Professional Documents

Culture Documents

Oil Manual Rev 01

Uploaded by

HosseinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oil Manual Rev 01

Uploaded by

HosseinCopyright:

Available Formats

Petrofac International Ltd.

Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

,tartu- and

O-eratin. /anual

Oil Processin. Facilities

For

Dorood Onshore Facilities & e! Plant

0har. Island

Elf Petroleum Iran

Doc o.1 I" #$ %11 &$$ %%$$$ P"' ($1)

Pre-ared 23

Petrofac International Ltd.

JI-163

"e+ o. Date Pre-ared 23 'erified 23 %--ro+ed 23

01 Feb. 2004 PFI G.Faber P.L. dHaussy

Page 1 of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

4%5LE OF 6O4E4,

1 I4"OD764IO............................................................................................................ 8

1.1 Project ,co-e......................................................................................................... 9

1.: ;eneral Descri-tion of the Facilit3.......................................................................)

1.2.1 Plant Capactes................................................................................................ 9

1.2.2 !ns"ore Ppelnes............................................................................................ 9

1.2.# !l $reat%ent.................................................................................................. 10

1.2.4 Gas $reat%ent and Co%presson...................................................................11

1.2.& 'ea(ater $reat%ent and In)ecton..................................................................11

1.2.* Produced +ater $reat%ent.............................................................................12

1.2., Flarng 'yste%s.............................................................................................. 12

1.2.- Fuel Gas 'yste%............................................................................................ 12

1.2.9 !t"er .tltes (t"n /e( Plant.......................................................................12

1.2.10 0uldngs......................................................................................................... 1#

1.3 5asis of Desi.n.................................................................................................... 1#

1.#.1 1esgn 0ass for 1orood #..............................................................................14

1.#.2 Flo( 2ates...................................................................................................... 14

1.# Fluid 6om-osition............................................................................................... 16

1.4.1 Producton Flud.............................................................................................. 1*

1.4.2 In)ecton Gas................................................................................................... 1*

1.4.# 'ea(ater........................................................................................................ 1,

1.4.4 Produced +ater.............................................................................................. 1-

1.( ,ite and /eteorolo.ical Data..............................................................................1)

1.&.1 !ns"ore 1esgn Condtons............................................................................19

1.&.2 !ffs"ore 1esgn Condtons............................................................................19

1.&.# Cl%atc Condton........................................................................................... 20

: P"O6E,, DE,6"IP4IO OF OIL P"O6E,,I; ,<,4E/,....................................:1

:.1 O+er+ie!............................................................................................................... :1

:.: Oil Producer =ellheads and Production /anifolds..........................................:1

2.2.1 Introducton on !l Producton.........................................................................21

2.2.2 +ell"eads....................................................................................................... 22

2.2.# Gat"erng 'yste%........................................................................................... 2#

2.2.4 Control 3 4ontorng....................................................................................... 2&

:.3 ,e-arator section................................................................................................ :9

2.#.1 Prncple of 'eparaton of +ater fro% !l n 'eparators..................................2-

2.#.2 1

st

'tage 'eparator......................................................................................... ##

2.#.# $est 'eparator................................................................................................ #,

2.#.4 LP 'eparator Feed Pre"eater5 6C7#1# 8909C91.............................................40

2.#.& 'econd 'tage 'eparator5 1'7#02...................................................................41

2.#.* !l 0ooster Pu%ps5 G: #10 890.....................................................................44

:.# Desalter ,ection................................................................................................... #6

2.4.1 Prncple of operaton...................................................................................... 4*

2.4.2 1esalters5 1' #20 890....................................................................................49

2.4.# +ater Crculaton Pu%ps5 G: #20 890............................................................&2

:.( ,ta2ili>er ,ection................................................................................................. ((

2.&.1 'tabl;er colu%n5 C8 #10...............................................................................&&

2.&.2 'tabl;er 2eboler5 6C #10.............................................................................&*

Page 2 of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

:.6 Product crude -um-in.?coolin..........................................................................()

2.*.1 'tabl;ed !l Pu%ps5 G: #11 890..................................................................&9

2.*.2 Feed 9 0otto%s 6<c"anger5 6C #1# 8909C91..................................................&9

2.*.# 'tabl;ed !l cooler5 60 #11 8909C91.............................................................&9

2.*.4 'tabl;ed !l $r% Cooler5 6C #12..................................................................*0

2.*.& !FF 'P6C Pu%ps5 G: #12 890.....................................................................*1

2.*.* !l 6<port lne................................................................................................. *2

:.8 Oil3 =ater 4reatment ,ection.............................................................................6(

:.9 @3drate miti.ation............................................................................................... 8$

2.-.1 Hydrate $endency........................................................................................... ,0

2.-.2 4n%u% Flo( for Producton Lnes................................................................,0

2.-.# 4n%u% Flo( for $est Lnes..........................................................................,#

2.-.4 '"utdo(n Condtons......................................................................................,*

:.) 6hemical Injection for Oil ,3stem......................................................................89

:.1$ @3drod3namic 6onsideration for the Pi-elines and the e! -lant.............91

2.10.1 Hydrodyna%c sluggng..................................................................................-1

2.10.2 '"utdo(n and 2estart....................................................................................-1

3 P"O6E,, 6O4"OL.................................................................................................. 93

3.1 6ontrol ,3stem Descri-tion................................................................................93

#.1.1 Process =producton> Control Functons =PC'>...............................................-#

#.1.2 Process =producton> '"utdo(n Functons =P''>...........................................-#

#.1.# PC'9P'' 'yste% General descrpton...........................................................-#

#.1.4 ''' '.0 '?'$64....................................................................................... -&

#.1.& FI26 3 G8' '.0 '?'$64. =FG'>................................................................-&

#.1.* 6lectrcal /et(or@ 4anage%ent 'yste%........................................................-*

#.1., 1C' $ranng '%ulator..................................................................................-*

#.1.- Aetty PC'9P''............................................................................................... -*

#.1.9 4an 4ac"ne Interface...................................................................................-,

3.: Process 6ontrol arrati+e...................................................................................99

#.2.1 Producton +ell"eads5 Flo( lnes and 4anfolds............................................--

#.2.2 'eparator 'ecton........................................................................................... -9

#.2.# 1esalter.......................................................................................................... 92

#.2.4 'tabl;er......................................................................................................... 94

#.2.& Product pu%png9coolng................................................................................9&

#.2.* !ly +ater $reat%ent 'yste%.........................................................................9*

# %L%"/,* 4"IP,* E,D %D EA7IP/E4 P"O4E64IO..........................................)8

#.1 P6, %larm ,et Point............................................................................................ )8

#.: E,D 4ri- %larm ,et Point..................................................................................1$1

#.3 Fire &;as ,3stem.............................................................................................. 1$(

#.# "elief 'al+es....................................................................................................... 1$6

#.( 5lo! do!n 'al+es.............................................................................................. 1$6

#.6 Emer.enc3 ,hutdo!n 'al+es...........................................................................1$8

( ,%FE4<..................................................................................................................... 1$9

(.1 Plant La3out....................................................................................................... 1$9

(.: Emer.enc3 ,hutdo!n ,3stem..........................................................................11$

&.2.1 !b)ectBe....................................................................................................... 110

&.2.2 'yste% 8rc"tecture...................................................................................... 110

&.2.# General Prncples......................................................................................... 110

Page # of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

&.2.4 6'1 Control Logc........................................................................................ 112

&.2.& Process '"utdo(n Logc...............................................................................112

&.2.* Cluster '"utdo(n Logc................................................................................114

(.3 Fire & ;as ,3stem............................................................................................. 11(

&.#.1 !b)ectBe....................................................................................................... 11&

&.#.2 F3G 'ub7'yste% 1escrpton.......................................................................11&

&.#.# $"e 'electon and Locaton of F3G 1etectors..............................................11*

&.#.4 Cotng Logc and 8ctons...............................................................................11-

(.# "elief and De-ressurisation ,3stems..............................................................11)

(.( Flare ,3stems..................................................................................................... 11)

(.6 Draina.e and ,-ill 6ontainment.......................................................................11)

(.8 Fire Protection ,3stem...................................................................................... 1:$

&.,.1 8ctBe Fre Protecton....................................................................................120

&.,.2 PassBe Fre Protecton.................................................................................120

(.9 Emer.enc3* E+acuation and "escue BEE"C Philoso-h3.................................1:1

&.-.1 Goals............................................................................................................ 121

&.-.2 6scape 2outes............................................................................................. 121

&.-.# 4uster 8rea.................................................................................................. 122

(.) "adio 6ommunication and P%;% ,3stem.......................................................1:3

&.9.1 General prncples......................................................................................... 12#

&.9.2 $ypes of 8lar%s............................................................................................ 124

&.9.# ProBsons at !ff7stes...................................................................................12&

(.1$ ,afet3 ,i.ns & Personnel Protection...........................................................1:(

&.10.1 'afety 'gns................................................................................................. 12&

&.10.2 Personnel Protecton.................................................................................... 12&

(.11 Emer.enc3 Po!er ,3stem............................................................................1:8

(.1: Li.htin............................................................................................................ 1:9

(.13 oise............................................................................................................... 1:9

6 ,4%"4 7P P"O6ED7"E,........................................................................................ 1:)

8 OPE"%4I; P"O6ED7"E,.....................................................................................13$

9 ,@74DO= P"O6ED7"E,.....................................................................................131

) 4"O75LE,@OO4I;............................................................................................... 13:

