Professional Documents

Culture Documents

IMD Brochure 2013 HQ PDF

Uploaded by

Benicio Joaquín Ferrero Brebes0 ratings0% found this document useful (0 votes)

61 views20 pagesINNOMAG has been manufacturing sealless, non-metallic, mag-drive pumps since 1998. Our "claim-to-fame" is our thrust-balanced product line, the TB-mag series. INNOMAG pumps can make a real difference for your environment, maintenance staff and operators alike.

Original Description:

Original Title

IMD_Brochure_2013_HQ.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentINNOMAG has been manufacturing sealless, non-metallic, mag-drive pumps since 1998. Our "claim-to-fame" is our thrust-balanced product line, the TB-mag series. INNOMAG pumps can make a real difference for your environment, maintenance staff and operators alike.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

61 views20 pagesIMD Brochure 2013 HQ PDF

Uploaded by

Benicio Joaquín Ferrero BrebesINNOMAG has been manufacturing sealless, non-metallic, mag-drive pumps since 1998. Our "claim-to-fame" is our thrust-balanced product line, the TB-mag series. INNOMAG pumps can make a real difference for your environment, maintenance staff and operators alike.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 20

For a cleaner tomorrow, is where it all starts.

Innovative Mag-Drive strives to keep

your work environment safe and clean by producing a zero emissions pump. Tomorrow re-

ally does start today.

We have been manufacturing Sealless, Non-metallic, Magnetically Driven Pumps since 1998.

Our claim-to-fame is our Thrust Balanced product line, the TB-mag series. Its introduction

revolutionized the non-metallic, mag-drive pumping industry as the frst fully thrust-balanced

pump with the ability to handle solids. This was truly a frst for this class of pumps, no longer

do you need perfectly clean liquids! When applied right, an INNOMAG pump can make a real

difference for your environment, maintenance staff and operators alike.

Innovative Mag-Drive is recognized as an innovator and leader in the sealless, non-metallic,

mag-drive pump market. The literature you are reading is not fancy marketing but rather

our attempt to explain to you some of our products and business philosophies.

Helping you create a cleaner tomorrow starts with our products, our distributors and of

course the INNOMAG team.

Sincerely,

The Owners & Employees

of Innovative Mag-Drive

INNOVATIVE MAG-DRIVE

Innomag.com

INNOMAG has strongly focused

on vertical integration and vertical

manufacturing for one reason and

one reason only, QUALITY! High

quality is the result of good raw

materials, making things yourself

and having employees who care

about what they make!

Why is INNOMAG so different?

Our answer is simple constant

involvement! Its not just the

concept of Thrust Balancing or

that each engineer has almost two

decades of sealless engineering

experience but rather everyones

relentless desire to stay involved

with every facet of the business.

So, you already have an INNOMAG

pump... what does this mean for

you? Well, quite a bit! Have com-

fort knowing that you have one

of the highest quality mag-drive

pumps in the market today. You

not only have the support of your

local Distributor but also the Engi-

neering staff at INNOMAG. If you

choose to call direct to the Factory,

we take great pride in answer-

ing the phone. NO VOICE-MAIL

run-around or endless prompts to

select from. If you do need to leave

a message, WE WILL RETURN your

call... PERIOD. WHY? Nothing short

of respect! We strive to sell solutions,

not problems and our No. 1 customer

is a repeat one!

This involvement starts from the

top-down... from helping a Distrib-

utor or end-user choose the right

pump, to direct oversight of every

manufacturing step, to assembling

and testing your pump, right down

to fnding out when your pump will

ship. Customers enjoy INNOMAG

because they know they have a

voice a voice that goes right to

the top!

Proudly Manufactured in the USA

Page 2

Materials... materials... materials! It goes without saying, in order to manufacture an excellent pump, you need to have

excellent raw materials. So when it comes to this area, INNOMAG spares no cost! Since our beginning in 1998, we have

worked constantly to improve all our products through engineering improvements and the purchase of better and higher

quality materials. Because of this, we know that you will be pleased with everything you fnd on the inside of our pumps.

Its not just the inside of the pump that needs chemical

resistance, durability and longevity. All metal surfaces

are coated with epoxy polyamide primer and catalyzed

aliphatic polyurethane top-coat.

Exterior Protection

A Fully sealed Inner Magnet Assembly is the heart of ev-

ery Impeller. INNOMAG understands permeation and how

it can shorten your pumps life. So whats our solution?

A doubly, hermetically

sealed magnet assem-

bly. First, the magnets

are covered with Stain-

less Steel thats welded

air-tight. Second, this is

completely covered with

our premium fuoroplas-

tics so any permeation

has a long way to go be-

fore it can damage your

pump.

Welded Inner Magnet

For ultimate strength and durability, all INNOMAG impel-

lers are one piece. They are formed with fuoroplastics

in a single-step injection molding process. This provides

the strongest possible

connection between

the impeller, magnets

and bearings. No bal-

ance problems, No

sloppy splines, No

trapped dirt and liq-

uids!

Single Piece Impeller

Innomag.com

With burst pressure rat-

ings of 3000 psi (+200

bar) its easy to see why

INNOMAG pumps are

water hammer resistant!

Composites

All INNOMAG Containment

Shells are made with Aramid

fbers for the ultimate in burst

pressure resistance.

