Professional Documents

Culture Documents

Istbu 1994 PDF

Uploaded by

rehynaldoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Istbu 1994 PDF

Uploaded by

rehynaldoCopyright:

Available Formats

DISCUSSION

Deformation of segmental

postltensioned precast bridges as a

result of corrosion of the tendons

Proc. Instn Civ.

Engrs Structs &

Bldgs, 1994, 104,

Aug., 335-342

Paper 95 79

R. J. Woodward and D. L. S. Wi l son

P. J. Andrews, Northamptonshire County

Council

When I first read the Paper, I was quite

concerned that there was an inference that the

deflection derived from the corrosion of

structures, the corrosion of tendons, could be

related to the risk that still remained in

structures. As I am a practising highway

structural engineer, risk is of great importance

to me, as it is to all chartered engineers, and I

actually wrote down four headings, namely risk

identification, examination investigation, cost

and solution. I put cost before solution because

I believe we need to look at the bridges which

we have. This Paper actually identifies a

number of areas to which we do not know the

answer. We therefore have two kinds of cost:

the cost of undertaking all the work and the

cost of developing the solutions. Paragraph 61

of the Paper actually caused me some concern.

This says : Current practice to BS 54009

requires that for segmental bridges there is

always compression across resin mortar joints

and at least 1.5 N/mm2 compression under

service loads for mortar joints. This should

reduce the risk of water penetration at joints. I

accept this totally. Unfortunately, however, this

condition does not exist in bridges built before

BS 5400, and although this is current practice, I

am concerned that we do not lose sight of the

fact that there are many pre-BS 5400 bridges

around. What are the Authors views on the

risk that we actually are running with these

sorts of structures?

74. The ICE, in conjunction with the

Institution of Structural Engineers, has, in fact,

at the response of the Standing Committee on

Structural Safety, set up a small working party

to write a guidance note on how post-tensioned

structures should be designed to prevent this

kind of thing from happening. This is useful for

how one designs in the future. The difficult

part-and I can assure you it is the difficult

part-is how one deals with the existing

structures, because although the Authors have

assumed linear corrosion in many cases-and I

think in fairness to them that is all they can do

because if you try to find out where the

corrosion is you have destroyed the ability to

test the structure-it does not corrode like

that. It corrodes in bits here and there. This is

an area which needs to be looked at further.

75. Do the Authors consider that this

post-tensioning problem seems to occur with

structures which are somewhat unusual in

design? By unusual , I mean not normal

in-situ sections, but a series of small concrete

sections which go together. Paragraph 67 states

that: The degree of corrosion at the joints did

not alter the shape of the curves but influenced

the load at which complete failure occurred ,

which I believe is a very important statement. I

believe that a certain amount of redistribution

occurs, and that one cannot actually attribute

any known level of risk to the deflection and

indeed to the elements of corrosion that are

obtained.

F. W. Williams, West Glamorgan

County Council

First of all, could the Authors give an

explanation regarding the results displayed in

Figs 4 and 7 of the Paper? Bearing in mind the

jacking and anchoring details, how is the loop

displayed in the moment deflection graph in

Fig. 4 possible? Do I presume that the jacks

were released and then retracted fully in order

to allow the beam to recover, and were then

reloaded? This is rather a minor point, but

there was apparently a 50 mm recovery in the

deflection.

77. A much more salient point I think is

displayed in Fig. 7, bearing in mind what the

purpose of the study was. With reference to

Beam A, it is stated in the Paper that the

eventual failure occurred at joints 3/4. Could

the Authors explain why the crack widths

within the range displayed in Fig. 7 were

greater at joints 5/6 and 7/ 8? Beam B raises a

similar problem, even though the graphs are

somewhat different, and the mode of failure

was different. I can understand the recovery of

the crack width within the segments once the

yielding has taken place, say, at the joints, but

again why does the crack width continue to .

increase at joint 5/6 and not follow the pattern

of joint 3/4 on the concrete section? Do I

presume that these are a function of the amount

of debonding that was taking place at the

joints?

corrosion of prestressing tendons, even in

segmental structures such as Ynys-y-Gwas,

Paperpublished:

cannot be detected by external visual

Proc. Instn Civ.

Engrs, Part 1,

inspections, and this was proven beyond any 1991, go, Apr.,

doubt in the investigation that followed the 397-419

78. It has been clearly established that the

335

DISCUSSION

dramatic collapse of the Ynys-y-Gwas Bridge.

