ratings yet

- JSA - Erection Boiler Install (SFILEDocument35 pagesJSA - Erection Boiler Install (SFILEHilman NugrahaNo ratings yet

- E 503 JsaDocument3 pagesE 503 Jsarizal azizanNo ratings yet

- Kta Alliance Spray /touch Up Painting of Project Materials: Job Safety Analysis (JSA)Document3 pagesKta Alliance Spray /touch Up Painting of Project Materials: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Shes Field Service - Job Safety AnalysisDocument2 pagesShes Field Service - Job Safety AnalysiseastNo ratings yet

- Job Safety Analysis: Kalco Alu System (P) LTDDocument2 pagesJob Safety Analysis: Kalco Alu System (P) LTDShekh BabulNo ratings yet

- Jha - TW - 22 - Tiling WorkDocument3 pagesJha - TW - 22 - Tiling WorkFikri HidayatNo ratings yet

- Boiler JSADocument42 pagesBoiler JSApankajbhatt376No ratings yet

- 14 - Jsa-Rain Water Harvesting Pit CleaningDocument3 pages14 - Jsa-Rain Water Harvesting Pit CleaningAKBAR ALINo ratings yet

- JSA Working at HeightDocument2 pagesJSA Working at HeightFadzira Syahira Fadzaleh100% (7)

- Shes Field Service - Job Safety AnalysisDocument2 pagesShes Field Service - Job Safety AnalysisNaz ッ WanyNo ratings yet

- JSA Confined Space To Carryout Manual Cleaning, Inspection, Grit Blasting and Painting Rev-00Document42 pagesJSA Confined Space To Carryout Manual Cleaning, Inspection, Grit Blasting and Painting Rev-00Syed Ahmed manzoor100% (1)

- Hazard Identification & Risk Analysis for Civil ReworksDocument3 pagesHazard Identification & Risk Analysis for Civil ReworksHARSHADNo ratings yet

- Risk Assesment Project VimalDocument7 pagesRisk Assesment Project VimalHASHIM TKNo ratings yet

- Abhay Ig2 XamDocument11 pagesAbhay Ig2 Xamabhilash sureshNo ratings yet

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocument1 pageJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseNo ratings yet

- Hirac TableDocument6 pagesHirac TableNor Syazwani Sharudin100% (1)

- Risk assessment of National Aluminium LLC. Ginco siteDocument23 pagesRisk assessment of National Aluminium LLC. Ginco siteNIRANJANMURTHY ASST.EXECUTVIE ENGINEERNo ratings yet

- jsa for paintingDocument3 pagesjsa for paintingNabi AkramNo ratings yet

- Job Safety Analysis for Hot Work ActivityDocument2 pagesJob Safety Analysis for Hot Work ActivityRaj Engineering ServicesNo ratings yet

- Construction Work JsaDocument21 pagesConstruction Work Jsaitsumar632No ratings yet

- 18.hot Tapping Preparation & Work.Document11 pages18.hot Tapping Preparation & Work.Zubair Ahmed KhaskheliNo ratings yet

- JSA - Foam RefillingDocument13 pagesJSA - Foam RefillingMuhammad Umar GondalNo ratings yet

- JHA For Shuttring and DeshuttringDocument2 pagesJHA For Shuttring and DeshuttringTigor GurningNo ratings yet

- Eta-Jsa Piping, Works Bolt Tightening Using Hydraulic ToolsDocument7 pagesEta-Jsa Piping, Works Bolt Tightening Using Hydraulic Toolslelu ojhaNo ratings yet

- EXPERT-JSA Structural, Piping & Welding WorksDocument9 pagesEXPERT-JSA Structural, Piping & Welding Worksarun vijayNo ratings yet

- King Faisal Air Academy Carpentry JSADocument1 pageKing Faisal Air Academy Carpentry JSAnabeelNo ratings yet