To make a non-metallic

pump you need non-

metallic materials. For

the ultimate in chemical

and corrosion resistance,

INNOMAG uses only the

highest grade of fuoroplas-

tic resins. Thats right, fuoroplastics! This is the technical

word that describes ETFE, PTFE and PFA. So, as you look

inside any INNOMAG pump, all the surfaces that you see

will be made of these materials. This includes injection

molded impellers and containment shells right down to

the rotationally molded pump lining. There is no substi-

tute for high quality, anything less will mean a short pump

life and a future problem for you.

Fluoroplastics

Simply the best! This grade of

ceramic is chemically inert, ex-

tremely hard and wear resistant.

As such, it is the standard ma-

terial found in every INNOMAG

pump.

Alpha Sintered Silicon

The Quality in Every INNOMAG Pump

Carbide

Page 4

The Quality in Every INNOMAG Pump

Specifications

Temperature Range: Maximum Discharge

Pressure:

Flange Connections:

Mounting:

Maximum Power:

Maximum Flow:

Maximum TDH:

ANSI Class 150

ANSI Class 300

ISO PN 16

JIS 10kg/cm^2

TB-mag A

TB-mag B

TB-mag C

295 gpm (66.9 m

3

/hr)

700 gpm (159 m

3

/hr)

1500 gpm (340.7 m

3

/hr)

190 ft (58.2m)

306 ft (93.2m)

503 ft (153m)

TB-mag A

TB-mag B

TB-mag C

300 psi (20.6 bar)

NEMA or IEC

14hp (10.4kW)

30hp (22.4kW)

100hp (74.6kW)

TB-mag A

TB-mag B

TB-mag C

Maximum Solids:

Size

Concentration

.25 inch

30 %

-20 to 250

o

F (-29 to 121

o

C)

Rated @ 3500 rpm

Apps: Services:

Metal Finishing - Pickling,

Etching and Plating

Tank Car Loading and

Unloading

Scrubber Systems

Chemical Processing

Reactor Feed

Chlor-Alkali

Waste Chemical Treat-

ment

Acetic Acid

Ammonia

Benzene

Caustic Soda

Chlorosulphonic Acid

Chromic Acid

Ferric Chloride

Hydrochloric Acid

Hydrogen Peroxide

Methyl Ethyl Ketone

Nitric Acid

Oleum

Phosphoric Acid

Sodium Hypochlorite

Sulfuric Acid

So what makes the TB-mag series

so much better than the competi-

tion? Thrust balancing and engi-

neering design. The TB-mag (short

for Thrust Balanced mag-drive) is

the most revolutionary engineer-

ing concept to enter the mag drive

market since the invention of the

mag drive pump itself.

The thrust balance technology be-

hind the TB-mag series completely

eliminates axial thrust bearings and

provides the basis for a controlled

internal environment. Superior en-

gineering design minimizes the is-

sue of secondary containment by

providing secondary bearings.

No other product on the market to-

day offers these features at such a

cost-effective and cost-competitive

price. In short, the TB-mag sets

new standards for non-metallic

sealless pumps in application of

use, product durability and cus-

tomer driven value.

The TB-mag Series

Innomag.com

Revolutionary Thrust Balancing The Benefts of Thrust Balancing

Wonder why the name TB-mag? Thrust balancing is not new to

the pump industry but it certainly is new to the non-metallic mag-drive

world!

Nearly every competing product in the market today is based

on thrust forward technology. This is the concept where under normal

operation the impeller will thrust forward towards the pump suction. As

an old design (more than 50 years) it has found a niche in the clean

liquids market but is well known to fail easily upon process upset or sys-

tem change.

The revolution of thrust balanc-

ing has added substantial durability along

with wider and greater application of use.

Those who deal in day-to-day reliability

truly understand the destruction that

thrust can cause. For those looking for a

product that will last longer and run better, the TB-mag is certainly what you should consider! As you

read, please understand that this is a simple explanation of what INNOMAG has created. For an in-

depth explanation, please call your local distributor and schedule a demonstration.

Thrust... this is where it starts! Engineers explain that thrust is one of several forces in a mag-drive pump and it can be

very destructive. When you think of a pump, the largest cause of force is from the very thing you want the pump to do, make

pressure. When engineers see pressure, they see it as a Force, which is Pressure x Area (F = P x A). When INNOMAG looked at

the inside of a pump, we saw a lot of unused pressure and unused areas that could solve a 50 year problem!

The picture to the upper left corner shows what INNOMAG created

and patented. The white arrows show the path that some of your liquid will

take when it goes through the TB-mag pump. The idea to keep in mind at

all times is that high pressure (colored red) will always fnd low pressure

(colored yellow). A good example is a balloon that you blow up and let go

of. The air comes out because pressure inside the balloon is higher than out-

side. The top left picture shows that the suction side (left side) of the pump

has the lowest pressure (colored yellow). The discharge will have the high-

est pressure (colored red). When the arrows are followed, the path traveled

is: liquid enters the suction of the pump and the center of the impeller. The

impeller then centrifugally creates pressure with the liquid (red colored area). As the pump housing is flled with the pressurized

liquid, some of the liquid will go around to the back side of the impeller and pass thru the back clearance ring set (picture upper

right side). This area is fxed and creates a constant, restricting pressure drop (red color changing to green color). From here,

the liquid will pass over the impeller (the magnet assembly) and go around to the impeller back end (balancing pressure). At this

point, it will travel through the center of the impeller (green area again) and fnd the suction (the low pressure area). Why? High

pressure will always go to low pressure (just like the balloon)!