Regrettably, therefore, the findings of the tests

and analytical studies reported in this Paper

have drawn a complete blank from say, another

avenue: i.e. it has been found that the moni-

toring of the structural deformation of these

post-tensioned structures is clearly not a

feasible method of detecting potential or

impending tendon failure in segmental

structures. This is extremely disappointing, as

bridge managers are still looking for a reliable

inspection and/or non-destructive testing

procedure to assist in the inspection and

assessment of segmental bridges.

to is risk assessment. The method that we

adopt is as follows. Firstly, the risk of

corrosion is assessed by studying the

constructional details of a bridge, and by

considering the bridge siting and the

environment in which it has to survive.

Thereafter, local areas of potential risk are

identified and analytical tests, such as chloride

tests, are carried out on the immediate

environment of the tendons within those risk

areas. Finally, there is no option but to gain a

direct viewing of the tendons at these critical

areas by coring of the cover concrete by drilling

and using endoscopes, or by simply chipping

away at the cover concrete to the tendons.

80. In the light of the current state of the

art, how has the development of non-

destructive tests, such as electrode potential,

resistivity surveys and so on, which are used

quite commonly in reinforced concrete

elements, been developed in recent years in the

context of post-tensioned structures?

81. As the Department of Transport are the

funders of the research into the management of

highway structures, is any special funding

going to be made available for this essential

development work? I ask this as a local

authority man who has to manage both local

authority bridges and bridges in Wales on

behalf of the Welsh Office. This is fundamental

development work and one can hardly rely on

the resources of the local authority. We are

talking about a national asset, and a substantial

asset at that, and my view is that a substantial

investment is necessary in the development of

new methods.

79. As I see it, the process we have to resort

A. McC. Low, Ove Arup & Partners

This Paper is very significant. I have been

designing bridges in post-tensioned concrete

believing that it is an inherently ductile

material, and that under an extreme situation,

distress would become apparent before

collapse ; this Paper, however, indicates

otherwise.

in hidden cables, designers are turning to

external prestressing systems in which the

83. To avoid the uncertainties of corrosion

cables are not bonded to the concrete. From Fig.

14 of the Paper, it will be seen that the Author's

computer program does not support what I

believe to be the normal understanding of the

way that unbonded cables behave. It shows

results for several models with different

degrees of bond, and for the unbonded one it

shows that, although it deflects a long way, it

carries a larger moment than the fully bonded

one. I find this extraordinary. Either there must

be a mistake in the computer model or there is a

mistake in the conventional understanding of

how unbonded prestressing behaves.

84. The usually assumed lack of ultimate

moment capacity is a significant factor which is

holding back the use of externally prestressed

concrete. There are penalties associated with

the additional prestressing required to

overcome it which may be as much as an extra

40%. With some systems, this extra can be

reduced because many of the losses can be

overcome in a restressing operation at the end

of the maintenance period. If the Authors'

model is correct, no extra is required.

Dr P. Lindsell, Gifford and Partners

One of the primary objectives of this Paper was

to look at means of detecting impending failure

in post-tensioned segmental bridges. Previous

research" into the demolition of post-tensioned

structures has provided the opportunity to

observe the behaviour of post-tensioned beams

up to and including the point of failure.

86. During the controlled demolition of

selected segmental beams from five post-

tensioned three-span continuous bridges in

1970, two 400 t tendons were severed at four

critical points in a predetermined sequence.

The tendons were initially severed over the

intermediate piers, but more than 90% of the

strands had to be burnt before the beams

collapsed on to the temporary supports. Even

under these extreme conditions, there was no

warning deflection before collapse, However,

obvious signs of impending failure were

apparent where the severed strands had

debonded and produced longitudinal cracks on

either side of the cut position up to 10 m from

the cut points.

87. The Authors produced a theoretical

model to examine the breakdown in bond where

a tendon is broken. The demolition trials"

carried out during the period 1983-87 showed

clearly that the extent of debonding depended

very much on the amount of local shear

reinforcement in addition to the condition of the

grout. The segmental bridges described above

were designed to CP115 principles, so the shear

reinforcement consisted of nominal amounts

near the cut positions. Subsequent tests on

bridge beams designed to BS 54001' indicated

that the local shear reinforcement acted like

end anchorage steel and it was the controlling

9.579

factor in limiting the longitudinal cracking and

debonding length. Modelling the breakdown in

bond represents only a small part of the story,

as the transverse bursting stresses become very

significant as tendon diameters increase.

