Professional Documents

Culture Documents

CMP.2001.0514 - Multi Stage Centrifugal Compressors Lores PDF

Uploaded by

Victor Cameron0 ratings0% found this document useful (0 votes)

79 views12 pagesElliott has designed, tested, and installed some of the industry's most rugged and dependable equipment. Some Elliott compressors and turbines installed in the 1940s and 1950s are still in operation today. Elliott's Multi-Stage Centrifugal Compressors lead the industry in both performance and reliability.

Original Description:

Original Title

CMP.2001.0514---Multi-Stage-Centrifugal-Compressors-lores(1).pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentElliott has designed, tested, and installed some of the industry's most rugged and dependable equipment. Some Elliott compressors and turbines installed in the 1940s and 1950s are still in operation today. Elliott's Multi-Stage Centrifugal Compressors lead the industry in both performance and reliability.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

79 views12 pagesCMP.2001.0514 - Multi Stage Centrifugal Compressors Lores PDF

Uploaded by

Victor CameronElliott has designed, tested, and installed some of the industry's most rugged and dependable equipment. Some Elliott compressors and turbines installed in the 1940s and 1950s are still in operation today. Elliott's Multi-Stage Centrifugal Compressors lead the industry in both performance and reliability.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 12

PRODUCTS

Multi-Stage Centrifugal Compressors

2

EVOLUTIONARY DESIGNS REVOLUTIONARY RESULTS

A History of Innovation and Success

Since 1910, Elliott Company has earned a reputation

for providing innovative solutions, unmatched

expertise, and frst-class service to the global

turbomachinery marketplace. Elliott has designed,

tested, and installed some of the industrys most

rugged and dependable equipment. In fact, some

Elliott compressors and turbines installed in the

1940s and 1950s are still in operation today, either

as originally supplied or upgraded to handle new

process conditions or more stringent environmental

standards.

We have been on the cutting edge of technological

advancement throughout our history, consistently

providing advanced technology in aerodynamics,

rotor dynamics, process simulation, and

metallurgy. Our customers have benefted from our

state-of-the-art production innovations, including

fabricated casing technology, high-pressure casing

technology, and impeller welding techniques. The

Elliott EDGETM development program evolved from

our commitment to providing new approaches,

processes, and technology while maintaining

the quality and reliability that our customers

have come to expect.

We understand that change is essential in achieving

and maintaining a competitive edge in todays

business environment. Together with our customers

and suppliers, we continue to innovate, improve,

and expand our extensive portfolio of products and

services that serve the energy industries.

Product Lines

Single/Multi-Stage Centrifugal Compressors

(API 617)

Axial Air Compressors (API 617)

Single/Multi-Stage Steam Turbines (API 611)

Multi-Stage Steam Turbines (API 612)

Applications

Oil Refneries

FCC Applications

Chemical/Petrochemical Plants

Ethylene Plants

Gas Lift/Gas Gathering

Gas Injection/Transport

LNG Facilities

Gas to Liquids

Ammonia Plants

Power Generation

3

ADVANCED TECHNOLOGY

Superior Performance Through

Advanced Technology

Through our EDGE development program, we

combine our comprehensive knowledge of

turbomachinery with the latest design software,

manufacturing processes, and machine tools. As a

result, Elliotts multi-stage centrifugal compressors

lead the industry in both performance and reliability.

Increased Aerodynamic Efciency

Elliott uses state-of-the-art interactive design

and prediction tools to optimize aerodynamic

performance and increase fange-to-fange

effciencies. Compressor impeller and matched

stationary fowpath components are developed

using Computational Fluid Dynamics (CFD) analyses

and other current design tools. Three-dimensional

blade profles, diffuser fow angles, crossover bend

curvature, area ratio, and return channel vane

shapes are optimized for each impeller stage to

provide the best possible effciency. Additional

performance enhancements are achieved by

improving the fow distribution channels at the inlet

and discharge volutes and sidestream mixing areas.

These enhancements allow us to provide some of

the industrys highest operational effciencies.