).1 /anifolds............................................................................................................ 13:

).: ,e-arators.......................................................................................................... 133

).3 Desalter.............................................................................................................. 13(

1$ %PPEDI6E,......................................................................................................... 138

1$.1 Effluent =ater 5alance..................................................................................138

1$.: ,3stem P&IDs................................................................................................. 139

1$.3 PacDa.e P&IDs............................................................................................... 13)

1$.# ,hut Do!n Lo.ic Dia.ram.............................................................................1#$

1$.( ,%FE 6harts................................................................................................... 1#1

Page 4 of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

Page & of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

Page * of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

Page , of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

Page - of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

Page 9 of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

;lossar3 of 4erms

01C 0lo( 1o(n CalBe

0!P1 0arrels of !l per 1ay

0P1 0arrels per 1ay

0'+ 0asc 'ed%ents and +ater

0+ 0ac@ +as"

0+2! 0rac@s" (ater 2eBerse !s%oss

CIP

100 1ouble 0loc@ and 0leed

1C' 1strbuted Control 'yste%

d9s do(nstrea%

61G 6%ergency 1esel Generator

6'1 6%ergency '"ut 1o(n

FG' Fre 3 Gas 'yste%

F2P Fberglass 2enforced Plastc

F+ Fre +ater

G!2 Gas to !l 2ato

G2P Glass renforced Plastc

G$G Gas $urbne Generator

HP Hg" Pressure

D! Dnoc@ !ut

L8$ Lo(est 8strono%cal $de

LC Loc@ed Closed

L! Loc@ed !pen

LP Lo( Pressure

40+P1 $"ousand 0arrels of +ater per 1ay

4CC 4otor Control Center

%g9l %llgra%s per lter

44I 4an 4ac"ne Interface

44'CF1 4llon 'tandard Cubc Feet per 1ay

4P 4edu% Pressure

/6 /ort" 6ast

/P'H /et PostBe 'ucton Head

/+ /ort" +est

!C' !perator Control 'taton

!2P

PC' Process Control 'yste%

PLC Progra%%able Logc 1agra%

ppb Parts per 0llon

pp% Parts per 4llon =eEuBalent to %g9lt>

P'' Process '"utdo(n 'yste%

P'C Pressure 'afety CalBe

ptb Pounds per $"ousand barrels

2! 2estrcton !rfce

2!C 2e%ote7!perated CalBe

rp% 2eBoluton per 4nute

'1C '"ut 1o(n CalBe

'' 'uspended 'olds

''' 'afety '"utdo(n 'yste%

'+ 'ea +ater

'+2! 'ea(ater 2eBerse !s%oss

Page 10 of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

$6G $r76t"ylene Glycol

$'' $otal 'uspended 'olds

.CP .nt Control Panel

.P' .nnterrupted Po(er 'upply

u9s .pstrea%

C1. Csual 1splay .nt

Page 11 of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

1 I4"OD764IO

$"e ob)ectBe of t"s docu%ent s to proBde 1orood !lfeld process and eEup%ent

descrpton5 plant protecton and control5 safety gudelnes5 ntal and nor%al start up

procedures5 nor%al and e%ergency s"utdo(n procedures.

$"s %anual s prepared (t" t"e use of pro)ect 9 Bendor docu%ents 9 dra(ngs aBalable at

t"e t%e of preparaton. $"s procedures 9 nstructons proBded n t"s %anual are

consdered as a base docu%ent and s"all be reBe(ed 9 %odfed at ste as dee%ed

necessary to reflect t"e as7bult dra(ngs 9 docu%ents =ncludng Bendor %anuals> and

operatng e<perence ganed durng t"e start up 9 s"utdo(ns and routne operaton.

$"e nstructons 9 procedures descrbed n t"s %anual 1! /!$ supersede t"e Bendor

reco%%ended procedures. Hence Bendor %anuals s"all be cross7referred ("ereBer

reEured.

It s assu%ed t"at t"e facltes are operated and %antaned by Eualfed and traned

personnel of approprate calber. It s reco%%ended t"at all t"e operatng and %antenance

personnel are fa%lar (t" t"e process and operaton before t"ey are actually assgned to

t"e )ob.

6Bery effort "as been ta@en to coBer all possble e%ergences and operatng condtons

reEured n %antanng safe and relable operaton of t"e facltes. Ho(eBer5 t"s %anual

%ay not coBer eac" and eBery step to be ta@en durng nor%al operaton 9 start up 9

s"utdo(n or coBer all possble contngences or e%ergences ("c" %ay occur. $"erefore5

so%e of t"e procedures and operatng condtons stated "ere %ay reEure %odfcaton to

%eet unusual or ot"er e%ergences.

!peratng condtons5 process Barables5 co%poston of nter%edate and product strea%s n

t"e desgn docu%ents 9 dra(ngs of 1orood !lfelds Pro)ect are based upon t"e results of

process desgn for ("c" t s ntended. 8ctual opt%u% operatng condtons5 as deter%ned

by operatng e<perence %ay Bary so%e("at fro% t"e desgn para%eters due to Baratons

n t"e feedstoc@ Eualtes and nnu%erable Barables nBolBed.

,tructure of /anual

8 bref descrpton of Barous sectons of t"e %anual s gBen belo(F

8n oBerBe( of t"e facltes and ts desgn fgures s gBen n secton 1.

1etaled descrpton of all syste%s s gBen n secton 2. 1escrptons of control and

safeguardng aspects are coBered as (ell. Per syste% are also gBen t"e lstngs of

all nstru%ents fro% !peratons Condtons %ontorng

1escrpton of t"e plant control syste%5 44I and Process control narratBes are gBen

n secton #.15#.2 and #.# respectBely

Lstng of all alar% and trp set ponts n PC'5 6'1 and F3G syste%s and of P'Cs

are gBen n secton 4

1escrpton of 'afety P"losop"y and all safety syste%s s gBen n secton &

'tart7up procedures per syste% are gBen n secton *. Procedures are proBded for

ntal start7up5 /or%al start7up5 'tart7up after GP'1 and 'tart7up after 6'1. $"e

oBerall 1orood7# facltes start7up seEuence s gBen at t"e start of t"e secton *.

Page 12 of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

!peratons procedures per syste% are gBen n secton ,.

Lstng (t" nor%al operatng Balues and settngs for all nstru%entaton per syste%

are ncluded n t"e operatons procedures n secton ,.

'"utdo(n procedures per syste% are gBen n secton -. $"e oBerall 1orood7#

facltes s"utdo(n seEuence s gBen at t"e start of t"e secton -.

$rouble s"ootng %atrces per syste% are proBded n secton 9.

2eference docu%ents l@e desgn sc"e%atcs are attac"ed n secton 10.

In the s3stem descri-tions some sim-lified sDetches ha+e 2een included as an aid to

EuicDl3 understand the main features of the o+erall s3stem. @o!e+er* it is to 2e

reali>ed that these sDetches are sim-lified and that for full understandin. of the

s3stem al!a3s reference shall 2e made to the latest as-2uilt P&IDFs.

1.1 Project Scope

$"e Pro)ect conssts of deBelop%ent of 1orood !lfelds5 located on D"arg Island n Isla%c

republc of Iran5 called t"e /e( Plant. $"e /e( Plant s on t"e (est sde of t"e Island and s

located at an appro<%ate eleBaton of && %eters fro% t"e %ean sea leBel.

$"e 1orood olfelds produces ol fro% a nu%ber of offs"ore and ons"ore (ells. $"e t(o

e<stng treat%ent facltes on t"e Island5 na%ely 1orood 1 and 1orood 2 proBde t"e

follo(ng t"ree treat%ent stepsF

LEud9gas separaton

!l de"ydraton =treat%ent for salt and 0'+>

!l stablsaton.

$"e pro)ect s e<ecuted t"roug"F

1rllng n7fll producton (ells5

I%ple%entng (ater and assocated gas n)ecton nto t"e feld5 and

Constructng addtonal ol treat%ent plant referred to as G1!2 #H.

$"e ne( facltes ncludeF

1. ,ea!ater Liftin.* 4reatment* and Injection

:. 6ommon Facilities and 7tilities. $"ese ncludeF

Gas s(eetenng and fuel gas dstrbuton5

6lectrcal po(er generaton5

Instru%ent ar5 ntrogen and ot"er utltes5

$ec"ncal buldngs.

3. Oil 4reatment

#. ;as treatment & Injection

(. Onshore Infield Pi-elines

Page 1# of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

1.2 General Description of the Facility

1.:.1 Plant 6a-acities

Capactes of t"e /e( Plant (ll beF

In)ected (ater F 2,0 40+P1

In)ected gas F 1#0 44'CF1 I #* JC a%bent te%perature5 or

F 120 44'CF1 I 4& JC a%bent te%perature

1!2 # ol treat%ent F -05000 0!P1

Fuel Gas =HeaBy Case>F 40 44'CF1 =1esgn>

21.9, 44'CF1 =/or%al>5

2#.99 44'CF1 =4a<%u%>

6ffluent (ater dsc"argeF &4- %#9" =/or%al>5 -,4 %#9" =4a<%u%>

/oteF

' F 'tandard condtons at 1&JC and 1 at%.