88. In 1983, demolition trials on four post-

tensioned concrete beams at Basingstoke'O

confirmed both the deflection behaviour before

collapse and the parameters controlling

debonding of a severed tendon. A video film

was produced at the time to illustrate the brittle

failure that occurs as bonded tendons are

gradually severed at a single point. No prior

visible deflection occurred and the collapse of

each beam took only a fraction of a second.

89. The controlled demolition of Taf Fawr

Bridge,13 a three-span segmental structure,

began in 1985, just before the collapse of

Ynys-y-Gwas Bridge. Simple deflection

calculations for a cantilever beam were based

on the standard formula from strain energy

principles

90. These calculations quickly showed that

the monitoring of deflections would be quite

inappropriate. Therefore, the procedure

adopted to detect impending failure was to

monitor the in-situ joints between precast

segments with vibrating wire strain gauges.

Advance warning of non-linear behaviour at

joints was obtained more than a week before

conditions became critical at the section.

91. One of the important results arising

from the monitoring of Taf Fawr Bridge was

that non-linear behaviour at the joints is likely

to occur when the residual compressive stress

lies in the range 1-2 N/mm2. Subsequent

laboratory tests and numerous large-scale load

tests on existing segmental post-tensioned

bridge decks have since confirmed that this is a

general rule for various forms of segmental

construction. Therefore, the Authors' theoret-

ical assumption that non-linear behaviour

occurs when zero compressive stress is created

in the soffit of the Ynys-y-Gwas Bridge beams

is likely to represent a significant departure

from reality. An assessment of prestress losses

on this basis could be clearly prone to serious

error.

Dr S . Jefferis, Golder Associates ( UK) Ltd

(formerly Queen Mary and Westfield College,

University of London)

There are a number of significant problems in

ensuring that ducts are completely filled with

grout and therefore that prestressing tendons

are properly protected from corrosion. In

particular, it is necessary to address the issues

of grout rheology and bleeding. I report here

some of the results of work on grout flow

carried out at Queen Mary and Westfield

College, University of London, under a contract

from the Transport Research Laboratory, with

Dr Woodward and later Dr Pate1 as the

supervising officer, and work on bleeding

supported by the Marine Technology

Directorate of the Science and Engineering

Research Council.14

93. The aim of the flow work was to

develop a rheological test (or tests) so as to be

able to ensure that a grout has the optimum

flow characteristics (rheology) to fill a duct. To

investigate the effects of grout rheology, a test

rig was constructed in which undulating ducts

of length up to 8 m and containing prestressing

strands could be grouted. The grouts were

prepared in a site-type grout mixer, and about

17 duct simulations were injected.

94. From this work, it was concluded that

grout rheology is not the prime control on duct

filling. Grouting procedure and, in particular,

duct venting were found to be of much greater

significance. In the simulations, grout was

injected from one end of the ducts, as would be

the usual practice on site. It was found that as

the grout was injected, it would satisfactorily

fill sections of the duct where the flow was

upwards. However, where the flow was

downwards, the grout flow would no longer

occupy the full cross-section of the duct but

would break away and run down to the next

low point where it would build up and trap a

void, as shown in Fig. 20. Clearly, break-away

from full duct flow will be more likely to occur

with thin grouts; and it had been hoped that if

a sufficiently stiff grout were used, it could be

squeezed along the duct rather like toothpaste,

and that the flow would continue to fill the full

duct cross-section even in the downward flow

limbs. However, break-away was found to occur

with all the grouts tested, including the stiffest

grout that could be pumped. It was concluded

that if there is injection from one end only and

if there is no intermediate venting system, then

there is no possibility of filling the whole of an

undulating duct.

95. If vents are not used, the grouting may

be improved by injection from both ends so that

all sections of the duct are subjected to upward

flow at some stage of the injection process.

Substantial quantities of grout must be passed

through the duct to ensure that all trapped air

is discharged. This may seem wasteful but the

cost of this grout will be trivial in comparison

to the cost of the structure. Grouting from both

ends may require a grout mixing plant at each

end of the duct.

96. Gas expansive admixtures are often

suggested as a means of preventing voids in

ducts. However, we never managed successfully

to fill a duct using a gas expansive agent.

During injection, one gets exactly the same

voids in the downward flow limbs as with

337

DISCUSSION

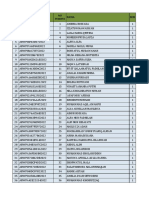

Fig. 20. Duct injected

with 0.45

waterlcement ratio

grout ; no venting

(Note bleed channel

shown in Detail 2)

1 2 3 4

4

\

normal grouts and there are further

complications in that the gas expansion can

blow channels in the grout as the gas pressure

dissipates into voids or to vents (see Fig. 21). It

should be noted that if a gas expansive agent is

to do anything, then the grout has to be able to

expand, and therefore there has to be some

venting. Gas expansive agents must be used

with great care and the amount of expansion

must be very carefully regulated. Such

materials have a special role in some grouting

operations but they cannot fill bulk voids left

by poor injection practice.