Looking at the picture located just above, we fnd that a way to

thrust balance the impeller is to simply combine the suction pressure and

the pressure on the front of the impeller to go against the pressure (and

thrust) from the back of the impeller (the green area). If the impeller

moves forward due to thrust (picture lower left corner) an opening con-

trolled by the impeller becomes larger and allows more liquid to leave the

green area, directly lowering the thrust and pressure. If too much thrust

or pressure is lost, the impeller will move backward, closing the opening

(picture lower right corner) causing the pressure or thrust in the green area

to directly increase against the suction and front impeller pressures.

This is INNOMAG dynamic thrust balancing, your process and the TB-mag pump work together to eliminate thrust!

Introducing the TB-mag

Pressurized Flowpath

No fashing at the radial bearings.

Bearing fuid pressure is 1/4 to 1/3 of dis-

charge pressure.

Bearing life greatly extended due to positive

liquid flm.

Low vapor pressure liquids easily handled.

High fow rate thru bearings keeps them

clean and cool for longer life.

Wear Ring

Clearance is 0.005

(.127mm)

Can never clog. As

long as the impeller

rotates, the clearance

is open for fow.

Upset Forgiveness

Balance system greatly re-

duces loads during upsets.

Survives suction starvation

events that competitors thrust

forward designs cant handle.

Higher Efficiency

No thrust bearing drag!

Less friction wear-and-tear.

Less friction means less

energy.

The bigger the pump, the

bigger the energy savings.

Optimized Casing

Modifed concentric

volute minimizes radial

loads.

Loads remain low over

entire operating range.

Confdently operate con-

tinuously from low-fow

to end-of-curve.

Page 6

Thrust Load

0

100

200

300

400

500

600

700

800

900

1000

6

8

10

C

o

m

p

e

t

i

t

i

o

n

Approximate Axial Loads

The Benefts of Thrust Balancing

Superior Solids Handling Capability

Innomag.com

Solids enter the pump through

the suction and pass out through the

discharge nozzle. Some of the solids

will try to leak around the impeller

past the wear rings. The leakage past

the front wear rings simply returns the

particles directly to the suction fow;

however, leakage past the back wear

rings could bring particles in contact

with the inner magnets, the contain-

ment shell and the radial bearings.

Fortunately, back wear rings restrict

solids larger than 0.005 (0.127 mm)

from entering the containment shell

area, keeping all bearings and critical

fow paths clear.

This illustration shows the main

solids laden stream around the impel-

ler and the clean stream behind the

impeller.

Back Wear Rings

0.005 (0.127 mm) Gap

A 0.005 (0.127 mm) gap allow

process fuids to pass through and

lubricate the bearings while block-

ing larger solids from entering these

critical areas between the contain-

ment shell and impeller where they

could damage the pump.

Superior Solids Handling Capability

Solids Handling

SiC Wear Rings, located front and

back of the impeller, keep solids

larger than 0.005 (0.127 mm)

from entering the containment

shell.

Only clean liquid can reach the

bearings and pump shaft.

No other non-metallic mag-drive keeps

the solids from entering these critical

areas behind the impeller.

Front Wear Rings

Liquid with solids

from microns up to 1/4

(6.35mm)

Page 8

Motor Adapter

Mates NEMA C-face or IEC

D-fange motors.

Integral foot mates to exist-

ing ANSI base plates. All

mounting bolts conveniently

accessed from outside the

adapter to simplify motor/

pump mating.

Bearing Frame

ANSI dimensioned bearing

frame.

Optional true metallic sec-

ondary seal.

Outer Drive

One outer drive per motor

frame size.

Dowel pins eliminate motor

shaft key for quick and easy

install.

Center drill & tap thread for

easy removal from motor

shaft.

Motor shaft position set with

visual alignment grove (no

special tools).

Containment Shell

One-piece carbon fber ETFE

molding for a combination

of strength and chemical

resistance.

Reinforced socket for pump

shaft.

Outer housing made of

aramid composite for high

pressure, high strength and

high shock resistance.

Containment Ring

Extra-heavy duty, one piece

ductile iron casting.

Separate from the adapter to

allow servicing of the motor

without opening the liquid

end of the pump.

Precisely aligns and supports

the containment shell in the

casing.

Precisely aligns motor

adapter to pump end.

Innomag.com

Pump Shaft

Pure alpha sintered silicon

carbide.

Cantilevered for lowest

NPSHr.

Oversized to handle all

radial loads.

Keyed for anti-rotation.

Barbed for maximum grip.

Pump Casing

One-piece cast ductile iron.

Full open pump suction for

lowest NPSHr.

Fully bonded ETFE liner

minimum of 1/8 (3 mm),

rated to full vacuum.

Fluoroplastic provides uni-

versal corrosion resistance.

Radial Bearings

Dual sintered silicon carbide

(SiC) bearings.

Flexible impeller mount for

optimal alignment to pump

shaft.

PTFE center spacer for

proper bearing position.

Individually replaceable.

Gasket

Standard FEP/FKM construc-

tion for maximum chemical

resistance.

Optional in EPDM or FKM.

INNOMAG

Competition

Impeller Assembly

Molded one-piece enclosed im-

peller with replaceable sintered

silicon carbide wear rings.

High effciency, low NPSHr

design with fully open impeller

eye.

Molded from carbon fber

reinforced ETFE for optimum

strength and chemical resis-

tance.

Patented double weld inner

magnet provides extreme cor-

rosion and permeation resis-

tant barrier.

DRAIN

Optional casing drain.

Standard cast stainless steel

blind fange.