4 F t"ousand

44 F %llon

CF1 F Cubc feet per day

0!P1 F 0arrels of ol per day

0+P1 F 0arrels of (ater per day

1.:.: Onshore Pi-elines

$"e deBelop%ent ncludes a total of 24 ons"ore (ells located n # clustersK na%ely5 /ort"7

+est5 /ort"76ast and 'out". $"ese (ells are of t"ree typesF

1# no. producton (ells

2 no. gas n)ecton (ells.

9 no. (ater n)ecton (ells5

$"e 1# ne( producton (ells (ll be routed to t"e ne( treat%ent faclty. $"ese are dBded

nto t"e # clusters5 as follo(sF

Cluster /o. of prod. (ells Lengt" of ppelne bet(een cluster and plant

/ort"east Cluster 4 &.& @%

/ort"(est Cluster 4 4.9 @%

'out" Cluster & 1.-& @%

$"e (ells n t"e ndBdual producton clusters are routed to et"er a 10H test "eader or an

1-H producton "eader. 6ac" cluster s proBded (t" dedcated test and producton "eaders

located n t"e /e( Plant. Producton control for eac" (ell s ac"eBed by a %anual c"o@e

BalBe proBded at t"e (ell"ead. $"e producton "eaders fro% eac" cluster are co%bned at

t"e producton %anfold n t"e /e( Plant and feed to t"e frst stage separator. '%larly5 t"e

test "eaders fro% eac" cluster co%bne at t"e test %anfold and enter t"e test separator.

$"e gas s n)ected to t(o gas n)ecton (ells n t"e 'out" Cluster Ba a 10H ppelne and t(o

-H flo( lnes. 8 20H gas lne fro% 1orood 2 faclty s also routed to t"e slug catc"er at t"e

Page 14 of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

/e( Plant and supples gas for 1orood # to %a@e7up t"e gas n)ecton and startup

reEure%ents. 8 10H DH64C! gas ppelne s also routed to t"e treat%ent faclty and s

ter%nated at t"e /e( plant.

$"e (ater n)ecton %anfold s dstrbuted nto t(o "eaders routng to t"e nort" and sout" of

t"e Island. !ne 1-H "eader goes to /ort"76ast and /ort"7+est Clusters5 eac" Cluster

"aBng t"ree (ater n)ecton (ells. $"e "eader to t"e sout" of t"e Island s 1*H and s routed

to t"e 'out" Cluster (t" t"ree *H (ater n)ecton branc"es. 8 12H lne s furt"er tapped off

fro% t"e 1*H "eader and ta@es (ater for n)ecton to offs"ore platfor% G.

$"e follo(ng table llustrates t"e nu%ber of producton and n)ecton (ells for eac" ClusterF

Cluster /o. of

Producton

+ell

/o. of +ater

In)ecton +ell

/o. of Gas

In)ecton +ell

/o. of 'pare

'lots

/ort"76ast 4 # 0 2

/ort"7+est 4 # 0 #

'out" & # 2 2

$!$8L 1# 9 2 *

'ea(ater s delBered to t"e /e( Plant for t(o serBcesF

+ater n)ecton5 process coolng5 (as" (ater for crude desalters

Fre (ater.

'ea(ater for (ater n)ecton and processng unts s delBered to t"e /e( Plant fro% t"e sea

s"ore Ba t(o 1-H G2P lnes. $"e fre(ater s delBered t"roug" one 1*H G2P lne.

1.:.3 Oil 4reatment

!ne test separator s proBded for t"e faclty. Producton fro% any gBen (ell can be routed

to t"e $est 4anfold. Fro% t"e $est 4anfold5 producton s routed nto t"e $est 'eparator

=1'7#00>5 ("c" s desgned for t"ree7p"ase separaton. 8ssocated gas s flas"ed fro% t"e

crude ol and routed to t"e 4P %anfold.

Fro% t"e producton %anfold n t"e /e( Plant5 producton s routed to a sngle frst7stage

separator =1'7#01>. $"e 1st 'tage 'eparator (ll operate as a t"ree7p"ase separaton of

ol5 gas and (ater. Produced (ater separated n t"e 1st stage separator (ll be routed to

t"e +ater $reat%ent 'yste% for re%oBal of entraned ol.

$"e separated ol fro% t"e frst stage separator and test separator s co%bned and s routed

to LP separator Feed Pre7"eater =6C7#1#>. In t"s e<c"anger5 t"e nco%ng crude s "eated

by t"e "ot stabl;er botto% flud. $"e "eated crude s t"en routed to LP separator =1'7#02>.

$"e crude fro% LP separator s pu%ped to t"e 1esalter =1'7#20 890>. $(o stages of

desaltng are proBded. $"e nco%ng "ot feed s %<ed (t" recycle (ater fro% t"e second

stage. 4<ed flud s passed t"roug" a %<ng BalBe. 8fter t"e %<ng BalBe5 flud enters 1st

stage 1esalter. $"e ol and (ater s separated under a "g" electrcal potental dfference.

$"e separated (ater s routed to t"e (as" (ater pre"eater and t"en to t"e (ater treat%ent

secton. !l flo(s out fro% t"e top and s routed to t"e ne<t 1esalter.

Page 1& of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

'eparated ol fro% t"e frst stage 1esalter s %<ed (t" pre"eated fres" (as" (ater and s

passed t"roug" a %<ng BalBe and t"en routed to t"e second stage 1esalter. 1ry ol

contanng L 0.2M by Bolu%e (ater fro% t"e 6lectrostatc 1e"ydrator5 s routed to t"e top of

t"e 'tabl;er Colu%n. ProBson s also aBalable for 1esalter operaton n bypass and

parallel %ode of operaton.

!l fro% desalter enters t"e top of t"e 'tabl;er Colu%n =C87#10>5 ("ere any Bapor

generated flas"es fro% t"e ol. Capor fro% t"e reboler passes up(ards t"roug" t"e colu%n5

contactng (t" descendng crude on t"e trays and strppng H2' and lg"t "ydrocarbons

fro% t"e crude. 'tabl;ed crude =L ,0pp% H2'> fro% t"e reboler drops nto t"e colu%n

botto%s secton fro% ("ere t s pu%ped out by t"e Crude ol transfer Pu%ps.

1.:.# ;as 4reatment and 6om-ression

Capor fro% t"e frst stage separator =1'7#01> and test separator =1'7#00> flo(s to t"e 4P

slug catc"er =1' #0&>. 4P gas fro% 1orood 2 plant s also connected to t"e slug catc"er.

Gas fro% t"e 4P %anfold feeds to a%ne unt =fuel gas> and 4P gas co%pressor =for gas

n)ecton>.

Co%pressed gas fro% t"e 4P Co%presson 'yste% =$(o stage centrfugal co%pressor> s

routed to t"e 4P boosted gas cooler. !utlet fro% t"s cooler enters 4P boosted gas

scrubber. $"e (et gas s t"en treated n a Gas 1e"ydraton 'yste% for t"e purpose of

re%oBng (ater fro% t"e gas. 4et"od of gas de"ydraton s by absorpton (t" lean $6G.

$"e syste% conssts of glycol contactor and rc" glycol regeneraton. 1e"ydrated gas =1e(

pont 0oC I 410 barg> fro% t"e syste% s routed to t"e HP Co%presson 'yste%. HP

co%presson syste% co%prses t(o7stage turbne drBen centrfugal co%pressor. 1sc"arge

fro% t"e second stage HP co%pressor s sent to t"e gas n)ecton (ells t"roug" t"e n)ecton

gas ppelne I 410 bara

1.:.( ,ea!ater 4reatment and Injection

'ea(ater s used for coolng purpose and n)ecton nto t"e (ater n)ecton (ells n t"e t"ree

/ort"76ast5 /ort"7+est and 'out" Clusters. +ater s transferred fro% t"e sea to an nta@e

staton basn close to t"e s"ore Ba t(o 42 nc" lnes. $"s basn s t"e sea(ater lft staton

and caters to sea(ater lftng pu%ps5 F+ )oc@ey pu%ps and F+ desel pu%ps. $"e lft

staton5 c"lornaton unt and poc@et flters are located close to t"e seas"ore at

appro<%ately #.& @% fro% t"e /e( Plant. $"e c"lornaton unt n)ects c"lorne n to t"e

sea(ater to suppress bologcal gro(t" n t"e lnes and do(nstrea% processng. 'ea(ater

s frst coarse fltered t"roug" poc@et flters to a t"res"old fltraton leBel of 100 %crons.

In t"e /e( Plant5 t"e sea(ater furt"er undergoes fne fltraton Ba pressure dual %eda

fltersK partcles up to 2 %crons are separated n t"ese flters. 4a)or porton of t"e fltered

sea(ater s drectly sent to a 1eaerator to re%oBe dssolBed o<ygen pror to t"e n)ecton to

t"e (ells. 2e%anng porton of t"e fltered (ater s sent to "eat e<c"angers as process

coolng (ater. 'ea(ater returns fro% t"e e<c"angers are also routed to t"e 1eaerator

colu%n. 1eaerated (ater fro% t"e botto% of t"e 1eaerator s fed to t"e %an (ater n)ecton

pu%ps usng sea(ater booster pu%ps.

Page 1* of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

1.:.6 Produced =ater 4reatment

Produced (ater fro% t"e 1st and 2nd stage separators5 test separator5 1esalter and

stabl;er colu%n s routed to t"e degassng s@%%er dru% =1'7400>. 8 part of t"e H2' and

C!2 are separated n t"s dru% and t"e separated ol s re%oBed usng s@%%ng deBce.