97. If vents are used to prevent voids then

positioning is important. The obvious location

is at the crowns (high points) of an undulating

duct. However, it was found that vents at the

crowns were not sufficient as they tended to get

blocked by the local grout flow. It was

necessary to include a second vent part way

down each descending limb (descending in the

direction of flow). The crown vent is to be

opened only when a significant quantity of

air-free grout has been allowed to discharge

from the downstream vent. It is still necessary

to vent substantial amounts of grout, and a

total discharge quantity of at least one duct

volume should be specified.

98. The ideal situation with regard to grout

injection in the duct is aways to grout from low

i. : , :

1 2

points to adjacent high points so as to ensure

that there is never downward flow. However,

installing the necessary injection points and

injecting from them can present severe

practical difficulties.

Grouts for prestressing tendons: prEN 445:

Test methods;15 prENV 446: Grouting

procedures;6 prEN 447: Specification f or

common grout. These standards include two

rheological tests. The first is a simple funnel

test. The funnel and test procedure are

specified but any funnel should be used with

caution for there are very many different

funnels and test procedures. To avoid

confusion any funnel results are being reported,

the following details should be included: the

quantity of grout put in the funnel; the

quantity of grout discharged; the diameter of

the funnel orifice; the flow time for water. prEN

447 specifies a flow time of <25 S ( <50 S for

high shear mixed grout) for grout before

injection into the duct, and >10 S for the grout

discharged from the duct; 10-50 S is

practically the useful range of the funnel. With

water, the flow time is of order 6 S ; if the grout

flow time goes much beyond 50 S, flow may

stop before the specified quantity has been

discharged.

100. The other test procedure in the

99. There are now three draft standards for

%.,.....

3 4 5

Fig. 21. Duct injected

with 0.38

waterlcement ratio

grout containing a

gas expansive

admixture; single

limited vent at crown

(Note channel created

by gas escape)

Slit at crown

for venting /

338

9579

standard is one that is less widely known-the

Otto Graf plunger or Immersion test. The

apparatus consists of a vertical tube in which a

close fitting bullet shaped plunger can work.

The clearance beween tube and plunger is 1.9

mm. In the test, the tube is filled to a prescribed

level with grout and the plunger is inserted into

the grout. The plunger is then released and the

time for it to fall 0.5 m is recorded. The test

appears to be suitable only for superplasticized

grouts. With normal grouts (unless of

unacceptably high water/cement ratio), the flow

time is very extended. The standard suggests a

range of 30-80 S (30-200 S for high sheared

mixes). Again, this is very much the useful

range of the instrument.

101. A problem with all rheological tests

was found to be that few tests suitable for use

on site have a significant dynamic range. Tests

almost have to be designed to suit individual

grouts. Therefore, with the prEN 445 funnel or

immersion test, flow may stop before the

specified end point, even with grouts that are

satisfactory for injection.

102. The source of the cement, the shear

level during mixing, the mix time and the batch

size can all cause substantial changes in

rheology. Therefore, if rheology is to be used as

a control parameter, then it is crucial that the

same cement and mix procedure are used

throughout the works and also in any pre-

works trials. In the work at Queen Mary and

Westfield College, three cements taken from

different works around the country were tested;

all could be classified as ordinary Portland

cement to BS 12. However, they showed

dramatically different rheologies: e.g. the

funnel flow times ranged from almost the time

for water to no flow at all.

103. Not only is rheology of limited

significance for duct filling but it is also a poor

indicator of the all important parameter-

water/cement ratio. For this, much more

reliable data can be obtained from density

measurements-although a relatively precise

measurement system is required.

104. There is also the problem of bleed once

the duct has been filled with grout. Grouts are

of necessity very porous systems (to make them

pumpable), and the solids will tend to settle and

so expel bleed water. For example, a 0.3

water/cement ratio grout has a volumetric

water content of the order of 50O/ o (' I.e. a

porosity of 50%) and would bleed very

substantially if it did not set.

using the self-weight consolidation theory

developed for soils. From this it can be shown

that the drainage path length is of critical

importance. In a vertical duct without a tendon

the drainage path length will be the height of

the duct, and almost no bleed may occur before

set. However, if there is a tendon, it can act as a

105. The bleeding of grouts can be modelled

drain and the consolidation will be radial with

a very short drainage path, and so substantial

bleed may occur. In trials with a 0.4

water/cement ratio grout in a 6 m vertical duct

without a tendon, the bleed was about 4 mm,

but with an unsealed tendon the bleed was 300

mm. Therefore, when laboratory bleed test

results are being related to full-scale ducts, it is

important to keep in mind that changes in

drainage can cause very substantial changes in

bleed. For critical situations, the duct drainage

conditions should be simulated in the

laboratory.

