Professional Documents

Culture Documents

Hydra Bio Accelerator For Land Soil Remediation

Uploaded by

AmyWhite110 ratings0% found this document useful (0 votes)

14 views4 pagesHydra Bio Accelerator is a beneficial composition to reduce organic pollutants and release oxygen slowly in soil. The product is concentrated, stable and has low soluble properties. Get more details: http://grease-eater.co.uk/land-soil-remediation.html

Original Title

Hydra Bio Accelerator for Land Soil Remediation

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHydra Bio Accelerator is a beneficial composition to reduce organic pollutants and release oxygen slowly in soil. The product is concentrated, stable and has low soluble properties. Get more details: http://grease-eater.co.uk/land-soil-remediation.html

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views4 pagesHydra Bio Accelerator For Land Soil Remediation

Uploaded by

AmyWhite11Hydra Bio Accelerator is a beneficial composition to reduce organic pollutants and release oxygen slowly in soil. The product is concentrated, stable and has low soluble properties. Get more details: http://grease-eater.co.uk/land-soil-remediation.html

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Hydra Bio Accelerator is used for enhanced aerobic bioremediation.

This is a process in which organic

contaminants found in soil and/or groundwater are degraded by indigenous or inoculated microorganisms

transforming them to innocuous end products.

Enhanced bioremediation with the use of Bio Accelerator is achieved through the extended release of oxygen into

the sub-surface to supplement the rate limiting oxygen requirement by aerobic micro-organisms.

The most common pollutants that can be treated include:

BTEX (benzene, toluene, ethylbenzene and xylenes).

MTBE (methyl tertiary butyl ether).

TPH (total petroleum hydrocarbons) from light and heavy fuel oils.

Non-halogenated volatile solvents such as methylethylketone, methanol,

ethanol, acetone, ethyl acetate, acetonitrile, tert-butyl alcohol (TBA), etc.

Phenols such as phenol and cresols.

PAHs (polycyclic aromatic hydrocarbons) such as naphthalene and

methylnaphthalenes.

Some halogenated compounds such as vinyl chloride (VC), chloroben-

zenes, pentachlorophenol (PCP), etc.

High explosives.

Heavy metals can also be oxidized using Hydra Bio Accelerator

All these advantages result in a very slow oxygen profile for Hydra Bio-Accelerator which translates into enhanced

bioremediation.

Many factors affect successful bioremediation using Hydra Bio Accelerator. These include:

Concentration

Hydra Bio Accelerator has a very high active oxygen, typically 17.3% or higher.

Formulation

Hydra Bio Accelerator has a proven extended oxygen release profile. In remediation the duration of oxygen release

depends upon many factors including soil type, its pH and buffering capacity, kind of contaminants and their

concentration, the presence of other organics or metals in the soil, etc.

Stability

The stability of calcium peroxide is also a factor of its formulation. A stable product does not release its oxygen

immediately in contact with water. This would result in premature loss of oxygen before injection, which leads to

excessive foaming. Hydra Bio Accelerator is a very stable product with very little foaming propensity when mixed

with water.

Bio Accelerator

Soil & Groundwater Remediation

Slow Oxygen Release Agent

For Enhanced Aerobic Bioremediation

Hydra International Limited

Cerberian House, Carters Lane,

Kiln Farm, Milton Keynes MK11 3ER, U.K.

Tel: 01908-265889 Fax: 01908-262097

Email: sales@hydra-int.com Web Site: www.hydra-bio.com

Purity

Hydra Bio Accelerator complies with the Food Chemicals Codex for food use. Its high degree of purity further

reduces its rate of decomposition, and avoids contamination of the environment.

Solubility

Hydra Bio Accelerator has a very low solubility in water which allows the product to continue to release its active

oxygen content for many months.

Particle size

A small particle size is most suitable for producing a homogeneous slurry. It is also essential when the product is to

be injected in the soil allowing for greater horizontal penetration in the soil without clogging the pores. The low

particle size distribution of Hydra Bio Accelerator enables efficient injection into the soil.

L = Low H= High A= Amenable R= Reluctant

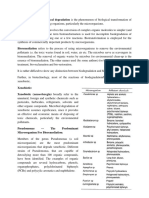

Contaminant

Category

Contaminants of

Concern (COCs)

Contaminant

Concentration

Remediation

Technology

Hydra Bio

Accelerator

BTEX Benzene, Toluene, Ethylbenzene, Xylenes L

H

Aerobic Bioremediation

Oxidation

A

A

MTBE

Methyl tert-butyl ether L

H

Aerobic Bioremediation

Oxidation

A

A

Light Fuel Oils

(LFO)

Total Petroleum Hydrocarbons (TPH) e.g.,

from kerosene, gasoline, diesel, heating oil

L

H

Aerobic Bioremediation

Oxidation

A

A

Heavy Fuel Oils

(HFO)

Total Petroleum Hydrocarbons (TPH) L

L/H

Aerobic Bioremediation

Oxidation

A

A

Non Halogenated

Volatile Solvents

Methylethylketone, tert-Butyl alcohol (TBA),

Ethanol, Methanol, Acetone, 1,4-Dioxane,

Ethyl Acetate, Acetonitrile, etc.