LEud effluent fro% 1'7400 s sent to flotaton unt =1'7401>5 ("ere ol specfcaton n (ater

s ac"eBed. 2e%anng H2' n t"e (ater s re%oBed n t"e (ater flas" Bessel =1'7402>

("c" operates under Bacuu%. $"e collected crude fro% 1'7400 and 1'7401 s recycled

bac@ to t"e 1esalter pac@age for furt"er treat%ent.

1.:.8 Flarin. ,3stems

$"e /e( Plant "as t"ree flare stac@s on a co%%on derrc@ structureK Hg" Pressure =HP>5

Lo( pressure =LP> and 8cd flares.

$"e HP Flare syste% conssts of one #0H C' (ar% "eader5 one 1*H '' cold "eader5 one HP

Flare D! 1ru%5 t(o Bertcal pu%ps and t"e HP flare tp. $"e condensate fro% HP flare D!

1ru% s pu%ped to 2nd stage separator.

$"e LP Flare syste% conssts of a 20H C' "eader and one LP Flare D! 1ru%. $"e acd

flare syste% ncludes a 12H leadng to a 1*H '' "eader and a Bertcal acd Flare D! 1ru%.

$"e condensate fro% bot" LP and acd flare D! 1ru%s are routed to closed dran.

1.:.9 Fuel ;as ,3stem

Fuel gas for t"e /e( Plant consu%pton5 because of ts "g" H2' content5 s s(eetened

do(n to 200 pp%B n t"e 8%ne s(eetenng unt. $"e s(eetenng s done by contactng (t"

counter current flo( of lean a%ne n t"e a%ne contactor.

$"e s(eetened gas co%ng out fro% top of a%ne contactor s separated nto t(o strea%s.

!ne s t"e lo( pressure =LP> fuel gas gong to LP fuel gas consu%ersK .e.5 flare5 stea%

bolers5 glycol unts5 etc. $"e ot"er strea% s co%pressed n t"e fuel gas co%pressor and

sent to %edu% pressure =4P> fuel gas consu%ersK .e.5 co%pressors turbnes5 (ater

n)ecton pu%ps turbnes5 and turbo generators.

1.:.) Other 7tilities !ithin e! Plant

$"e follo(ng utltes are also generated at ste and aBalable n t"e /e( PlantF

Fres" +ater

0oler Feed (ater5

Lo( pressure stea%5

Po(er generaton5

/trogen5

Instru%ent ar5

1esel5 and

C"e%cal n)ecton syste%s

Page 1, of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

Closed dran syste% receBes all process lEud9condensate drans. 8ll non process ols fro%

eEup%ent dran and floor (as"ng of pu%ps pedestals are routed to t"e open dran syste%.

8ll (ater strea%s fro% t"e plant are routed to t"e retenton pt and t"en nto retenton pool

("c" ult%ately flo(s to t"e sea. $"s ncludes treated oly (ater5 non7conta%nated coolng

and flter bac@(as" (ater5 oBerflo( fro% open dran syste%5 ran(ater fro% conta%nated

paBed areas5 etc.

1.:.1$ 5uildin.s

$"e faclty ncludes t"e follo(ng buldngs and all necessary roads5 fences5 etc.

!ffce buldng5

$ec"ncal bloc@ buldng consstng of control roo%5 nstru%ent tec"ncal roo%5

utltes roo%5 and laboratory5

6lectrcal substaton buldng5

+are"ouse and (or@s"op

Page 1- of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

1.3 Basis of Design

1.3.1 Desi.n 5asis for Dorood 3

$"e desgn bass for 1orood # s gBen belo(F

1.3.1.1 Feed to New Plant

Co%poston F Producton fro% ne( clusters5 as per 'ecton 1.4.1

of t"s operatng %anual

1esgn G!2 F 1-&07#000 scft9bbl

Flo( 2ate F !l effluent N (ater to produce -05000 '0!P1

+ater Cut F 0 to #0M

+ater Flo( 2ateF #05000 0+P1 =4a<.>

+ater 'alt contentF 2efer to produced (ater c"aracterstcs ='ec. 1.4.4>

4a<. Gas Flo( 2ateF 240 44'CF1 =as total separated gas>

$urndo(n F #05000 0!P1

1esgn CapactyF 110M of flo( rates

1.3.1.2 Oil Prodct Specifications

Producton 2ateF -05000 0!P1 =at 'tandard condtons>

$rue Bapor pressureF L 14.& psa I &0J C

2ed Bapor pressure =2CP>F L -.& psa I 100J F

H2' contentF L ,0 pp% (t.

0'+F L 0.&M Bol.

'alt contentF L *0%g9l =or 20 ptb>

!l pressure at 0attery l%t * bar g %n5

1.3.: Flo! "ates

1.3.2.1 Oil Prodction

$"e desgn flo( rate fro% eac" cluster flo( rate s s"o(n belo(F

Cluster $otal !l N +ater

Flo( 2ate

=1>

5 0P1

+ater Cut Gas Flo( 2ate

=2>

5

44'CF1

/ort"76ast 405000 0 O #0M -0

/ort"7+est 405000 0 O #0M -0

'out" 405000 0 O #0M -0

/otesF

1> 1esgn producton flo( fro% eac" (ell s 125000 0P1 of !l N +ater

2> 1esgn assocated gas flo( fro% eac" (ell s #0 44'CF1

Page 19 of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

1.3.2.2 Gas !njection

Gas n)ecton s for only t(o (ells n t"e 'out" Cluster. $"e desgn bass for Gas n)ecton

flo( and condtons are presented n t"e follo(ng tableF

/o%nal Gas In)ecton Flo( 2ate 120 44'CF1

1esgn Gas In)ecton Flo( 2ate 1#0 44'CF1 at #* JC e<ternal te%perature5 or

120 44'CF1 at 4& JC e<ternal te%perature

HP dsc"arge pressure 410 bar abs

+ater 1e( Pont n In)ecton Lnes 0 JC at 410 bar abs

2eEured Pressure at In)ecton +ell"ead 400 bar abs at all flo( rates up to t"e desgn flo(

rate

1esgn Gas In)ecton Flo( 2ate per

+ell

*& 44'CF1

$"e gas lne fro% 1orood 2 to t"e /e( Plant s desgned for a %a<%u% flo( of 200

44'CF1 and a pressure of 11 bar abs at t"e /e( Plant.

1.3.2.3 "ater !njection

Flo( CapactyF

$otal (ater n)ecton nor%al capacty of t"e faclty s 1-00 %#9"r. $"e desgn capacty s

19-0 %#9"rK .e.5 1005000 0+P1 =**0> %#9"r of (ater n)ected nto eac" of t"e #

clusters. $"e desgn (ater n)ecton nto eac" (ell s #05000 0+P1 =199 %#9"r>.

2eEured PualtyF

'ource F 'ea(ater

2esdual partcle F L 2 %% =$"e fne flters s"all re%oBe 9-M of all

partcles greater t"an 2 %crons>

!<ygen Content F L #0 ppb I #, JC

2eEuested PressureF

8t ons"ore n)ecton (ell"eadsF 2#& bar abs.

Page 20 of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

1.# Flid $o%position

1.#.1 Production Fluid

$"e co%poston of producton flud for t"ree Gas to !l 2atos =G!2> n %ole percent dry

bass sF

Co%ponent G!2 Q 1-&0 G!2 Q 2400 G!2 Q #000

H

2

' 9.490 ,.*1& ,.,*

C!

2

&.4#& &.1,4 &.2,

C

1

4#.&11 &1.149 &#.*,

C

2

*.*01 -.*02 9.0#

C

#

#.**2 #.-* #.,*

C

4

0.,91 0.,2- 0.,1

nC

4

1.-90 2.014 1.9*

C

&

1.401 0.,,2 0.,0

nC

&

2.,,* 1.0&# 0.9*

nC

*

2.4&& 2.2&* 2.0&

nC

,

2.94# 2.4*, 2.14

nC

-

2.12& 1.,- 1.&&

nC

9

1.4-* 1.249 1.0-

nC

10

1.204 1.011 0.--

C/18 4.1*& 2.,#2 2.2#

C/1C -.1#1 &.&4,& 4.&#

C/12 0.,,2 1.,2*2 1.4&

/

2

1.1*# 0.2&&2 0.2,

Pseudo7co%ponents areF

Pseudo7Co%ponent 4+ 'tandard densty =g9c%#>

C/18 290.94 1.0##

C/1C 2*,.94 0.9&-

C/2 &&-.00 1.090

8Berage te%perature of t"e producton flud s ,0JC. 6st%ated range of flo(ng

te%perature at producton (ell"ead s *079&JC.

1.#.: Injection ;as

$"e co%poston of n)ecton gas5 for t(o lg"t and "eaBy cases at t"e co%pressor

dsc"arge5 n %ole M s s"o(n belo(F

Co%ponent Lg"t Case HeaBy Case

H

2

' *.&1 11.*0

C!