106. It should be remembered that if bleed

water is seen dripping from a tendon after the

completion of grout injection, then a void must

be developing in the duct.

D. I. Cooper, Flint and Neill Partnership

Unbonded or poorly bonded tendons seem to

give weaker but more ductile structures. Do the

Authors believe that this might be a useful

characteristic resulting from poor quality

construction, particularly as proper grouting is

seen to be so important?

A. C. E. Sandberg, Messrs Sandberg

I remember discussions on the mechanism that

could cause failure under no live load. Were

there any conclusions in this respect?

109. Although perhaps not part of the

Paper, any developments in methods of

detection of corroded tendons would be of great

interest to all.

Dr J. Manning, Messrs Sandberg

For many years, the phenomenon of brittle

fracture of high strength wires used for

prestressing strands has been questioned as a

quantifiable risk of failure for prestressed

concrete, and has been dismissed.

Investigations into the more common

occurrence of brittle fracture of strands when

used for ground anchors has perhaps thrown

light on why, in spite of metallurgists'

predictions, this occurrence is rare for bridges.

Experimental work conducted on ground

anchors in a marine environment grouted with

epoxy resin reproduced chemical conditions

which were conducive to brittle fracture (by

stress corrosion cracking) and the influence of

small quantities of particular chemicals had a

marked effect on the time (from a few months

to up to 30 years) and mechanism by which

failure occurred.

111. The factor having most influence was,

however, the stress level in the tendons, and

brittle fracture could not be reproduced below a

stress of 50-55% of ultimate tensile strength.

Losses in prestressing tendons due to friction,

relaxation of steel, creep of concrete, anchorage

slip normally results in a final long-term stress

level of this order, whereas short ground

339

DISCUSSION

anchor tendons generally maintain higher

levels in a potentially more aggressive

environment. There may well be a case,

therefore, for limiting final stress levels for

both prestressing tendons and ground anchors

to eliminate the risk of sudden failure of

individual wires. Sustaining the tendon force

rather than consideration of stress levels in

individual wires usually influences stiffeners of

the prestressed member. However, corrosion of

individual wires could result in transfer of

stress to a reduced area and hydrogen

embrittlement.

112. The relationship between chemical

environment, stress level and potential for

brittle fracture needs further investigation.

R. F. Barker, Member

The Authors conclude that deformation

characteristics associated with gradual loss of

tendon area offer no observable warning of

impending failure. I am not convinced.

114. By and large, I do not feel that the

load/deflection information obtained by testing

the edge beams has, or is likely, to provide an

insight into the deflection characteristics of the

inner beams during gradual corrosion of the

tendons. The internal deck did not fail under

applied external load. Rather, effective tendon

areas were reduced until the deck was no longer

able to support its own weight.

115. Would it not have been possible to

monitor the beams deflection profile during the

progressive remote cutting of tendon wires, or

to simulate such conditions with scale models?

116. At failure, the prestressing forces will

have been largely dissipated and it seems

reasonable to expect that some, if not all, of the

prestressing deflection (hog) will have been

lost. The question is: Can one expect a trained

Inspector to observe this? .

117. To develop this notion further, the

extent to which prestress will have been

dissipated at failure needs to be assessed. This

can be estimated by equating the residual

stress capacity in the remaining tendon wires

to that attributable to self weight, with the

beam now acting as a reinforced concrete

member rather than as a prestressed concrete

member.

118. This type of exercise indicates that

some two thirds of effective tendon area will

have been lost at failure.

119. Midspan deflections (of the order of)

can be summarized as follows

those attributable to final

prestress +60 mm

those attributable to self weight -30 mm

Residual +30 mm

those attributable to loss of

prestresses 2/3 X 60 -40 mm

Residual at failure -10 mm

120. Changes in soffit profile of this order

are detectable by eye, particularly in

foreshortened views, and also by using precise

levelling techniques.

121. In this particular case, the relationship

between inner beams and edge beams will have

provided a further reference point.