Improved Rotor Stability Characteristics

Through extensive research in the felds of

rotor-dynamic stability, aerodynamic cross-coupling

stiffness, and rotor-bearing systems, we have

developed proprietary analytical tools. Incorporating

these developments into Elliott compressor designs

has produced a number of product enhancements.

For example, weve increased rotor stiffness

by increasing shaft diameter, reducing impeller

weight, and increasing journal bearing sizes. This

allows higher torque transmission capabilities

and higher-speed operation, with improved rotor

stability characteristics, which are essential as

gas densities and operating pressures increase.

4

CASING FEATURES

EDGE Casing Advantages

Integral horizontal fanges on small and medium

frames

Solid endwalls with machined fats for bearing

and seal connections

Machined fats with SAE fanges for most drain

or

injection connections

Through-bolts for casing horizontal fanges

Allowable forces and moments per API 617

Three-dimensional solid modeling for improved

design and engineering review capability

Pro/ENGINEER solid modeling fles to enhance

precision during component manufacture

Elliott designed our EDGE compressor casings

to reduce the required manufacturing steps and

simplify feld assembly. To achieve higher operating

pressures, we applied state-of-the-art solids

modeling and fnite element analysis techniques.

Small and mid-sized horizontally split casing

sections are made from a single piece of rolled steel

plate with horizontal fanges that are machined

not weldedinto the side. Cast steel casings are

used for some applications. High-strength casing

through-bolts provide superior clamping forces.

Endwalls are made from a single solid plate. The

resulting casing has fewer sealing surfaces, is easier

to manufacture and assemble, and has increased

pressure capabilities compared to conventional

designs. Larger horizontally split casings have

rolled barrel sections with welded-on endplates and

welded-on horizontal fanges.

Vertically split MB-line compressors feature a

complete inner casing assembly. This includes

a horizontally split inner casing with diaphragms,

stationary seals, rotating elements, bolted-on

endwalls, and shaft end seals. This module can

be inserted or removed from the outer casing

as a single piece, which simplifes compressor

assembly and reduces turn-around times.

We typically use milled fats for SAE fanged

connections, including endwall, spray nozzle,

casing drain, bearing retainer, and equalizing

line connections. On smaller casings where space

is limited, SAE fanges provide higher ratings and

more compact designs than ANSI fanges.

5

AERODYNAMIC COMPONENTS

A key achievement of the EDGE development

program is our ability to offer superior, three-

dimensional impeller designs and stationary

diaphragms. We do this by maximizing performance

over a broad range of pressure and fow applications

using the latest aerodynamic design and analysis

technologies. To verify predicted performance,

single-stage testing is performed in various

confgurations, such as with vaneless or vaned

diffusers, or using high or low tip Mach numbers.

Higher and lower fow stage ratings are derived from

the prototype test data to form a family of stages.

Within each stage family, impeller geometry is fxed;

blade heights are varied for higher or lower fows.

Using this methodology, several stage families are

used to span the desired fow coeffcient range.

Impellers and stationary components are then scaled

up or down for different frame sizes. For maximum

fexibility, EDGE aerodynamic components are also

scalable from 90 percent to 100 percent size within

each compressor

frame size.

Impeller manufacturing applies fve-axis milling to

ensure the quality of the advanced impeller designs.

Impellers are stress relieved, machine fnished,

balanced statically and dynamically, spin tested,

and then mounted with an interference-ft onto

the shaft. Shaft-to-impeller keys are used for extra

stability in high pressure or high power applications.

EDGE compressors use either fabricated steel

diaphragms or a combination cast-and-fabricated

steel design where thickness precludes using

steel plate alone. Precision machining ensures

dimensional accuracy and signifcantly improves

the diaphragm surface fnish. Diaphragms are

horizontally split and fnished at all horizontal and

peripheral joints and on gas path surfaces.