2

*.,4 ,.4,

Page 21 of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

Co%ponent Lg"t Case HeaBy Case

C

1

,1.09 *2.,-

C

2

9.#* -.*2

C

#

#.** #.9#

C

4

0.&0 0.*4

nC

4

0.9& 1.##

C

&

0.#* 0.&-

nC

&

0.&* 0.94

nC

*

0.1, 0.29

nC

,

0.0, 0.09

nC

-

0.02 0.02

nC

9

0.0 0.0

nC

10

0.0 0.0

C/18 0.0 0.0

C/1C 0.0 0.0

C/12 0.0 0.0

/

2

0.0 1.,1

1.#.3 ,ea!ater

'ea(ater c"aracterstcs at t"e lft staton s e<pected to "aBe t"e follo(ng propertesF

Property .nt 'ea(ater

pH 77 -.2

$e%perature JC 20 O #&

1ensty @g9%# 10#0

Cscosty cP 1.0

!<ygen ppb 'aturated

ConductBty R%"os9c% I20JC *45000

$1' %g9l 405-40

$'' %g9l 2&

$otal Hardness %g9l as CaC!

#

,5*00

Ca

2N

%g9l as Ca -00

4g

2N

%g9l as 4g 15#*0

'!

4

27

%g9l as '!

4

25--0

'lca %g9l as '!

2

0.1&

/!

#

7

%g9l as /!

#

0.2&

Cl

7

%g9l as Cl 215910

HC!

#

7

%g9l as HC!

#

1,,

!rgancs =$!C> %g9l as C &.*

!l %g9l 1

/a

N

%g9l 12519&

D

N

%g9l 2#0

Fe

2N

%g9l 0.1

0a

2N

%g9l L 0.1

/aCl %g9l as /aCl #05990

'alnty g9l #*.1

Page 22 of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

$"e n)ected (ater s e<pected to "aBe t"e sa%e c"aracterstcs as s"o(n aboBe e<cept for

suspended solds and dssolBed gases. 9-M of suspended partcles greater t"an 2 %crons

are re%oBed fro% t"e n)ecton sea(ater. !<ygen and carbon do<de content of t"e (ater

are reduced after "aBng passed t"roug" t"e 1eaerator. !<ygen content of n)ecton

sea(ater s #0 ppb or less.

1.#.# Produced =ater

Produced (ater Eualty used n t"e desgn s s"o(n belo(F

Property .nt Produced

+ater

pH 77 ,.0

ConductBty R%"os9c% I20JC 4,&5#20

$1' %g9l #005100

$'' %g9l 4#0

Ca

2N

%g9l as Ca 195000

4g

2N

%g9l as 4g #5240

'!

4

27

%g9l as '!

4

2-0

Hydrogen

'ulfde

%g9l as H

2

' *&.9

/H

4

N

%g9l as /H

4

L 0.02

'lca %g9l as '!

2

-0

Cl

7

%g9l as Cl 1*15-00

HC!

#

7

%g9l as HC!

#

#22

C!

2

%g9l as C!

2

2*.4

$!C %g9l as C 91

!l %g9l &.2

/a

N

%g9l ,-5100

D

N

%g9l #5#-0

Fe

2N

%g9l L 0.02

'r

2N

%g9l *20

/aCl %g9l as /aCl 19-5**0

'alnty g9l 2*,

Page 2# of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

1.& Site and 'eteorological Data

$"e ste data pertan to t"e /e( Plant on D"arg Island.

1.(.1 Onshore Desi.n 6onditions

1.&.1.1 Baro%etric Pressre

0aro%etrc pressure F 1010 % bar

1.&.1.2 (le)ation

/e( plant locaton F around && %

1.&.1.3 *e%peratre

Hg"est %ont"ly aBerage N &JF F #* J C =9*.- J F>

Lo(est %ont"ly aBerage 710JF F 11 J C =&1.- J F>

4a<%u% 1esgn $e%perature F 4* J C

4n%u% 1esgn $e%perature F 11 J C

1.&.1.# +elati)e ,%idity

1esgn 2elatBe Hu%dty F -, M

1.&.1.& +ainfall intensity

1esgn 2anfall Intensty F 19*.& %%9day5 2#* %% 9year

1.&.1.- "ind

1esgn Belocty =for 'tructural 1esgn>F 1#0 @%9"

PreBalng drecton F /ort" +estO/ort"

1.(.: Offshore Desi.n 6onditions

1.&.2.1 Seawater Properties

2efer to 'ecton 1.4.# of t"s operatng %anual.

1.&.2.2 +ainfall

Hg"est 8nnual F #&-.1 %%9year

8Berage 8nnual F 2#*.0 %%9year

4a<%u% 1aly F 19*.& %%9year

4a<%u% 4ont"ly F #2-.1 %%9%ont"

1.&.2.3 .ir *e%peratre

4a<%u% 'urface $e%perature F -0JC =n drect sunlg"t>

4a<%u% 8%bent F 4*JC

4n%u% 8%bent F 0JC

4ean 8%bent F 24JC

Page 24 of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

1.&.2.# +elati)e ,%idity

4a<%u% F -,M

1.&.2.& Baro%etric Pressre

!ffs"ore 4n%u% F 991 %bar

!ffs"ore 4a<%u% F 102- %bar

1.(.3 6limatic 6ondition

8r $e%perature Puarter of t"e ?ear =Gregoran>

Frst 'econd $"rd Fourt"

8Berage 4a<%u% #*.1 JC

8Berage 4n%u% 10.&JC

4a<%u% 2ecorded 4*JC

4n%u% 2ecorded 0JC

2elatBe Hu%dty Puarter of t"e ?ear =Gregoran>

Frst 'econd $"rd Fourt"

4n%u% *& M

4a<%u% 100 M

2anfal Puarter of t"e ?ear =Gregoran>

Frst 'econd $"rd Fourt"

4a<%u% 1aly 19*.&

%%9day

+nd Puarter of t"e ?ear =Gregoran>

Frst 'econd $"rd Fourt"

PreBalng +nd

1rectonF /+7/

1esgn Celocty &&.9 @%9"

Page 2& of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

: P"O6E,, DE,6"IP4IO OF OIL P"O6E,,I;

,<,4E/,

2.1 O)er)iew

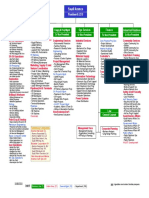

C"apter 2 proBdes t"e reader (t" a descrpton of all facltes aBalable for ol treat%ent to

allo( a clear understandng of t"e operatons. 8 sc"e%atc dagra% s"o(ng t"e oBerall

treat%ent process s gBen n fgure 2.1.1 at t"e end of t"s secton.

2.2 Oil Prodcer "ellheads and Prodction 'anifolds

2efer PF1 I2 40 111 :00 88100 888 0240 '"eet 1

2efer P3I1 I2 40 111 :00 88100 888 1,10 '"eet 1 of #.

I2 40 111 80* 88100 888 1,11 '"eet 1929# of #

I2 40 011 002 88#00 888 1940 '"eet 192 of 2

:.:.1 Introduction on Oil Production

Crude ol fro% t"e ol reserBors flo(s out t"roug" t"e (ell"eads under t"e pressure of t"e

reserBor. !l produced fro% %any reserBors contans produced (ater =For%aton (ater>

and gas. $"e content of gas s nor%ally e<pressed by a factor called as Gas to !l 2ato =or

Gas to lEud rato5 G!29 GL2>. $"e (ater content of ol s e<pressed as (ater cut

percentage =Col. M> of t"e total fluds.

$"e ol co%poston5 Bscosty and specfc graBty =Bscosty and specfc graBty depends on

t"e co%poston of crude> of crude produced fro% ol feld Bares fro% reserBor to reserBor.

Generally t s %ore dffcult to separate (ater fro% crude (t" "g" specfc graBty and

Bscosty.

4he .as associated !ith the crude consists of mainl3 methane* ethane* -ro-ane and

2utane and non-h3drocar2on .ases such as nitro.en* car2on dioGide and -ossi2l3

h3dro.en.

8l%ost all of t"e salt present n t"e crude s contaned n t"e for%aton (ater. $"e produced

(ater n crude s present n t(o for% na%ely free (ater and e%ulsfed (ater. Free (ater s

easly separated n t"e t"ree p"ase separators and n t"e storage tan@ (t"n reasonable

settlng t%e.

$"e co%poston and flo( condton of crude produced fro% t"e (ells s tested perodcally5

by connectng t"e (ells to t"e test separator.

Generally t"e (ater content of t"e crude produced fro% a reserBor ncreases (t" t%e and

to(ards t"e end of t"e lfe of a reserBor t"e (ater content s %a<%u%.

Page 2* of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

:.:.: =ellheads

2.2.2.1 "ellhead description

8s part of 1!2 # pro)ect5 1# ne( producton (ells (ll be routed to t"e ne( treat%ent

facltes. $"ese are dBded nto # clusters5 ("c" areF

/ort"east Cluster F 4 (ells

/ort"(est Cluster F 4 (ells

'out" Cluster F & (ells

6ac" (ell s eEupped (t"F

7 Hydraulcally operated do(n "ole safety BalBe ='urface controlled 'ub7surface

'afety BalBe5 'C''C>

7 Hydraulcally operated %aster BalBe ='urface 'afety BalBe5 ''C>

7 4anually operated 4aster BalBe

7 4anually operated (ng BalBe

7 4anually operated (re lne BalBe ='+80 C8LC6>

7 4anually operated C"o@e BalBe.

7 +ell"ead pressure gauge located upstrea% of t"e (ng BalBe

$"e 'C''C and t"e ''C are "ydraulcally actuated and controlled by t"e (ell"ead control

panel and t"ey are nor%ally et"er fully closed or fully opened.