122. The Paper gives little information on

the beams which actually failed: i.e. the

internal beams. Was the extent of wire

corrosion observed, and did the transverse

tendons have any influence other than to ensure

the failure of the entire internal deck rather

than of a single beam? Presumably, the

transverse tendons did not extend to the edge

beams?

Authors reply

MY Andrews asks for our views on the risks we

are running with segmental bridges which are

not designed to have a minimum compression

of at least 1.5 N/mm2 across the joints under

service loads. Much was made of this point

when the original paper on the collapse of

Ynys-y-Gwas bridge was presented to the ICE.

It was pointed out then that whether or not a

structure complies with this rule in design is

dependent on the loads and effects which are

considered in the calculations: for example,

whether or not they include differential

temperature, shrinkage, etc., and what live load

is taken as the service load. Therefore, whether

a structure is designed for no tension or a

minimum compression, 1.5 N/mmz makes little

difference because the actual stress could vary

by a much greater amount. So while a minimum

compression would appear to give better

protection against ingress of chlorides, it

should not be relied on.

124. With regard to Mr Andrews second

question, we do not believe it is safe to assume

that problems occur only with structures that

are somewhat unusual in design. All structures

have a degree of uniqueness, but there is no

evidence that seemingly normal structures

are immune from problems.

125. Mr Williams asks how the loop

displayed in the moment deflection graph in

Fig. 4 is possible. After the deflection had

reached 180 mm, the jacks were retracted and

the beam left overnight, leaving a small load

locked in the beam; the deflection recovered

only 50 mm. The load was reapplied the

following morning, thus producing the loop.

widths displayed in Fig. 7 for beam A are

greater at joints 5/6 and 6/7 than at joint 3/4

where the failure occured. The failure of this

beam was attributed to the simultaneous

fracture of tendons in the bottom flange of the

box, and the low maximum deflection of 105

mmwas attributable to a high bond stress

between the tendons and the grout. On account

126. MY Williams also asks why the crack

340

9579

of the high bond stress, the strain was localized

to the joint which therefore opened less than

the other two joints in the constant moment

region. With regard to beam B, we agree with

Mr Williams that the opening of the joints was

a function of the amount of debonding that was

taking place. Indeed, there was considerable

creaking as the beam was deflected beyond the

maximum load, and this was thought to be

attributable to debonding of the tendons.

in $ 79, and note that they are similar to the

procedure adopted by the Department of

Transport in their draft Advice Note on ' The

planning organisation and methods for

carrying out for special inspections '.

128. Both Mr Williams and Mr Sandberg

refer to the need for methods for detecting

corroded tendons. Many of the methods used to

assess the corrosion risk in reinforced concrete

can be applied to post-tensioned concrete to

give an indication of the risk of corrosion in the

vicinity of the duct. However, it is much more

difficult to assess the risk of corrosion of

tendons. It is not possible to make surface

measurements of their electrode potential in

lined ducts as they are screened by the metal

sheathing. For unlined ducts it is not possible

to determine whether the potentials measured

are those of the tendons or secondary

reinforcement, unless holes are drilled to allow

measurements to be made adjacent to the

tendons. Another problem is that where there

are voids, there is no continuity of the

electrolyte.

129. There are no NDT methods that can

reliably detect corrosion. Radiography might

detect fractures or serious loss of section if a

radiograph was taken in the right place. The

French have developed a radiographic

technique that can scan along tendons and

inspect them in real time. While this is an

improvement on existing techniques, the

number of structures that are suitable for this

technique is limited by geometrical and safety

considerations, and the number of positions at

which radiographs can be taken are limited by

geometry. Radar can be used to locate metal

ducts but cannot penetrate the sheathing. It can

inspect tendons in unlined ducts but interpre-

tation is difficult. Ultrasonic methods might be

used to detect wire fractures near an anchorage

but require good access to the anchorage. There

are a number of other methods which it is

claimed can be used to detect voids and

corrosion, but none that have been proven in

service.

or not the study has contradicted the usual

understanding that structures with unbonded

tendons have a lower ultimate bending capacity

than that of their bonded counterparts. The

purpose of the model was to investigate the

127. We agree with Mr Williams' comments

130. Mr Low is right in questioning whether

load-deflection characteristics of the beam.

The Fig. 14 graphs were plotted to investigate

the effect of bond strength on the shape of the

moment-deflection curve (see $ 37), not to

calculate the ultimate bending capacity of the

beam. The unbonded case was run to give the

limiting lowest bond strength case and the

failure criterion was based solely on the steel

strain reaching a predetermined level.