Optional lined drain fange

with 3/8 NPT.

Optional casing fange

adapter to 1 ANSI fange.

Competition

INNOMAG

Page 10

Dry-run mechanical seal

The bearing frame

bolts in place similar

to a standard sealed

pump.

(2) 1/2 NPT connections

for drain / leak detector

Standard wet end

Our patented design combines

a simple, yet proven, off-the-shelf dry

run cartridge seal with our long couple

bearing frame.

Imagine all the benefts of a

Non-metallic mag-drive pump with all

the security of a metallic secondary

containment. Consult your authorized

INNOMAG distributor today or call us

for more details on sizing your next

application.

Innomag.com

True Secondary Containment

Normal extent of process

fuid contained by the

pump.

ANSI Group 2 dimensional,

or extended length Group 1

centerline mountable.

Standard stuffng box

style construction.

Close-coupled JM pump motor

mounting available.

Dry running seal eliminates

the need for nitrogen purge

or seal fush.

In the unlikely event of a breach, the process

fuid is mechanically sealed from leakage.

No external connections required.

Page 12

CP Y

X

D

CP Y

X

D F

2E

1

2E

2

O

O

F

2E

1

2E

2

M

2

ANSI ISO

Innomag.com

TB-Mag Pump Dimensions - ANSI / ISO

Series Model (Size) D 2E

1

2E

2

F O X Y CP SF DF

ANSI

No.

lb

(kg)

AL - (1.5x1x6LF)

Low Flow

A1 - (1.5x1x6)

A3 - (3x1.5x6)

A4 - (3x2x6)

1.50

(38)

1.00

(25)

80

(36)

AA

AA

AB

- -

TB-mag

A

Series

3.00

(76)

90

(41)

1.50

(38)

2.00

(51)

8.70

(221)

TB-mag

B

Series

B1 - (1.5x1x8)

BL - (1.5x1x8LF)

Low Flow

B3 - (3x2x6)

short 11.75

B4 - (3x1.5x8)

B5 - (3x2x6)

tall 16.75

B6 - (4x3x6)

AA

AA

A50

A10

- -

- -

5.25

(133)

6.00

(152)

N/A 7.25

(184)

11.75

(298)

6.50

(165)

4.00

(102)

8.25

(210)

9.75

(248)

7.25

(184)

12.50

(318)

8.50

(216)

16.75

(425)

16.50

(419)

11.30

(287)

1.50

(38)

1.00

(25)

125

(57)

135

(61)

153

(70)

145

(65)

185

(84)

3.00

(76)

2.00

(51)

4.00

(102)

3.00

(76)

10.00

(254)

16.75

(425)

8.25

(210)

CL - (2x1x10LF)

Low Flow

C1 - (3x2x8)

C2 - (4x3x8)

C3 - (2x1x10)

C4 - (3x1.5x10)

C5 - (3x2x10)

C6 - (4x3x10)

C7 - (4x3x10H)

C8 - (6x4x10H)

C9 - (6x4x8)

TB-mag

C

Series

A60

A70

A05

A50

A05

A60

A70

A80

A80

A70

17.75

(451)

19.25

(489)

17.75

(451)

19.25

(489)

23.50

(597)

8.50

(216)

9.50

(241)

11.00

(279)

9.50

(241)

11.00

(279)

13.50

(343)

2.00

(51)

3.00

(76)

4.00

(102)

3.00

(76)

4.00

(102)

6.00

(152)

1.00

(25)

2.00

(51)

3.00

(76)

2.00

(51)

3.00

(76)

4.00

(102)

1.50

(38)

174

(79)

159

(72)

195

(88)

189

(86)

219

(99)

269

(122)

188

(85)

205

(99)

E3 - (65x50x160)

EL - (50x32x160LF)

Low Flow

E1 - (50x32x160)

TB-mag

A

All ISO products can be Mounted to either IEC or NEMA style Motors

D 2E

1

2E

2

M2 F O X Y CP SF DF

lb

(KG)

Series Model Size

5.20

(132)

7.48

(190)

4.33

(110)

2.76

(70)

7.25

(184)

11.50

(292)

6.29

(160)

3.15

(80)

8.39

(213)

1.97

(50)

2.56

(65)

1.26

(32)

1.97

(50)

80

(36)

86

(39)

F1 - (50x32x200)

FL - (50x32x200LF)

Low Flow

F4 - (65x40x200)

TB-mag

B

TB-mag

C

G2 - (100x65x200)

6.29

(160)

7.09

(180)

8.35

(212)

9.84

(250)

3.74

(95)

9.91

(252)

15.94

(405)

8.86

(225)

13.39

(340)

7.09

(180)

3.97

(100)

11.16

(284)

168

(76)

2.56

(65)

3.93

(100)

144

(65)

1.57

(40)

2.56

(65)

1.97

(50)

1.26

(32)

133

(60)

Page 14

ALL Pump Models use ONE Impeller for Stated Power Range Power Range

G2-100x65x200

F1-50x32x200 F4-65x40x200

E3-65x50x160 E1-50x32x160

to 46.4kW @ 2950 rpm

to 18.5kW @ 2950 rpm

to 8.7kW @ 2950 rpm

G2

F1

F4

E3

E1

Capacity (US gpm)

Capacity (m/hr)

T

D

H

(

m

)T

D

H

(

f

t

)

0

2.5

5

7.5

10

12.5

15

17.5

0 10 20 30 40 50 60 70 80

0

10

20

30

40

50

60

0 50 100 150 200 250 300 350

G2

F4

F1

E3

E1

T

D

H

(

f

t

)