$"e opt%u% poston of t"e %anual c"o@e BalBe (ll be deter%ned durng t"e (ell tests

follo(ng t"e start up. $"ereafter5 t"e c"o@e openng s"all only be c"anged after consultaton

of producton engneerng and geoscences depart%ents.

2.2.2.2 "ellhead $ontrol Panels

2efer to Cendor =Petro Controls> P3I1F I240 1 #04, :00 88000 88D 0010

6ac" +HCP s po(ered by %otor drBen N "and pu%p5 proBdes fal7safe close actuaton of

t"e ''C 3 'C''C5 co%bned (t" (ell s"utdo(n n case fre or "g" 9 lo( flo( lne pressure

and re%ote 6'1. $"e safety cabnet s co%posed of t"e follo(ng te%sF

Ite%s co%%on to t"e ''C and 'C''C crcutsF

7 Flud reserBor (t" ol ndcator

7 6lectrc pu%p (t" standby "and pu%p to generate 2007barg "ydraulc pressure.

8 safety relef BalBe set at #14 barg s proBded on t"e pu%p dsc"arge.

!n t"e control crcutF

7 8 safety relef BalBe set at *.0 barg nstalled on t"e control crcut

7 8 "ydraulc accu%ulator (t" a capacty of 0.& lter pre7c"arged at #.& barg.

!n t"e ''C "ydraulc crcut =HP>F

7 8 "ydraulc accu%ulator (t" a capacty of #2 lter pre7c"arged at 1#& barg5

nstalled on t"e "ydraulc "eader.

7 8 pressure regulator set at &.& barg to energ;e t"e control crcut

Page 2, of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

!n t"e 'C''C "ydraulc crcut =CHP>F

7 8n ntensfer to step up t"e pressure fro% 200 barg to #00 barg

7 'afety relef BalBe set at 490 barg

7 8 "ydraulc accu%ulator (t" a capacty of 2.& lters pre7c"arged at 220 barg5

nstalled on "ydraulc "eader.

7 8n ad)ustable t%e delay crcut for seEuental operaton of t"e 'C''C.

:.:.3 ;atherin. ,3stem

2.2.3.1 Description

$"e producton fro% t"e (ell"ead clusters (ll be routed to t"e 1orood7# faclty as per t"e

table belo(F

Production B,our EffluentC

Fro% /ort"east /ort"(est 'out"

$o /e( Plant /e( Plant /e( Plant

/u%ber of Producton (ells 4 4 &

Flo( rate producton lne 40000 bpd 40000 bpd 40000 bpd

Flo( rate test lne 12000 bpd 12000 bpd 12000 bpd

$"e /e( Plant s s;ed for -0000 bopd and #05000 b(pd. 'o all t"e 1# producton (ells

need not produce at t"e sa%e t%e.

8 sc"e%atc of t"e gat"erng syste% s s"o(n n fgure 2.2.1 at t"e end of t"s secton. $"e

(ells n t"e ndBdual clusters are routed to et"er a 10H test "eader or an 1-H producton

"eader. 6ac" cluster s proBded (t" dedcated test and producton "eaders. $"e producton

control for eac" (ell s ac"eBed by a %anual c"o@e BalBe proBded at t"e (ell "ead. $"e

producton "eaders fro% eac" cluster are co%bned at t"e producton %anfold n t"e ne(

plant and feed to t"e frst stage separator. '%larly5 t"e test "eaders fro% eac" cluster are

co%bned at t"e test %anfold and feeds to t"e test separator. 2outng of t"e (ells to a

producton "eader or to a test "eader s ac"eBed by operatng t"e %anual solaton BalBes

proBded.

Corroson n"btor n)ecton proBson s aBalable at clusters. 2efer secton 2.9 for detals on

t"e c"e%cal n)ecton.

2.2.3.2 Pressre Protection

Fgure 2.2.2 at t"e end of t"s secton s"o(s a s%plfed s@etc" of t"e pressure protecton

syste% proBded for t"e gat"erng syste%. 8ll flo(lnes and cluster %anfolds are desgned

for t"e (ell"ead s"ut7n pressure. $"e ppelnes fro% t"e Clusters to t"e /e( Plant and t"e

nlet %anfolds at t"e /e( Plant "aBe a 900S ratng. Protecton of t"e 900S syste% for

oBerpressure s as follo(sF 6ac" flo(lne s proBded (t" a P'HH set at #- barg. +"en t"s

one s actBated t (ll ntate closure of t"e %aster BalBe of t"e concerned (ell"ead Ba t"e

+HCP. 6ac" (ell"ead lnes connectng to t"e cluster %anfold "as an 6'1C. $"ere s

Page 2- of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

anot"er 6'1C on t"e co%%on test and producton "eaders orgnatng fro% eac" cluster.

$"ese 6'1Cs are operated on t"e 2 out of # Botng "g" pressure s(tc"es on t"e

producton and test %anfolds =set at ,0 barg>. 2efer secton 4.* for t"e tag nu%bers for t"e

ndBdual (ell "ead 9 flo( lnes.

6'1Cs are nstalled also on t"e test9producton lnes at t"e nlet to t"e ne( plant. 8part fro%

plant 6'1 eBents5 t"ese (ll be actBated by P'HHs on t"e nco%ng pplnes5 set at #-

barg. In order to protect t"e ppelne fro% (ell "ead s"ut n pressure5 safety BalBes are

nstalled on t"e producton and test lnes co%ng fro% clusters =set at 12, barg>. 2efer

secton 4.& for t"e tag nu%bers for t"e P'Cs nstalled on ndBdual cluster test9producton

"eaders co%ng to t"e plant. $"ese P'Cs can relef t"e full cluster producton.

$"e Producton and $est 'eparators "aBe a desgn pressure of 2, barg and are protected

by nlet '1Cs actBated by P'HHs =set at 24 barg> and P'Cs =set at 2, barg>.

In case of a Plant 6'15 t"e 6'1Cs at t"e plant nlet (ll be closed. $"s (ll result n a

pressure rse at t"e (ell"eads5 suc" t"at t"e flo(lne P'HHs (ll close t"e (ell"eads %aster

BalBes. In case of falure to close of one or %ore of t"e (ell"eads5 t"e P'HHs on t"e

Cluster %anfolds (ll close t"e 6'1Cs at nlet and outlet of t"e cluster %anfolds. !nly n

case of t"e co%bned falure to close of t"e 6'1C n t"e sa%e flo(lne as ("ere t"e (ell

faled to close and t"e %anfold outlet 6'1C of t"e %anfold to ("c" t"at flo(lne (as

connected5 t"e P'C at t"e plant nlet (ll be actBated.

2.2.3.3 $lster (SD/ panels

2efer to Cendor =Petro Controls> P3I1sF

'out" Cluster F I240 1 #04, :00 88000 88D 001#

I240 1 #04, :00 88000 88D 0014

I240 1 #04, :00 88000 88D 001&

I240 1 #04, :00 88000 88D 001*

/ort" 6ast ClusterF I240 1 #04, :00 88000 88D 001,

I240 1 #04, :00 88000 88D 001-

I240 1 #04, :00 88000 88D 0019

/ort" +est ClusterF I240 1 #04, :00 88000 88D 0020

I240 1 #04, :00 88000 88D 0021

I240 1 #04, :00 88000 88D 0022

$"e 6'1C panel s po(ered by 2 %otor drBen and one "and pu%p5 proBdes fal safe close

actuaton of t"e 6'1 BalBes5 co%bned (t" (ell s"utdo(n control n case of fre or "g"

ppelne pressure and re%ote 6'1. $"e 6'1C panel s co%posed of t"e follo(ng te%sF

7 $(o %otor drBen N one "and pu%p (t" safety relef BalBes set at #14 barg to

generate 200 barg of "ydraulc pressure to 6'1 BalBes at t"e cluster %anfolds.

7 $(o pressure regulators set at &.& barg to energ;e t"e plot crcut and 6'1

control crcut

7 8 safety relef BalBe set at , barg nstalled on t"e plot crcut and 6'1 control

crcut

7 $(o "ydraulc accu%ulators pre7c"arged at 140 barg5 nstalled on t"e "ydraulc HP

supply "eader.

7 !ne "ydraulc accu%ulator pre7c"arged at # barg5 nstalled on t"e "ydraulc control

"eader.

7 Flud reserBor

7 !l ndcator

Page 29 of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

7 Hydraulc control logc for perfor%ng t"e reEured 6'1 actons

2.2.3.# $lster Drainage

2efer P3I1F I24071117:0078810078887&0-#

8 dranage syste% s proBded at eac" cluster for depressur;aton9 dranage of (ell"ead

annulus5 flo(lnes and %anfolds. 8t eac" cluster s nstalled one %ult7purpose dran "eader.

Ca a nu%ber of portable spools t"e Barous Bent and dran ponts on t"e faclty can be

connected to t"s dran "eader. !ne %oble burner unt s proBded t"at can be connected to

t"e dran "eader at any of t"e clusters to allo( for safely dsposal of t"e fluds.

1etaled operatng procedures for t"s syste% are proBded nF !IL9!P90*5 G+ell 8nnulus

0leed ProcedureH and !IL9'190*5 GCluster Isolaton5 1ranage and +ater Flus"ngH.

:.:.# 6ontrol & /onitorin.