131. In $38, it is noted that a higher bond

results in a shorter transfer length. This means

the change in length of the tendon across a

joint is carried on a shorter length of tendon as

the bond strength increases. For an unbonded

tendon, the local change in length at a joint is

dissipated over the total length of the tendon,

resulting in a much smaller increase in strain

than for bonded tendons. Fig. 14 therefore

shows that the ultimate bending capacity

of the beam with an unbonded tendon, based

only on a limiting steel strain criterion, is

higher than that of a beam with a bonded

tendon.

132. If the model had been established to

investigate the ultimate bending capacity of

beams with unbonded tendons, it would have

taken into account the differences in behaviour

between beams with bonded and unbonded

tendons. Additional characteristics such as the

friction between the duct and the tendon and

the different development of cracking in the

beam due to the lack of bond would have been

incorporated. It is likely that an appropriate

model would have confirmed conventional

wisdom.

that the debonding of a fractured tendon in a

fully grouted duct may produce longitudinal

cracking on either side of the fracture.

However, this does not affect the principal

conclusion of the Paper that localized corrosion

that has not caused actual failure of wires or

tendons is essentially undetectable by

measurement of deflection, joint opening and

cracking.

134. We agree that it would be unwise to

rely on the assumption that the onset of

non-linear behaviour occurs when there is zero

compressive stress in the soffit. The method

used was to detect joint opening on the second

loading cycle, although this was only one of

several methods used to estimate the

prestressing force in the tendon.

135. We would endorse Dr Jeffeeris's

comments on the difficulty of ensuring that

ducts are fully grouted. However, fully grouted

ducts will not guarantee protection against

corrosion. Grout is only one link in the chain. It

is necessary to ensure that chlorides cannot

enter the ducts, and this necessitates paying

proper attention to details such as the integrity

of the waterproofing, protection at the

anchorages and ensuring that there are no

133. We agree with Dr Linsell's observation

341

DISCUSSION

paths within the structure which might allow

chlorides to gain access to the ducts.

136. MY Barkers assertion that loss of

prestress would give rise to changes in the

soffit profile that could be detected by eye, or

by precise levelling, is correct where tendons

are ungrouted. However, where ducts are well

grouted, the loss of prestressing force will be

localized to the section at which corrosion is

occurring and there will be no measurable

change in deflection.

137. MY Coopers suggestion that the more

ductile behaviour of poorly grouted structures

is a useful characteristic might apply if the

grouting and degree of bond could be quan-

tified by inspection. However, if the degree of

bond is unknown, then absence of deflections

does not give assurance that there has been no

loss of prestress.

138. MY Sandberg and MY Barker both ask

about the collapse mechanism for Ynys-y-Gwas

Bridge. This was not addressed in the Paper.

However, the small deflections resulting from

localized corrosion might explain why no

evidence of distress was observed before

collapse. As for there not being a vehicle on the

structure when it collapsed, it should be

remembered that failure of concrete beams can

take several minutes. Therefore, if a vehicle

had initiated a collapse, it would have been on

the bridge only for a few seconds and could

have been some distance away when the

collapse occurred.

risk of stress corrosion. To our knowledge,

139. Dr Manning is concerned about the

stress corrosion of post-tensioned tendons is

not regarded as a problem in grouted ducts in

the UK. Where failures have been reported

abroad, it is usually either because the tendons

were left stressed and unprotected for long

periods or because of the use of quenched and

tempered steel which is more susceptible to

stress corrosion.

References

10. BUCHNER S. H., LINDSELL P. and ROBINSON S. Pre-

stressed losses in full-scale structures. CIRIA

Research Project, University of Surrey, Nov. 1984,

Internal Report R/M/CVL 84/2.

crete. Concrete, 1975, 9, No. 1, J an.

stressed concrete structures during demolition.

Conf. on Structural Assessment. The use of full

and large scale testing. Butterworths, 1987.

13. PRICE W. I. J ., LINDSELL P. and BUCHNER S. H.

Monitoring of a post-tensioned bridge during

demolition. ZABSE Colloquium, Bergamo, 1987.

14. J EFFF.RIS S. A. and FORRPSTER J. A. Development of

site testsforgrout. Contractor Report to be

published by the Transport Research Laboratory,

Crowthorne.

Methods, 1992

Groutingprocedure, 1992

cification for common grout, 1992

problems of off-shore grouting. Grouts and grout-

ing f or construction and repair of offshore struc-

tures. HMSO, London, 1988,72-90.