L

H

H

Aerobic Bioremediation

Oxidation

Aerobic Bioremediation

A

A

A

Phenols Phenol, Cresols L

H

Aerobic Bioremediation

Oxidation

A

A

PAHs Polycyclic Aromatic Hydrocarbons (rings < 3)

e.g., Naphthalene, Methylnaphthalenes

L

H

Aerobic Bioremediation

Oxidation

A

A

Polycyclic Aromatic Hydrocarbons (rings > 3)

e.g, from creosote, coal-tar, diesel fuel

L

H

Aerobic Bioremediation

Oxidation

R

R

PCBs Polychlorinated biphenyls L/H Oxidation R

High Explosives RDX, TNT, HMX, etc. L

H

Aerobic Bioremediation

Oxidation

A

A

Volatile

Halogenated

Compounds

Perchloroethylene (PCE), Trichloroethane

(TCA)

L/H Oxidation A

Trichloroethylene (TCE), Dichloroethylene

(DCE)

L

H

Aerobic Bioremediation

Oxidation

R

A

Vinyl Chloride (VC) L

H

Aerobic Bioremediation

Oxidation

A

A

Dichloroethane (DCA), Dichloromethane

(MC), Carbon Tetrachloride (CT)

L/H Aerobic Bioremediation

Oxidation

R

Semi Volatile

Halogenated

Compounds

Chlorobenzene (CB), Dichlorobenzene, Penta-

chlorophenol (PCP), etc.

L

H

H

Aerobic Bioremediation

Aerobic Bioremediation

Oxidation

A

A

A

Sulfur

Compounds

Carbon Disulfide L/H Oxidation A

Cr (VI) L/H Immobilization Sodium

Sulfite

Others L/H Oxidation + Extraction A

Heavy Metals

Other Applications

In agriculture it is used:

As fertilizing rich with oxygen.

For stimulating seed growth and their germinating power.

For pre-sowing treatment of rice seed, which allows to do planting not by seedlings, but by dry seeds. such a

technique sufficiently decreases work expenditure and increases crop capacity.

In cattle-breeding it is used:

For prophylaxis of casein-stone formation in the abomasums and diarrhea with newborn calves.

As an anti-microbic effect.

For stimulating protective organism strength

For normalizing activity of the alimentary canal

For activating digestion work.

For great increasing live-stock safety.

In poultry-raising it is used:

To decontamination of fodder

To increase productivity.

Hens safety and improving their eggs

In bakery industry it is used:

To improve bread crumb and its porosity.

To keep moisture in dough during its baking.

To initiate yeast growth.

In aquaculture it is used:

Provide sufficient dissolved oxygen.

To adjust pH value

To reduce the sub aqueous content of ammonium and nitrogen

To eliminate carbon dioxide and hydrogen sulphate.

To prevent and/anaerobe from proliferation and killing nosogenetic bacteria, defecating aqueous body of water.

In precious metal production it is used:

For leaching precious metals in the formation of cyano complexes (particularly complexes with gold or silver)

from ores, ore concentrates, and other particle-shaped, solid materials.

In waste water treatment:

Stops bad odour in sludge / municipal drains / industrial waste water caused by toxic and inflammable hydrogen

sulphide.

Improves dissolved oxygen in water by continuous and slow release of oxygen.

Destroys organic compounds and reduces COD and BOD values in effluent waters.

Neutralises acids in waste water.

Precipitates heavy metals from industrial waste water.

Precipitates phosphate from water.

Improves settling of sludge in clarifiers.

Improves dissolved oxygen in water by continuous and slow release of oxygen.

Dosage Rates

Bio Remediation:

Once you know the total mass of contaminates, you can calculate the amount of oxygen required. As a rule of thumb

3 kilos of Hydra Accelerator are required per 1 kilo of hydrocarbon.

Dosage for Oxygen-lacking Pond - Depth per metre, Dosage rate kilo per 666m2:

1 metre depth @ 2-3 kilo, 1.5 metre depth @ 3-4 kilo; 2 metre depth @ 4-5 kilo;

2.5 metre depth @ 5-6 kilo; 3 metre depth @ 6-8 kilo.