T

D

H

(

m

)

Capacity (m/hr)

Capacity (US gpm)

0

13

25

38

50

63

75

0 20 40 60 80 100 120 140 160 180

0

50

100

150

200

250

0 100 200 300 400 500 600 700

ALL Pump Models use ONE Impeller for Stated Power Range Power Range

CL-2x1x10LF (low fow)

BL-1.5x1x8LF (low fow) W1-2x1.5x8 (ANSI vertical)

AL-1.5x1x6LF (low fow) V1-2x1.5x6 (ANSI vertical)

to 75hp @ 3500 rpm

to 30hp @ 3500 rpm

to 15hp @ 3500 rpm

CL

W1

BL

V1

AL

0

20

40

60

80

100

120

140

0 20 40 60 80 100 120

0

5

10

15

20

25

30

35

40

0 5 10 15 20 25

Capacity (US gpm)

Capacity (m

3

/hr)

T

D

H

(

m

)

T

D

H

(

f

t

)

CL

W1

BL

V1

AL

0

100

200

300

400

500

600

0 50 100 150 200 250

0

20

40

60

80

100

120

140

160

180

0 10 20 30 40 50

Capacity (US gpm)

Capacity (m

3

/hr)

T

D

H

(

m

) T

D

H

(

f

t

)

C8

C7

C9

C6

C5

C4

C3

C2

C1

B1

B6

B4

A3/4

B3/5 A1

0

20

40

60

80

100

120

140

0 200 400 600 800 1000 1200 1400 1600

0

5

10

15

20

25

30

35

40

0 50 100 150 200 250 300 350

Capacity (m/hr)

Capacity (US gpm)

T

D

H

(

f

t

)

T

D

H

(

m

)

C9

C6

C5

C4

C3

C2

C1 B4

B1

B6

B3/B5

A3/A4

A1

0

100

200

300

400

500

600

0 200 400 600 800 1000 1200 1400 1600

0

20

40

60

80

100

120

140

160

180

0 50 100 150 200 250 300 350

Capacity (m/hr)

T

D

H

(

f

t

)

T

D

H

(

m

)

Capacity (US gpm)

ALL Pump Models use ONE Impeller for Stated Power Range Power Range

C6-4x3x10 C7-4x3x10H C8-6x4x10H C9-6x4x8

C5-3x2x10 C4-3x1.5x10 C3-2x1x10 C2-4x3x8 C1-3x2x8

B1-1.5x1x8 B3/B5-3x2x6 B4-3x1.5x8 B6-4x3x6

A3-3x1.5x6 A1-1.5x1x6 A4-3x2x6

to 75hp @ 3500 rpm

to 30hp @ 3500 rpm

to 15hp @ 3500 rpm

TB-mag Special Pumps

TB-mag Hydraulic Curves

TB-mag ISO/JIS

TB-Mag Pump Dimensions - ANSI / ISO

Specifications

Capacities: Power:

- 450 gpm Up to 14 hp

(0.1-102 m

3

/hr) (10.5 kW)

Heads: Temperature:

Up to 165 ft -20 to 250F

(50 m) (-29 to 121C)

Working Pressure: Materials:

300 psi CF ETFE (Std)

(21 bar) High Purity PFA

Comfortable with the older, thrust forward

designs but want INNOMAG quality? The

U-mag series is your solution. Made with

the exact same high quality materials as the

TB-mag but designed for smaller and more

refned applications.

The U-mag series is offered in a variety of

fuoroplastic materials including High Purity

PFA.

Innomag.com

Chemical processing Chromic Acid

Metal Plating Hydrochloric Acid

Parts washing HydroFlouric Acid

Circuit board mfg. Nitric Acid

Photo processing Ferric Chloride

Pharmaceuticals Sodium Hydroxide

Pure Water, RO & DI Sodium Hypochlorite

Food processing Sulfuric Acid

Wet scrubbers

Semi-conductor

Heat exchangers

Apps: Services:

The U-mag Series

Universal Mag-Drive Dimensions Universal Chemical Compatibility Worldwide Approval

Capacities: Power:

- 450 gpm Up to 14 hp

(0.1-102 m

3

/hr) (10.5 kW)

Heads: Temperature:

Up to 165 ft -20 to 250F

(50 m) (-29 to 121C)

Working Pressure: Materials:

300 psi CF ETFE (Std)

(21 bar) High Purity PFA

Motor Adapter Outer Drive Ultra High Purity PFA

Containment shell Impeller Assembly Pump Casing

Mates NEMA C-faced or IEC

D-fange motors directly (no

spacer plates required).

Universal foot supports entire

pump load.

One outer drive per motor

frame size.

Dowel pins eliminates motor

shaft key for quick and easy

install.

Center drill & tap thread

for easy removal from motor

shaft.

Optional High Purity PFA

fuoroplastic.

Ultra low contaminants (ppb)

Excellent for semi-con, LCD

and circuit board manufac-

turing.

Particulate control ring helps

to protect radial bearing

and containment shell from

solids.

Reinforced socket for pump

shaft.

Outer pressure housing

made of Aramid composite

for high pressure, strength &

shock resistance.

Universal chemical resistance

with fuoroplastic ETFE as

standard.

Front wear ring made of pure

SiC or CFR / PTFE.

Patented double weld inner

magnet provides extreme

corrosion and permeation

resistance.

Fully bonded ETFE liner

- minimum of 1/8 (3 mm)

thick and rated to full

vacuum.