6

PROVEN TURBOMACHINERY TECHNOLOGY

Cast nozzles reduce manufacture time

and allow higher ratings

Elimination of dished heads

increases pressure ratings

Increased journal bearing

and shaft seal sizes

Non-radial inlet guide vanes

improve fow distribution

7

PROVEN TURBOMACHINERY TECHNOLOGY

Increased shaft diameter

enhances rotor dynamics

Precisely designed and

machined diaphragms

CFD ensures proper

sidestream mixing

High-effciency impellers scale

frame-to-frame

8

OTHER FEATURES

As part of our comprehensive EDGE development

program, Elliotts engineers examined each

compressor component to fnd ways to support

our goals of higher effciency, lower cost, simpler

maintenance, and reduced cycle time. Our designs

refect our commitment to making our products the

best in the industry, down to the last detail.

Interstage and balance piston sealing is

accomplished through two component features.

First, we use abradable or defection-tolerant

materials such as fuorosint or nickel-graphite on

stationary sealing surfaces. Second, we machine

teeth onto the rotating surfaces. These features

increase effciency by reducing gas recirculation

and minimizing the potential for shut-downs resulting

from damaged seals.

Elliott offers shaft seals to meet our customers

needs in all applications. Dry gas seals are

standard and are available as single, tandem,

double, or triple designs. The tandem or triple

gas seal designs include an intermediate labyrinth,

which can be buffered for additional emissions

protection. Our customers realize cost savings

by eliminating expensive seal oil systems and

the need to dispose of contaminated oil. Gas seal

buffer system engineering and manufacturing

are available at Elliotts Donora, Pennsylvania, plant.

Alternative seal designs include labyrinth or

dry carbon ring seals for low pressure services,

mechanical contact seals (Elliotts patented Iso-

carbonTM design), and bushing seals (Elliotts

Iso-sleeveTM design). For mechanical contact and

bushing seals, a cartridge design is also available.

This enables easier installation and removal of the

complete seal assembly. Buffer connections are

standard for all seal designs.

Reliability, quality, and safety are hallmarks of all

Elliott-designed components. For example, as a

design standard, replaceable journal bearings are

steel-backed and babbitt-lined with a fve-shoe

tilting pad. Thrust bearings are double-acting and

self-equalizing. Center pivots typically are used to

make assembly easier and to provide maximum

protection if reverse rotation occurs. Chrome-copper

pads are applied for both journal and thrust bearings

for high oil temperature applications.

9

MANUFACTURING AND TESTING CAPABILITIES

GLOBAL SERVICE AND SUPPORT

Elliott employs high-quality production techniques that minimize cycle time and costs while providing our

customers with the most competitive and reliable products. Our engineering and manufacturing facilities in

Jeannette, Pennsylvania, and Sodegaura, Japan, rank among the worlds most advanced for turbomachinery

design, production, and testing.

Our combined manufacturing capabilities include Masterhead machining centers for casing machining, rotor

machining centers, and diaphragm machining centers. Our rotor balancing facilities include a state-of-the-art

Schenck Trebel-designed balancing machine housed in a bunker-style vacuum chamber. The top of this

reinforced concrete facility slides away via hydraulic motors, permitting rotors to be lowered onto the balancing

equipment.

Our recently expanded test facilities enable us to validate the mechanical integrity and performance of

our components and overall systems. Our new main test facility, which increased our capacity by 50 percent,

contains a high-volume, closed loop, specially designed cooling system with the capacity for testing gas turbine-

driven compressor trains at full loads up to 100,000 HP.

Masterhead casing center

Compressor installation

Diaphragm machining cell

Reverse engineering

Elliott offers comprehensive service and support for all types of turbomachinery regardless of the original

manufacturer. Our experienced engineers, metallurgists, technicians, welders and mechanics have the expertise

and experience to keep equipment performance high and maintenance costs low.

Elliotts global service network is ISO 9001:2008 certifed and provides installation, maintenance, repair,

overhauls, parts, rerates, modifcations and training, 24 hours a day, 7 days a week. Supported by our

service centers throughout the world, feld service teams are recognized for their hands-on experience with

comprehensive overhauls; project management; resource planning; subcontractor control; installation and

commissioning and on-site repair. Elliott Technical Services provides practical, timely and cost-effective solutions

for complex turbomachinery problems. Rerates and modifcations by Elliott Engineered Solutions enhance

operating effciency and extend the life of rotating equipment from any manufacturer.