- Job Activity Hazard Effect Control Measures: Project in ChargeDocument3 pagesJob Activity Hazard Effect Control Measures: Project in Chargeperquino oasanNo ratings yet

- Construction Safety: Page 1 of 4Document4 pagesConstruction Safety: Page 1 of 4ryan.aniceteNo ratings yet

- Hira SMSDocument51 pagesHira SMSAbrar ArijitNo ratings yet

- JSA for Instrumentation WorkDocument6 pagesJSA for Instrumentation Workabhijit janaNo ratings yet

- cONSTRUCTION WORK JSADocument21 pagescONSTRUCTION WORK JSAMohammed AlshehhiNo ratings yet

- Pedestal Reinforcement JSA HSE ProfessionalsDocument1 pagePedestal Reinforcement JSA HSE ProfessionalsSamadov 13No ratings yet

- Maintaining Structural Beams SafelyDocument1 pageMaintaining Structural Beams SafelySajith C PauloseNo ratings yet

- Lizof Jsa For ExcavationDocument2 pagesLizof Jsa For ExcavationOgunwa EmmanuelNo ratings yet

- Job Hazard AnalysisDocument35 pagesJob Hazard AnalysisMichael NullasNo ratings yet

- JSA - 003 - Tripod Rig Erection, Operation and DismantlingDocument2 pagesJSA - 003 - Tripod Rig Erection, Operation and DismantlingAbhijit JanaNo ratings yet

- CBC Able Seafarer Deck NC II (II 5)Document78 pagesCBC Able Seafarer Deck NC II (II 5)Julius BagamasbadNo ratings yet

- TEXTO DE INGLES TECNICO 1pDocument50 pagesTEXTO DE INGLES TECNICO 1pMario BrossNo ratings yet

- Safety N/A Ergonomics N/A Environment 1. Dust Prone Zone. Positive Isolation & Work Permit Special Climatic ConditionsDocument8 pagesSafety N/A Ergonomics N/A Environment 1. Dust Prone Zone. Positive Isolation & Work Permit Special Climatic ConditionsAnjanav RoyNo ratings yet

- Amal A5Document4 pagesAmal A5Asif NNo ratings yet

- 38 chipping work at height -co genDocument3 pages38 chipping work at height -co genKoneti JanardhanaraoNo ratings yet

- JSA Demolition Wall B#3Document2 pagesJSA Demolition Wall B#3tit somm100% (3)

- Kti Jsa For Routine Survey ActivitesDocument1 pageKti Jsa For Routine Survey ActivitesOgunwa EmmanuelNo ratings yet

- JSA for new wear house excavation barrication Activitys gkr construction (1)Document3 pagesJSA for new wear house excavation barrication Activitys gkr construction (1)Koneti JanardhanaraoNo ratings yet

- WPA - Margaret - MINUS APPENDIXDocument13 pagesWPA - Margaret - MINUS APPENDIXlimah yahyaNo ratings yet

- Barbending HirarcDocument2 pagesBarbending HirarcSuraindran ManoharanNo ratings yet

- Barbending HiracDocument2 pagesBarbending HiracSuraindran ManoharanNo ratings yet

- JSA Mengelas Di Dalam Tanki Boiler (Rev1)Document3 pagesJSA Mengelas Di Dalam Tanki Boiler (Rev1)DanangNo ratings yet

- Able Seafarer DeckDocument7 pagesAble Seafarer DeckdraNo ratings yet

- 02-1. Risk Assessment Guide LineDocument67 pages02-1. Risk Assessment Guide LinePEng. Tech. Alvince KoreroNo ratings yet

- Barbending HiracDocument2 pagesBarbending HiracJohn Ha71% (7)

- Work Method Statement - Soil ProtectionDocument2 pagesWork Method Statement - Soil ProtectionAugust Caezar LagatNo ratings yet

- Base de Datos Proyecto A y BDocument9 pagesBase de Datos Proyecto A y BJeffrey Sanchez RojasNo ratings yet