Full open suction for lowest

NPSHr.

Compact, heavy duty, non-metallic magnetic drive pump.

Universal fange design - meets ANSI, ISO and JIS piping connections.

Fluoroplastic ETFE and Ultra High Purity PFA provide universal chemical compatibility.

Optional Ultra High Purity PFA allows for ultra low contaminants (ppb).

Powerful neodymium magnets provide maximum torque up tp 14 hp (10.5kW).

Pump housing based on modifed concentric volute to minimize radial loads and help extend bearing life.

Cantilevered pump shaft allows for full opened pump suction, providing for the lowest NPSHr.

Designed for easy pump service (if required).

Liquid end and drive end independently serviceable.

100% replaceable wear parts including all rotating and stationary rings.

Heads to 165 ft (50m) / Flows to 450 gpm (102 m

3

/hr).

Quick Summary of Features

Page 16

U-mag Dimensions & Flow Curves

Z

W

U3 - 3x2.5x6

U4 - 2.5x2x6

U1 - 2x1.5x6

U0 - 1.5x1x5

UL - 1.5x1x5LF

T

D

H

(

f

t

)

Capacity (US gpm)

T

D

H

(

m

)

Capacity (m

3

/hr)

0

1

2

3

4

5

6

7

8

9

10

0 10 20 30 40 50 60 70 80 90

0

5

10

15

20

25

30

0 50 100 150 200 250 300 350

U4 - 2.5x2x6

U1 - 2x1.5x6

U0 - 1.5x1x5

UL - 1.5x1x5LF

T

D

H

(

f

t

)

Capacity (m

3

/hr)

T

D

H

(

m

)

Capacity (US gpm)

0

5

10

15

20

25

30

35

0 10 20 30 40 50 60

0

20

40

60

80

100

0 50 100 150 200 250

0

5

10

15

20

25

30

35

40

45

50

0 25 50 75 100 125 150 175 200 225 250 275 300 325 350 375 400 425 450 475

0

5

10

15

0 10 20 30 40 50 60 70 80 90 100

U3 - 3x2.5x6

U4 - 2.5x2x6

U1 - 2x1.5x6

U0 - 1.5x1x5

UL - 1.5x1x5LF

T

D

H

(

m

)

Capacity (m

3

/hr)

T

D

H

(

f

t

)

Capacity (US gpm)

U4 - 2.5x2x6

U1 - 2x1.5x6

U0 - 1.5x1x5

UL - 1.5x1x5LF

0

20

40

60

80

100

120

140

160

180

0 25 50 75 100 125 150 175 200 225 250 275 300

0

10

20

30

40

50

0 5 10 15 20 25 30 35 40 45 50 55 60 65

T

D

H

(

m

)

Capacity (US gpm)

T

D

H

(

f

t

)

Capacity (m

3

/hr)

Innomag.com

2E

2

2E

1

F G

O

CP Y

X

D

UL-1.5x1x5LF

(40x25x156mm)

U1 - 2x1.5x6

(50x40x156mm)

U3 - 3x2.5x6

(80x65x156mm)

U4 - 2.5x2x6

(65x50x156mm)

U0 - 1.5x1x5

(40x25x156mm)

2E

1

2E

2

F G W X Y Z Model (Size)

8.00

(203)

8.00

(203)

5.50

(140)

3.69

(94)

9.64

(245)

3.15

(80)

3.15

(80)

3.42

(87)

3.94

(100)

3.15

(80)

2.34

(59)

2.34

(59)

2.56

(65)

0.00

(0)

0.00

(0)

Suction Flange Discharge Flange

ANSI

(Class 150)

ANSI

(Class 150)

ISO

(PN16)

ISO

(PN16)

JIS

(10kg/cm

2

)

JIS

(10kg/cm

2

)

lb

(kg)

1.50

1.50

2.00

3.00

2.50 2.00

2.50

1.50

1.00

1.00 40mm

40mm

50mm

80mm

65mm

40mm

40mm

50mm

80mm

65mm

25mm

25mm

40mm

65mm

50mm

25mm

25mm

40mm

65mm

50mm

55

(25)

63

(29)

63

(29)

91

(41)

71

(32)

5.50

(140)

7.10

(180)

6.30

(160)

UL-1.5x1x5LF

(40x25x156mm)

U1 - 2x1.5x6

(50x40x156mm)

U3 - 3x2.5x6

(80x65x156mm)

U4 - 2.5x2x6

(65x50x156mm)

U0 - 1.5x1x5

(40x25x156mm)

Model (Size)

NEMA IEC

56C 143/5TC 182/4TC 213/5TC 80/90SL 100L/112M 132

D CP D CP D CP D CP D CP D CP D CP

4.50

(114)

4.50

(114)

6.10

(156)

6.10

(156)

4.50

(114)

4.50

(114)

6.10

(156)

6.10

(156)

4.50

(114)

4.50

(114)

6.10

(156)

6.10

(156)

4.50

(114)

4.50

(114)

6.10

(156)

6.10

(156)

5.25

(133)

5.25

(133)

6.10

(156)

6.10

(156)

7.52

(191)

7.52

(191)

7.52

(191)

7.52

(191)

7.52

(191)

6.10

(156)

6.10

(156)

6.67

(169)

6.85

(174)

INNOMAG Custom Accessories

At Innovative Mag-Drive, we understand that a pump is not your only concern, its just one of many

items to make your process work. To speed your installation, we offer many accessories and piping

adapters for those tough-to-ft spots.