Elliott is fully compliant with all relevant industry standards including API, ANSI, APO, CRN, CSA, and CE/

PED. We are accredited by the American Society of Mechanical Engineers (ASME), holding both the U and the

R Boiler and Pressure Vessel (BPV) certifcations, and we adhere to the principals of the American Society of

Nondestructive Testing (ASNT) and are SNT-TC 1A complaint.

10

Standardization of Components

In developing the EDGE compressor product line, we focused on standardizing components and hardware to

reduce costs and improve reliability across a wide array of applications. The EDGE product line consists of 15

standard frame sizes, which are scaled from the 38M median frame size. Casing bores and internal aerodynamic

hardware, such as impellers, diaphragms, and shafts, are scaled. Scaling aerodynamic components improves

performance predictability and increases reliability by preserving geometric similarity across frame sizes. Bearings

and seals are selected from vendor standard sizes for each application.

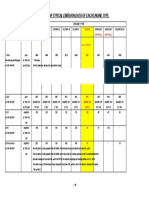

COMPRESSOR FRAME SUMMARIES

Frame Max Flow Impeller Diameter Speed Confguration Casing Rating

m

3

/hr CFM mm in RPM

M (Horizontal Split)

MB (Vertical Split)

BARG PSIG

10 10,900 6,400 264 10.4 19,800

M

MB

69

345

1,000

5,000

15 14,400 8,500 303 11.9 17,300

M

MB

69

689

1,000

10,000

20 19,000 11,200 348 13.7 15,000

M

MB

69

689

1,000

10,000

25 25,000 14,700 401 15.8 13,100

M

MB

69

689

1,000

10,000

29 33,000 19,400 461 18.2 11,400

M

MB

69

689

1,000

10,000

32 43,500 25,600 530 20.9 9,900

M

MB

69

345

1,000

5,000

38 57,400 33,800 610 24.0 8,600

M

MB

69

345

1,000

5,000

46 75,900 44,700 701 27.6 7,500

M

MB

69

217

1,000

3,150

56 100,200 59,000 806 31.7 6,500

M

MB

69

217

1,000

3,150

60 132,500 78,000 927 36.5 5,600

M

MB

69

138

1,000

2,000

70 175,000 103,000 1,066 42.0 4,900

M

MB

52

103

750

1,500

78 231,100 136,000 1,226 48.3 4,300

M

MB

41

103

600

1,500

88 305,800 180,000 1,410 55.5 3,700

M

MB

41

69

600

1,000

103 404,400 238,000 1,622 63.8 3,200 M 26 380

110 535,200 315,000 1,865 73.4 2,800 M 7 100

Note: Table does not include specifcations for double fow confguration.

11

WEIGHTS, DIMENSIONS AND CONFIGURATIONS

In-Line

In-Line

with Iso-Cooling

Double-Flow

Back-to-Back

Iso-Cooler Optional

In-Line

with Side-Streams

Frame

Size

Minimum

Rotor Length

(in. / mm)

Maximum

Rotor

Length

(in. / mm)

Casing Width

(includes

supports)

(in. / mm)

Casing Height

(exc. supports)

(in. / mm)

Minimum Cas-

ing Weight

(lb/kg)

Maximum Casing

Weight

(lb / kg)