- Base de Datos Proyecto ADocument4 pagesBase de Datos Proyecto AJeffrey Sanchez RojasNo ratings yet

- Wbs Prince TowerDocument1 pageWbs Prince TowerJeffrey Sanchez RojasNo ratings yet

- Solutions Manual: Financial Accounting: Reporting, Analysis and Decision MakingDocument61 pagesSolutions Manual: Financial Accounting: Reporting, Analysis and Decision MakingJeffrey Sanchez Rojas100% (2)

- PrimaveraDocument32 pagesPrimaveraJeffrey Sanchez RojasNo ratings yet

- The Importance of Having A Good VocabularyDocument36 pagesThe Importance of Having A Good VocabularyJeffrey Sanchez RojasNo ratings yet

- 1Document1 page1Jeffrey Sanchez RojasNo ratings yet

- PROJECTDocument2 pagesPROJECTJeffrey Sanchez RojasNo ratings yet

- Electrical Installations and Instrumentation at Vizcachas Dam and Titire Water IntakeDocument12 pagesElectrical Installations and Instrumentation at Vizcachas Dam and Titire Water IntakeJeffrey Sanchez RojasNo ratings yet

- TPO 5 Jeffrey 19 - 05 - 16 04 - 32 (ZabanExam - Com)Document6 pagesTPO 5 Jeffrey 19 - 05 - 16 04 - 32 (ZabanExam - Com)Jeffrey Sanchez RojasNo ratings yet

- EMGT Recommendation FormDocument5 pagesEMGT Recommendation FormJeffrey Sanchez RojasNo ratings yet

- Amazon Support ID#343609Document1 pageAmazon Support ID#343609Jeffrey Sanchez RojasNo ratings yet

- (READ - Download Preguntas para La Certificacion PMP: 600 Preguntas Con Explicaciones de Respuesta FULLDocument8 pages(READ - Download Preguntas para La Certificacion PMP: 600 Preguntas Con Explicaciones de Respuesta FULLJeffrey Sanchez Rojas0% (2)

- PACK2Document2 pagesPACK2Allison VasquezNo ratings yet

- Cauce PrincipalDocument1 pageCauce PrincipalJeffrey Sanchez RojasNo ratings yet

- Non ConformitiesDocument13 pagesNon ConformitiesJeffrey Sanchez RojasNo ratings yet

- P6PPM v62 QIGDocument9 pagesP6PPM v62 QIGJeffrey Sanchez RojasNo ratings yet

- Concrete Shear Wall Frame InteractionsDocument20 pagesConcrete Shear Wall Frame Interactionsrobersasmita96% (27)

- Volume ReportDocument8 pagesVolume ReportJeffrey Sanchez RojasNo ratings yet

- Jumbo 801 Round 1424Document16 pagesJumbo 801 Round 1424Jeffrey Sanchez RojasNo ratings yet

- Lec-2 Structural Steel PropertiesDocument10 pagesLec-2 Structural Steel PropertiesRifat HasanNo ratings yet

- 20MCC New Brochure Compressed-CompressedDocument22 pages20MCC New Brochure Compressed-Compressedfranchise.adajanNo ratings yet

- Glossery of Terms: AggregateDocument7 pagesGlossery of Terms: AggregateAssane RoqueNo ratings yet

- CHP SopDocument26 pagesCHP Sopkalyanm20351550% (2)

- AMMIE 2023 Conference on Advanced Materials and ManufacturingDocument9 pagesAMMIE 2023 Conference on Advanced Materials and ManufacturingrjNo ratings yet

- Alternative Filter Elements NOT FOR DISTRIBUTION (Rev.1)Document64 pagesAlternative Filter Elements NOT FOR DISTRIBUTION (Rev.1)daniel100% (1)

- QB 5 - Basic NDT - LT QBDocument5 pagesQB 5 - Basic NDT - LT QBprabhakaran.SNo ratings yet