2.2.#.1

2.2.#.2

Control and %ontorng sc"edule for t"s secton s as belo(

Page #0 of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

4a. o. 43-e Function?Location

PG 1T

0P:::

Pressure Gauge !l Producer +ell C"rst%as tree

PG 1T

1P:::

Pressure Gauge !l Producer +ell lne to cluster

PG 1T

2P:::

Pressure Gauge !l Producer +ell lne depressur;aton connecton

PG 1T

#P:::

Pressure Gauge !l Producer +ell 8nnulus bleed

PG 1T

4P:::

Pressure Gauge !l Producer +ell 8nnulus bleed

PG 1T

&P:::

Pressure Gauge !l Producer +ell 8nnulus bleed

P'HH O

1::2P

Pressure '(tc" !l Producer +ell lne to cluster

P'LL O

1::#P

Pressure '(tc" !l Producer +ell lne to cluster

''C 1::1P 4aster CalBe !l Producer +ell

'C''C

1::0P

'ub7 'urface 'afety CalBe !l Producer +ell

$G 17

0::!P

$e%perature Gauge !l Producer +ell lne to cluster

6'1C 10-17

10-*

6%ergency '"utdo(n

BalBes

/ort" east cluster e%ergency s"utdo(n BalBes

6'1C 10917

109*

6%ergency '"utdo(n

BalBes

/ort" (est cluster e%ergency s"utdo(n BalBes

6'1C 11017

110,

6%ergency '"utdo(n

BalBes

'out" cluster e%ergency s"utdo(n BalBes

FG -#,05

-#-05 -#90

Flo( Gauge /65/+ 3 'out" cluster C"e%cal In). Pu%ps

1sc"arge

LG -#,05

-#-05 -#90

LeBel Gauge /65/+ 3 'out" cluster C"e%cal In)ecton $an@

LeBel

L'LL -#,05

-#-05 -#90

LeBel '(tc" /65/+ 3 'out" cluster C"e%cal In)ecton $an@

LeBel s(tc"

PG -#,15

-#-15 -#91

Pressure Gauge /65/+ 3 'out" cluster C"e%cal In). Pu%ps Inlet

Pr.

PG98 -#,05

-#-05 -#90

Pressure Gauge /65/+ 3 'out" cluster C"e%cal In). Pu%ps

1sc"arge Pr.

PG90 -#,05

-#-05 -#90

Pressure Gauge /65/+ 3 'out" cluster C"e%cal In). Pu%ps

1sc"arge Pr.

P'HH

10-&8505C

Pressure Plots HH pressure s(tc" /6 cluster test "eader

P'HH 109&

8505C

Pressure Plots HH pressure s(tc" /+ cluster test "eader

P'HH 110&

8505C

Pressure Plots HH pressure s(tc" sout" cluster test "eader

P'HH

10-*8505C

Pressure Plots HH pressure s(tc" /6 cluster producton "eader

P'HH 109*

8505C

Pressure Plots HH pressure s(tc" /+ cluster producton "eader

Page #1 of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

4a. o. 43-e Function?Location

P'HH 110*

8505C

Pressure Plots Fro% !l +ell to Producton Header

P'C -#,05

-#-05 -#90

Pressure 'afety CalBe /65/+ 3 'out" cluster C"e%cal In). Pu%ps

dsc"arge

PG 10#0 Pressure Gauge /ort" 6ast Cluster $est nlet 4anfold

PG 10#2 Pressure Gauge /ort" 6ast Cluster nlet 4anfold

PG 10#* Pressure Gauge /ort" (est Cluster $est nlet 4anfold

PG 10#, Pressure Gauge /ort" +est Cluster nlet 4anfold

PG 10#- Pressure Gauge 'out" Cluster $est nlet 4anfold

PG 10#9 Pressure Gauge 'out" Cluster nlet 4anfold

PG 1000 Pressure Gauge /ort" 6ast Cluster $est Inlet 4anfold

PG 1002 Pressure Gauge /ort" 6ast Cluster Inlet 4anfold

PG 100* Pressure Gauge /ort" +est Cluster $est Inlet 4anfold

PG 100, Pressure Gauge /ort" +est Cluster Inlet 4anfold

PG 100- Pressure Gauge 'out" Cluster $est Inlet 4anfold

PG 1009 Pressure Gauge 'out" Cluster $est Inlet 4anfold

PI 1020 Pressure Indcator /ort" 6ast Cluster $est Inlet 4anfold

PI 102# Pressure Indcator /ort" 6ast Cluster Inlet 4anfold

PI 102* Pressure Indcator /ort" +est Cluster $est Inlet 4anfold

PI 102, Pressure Indcator /ort" +est Cluster Inlet 4anfold

PI 102- Pressure Indcator 'out" Cluster $est Inlet 4anfold

PI 1029 Pressure Indcator 'out" Cluster Inlet 4anfold

P'HH 1010 Cery Hg" Pressure '(tc" /ort" 6ast Cluster $est Inlet 4anfold

P'HH 1012 Cery Hg" Pressure '(tc" /ort" 6ast Cluster Inlet 4anfold

P'HH 101* Cery Hg" Pressure '(tc" /ort" +est Cluster $est Inlet 4anfold

P'HH 101, Cery Hg" Pressure '(tc" /ort" +est Cluster Inlet 4anfold

P'HH 101- Cery Hg" Pressure '(tc" 'out" Cluster $est Inlet 4anfold

P'HH 1019 Cery Hg" Pressure '(tc" 'out" Cluster Inlet 4anfold

P'LL 1010 Cery Lo( Pressure '(tc" /ort" 6ast Cluster $est Inlet 4anfold

P'LL 1012 Cery Lo( Pressure '(tc" /ort" 6ast Cluster Inlet 4anfold

P'LL 101* Cery Lo( Pressure '(tc" /ort" +est Cluster $est Inlet 4anfold

P'LL 101, Cery Lo( Pressure '(tc" /ort" +est Cluster Inlet 4anfold

P'LL 101- Cery Lo( Pressure '(tc" 'out" Cluster $est Inlet 4anfold

P'LL 1019 Cery Lo( Pressure '(tc" 'out" Cluster Inlet 4anfold

P$ 1020 Pressure $rans%tter /ort" 6ast Cluster $est Inlet 4anfold

P$ 102# Pressure $rans%tter /ort" 6ast Cluster Inlet 4anfold

P$ 102* Pressure $rans%tter /ort" +est Cluster $est Inlet 4anfold

P$ 102, Pressure $rans%tter /ort" +est Cluster Inlet 4anfold

P$ 102- Pressure $rans%tter 'out" Cluster $est Inlet 4anfold

P$ 1029 Pressure $rans%tter 'out" Cluster Inlet 4anfold

Page #2 of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

2.3 Separator section

2efer PF1F I2 40 011 002 88#00 0240 '"t 001

$"s syste% s desgned to process producton flud fro% ol (ells to produce -05000 bopd of

ol and assocated gas and (ater. $"e secton conssts of t"e follo(ng eEup%ent.

1

st

stage separator =1' #01>

$est 'eparator =1' #00>

LP separator feed pre"eater =6C #1#>

2

nd

stage separator =1' #02>

!l booster pu%ps =G: #10 890>

:.3.1 Princi-le of ,e-aration of =ater from Oil in ,e-arators

$"e functon of a separator s to proBde re%oBal of free gas fro% ol and 9 or (ater at a

specfc pressure and te%perature. 8ll t"e separators n t"e /e( plant are desgned to %eet

t"e follo(ng reEure%entsF

7 LEud %ust be separated fro% gas n a pr%ary separatng secton

7 Gas Belocty %ust be lo(ered to allo( lEuds to drop out

7 Gas %ust be scrubbed t"roug" an effcent de%ster

7 +ater and ol %ust be dBerted to a turbulence7free secton of t"e Bessel

7 LEuds %ust be retaned n t"e Bessel long enoug" to allo( separaton

7 $"e (ater O ol nterface %ust be %antaned

7 +ater and ol %ust be re%oBed fro% t"e Bessel at t"er respectBe outlets

$"e basc prncple of separaton of (ater fro% crude ol n t"e separators s by settlng of t"e

"eaBer p"ase =(ater> under graBtatonal force. In a %<ture of %%scble lEuds t"e "eaBer

p"ase traBels do(n(ards and t"e lg"ter p"ase traBels up(ards.

1ensty of (ater droplets s "g"er t"an t"e densty of ol =contnuous p"ase>. 1ue to t"s

dfference n denstes5 (ater droplets (ll traBel do(n(ards under graBtatonal forces. $"e

"g"er t"e s;e of a (ater droplets5 t"e faster (ll be t"e speed of do(n(ard %oBe%ent.

'%larly ol droplets n (ater p"ase (ll traBel up(ards due to buoyancy forces. $"s

separaton of ol and (ater =free (ater> p"ases by graBtatonal forces due to densty

dfference s called as GraBty settlng.

0ul@ of t"e (ater n t"e ol s easly separated as t enters nto t"e separators. For relatBely

large s;e droplets =aboBe 1000 %crons>5 /e(tons La( gBen belo( goBerns t"e separaton

of (aterK

C

t

Q 1.,4

+"ereF

Ct Q $er%nal Belocty of (ater drop ft9sec

g Q 8cceleraton due to graBty #2.2 ft9sec2

Page ## of 149

g < 1

p <

=

(

l

U>

g

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

1P Q 1a%eter of (ater droplet5 ft

(

Q LEud densty lb9ft#

l

Q !l densty lb9ft#

$"e Belocty of s%all (ater droplets =free coalesced (ater> n !l p"ase s goBerned by t"e

follo(ng 'to@es La(.