1. IDENTIFICATION Bio-Accelerator

2. HAZARDS IDENTIFICATION Irritant

3. COMPOSITION

A powder blend of Hydrogen Peroxide, Calcium, Calcium Hydroxide

4. FIRST AID MEASURES

EYES Flush with copious amounts of water and seek medical advice

SKIN Wash with soap and water

INHALATION Not applicable

INGESTION In the unlikely event of ingestion seek medical aid immediately

Give nothing by mouth to an unconscious person

5. FIRE HAZARD &

FIRE FIGHTING PROCEDURES

Non flammable

6. ACCIDENTAL RELEASE

MEASURES

SMALL SPILLS Wash away with large amounts of water

LARGE SPILLS Contain and cover spillage with neutralizing agent (Soda Ash).

Pick up and hold for waste disposal

7. HANDLING AND STORAGE Closed containers above 5

o

C. Do not mix with other chemicals

8. EXPOSURE CONTROLS AND

PERSONAL PROTECTION

RESPIRATORY PROTECTION Not applicable

VENTILATION Not applicable

PROTECTIVE GLOVES Wear PVC or Rubber Gloves as appropriate

EYE PROTECTION Wear goggles if task or application method could result in

eye contact from accidental splash or spray

OCCUPATIONAL EXPOSURE LIMIT Not applicable

9. PHYSICAL AND CHEMICAL

PROPERTIES

PHYSICAL STATE Liquid

COLOUR Blue

ODOUR Fresh

FLASHPOINT Non Flammable

SOLUBILITY Water Soluble

SPECIFIC GRAVITY 1.094 + -0.01 @ 20

o

C

10. STABILITY & REACTIVITY DATA

CHEMICAL REACTIVITY Reacts as an acid

STORAGE STABILITY Stable

INCOMPATIBILITY Do not mix with bleach or other chemicals

HAZARDOUS DECOMPOSITION None

AND COMBUSTION PRODUCTS

11. TOXICOLOGICAL INFORMATION

EYES Corrosive

SKIN Irritant

INHALATION Not applicable

INGESTION Harmful

12. ECOLOGICAL INFORMATION Not classified as dangerous to the environment

13. DISPOSAL CONSIDERATION As per current rules of local authority

14. TRANSPORTATION INFORMATION Not dangerous for transport

15. REGULATORY INFORMATION

RISK PHRASES

SAFETY PHRASES

HAZARD SYMBOL

LABELLING INFORMATION

R36/38 Irritating to eyes and skin

S24/25 Avoid contact with skin and eyes

S26 In case of contact with eyes, rinse immediately with plenty of water and seek medical advice

Irritant

16. OTHER INFORMATION 1st September 2010

The information contained in this document is provided in accordance with the requirements of Chemicals (Hazard Information & Packing) Regulations. The product should not be

used for any purpose other than as stated on the label without obtaining specific written instructions directly from the suppliers Head Office. As specific conditions of use are out-

side the suppliers control the user is responsible for ensuring the requirements of relevant legislation are complied with. The user assumes all liability for damage or injury caused

from abnormal use, failure to follow recommended practices & any hazard inherent in the nature of the product.

Material Safety Data Sheet

All the information on this sheet relates to the concentrated product only, in use dilution will decrease any possible hazard significantly.

Manufacturer

Hydra International Ltd

Cerberian House, Carters Lane, Kiln Farm, Milton Keynes MK11 3ER UK

Tel: 01908-265889 Fax: 01908-262097

E-mail: sales@hydra-int.com Web Site: www.hydra-bio.com

You might also like

- British Water - Code of Practice For Food IndustryDocument32 pagesBritish Water - Code of Practice For Food IndustryCherry RoshNo ratings yet

- Hydra Bio Blocks For Grease Trap Bacteria TreatmentDocument4 pagesHydra Bio Blocks For Grease Trap Bacteria TreatmentAmyWhite11No ratings yet

- Hydra Grease-Eater Enzyme LiquidDocument13 pagesHydra Grease-Eater Enzyme LiquidAmyWhite11No ratings yet

- Remove Bad Smell From Septic TankDocument3 pagesRemove Bad Smell From Septic TankAlen ClarkNo ratings yet

- Sewage Sludge TreatmentDocument4 pagesSewage Sludge TreatmentAmyWhite11No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Waste Management: V. Mcmahon, A. Garg, D. Aldred, G. Hobbs, R. Smith, I.E. TothillDocument11 pagesWaste Management: V. Mcmahon, A. Garg, D. Aldred, G. Hobbs, R. Smith, I.E. TothillJulian Rios OsornoNo ratings yet

- Soil WashingDocument19 pagesSoil WashingLTE002No ratings yet

- Role of Biotechnology in Improving Human HealthDocument7 pagesRole of Biotechnology in Improving Human HealthdeepaksagarNo ratings yet

- Environmental Biotechnology Book InfoDocument2 pagesEnvironmental Biotechnology Book InfoMahita SainiNo ratings yet