Typical Weights and Dimensions for Elliott Horizontal Split Compressors*

10M 35 / 890 64 / 1,625 37.3 / 947.4 36.25 / 921 4,700 / 2,130 9,000 / 4,080

15M 35 / 890 75 / 1,905 42.5 / 1,080 41.38 / 1,051 5,600 / 2,540 12,700 / 5,760

20M 40 / 1,015 80 / 2,030 48.5 / 1,232 47.85 / 1,215 8,200 / 3,720 18,000 / 8,165

25M 45 / 1,145 90 / 2,285 55.1 / 1,400 54.12 / 1,375 11,100 / 5,035 24,500 / 11,100

29M 50 / 1,270 110 / 2,795 65.4 / 1,661 59.25 / 1,505 14,000 / 6,350 32,000 / 14,500

32M 50 / 1,270 124 / 3,150 70.5 / 1,791 65.75 / 1,670 15,700 / 7,120 45,000 / 20,400

38M 55 / 1,400 135 / 3,430 76.3 / 1,938 70.62 / 1,794 23,000 / 10,430 62,000 / 28,100

46M 70 / 1,780 155 / 3,940 66.5 / 1,689 89.5 / 2,273 32,500 / 14,740 87,000 / 39,500

56M 80 / 2,032 175 / 4,445 76 / 1,930 93.38 / 2,372 51,500 / 23,360 127,000 / 57,600

60M 90 / 2,285 190 / 4,825 89.7 / 2,278 97 / 2,464 59,000 / 26,760 170,000 / 77,100

70M 100 / 2,540 230 / 5,840 103.5 / 2,629 113.88 / 2,893 71,000 / 34,000 210,000 / 95,250

78M 100 / 2,540 250 / 6,350 109.5 / 2,781 125.5 / 3,188 95,000 / 43,100 295,000 / 133,800

88M 115 / 2,920 275 / 6,985 133 / 3,378 137.5 / 3,492 130,000 / 59,000 380,000 / 172,400

103M 135 / 3,429 300 / 7,620 156 / 3,962 158.5 / 4,025 215,000 / 97,500 525,000 / 238,100

110M 140 / 3,556 325 / 8,255 182 / 4,623 182 / 4,630 270,000 / 122,470 690,000 / 312,980

Typical Weights and Dimensions for Elliott Vertical Split Compressors*

10MB 35 / 890 62 / 1,575 43 / 1,092 42.5 / 1,080 7,000 / 3,175 13,000 / 5,900

15MB 35 / 890 72 / 1,830 46 / 1,168 48 / 1,219 8,400 / 3,810 17,500 / 7,940

20MB 40 / 1,015 80 / 2,030 50 / 1,270 53.75 / 1,366 12,000 / 5,440 25,000 / 11,340

25MB 45 / 1,145 88 / 2,235 58.5 / 1,486 62 / 1,575 18,400 / 8,345 36,000 / 16,330

29MB 50 / 1,270 105 / 2,670 64.3 / 1,633 64 / 1,626 23,000 / 10,435 49,000 / 22,225

32MB 50 / 1,270 120 / 3,050 71.7 / 1,821 76.5 / 1,943 28,500 / 12,900 69,000 / 31,300

38MB 55 / 1,400 130 / 3,300 78.5 / 1,994 83.25 / 2,115 36,500 / 16,560 89,000 / 40,400

46MB 70 / 1,780 150 / 3,810 96.5 / 2,451 86.5 / 2,197 47,500 / 21,500 115,000 / 52,200

56MB 80 / 2,030 170 / 4,320 104.2 / 2,647 102.12 / 2,594 70,000 / 31,750 160,000 / 72,600

60MB 90 / 1,525 185 / 4,700 113 / 2,870 112.5 / 2,858 90,000 / 41,000 200,000 / 91,000

70MB 100 / 2,540 225 / 5,715 115.2 / 2,926 120.96 / 3,064 100,000 / 45,350 251,000 / 113,900

78MB 100 / 2,540 245 / 6,225 120 / 3,048 140 / 3,556 125,000 / 56,700 315,000 / 143,000

88MB 115 / 2,920 265 / 6,730 137 / 3,480 148 / 3,759 205,000 / 93,000 465,000 / 211,000

2014 Elliott Group CMP.2001.00514

901 North Fourth Street

Jeannette, PA 15644-1473

Telephone: 724-527-2811

Fax: 724-600-8442

Email: info@elliott-turbo.com

www.elliott-turbo.com

Elliott Group is a global leader in the

design, manufacture and service of

technically advanced centrifugal com-

pressors, steam turbines, power recov-

er expanders and axial compressors

used in the petrochemical, refning, oil

& gas and process industries, as well as

in power applications. Elliott Group is a

wholly owned subsidiary of Ebara Cor-

poration, a major industrial conglomer-

ate headquartered in Tokyo, Japan.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- EjectorDocument269 pagesEjectormbsahgNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Rolling Bearings GuideDocument245 pagesRolling Bearings GuideMiloradRadnovicNo ratings yet