C

t

Q 14-- < g < 1

p

2

< =

(

V 7

l

U >

+"ereF

Ct K $er%nal Belocty ft9sec

g K 8cceleraton due to graBty #2.2 ft9sec2

1p K 1a%eter of lEud partcle ft

( K LEud densty lb9ft#

l K !l densty lb9ft#

$"e aboBe eEuaton s not applcable to Bery s%all lEud droplet s;es. Cery s%all (ater

droplets =stable e%ulson> n ol e%ulson (ll %oBe (t" e<tre%ely lo( Belocty and t"ey can

not be separated =n reasonable t%e> n nor%al separators.

'eparaton of LEud n Gas

$"e Bertcally do(n(ard Belocty of a lEud partcle n t"e gas p"ase s goBerned by t"e

follo(ng eEuaton.

C

t

Q D

+"ereF

C

t

Q $er%nal Belocty of (ater drop ft9sec

D Q Factor dependng on t"e geo%etry of separator

(

Q LEud densty lb9ft#

l

Q !l densty lb9ft#

$"e aboBe eEuaton s generally used for s;ng t"e Bessel da%eters. For furt"er nfor%aton

refer to 8PI 12 A.

,e-arator ,ections

$"e purpose of a separator s re%oBal of free gas and (ater =t"ree7p"ase separator> fro%

t"e ol. For effcent operaton of t"e gas lEud separators5 t"e follo(ng features are adopted

for t"e desgn of separators.

2efer to t"e attac"ed fgure for t"e detals of t"e separator.

Page #4 of 149

1-

=

(

l

U>

g

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

Page #& of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

Inlet de+ice 0Pri%ary separation section1

$"e nlet strea% co%es upon t"e nlet deflector5 ("c" acts as a %o%entu% brea@er =Ite%1>.

Collson of %<ed flo( (t" t"s deflector causes a pr%ary separaton of gas and lEuds.

$"s deBce s consttuted of 2 ro(s of "or;ontal angle bars rectangular to t"e drecton of

t"e flo(. It s fr%ly f<ed to t"e Bessel s"ell n order to support t"e %portant loads and

stresses nduced by t"e %pnge%ent.

,trai.htenin. section 0Secondary separation section1

8fter t"e pr%ary separaton gas flo(s t"roug" t"e coalescng secton consstng of

structured pac@ng =Ite%2>.

$"e purpose of t"s syste% s to cal% and strag"ten t"e gas p"ase furt"er t"e nlet deBce.

4a)or part of lEud droplets contaned n t"e gas flo( s re%oBed by coalescng on t"s

secton.

Purpose of t"s eEup%ent s to brea@ foa%5 as gas s foa%y.

Final .as clean-u- section

8fter t"ese t(o stages of gas7lEud separaton5 t"e gas enters nto t"e fnal gas clean up

secton =Ite% #> n ("c" t"e re%anng lEud droplets are re%oBed by coalescng effect.

8 sngle entry type gas bo<5 ftted (t" one (re %es" de%ster pad consttutes t"s secton.

8 dran tube s located do(nstrea% of t"e de%ster to proBde dranng of t"e coalesced

lEud and s sealed by t"e separator lEud leBel.

$"s secton toget"er (t" t"e Bapour dsengagng space aboBe "g" ol leBel proBdes t"e

lEud carryoBer perfor%ance of t"e separator. LEud carry oBer fro% separators s nor%ally

less t"an 0.1 gallons per 44'CF.

LiEuid accumulator section

$"e lEuds are collected n t"s secton ("ere ol and (ater separaton s obtaned by graBty

settlng.

$o aBod dsturbance n lEud p"ases5 and t"en for effcent separaton5 Bertcal lEud

stablsers =perforated baffles> "aBe been nstalled =Ite% &>.

$"e lEud secton s dBded n t(o co%part%ents by a Bertcal (er =Ite%4>.

In frst co%part%ent ol and (ater are separated by graBty settlng and (ater s re%oBed n

a su%p. $"e second co%part%ent collects t"e ol.

Oil-!ater se-aration com-artment

GraBty separaton s ac"eBed. Free (ater s re%oBed ol and (ater s"all not for% a stable

e%ulson. $"e desgn of t"s co%part%ent s based on 'to@es la( and retenton t%es. For a

gBen retenton t%e5 t"e Bertcal traBel of (ater or ol droplets "aBe to be greater t"an t"e

"eg"t of contnuous p"ase =ol or (ater> to ac"eBe a gBen perfor%ance or separaton

effcency.

Page #* of 149

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

+8$62 !l P"ase

Partcles

!IL

Partcles +ater p"ase !l p"ase

Oil com-artment

$"e second co%part%ent s ol7collectng co%part%ent. !l oBerflo(s t"e Bertcal (er

("ose "eg"t s c"osen5 to aBod any (ater carry oBer n co%part%ent for all t"e specfed

flo( rates. =$"s (er s ad)ustable to co%ply (t" all operatng cases>.

8 Borte< brea@er s located oBer t"e ol and (ater outlet no;;les to preBent gas entran%ent.

Formation of Emulsions

'eparaton of e%ulsfed (ater ta@es a Bery long t%e for settlng and t s not possble to

separate e%ulsfed (ater =stable e%ulsons> n separators. $"e e%ulsfed produced (ater f

not separated at t"e treat%ent plant5 (ll be carred nto t"e e<port lnes and to t"e end

users. 1e%ulsfer c"e%cals are n)ected at t"e upstrea% of t"e separators to (ea@en or

re%oBe t"e effect of e%ulsfyng co%ponents n ol5 so t"at t"e (ater droplets can coalesce

nto larger droplets for separaton n t"e separators.

6%ulson s a stable %<ture =.e.5 s%all (ater droplets do not %oBe do(n (ards under

graBtatonal forces> of t(o %%scble lEuds5 t"e nner p"ase =dspersed> beng dstrbuted

as droplets n t"e contnuos =bul@ part> p"ase. $"e for%aton of stable e%ulson reEures t(o

%%scble lEuds5 agtaton and presence of co%pounds5 ("c" stabl;e t"e e%ulson.

$"e follo(ng are t"e t(o types of e%ulsons t"at can occur n ol (ater separatonK

a> +ater n !l typeK (ater p"ase dspersed as s%all droplets n t"e contnuous !l p"ase.

$"s poses proble%s n t"e separaton of (ater n t"e 'eparators and 'torage $an@s.

b> !l n +ater typeK !l p"ase dspersed as s%all droplets n t"e contnuous (ater p"ase.

$"s poses proble%s n reducng t"e ol concentraton n t"e effluent (ater.

1e%ulsfyng c"e%cals are added for brea@ng t"e stable e%ulsons and coalescng t"e

s%all droplets nto bgger droplets.

1e%ulsfyng c"e%cals "aBe t"e follo(ng c"aracterstcsK

It "as preference to get adsorbed at t"e nterface of t"e (ater droplets.

It can effectBely dsplace t"e co%pounds t"at stabl;e t"e ol (ater nterface.

It can %a@e t"e droplets prone to coalesce =loosen t"e t"c@ nterface fl%>.

Page #, of 149

+

6

I

2

Petrofac International Ltd. Elf Petroleum Iran

JI-163 Dorood Project Onshore Facilities & e! Plant

Doc. o. I"#$-%11-&$$-%%%$$$-P"'-($1)*

"e+ $1

,tart u- and O-eratin. /anual

Oil Processin. Facilities

$o dsperse t"e de%ulsfer t"oroug"ly (t" t"e crude t"e de%ulsfer s"all be at any pont

("ere suffcent turbulent condtons e<st n t"e crude flo( to "aBe good %<ng.

8fter re%oBal of t"e e%ulsfyng agent by t"e de%ulsfer c"e%cal5 coalescng of t"e (ater

drops can ta@e place5 or t"e droplets can co%e closer (t" only a t"n5 (ea@ fl%

surroundng eac" drop.

$"e %olecular attracton bet(een drops beco%es stronger t"an before snce less dstance

separates t"e drops. +"en t(o (ater drops co%e nto contact and t"e attracton bet(een

t"e tny (ater drops n e%ulson s strong enoug" to brea@ t"e surroundng fl%5 t"e droplets

coalesce nto larger drops. $"e larger drops of (ater drop do(n by graBty nto t"e (ater

layer and get separated fro% t"e ol. $"s process s @no(n as C"e%cal Coalescng.

6onser+ation of Oil

$"e content of ol t"at can be produced fro% t"e +ell flud s referred as 'toc@ $an@ !l.

'toc@ $an@ !l s n eEulbru% (t" t"e Bapor at at%osp"erc pressure of 1.0# 0ara and at

a%bent te%perature. 8ll of t"e (ater fro% t"e (ell flud s e<cluded n t"e ,tocD 4anD.

If t"e (ell flud contans large a%ount of gaseous co%ponents5 t"e content of stoc@ $an@ ol

(ll be less. 8ll of t"e gas s separated n t"e separators and any re%anng dssolBed gas s

separated n t"e storage $an@s. Ideal separaton of gas fro% crude ol reEures t"at all C&N

co%ponents s"all be retaned n t"e crude. Ho(eBer n t"e nor%al separaton process

consderable a%ount of C& s also lost along (t" t"e Bapor.

/ulti ,ta.e ,e-aration

'ngle stage flas"ng of (ell flud fro% (ell"ead pressure to at%osp"erc pressure (ll result