Priming tanks

and priming

systems

Lined specialty pipe

and spool pieces

Low-fow models to

save you energy

Wide variety of

power monitors

Steam heat

jackets

Wide selection of

baseplates

Alternative cast-

ings and fanges

to speed odd

installs

Direct mount engine driven options for

tanker trucks and remote locations

Page 18

Vertical pumps

W3 - 3 x 2 x 6

W1 - 2 x 1.5 x 8

V1 - 2 x 1.5 x 6

Please call INNOMAG or your Authorized Dealer for more information.

For Clean Manufacturing

Call INNOMAG or visit us at innomag.com

Note: Information contained herein is subject to change without notice. Pump

curves and illustrations for print reproduction; actual data may very. Always

consult your Authorized Dealer or Innovative Mag-Drive for certifed data.

INNOMAG is a Registered Trade Mark of Innovative Mag-Drive

INNOMAG products are covered by one or more of the following

US Patents: 6,135,728\6,234,748\6,264,440\6,293,772\6,908,291

\6,997,688 2013 by Innovative Mag-Drive

Innovative Mag-Drive

409 S Vista Ave

Addison, IL 60101

Phone: (630) 543 - 4240

Fax: (630) 543 - 4245

www.innomag.com

Proudly Made in The USA

Your Authorized Distributor:

You might also like

- Pedrollo 2CPDocument8 pagesPedrollo 2CPBenicio Joaquín Ferrero BrebesNo ratings yet

- Ensival Moret PumpsDocument5 pagesEnsival Moret PumpsBenicio Joaquín Ferrero Brebes0% (1)

- OPPS Pumps OA65-32-2900Document1 pageOPPS Pumps OA65-32-2900Benicio Joaquín Ferrero BrebesNo ratings yet

- OPPS PumpsDocument1 pageOPPS PumpsBenicio Joaquín Ferrero BrebesNo ratings yet

- Sellos T-5610 T-5610QDocument8 pagesSellos T-5610 T-5610QBenicio Joaquín Ferrero BrebesNo ratings yet

- Ensival Moret PRE Pumps (French-English)Document3 pagesEnsival Moret PRE Pumps (French-English)Benicio Joaquín Ferrero BrebesNo ratings yet

- BurgmannDocument1 pageBurgmannBenicio Joaquín Ferrero BrebesNo ratings yet

- Sulzer Ahlstar PP E00545Document16 pagesSulzer Ahlstar PP E00545Benicio Joaquín Ferrero Brebes100% (1)

- API Plan 41Document2 pagesAPI Plan 41Benicio Joaquín Ferrero BrebesNo ratings yet

- Roper PumpsDocument90 pagesRoper PumpsBenicio Joaquín Ferrero BrebesNo ratings yet

- NOS NT ENG 50HzDocument40 pagesNOS NT ENG 50HzBenicio Joaquín Ferrero BrebesNo ratings yet

- RuhrpumpenDocument2 pagesRuhrpumpenBenicio Joaquín Ferrero BrebesNo ratings yet

- John Crane Acoplamientos Serie LDocument8 pagesJohn Crane Acoplamientos Serie LBenicio Joaquín Ferrero BrebesNo ratings yet

- ISO 9001 CERTIFIED NORMALIZED PUMPS FOR INDUSTRIAL APPLICATIONSDocument6 pagesISO 9001 CERTIFIED NORMALIZED PUMPS FOR INDUSTRIAL APPLICATIONSBenicio Joaquín Ferrero Brebes100% (1)

- Burgmann Design Manual 155Document152 pagesBurgmann Design Manual 155Benicio Joaquín Ferrero BrebesNo ratings yet

- BurgmannDocument13 pagesBurgmannBenicio Joaquín Ferrero BrebesNo ratings yet

- E P01-2015 eSV-50Hz EN L218x305Document72 pagesE P01-2015 eSV-50Hz EN L218x305Benicio Joaquín Ferrero BrebesNo ratings yet

- BurgmannDocument1 pageBurgmannBenicio Joaquín Ferrero BrebesNo ratings yet

- Manual Bomba Layne BowlerDocument21 pagesManual Bomba Layne BowlerBenicio Joaquín Ferrero BrebesNo ratings yet

- Catalogo Fire 2009Document7 pagesCatalogo Fire 2009Benicio Joaquín Ferrero BrebesNo ratings yet

- ISO 9001 CERTIFIED NORMALIZED PUMPS FOR INDUSTRIAL APPLICATIONSDocument6 pagesISO 9001 CERTIFIED NORMALIZED PUMPS FOR INDUSTRIAL APPLICATIONSBenicio Joaquín Ferrero Brebes100% (1)

- RuhrpumpenDocument4 pagesRuhrpumpenBenicio Joaquín Ferrero BrebesNo ratings yet

- Aurora Fire Pump System SpecsDocument14 pagesAurora Fire Pump System SpecsBenicio Joaquín Ferrero BrebesNo ratings yet

- Viking Heavy Duty Pumps: SERIES 4193 AND 493 Steel ExternalsDocument12 pagesViking Heavy Duty Pumps: SERIES 4193 AND 493 Steel ExternalsBenicio Joaquín Ferrero BrebesNo ratings yet

- Screw Pump HC 232 - 80/2 / N: 1.0 Project DataDocument1 pageScrew Pump HC 232 - 80/2 / N: 1.0 Project DataBenicio Joaquín Ferrero BrebesNo ratings yet