11. LINDSELL P. Demolition of post-tensioned con-

12. BUCHNER S. H. and LINDSELL P. Testing of pre-

15. prEN 445 Grouts forprestressing tendons: Test

16. prENV 446 Grouts forprestressing tendons:

17. prEN 447 Grouts forprestressing tendons: Spe-

18. Application of bleed and settlement theory to

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- IG Report - Hillary Clinton Has Committed Sexual Crimes Against Children' - The Republic PostDocument1 pageIG Report - Hillary Clinton Has Committed Sexual Crimes Against Children' - The Republic PostZsi Ga70% (10)

- 107 Butterflies Coloring PagesDocument107 pages107 Butterflies Coloring PagesGenerallyCrispy100% (5)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Value of Hawai'i Knowing The Past, Shaping The FutureDocument266 pagesThe Value of Hawai'i Knowing The Past, Shaping The FutureGigi CostelusNo ratings yet

- Lynn E. Szymoniak Notice of Us Government Not InterveningDocument3 pagesLynn E. Szymoniak Notice of Us Government Not InterveningBSmith1264No ratings yet

- StonaDocument6 pagesStonaJyotsna PandeyNo ratings yet

- 1 CV Handbook Final Nov 2012Document140 pages1 CV Handbook Final Nov 2012Thomas KidandoNo ratings yet

- Marriage Registration ProformaDocument10 pagesMarriage Registration ProformaRakesh PaalNo ratings yet

- Foreign Policy in The 21st Century - Chris HillDocument396 pagesForeign Policy in The 21st Century - Chris HillZulkhairee Sulaiman75% (8)

- Sambajon Vs Suing A.C. No. 7062Document2 pagesSambajon Vs Suing A.C. No. 7062CeresjudicataNo ratings yet

- GARCIA VsDocument1 pageGARCIA VsJenifer PaglinawanNo ratings yet

- SW 116: Social Welfare Agency AdministrationDocument17 pagesSW 116: Social Welfare Agency AdministrationMarion DeriloNo ratings yet

- Montebon Vs COMELECDocument1 pageMontebon Vs COMELECMelanie CabanlasNo ratings yet

- Government of India, Ministry of Railways Railway Recruitment Cell, Central RailwayDocument21 pagesGovernment of India, Ministry of Railways Railway Recruitment Cell, Central RailwayAbdul Samad PathanNo ratings yet

- Physiotherapy Home Visit Service in MumbaiDocument3 pagesPhysiotherapy Home Visit Service in MumbaiDr. Krishna N. SharmaNo ratings yet

- The Right and Duties of Other States in The EEZDocument6 pagesThe Right and Duties of Other States in The EEZOmank Tiny SanjivaniNo ratings yet

- Urgent Motion For Early ResolutionDocument2 pagesUrgent Motion For Early ResolutionAliNo ratings yet

- USA Vs Ruiz Doctrine of Immunity From SuitDocument2 pagesUSA Vs Ruiz Doctrine of Immunity From SuitJM CamposNo ratings yet

- Equality Under The Singapore ConstitutionDocument7 pagesEquality Under The Singapore ConstitutionInaanekidNo ratings yet

- Sano Vs ComelecDocument22 pagesSano Vs ComeleccitizenNo ratings yet

- BFB 0445 FC 0 ADocument284 pagesBFB 0445 FC 0 Atau desiNo ratings yet

- Quiz 1 IB1606 LOG LAW102Document4 pagesQuiz 1 IB1606 LOG LAW102Hữu Đạt ĐồngNo ratings yet

- PICE Life Membership Application Form 10yrsDocument1 pagePICE Life Membership Application Form 10yrsdvduron100% (1)

- SLM S.Y. B.A. HindiDocument188 pagesSLM S.Y. B.A. HindiArman ShaikhNo ratings yet

- Research Paper Topics in Homeland SecurityDocument5 pagesResearch Paper Topics in Homeland Securityfvjawjkt100% (1)

- Land Law Tutorial 1 BDocument22 pagesLand Law Tutorial 1 BizzatiNo ratings yet

- Ba'athismDocument10 pagesBa'athismRodrigo BacelarNo ratings yet

- Enlightenment PhilosophersDocument11 pagesEnlightenment PhilosophersDavid LaneNo ratings yet

- Features of Indian EconomyDocument7 pagesFeatures of Indian Economyizharalam550No ratings yet

- Government of Goa Directorate of Official Language Panaji - GoaDocument56 pagesGovernment of Goa Directorate of Official Language Panaji - GoaEdwin D'SouzaNo ratings yet

- Pembagian Sesi Tes TulisDocument8 pagesPembagian Sesi Tes TulisRangga SaputraNo ratings yet