- NETA Handbook Series I Insulating Oils PDFDocument112 pagesNETA Handbook Series I Insulating Oils PDF1981todurkar50% (2)

- Lempor Ejector Calculator Beta 1.1Document21 pagesLempor Ejector Calculator Beta 1.1myungkwan haNo ratings yet

- X Steam Tables (English Units)Document8 pagesX Steam Tables (English Units)Troy ThennisNo ratings yet

- API 510 PC 20 31 Aug05 Final Exam OpenDocument4 pagesAPI 510 PC 20 31 Aug05 Final Exam OpennikafiqNo ratings yet

- Basic principles of vacuum technology overviewDocument54 pagesBasic principles of vacuum technology overviewFederico Leon100% (1)

- ZR Handbook Rev2 PDFDocument80 pagesZR Handbook Rev2 PDFmyungkwan haNo ratings yet

- Emission Calculation 2Document12 pagesEmission Calculation 2myungkwan haNo ratings yet

- Ejectors: Wide Uses & Selection GuideDocument6 pagesEjectors: Wide Uses & Selection Guidehappale2002No ratings yet

- MotorDocument1 pageMotormyungkwan haNo ratings yet

- PSV Calculation SheetDocument9 pagesPSV Calculation Sheetmyungkwan haNo ratings yet

- DOE 1090 Chap11Document45 pagesDOE 1090 Chap11harrinsonfNo ratings yet

- Duct Bulk Materials Calculation Sheet Project Name: SraacDocument6 pagesDuct Bulk Materials Calculation Sheet Project Name: Sraacmyungkwan haNo ratings yet

- Design Concept of Once-Through CW SystemDocument12 pagesDesign Concept of Once-Through CW Systemmyungkwan haNo ratings yet

- Comparision Table For Typical Emission Data of Each Engine TypeDocument1 pageComparision Table For Typical Emission Data of Each Engine Typemyungkwan haNo ratings yet

- Boiler Tuning BasicsDocument14 pagesBoiler Tuning Basicsveeru290683_20976731No ratings yet

- Radiator Fan Moterating CalculationDocument20 pagesRadiator Fan Moterating Calculationmyungkwan haNo ratings yet

- Motor torque calculations for two load casesDocument4 pagesMotor torque calculations for two load casesmyungkwan haNo ratings yet

- Comparision of EmissionDocument13 pagesComparision of Emissionmyungkwan haNo ratings yet

- Heat Exchanger DesignDocument2 pagesHeat Exchanger DesignAmit Sharma ParasharNo ratings yet

- Lecture 5Document40 pagesLecture 5Harry RamzaNo ratings yet

- Appendix B PDFDocument1 pageAppendix B PDFLuis Felipe Mera GrandasNo ratings yet

- Indoor Air Unit Conversions PDFDocument4 pagesIndoor Air Unit Conversions PDFmyungkwan haNo ratings yet

- 5EH Steam Jet Ejectors Brochure PDFDocument19 pages5EH Steam Jet Ejectors Brochure PDFB R RavichandranNo ratings yet

- How To Measure Carbon Dioxide: Operation Principle of Infrared SensorsDocument4 pagesHow To Measure Carbon Dioxide: Operation Principle of Infrared SensorsDejan BošnjakNo ratings yet

- Entropy 17 07869Document22 pagesEntropy 17 07869Victor VazquezNo ratings yet

- Ejector Configuration For Designing A Simple and High Performance Solar Cooling SystemDocument8 pagesEjector Configuration For Designing A Simple and High Performance Solar Cooling Systemmyungkwan haNo ratings yet

- 5EH Steam Jet Ejectors Brochure PDFDocument19 pages5EH Steam Jet Ejectors Brochure PDFB R RavichandranNo ratings yet

- Ejectormodeling 82-A563Document7 pagesEjectormodeling 82-A563jlcheefei9258No ratings yet