- Catalogo OMEGADocument20 pagesCatalogo OMEGABenicio Joaquín Ferrero BrebesNo ratings yet

- Peerless FireDocument24 pagesPeerless FireBenicio Joaquín Ferrero BrebesNo ratings yet

- World of Industrial Applications Brochure 2011-02 CPCEIDAPDocument44 pagesWorld of Industrial Applications Brochure 2011-02 CPCEIDAPMarcelo Palacios SantanaNo ratings yet

- Spec Sheet - JU6H-LS - C13556 - 04-05Document2 pagesSpec Sheet - JU6H-LS - C13556 - 04-05Benicio Joaquín Ferrero BrebesNo ratings yet

- 248Document8 pages248Benicio Joaquín Ferrero BrebesNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Service Menu - SamyGODocument5 pagesService Menu - SamyGOVenkatesh SubramanyaNo ratings yet

- BPCL Kochi Refinery MS BLOCK PROJECT Piping Material SpecificationDocument1 pageBPCL Kochi Refinery MS BLOCK PROJECT Piping Material SpecificationDeepak DayalNo ratings yet

- 2 CAD Connecting Rod ForgingDocument56 pages2 CAD Connecting Rod ForgingIsrar EqubalNo ratings yet

- Cassette toilet spare parts guide for models C2, C3 and C4Document21 pagesCassette toilet spare parts guide for models C2, C3 and C4georgedragosNo ratings yet

- Operator Interface Hmi Touch Screen Cmore - 10Document54 pagesOperator Interface Hmi Touch Screen Cmore - 10QuantumAutomation100% (1)

- Wrangling Logs With Logstash and ElasticSearch PresentationDocument38 pagesWrangling Logs With Logstash and ElasticSearch PresentationMohammad Syafiq Bin HussainNo ratings yet

- 01 4G64S4M & 4G69S4N Engine-2Document38 pages01 4G64S4M & 4G69S4N Engine-2vitor santosNo ratings yet

- W 7570 enDocument276 pagesW 7570 enthedoors89No ratings yet

- For Steel Cage Lapping by Using U-ClipDocument4 pagesFor Steel Cage Lapping by Using U-Cliptin aungtunNo ratings yet

- Stress-Strain Behaviour of Steel-Fibre-Reinforced Recycled Aggregate Concrete Under Axial TensionDocument16 pagesStress-Strain Behaviour of Steel-Fibre-Reinforced Recycled Aggregate Concrete Under Axial TensionAndrucruz CruzNo ratings yet

- Staircase Preliminary Design Based On NBC and IS CodeDocument10 pagesStaircase Preliminary Design Based On NBC and IS CodeEducation. HubNo ratings yet

- NDI Manual 2013 - v10Document13 pagesNDI Manual 2013 - v10Yudha Bhakti NugrahaNo ratings yet

- Versys Parts Catalogue (UK)Document111 pagesVersys Parts Catalogue (UK)BaronBaz001No ratings yet

- Velp ZX3 Vortex PDFDocument5 pagesVelp ZX3 Vortex PDFarodassanchez0% (1)

- InverterDocument8 pagesInverterrajinipre-1No ratings yet

- Guess Questions of Aramco Written Examination For Hse Supervisor / Engineer / OfficerDocument31 pagesGuess Questions of Aramco Written Examination For Hse Supervisor / Engineer / OfficerAlam Shamsher0% (1)

- Applied Fluid Mechanics: Viscosity of FluidsDocument22 pagesApplied Fluid Mechanics: Viscosity of FluidsMaggie HepditchNo ratings yet

- NIKI V4 Infusion Pump Service ManualDocument54 pagesNIKI V4 Infusion Pump Service ManualIgor Simonelli BermudesNo ratings yet

- Alketerge EDocument4 pagesAlketerge EYohanes OktavianusNo ratings yet

- Bilge Alarm Monitor OMD 11Document22 pagesBilge Alarm Monitor OMD 11Lucian Iftemie100% (3)

- XHLE Long Coupled Centrifugal Pump EnglishDocument8 pagesXHLE Long Coupled Centrifugal Pump Englishgagi1994brahimNo ratings yet

- Communication System (LC-ECE204G) LAB ManualDocument54 pagesCommunication System (LC-ECE204G) LAB ManualBindia HandaNo ratings yet

- Wacker Neuson-Dpu - 25 KNDocument3 pagesWacker Neuson-Dpu - 25 KNMilutin BožovićNo ratings yet

- How rock layers are formedDocument3 pagesHow rock layers are formedAlemar AllecerNo ratings yet

- Technical Presentation - Arik Ethan Kinajil (25231)Document5 pagesTechnical Presentation - Arik Ethan Kinajil (25231)Arik EthanNo ratings yet

- Conventional and Non-Conventional Energy Resources of India: Present and FutureDocument8 pagesConventional and Non-Conventional Energy Resources of India: Present and FutureAnkit SharmaNo ratings yet

- Inventory Management PreetDocument28 pagesInventory Management PreetKawalpreet Singh MakkarNo ratings yet

- How To Install GmtsarDocument24 pagesHow To Install GmtsardedetmixNo ratings yet

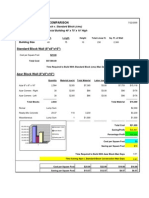

- AZAR Block CostcomparisonDocument8 pagesAZAR Block CostcomparisontckittuNo ratings yet

- Crompton Greaves LimitedDocument3 pagesCrompton Greaves LimitedNitish SinghNo ratings yet