- ZAK Expo 2023 InviteDocument6 pagesZAK Expo 2023 Inviteprajapatimanish806100% (1)

- Cable Impedance Calculations - Open ElectricalDocument4 pagesCable Impedance Calculations - Open Electricaludayakumart100% (1)

- Acids, Bases, Salts-IG ChemistryDocument16 pagesAcids, Bases, Salts-IG ChemistryRashi GhadiyaNo ratings yet

- Vendors ListDocument59 pagesVendors ListGoliBharggav100% (1)

- S# Isin CFI Code (As Per New ISO) Security Name Security Symbol Sector Name Security Type StatusDocument25 pagesS# Isin CFI Code (As Per New ISO) Security Name Security Symbol Sector Name Security Type StatusahmedalishNo ratings yet

- Coutnry Wise All Commodities 2023 by IndiaDocument9 pagesCoutnry Wise All Commodities 2023 by IndiaindienkhanNo ratings yet

- Poly (Vinyl Chloride) (PVC) Plastic Drain, Waste, and Vent (DWV) Pipe and Fittings Having Post-Industrial Recycle ContentDocument7 pagesPoly (Vinyl Chloride) (PVC) Plastic Drain, Waste, and Vent (DWV) Pipe and Fittings Having Post-Industrial Recycle Contentastewayb_964354182No ratings yet

- Dies and Inserts Catalog 2018Document36 pagesDies and Inserts Catalog 2018Ahmed MohamedNo ratings yet

- ATA24 Bombardier q400 Electrical PowerDocument85 pagesATA24 Bombardier q400 Electrical PowerAbiyot AderieNo ratings yet

- Nace Standards and Specifications Related Oil Natural Gas InfrastructureDocument5 pagesNace Standards and Specifications Related Oil Natural Gas InfrastructurePharmacist ShimaaNo ratings yet

- Warning: Keystart 9620/9621Document4 pagesWarning: Keystart 9620/9621John GarnetNo ratings yet

- Almex Light Weight BrochureDocument16 pagesAlmex Light Weight BrochureGijoNo ratings yet

- AS/NZS 3008.1.1 Amendment 1 Aug 2011 Cable Selection StandardsDocument7 pagesAS/NZS 3008.1.1 Amendment 1 Aug 2011 Cable Selection Standardslastwest1No ratings yet

- Samsung Refrigeretor - RS265TD Fast Track R2Document6 pagesSamsung Refrigeretor - RS265TD Fast Track R2Dan DrambareanuNo ratings yet

- Valve Regulated Lead Acid Battery ManualDocument22 pagesValve Regulated Lead Acid Battery Manualevanelizan100% (1)

- Stress Corrosion Cracking of ASTM A517 Steel in Liquid Ammonia - Environmental FactorsDocument11 pagesStress Corrosion Cracking of ASTM A517 Steel in Liquid Ammonia - Environmental FactorsEzzah HanifNo ratings yet

- Solid Waste Management System-1Document7 pagesSolid Waste Management System-1husnasyahidahNo ratings yet

- Astm D 6184Document3 pagesAstm D 6184김인식No ratings yet

- KSB OmegaDocument2 pagesKSB OmegaAnne 90No ratings yet

- Wieland ConnectorsDocument900 pagesWieland ConnectorsswasthikamanaramNo ratings yet

- Manuf Pacop Pink Green Blue RedDocument46 pagesManuf Pacop Pink Green Blue RedShane KimNo ratings yet

- Rehabilitation and Upgradation of Nipania- Bitkuli - Latuva - Baloda Bazar Road PackageDocument6 pagesRehabilitation and Upgradation of Nipania- Bitkuli - Latuva - Baloda Bazar Road PackageShrikishan Barbrik Joint Venture Pkg-07No ratings yet

- Zero Waste Europe Policy-Briefing Waste Prevention Framework enDocument12 pagesZero Waste Europe Policy-Briefing Waste Prevention Framework enFernanda BenedettiNo ratings yet