- Pump Installation: Tim Sullivan, P.EDocument61 pagesPump Installation: Tim Sullivan, P.ELeo NardoNo ratings yet

- Ejectormodeling 82-A563Document7 pagesEjectormodeling 82-A563jlcheefei9258No ratings yet

- Atomic Bonding LectureDocument15 pagesAtomic Bonding LectureSarahNo ratings yet

- Is 11384Document19 pagesIs 11384Akhlaq HussainNo ratings yet

- Title: Tensile TestDocument5 pagesTitle: Tensile TestAbdulrahmanNo ratings yet

- EN 287-1-2011-Otkl (Grupi Celici)Document1 pageEN 287-1-2011-Otkl (Grupi Celici)Vasko MandilNo ratings yet

- Marcet BoilerDocument7 pagesMarcet BoilerSt Oong100% (1)

- DynamicsDocument15 pagesDynamicstomtom9649100% (4)

- Dimensional analysis and chemical engineering equationsDocument8 pagesDimensional analysis and chemical engineering equationsleishara0% (1)

- ETA210756 CrossFix Facade System ConsDocument34 pagesETA210756 CrossFix Facade System ConsJelena GraovčevićNo ratings yet

- DistributionatalogueDocument38 pagesDistributionatalogued22027lingmail.comNo ratings yet

- Jorg B. Gotte Et Al - Light Beams With Fractional Orbital Angular Momentum and Their Vortex StructureDocument14 pagesJorg B. Gotte Et Al - Light Beams With Fractional Orbital Angular Momentum and Their Vortex StructureVing666789No ratings yet

- Annual Xi Sample Paper 22-23Document6 pagesAnnual Xi Sample Paper 22-23Cat ChanNo ratings yet

- Manufacturing Lab Manual and ScheduleDocument22 pagesManufacturing Lab Manual and ScheduleSunitNo ratings yet

- Heat Shrinking AllDocument46 pagesHeat Shrinking AllCaylie KirbyNo ratings yet

- Spark LightningDocument92 pagesSpark LightningaaNo ratings yet

- Đề ANH chuyên 5Document7 pagesĐề ANH chuyên 5Phạm Ngô Hiền MaiNo ratings yet

- Bismuth TellurideDocument6 pagesBismuth Tellurideramin pouriaNo ratings yet

- Thermodynamics of Ag CL H, O, Ag BR H, ODocument9 pagesThermodynamics of Ag CL H, O, Ag BR H, Oहरिओम हरीNo ratings yet

- Polymers PDFDocument11 pagesPolymers PDFMy StudymateNo ratings yet

- BIOSEMDocument18 pagesBIOSEMAllan DuplaNo ratings yet

- Design of an Ice PlantDocument30 pagesDesign of an Ice PlantJonan TutaanNo ratings yet

- Turbulent Flow Through Pipes: Friction Factor and Velocity DistributionDocument17 pagesTurbulent Flow Through Pipes: Friction Factor and Velocity Distributiondurga345No ratings yet

- Pile Foundation Design: Dr. Magdi ZumrawiDocument19 pagesPile Foundation Design: Dr. Magdi Zumrawiahmed_cv30No ratings yet

- BNT Quartet BrochureDocument2 pagesBNT Quartet BrochureAnonymous 0oFWTQFNo ratings yet

- Laser Beam Expanders Basics and Applications: Vision System Vision SystemDocument6 pagesLaser Beam Expanders Basics and Applications: Vision System Vision SystemAtul SharmaNo ratings yet

- Geosphere and GeochemistryDocument20 pagesGeosphere and GeochemistrygengkapakNo ratings yet

- Free Electron TheoryDocument68 pagesFree Electron TheoryV Sree Suswara SuswaraNo ratings yet

- UNIVERSITI TUNKU ABDUL RAHMAN Mechanics Tutorial Rotational Motion & DynamicsDocument3 pagesUNIVERSITI TUNKU ABDUL RAHMAN Mechanics Tutorial Rotational Motion & DynamicsYong HaoNo ratings yet

- MP ProblemsDocument2 pagesMP Problemskartikesh prasadNo ratings yet