- Isolation and Characterization of Various Fungal Strains From Textile Effluent For Their Use in BioremediationDocument6 pagesIsolation and Characterization of Various Fungal Strains From Textile Effluent For Their Use in BioremediationIordache OvidiuNo ratings yet

- Bioremidiation of XenobioticsDocument17 pagesBioremidiation of XenobioticsRajeev PotadarNo ratings yet

- Bioremediation Techniques ExplainedDocument40 pagesBioremediation Techniques ExplainedResna N K ResiNo ratings yet

- Spent Automobile Oil Degradation Potential of Bacteria Isolates Within Makurdi Town Journal of Environmental Science April 2023Document12 pagesSpent Automobile Oil Degradation Potential of Bacteria Isolates Within Makurdi Town Journal of Environmental Science April 2023International Journal of Innovative Science and Research TechnologyNo ratings yet

- Treatment of Oil-Based Mud Cuttings Via Bio RemediationDocument1 pageTreatment of Oil-Based Mud Cuttings Via Bio RemediationMuhammad Rizwan ShahidNo ratings yet

- 55924-Article Text-94180-1-10-20100628Document5 pages55924-Article Text-94180-1-10-20100628Weixuan ZhangNo ratings yet

- Thermal Desorption Remediates SoilDocument29 pagesThermal Desorption Remediates SoilShafiaNo ratings yet

- MicrobialWorld PDFDocument20 pagesMicrobialWorld PDFرمضان كريمNo ratings yet

- Valorizacion Del Desecho de Aguas Residuales Del Prosamiento de AceitunasDocument11 pagesValorizacion Del Desecho de Aguas Residuales Del Prosamiento de AceitunasJalcamNo ratings yet

- 8th Gogreen Summit focuses on shaping a greener futureDocument9 pages8th Gogreen Summit focuses on shaping a greener futureAnisatus Sa'iedahNo ratings yet

- World Congress on Biotechnology PostersDocument32 pagesWorld Congress on Biotechnology PostersFiqa SuccessNo ratings yet

- Soil Sampling at LandfillDocument20 pagesSoil Sampling at LandfillSITI FARHANA ABDUL RAOFNo ratings yet

- Crude Oil Spiled Water TreatmentDocument9 pagesCrude Oil Spiled Water TreatmentDicky Andre SaputraNo ratings yet

- The Effect of Cassava Effluent and Empty Oil Palm Fruit Bunch On Remediation of Petroleum Polluted Soil and Crop Production in The Tropics A ReviewDocument13 pagesThe Effect of Cassava Effluent and Empty Oil Palm Fruit Bunch On Remediation of Petroleum Polluted Soil and Crop Production in The Tropics A ReviewIchipi-ifukor Patrick ChukuyenumNo ratings yet

- Recent Advances in Glyphosate BiodegradationDocument11 pagesRecent Advances in Glyphosate BiodegradationYudhaNo ratings yet

- Dp-40 Dye Penetrant 20091105Document14 pagesDp-40 Dye Penetrant 20091105normansetonNo ratings yet

- Bioremediation of Hexavalent Chromium in Wastewater Effluent by Pseudomonas Putida (MTCC 102)Document7 pagesBioremediation of Hexavalent Chromium in Wastewater Effluent by Pseudomonas Putida (MTCC 102)safiraNo ratings yet

- UntitledDocument21 pagesUntitledPravinNo ratings yet

- 1 PBDocument8 pages1 PBAnissa SitumorangNo ratings yet

- 2009-10 T.Y.B.Sc. BiotechnologyDocument18 pages2009-10 T.Y.B.Sc. BiotechnologyStacy Sabrina VazNo ratings yet

- Pesticide Biodegradation: Mechanisms, Genetics and Strategies To Enhance The ProcessDocument39 pagesPesticide Biodegradation: Mechanisms, Genetics and Strategies To Enhance The ProcessLia MaldivesNo ratings yet

- Contaminated Land Management and Control Guidelines No-3 - Remediation of Contaminated SitesDocument51 pagesContaminated Land Management and Control Guidelines No-3 - Remediation of Contaminated Siteshard studyNo ratings yet

- Biostimulation Treatments of Hydrocarbon-Contaminated SoilDocument6 pagesBiostimulation Treatments of Hydrocarbon-Contaminated SoilGeorgian-Răzvan CheșcaNo ratings yet

- BT503 FINAL TERM by DINNING DISSCUSION-1Document37 pagesBT503 FINAL TERM by DINNING DISSCUSION-1JawadNo ratings yet

- 2006 Bioremediation - in - Shrimp - Culture - SystemsDocument6 pages2006 Bioremediation - in - Shrimp - Culture - SystemsChristian LeonNo ratings yet

- Jntuk M Tech r16 Ee SyllabusDocument28 pagesJntuk M Tech r16 Ee SyllabusRamya SriNo ratings yet