Professional Documents

Culture Documents

AQV24PSBN Troubleshooting PDF

Uploaded by

stefanovigano8579Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AQV24PSBN Troubleshooting PDF

Uploaded by

stefanovigano8579Copyright:

Available Formats

l2-l Samsung Llectronlcs

12. 7roubIeshooting

12-1 Items to be checked first

l. The lnput voltage should be ratlng voltage l0% range.

The alr condltloner may not operate properly lf the voltage ls out of thls range.

2. |s the llnk cable llnklng the lndoor unlt and the outdoor unlt llnked properly!

The lndoor unlt and the outdoor unlt shall be llnked by 5 cables.

Check the termlnals lf the lndoor unlt and outdoor unlt are properly llnked by the same number of cables.

Otherwlse the alr condltloner may not operate properly.

3. when a problem occurs due to the contents lllustrated ln the table below lt ls a symptom not related to the malfunctlon of the

alr condltloner.

No Dperation of air conditioner xpIanation

1 The OPLPAT|ON lndlcatlon LLD(8LUL) bllnks when a power

plug of the lndoor unlt ls plugged ln for the flrst tlme.

|t lndlcates power ls on. The LLD stops bllnklng lf the operatlon

ON/OPP button on the remote control unlt ls pushed.

2 |n a COOL operatlon mode, the compressor does not

operate at a room temperature hlgher than the settlng

temperature that the |NDOOP PAN should operate.

[In case of heat pump modeI]

|n a HLAT operatlon mode, the compressor does not

operate at a room temperature lower than the settlng

temperature that lndoor fan should operate.

|n happens after a delay of 3 mlnutes when the compressor ls

reoperated. The same phenomenon occurs when a power ls on.

As a phenomenon that the compressor ls reoperated after a

delay of 3 mlnutes, the lndoor fan ls ad[usted automatlcally wlth

reference to a temperature of the alr blew.

3

Pan speed settlng ls not allowed ln DP( ) mode.

The speed of the lndoor fan ls set to LL ln DP mode.

Pan speed ls selected automatlcally ln AUTO mode.

4

Compressor stops operatlon lntermlttently ln DP( )

mode.

Compressor operatlon ls controlled automatlcally ln DP mode

dependlng on the room temperature and humldlty.

5 Tlmer LLD(OPANGL) of the lndoor unlt llghts up and the

alr condltloner does not operate.

Tlmer ls belng actlvated and the unlt ls ln ready mode.

The unlt operates normally lf the tlmer operatlon ls cancelled.

6 The compressor stops lntermlttently ln a COOL mode or

DP mode, and fan speed of the lndoor unlt decreases.

The compressor stops lntermlttently or the fan speed of the

lndoor unlt decreases to prevent lnslde/outslde alr frozen

dependlng on the lnslde/outslde alr temperature.

7 [In case of heat pump modeI]

Compressor of the outdoor unlt ls operatlng although lt ls

turned off ln a HLAT mode.

when the unlt ls turned off whlle de-lce ls actlvated, the

compressor contlnues operatlon for up to 9 mlnutes(maxlmum)

untll the delce ls completed.

8 [In case of heat pump modeI]

The compressor and lndoor fan stop lntermlttently ln HLAT

mode.

The compressor and lndoor fan stop lntermlttently lf room

temperature exceeds a settlng temperature ln order to protect

the compressor from overheated alr ln a HLAT mode.

9 [In case of heat pump modeI]

|ndoor fan and outdoor fan stop operatlon lntermlttently

ln a HLAT mode.

The compressor operates ln a reverse cycle to remove

exterlor lce ln a HLAT mode, and lndoor fan and outdoor

fan do not operate lntermlttently for wlthln 20% of the total

heater operatlon

Sams ung Electronics

12-2

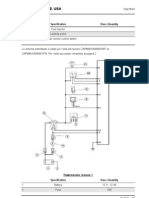

12-2-1.Communication error

Indoor display Communication error

Outdoor display 1min. Time out Comm.

1.Checklist :

1) Is the cable between the indoor unit and outdoor unit connected correctly?

2) Isn't the power cable and communication cable cross?

2. Troubleshooting procedure

Abnormal Communication

Is the communicaton error

occurred again?

Restart afer power o.

Terminate the service.

NO

Is the connecton of power cable

and communicaton cable normal?

Correct the wrong cable.

NO

YES

Exchange the indoor unit PBA.

Is the communicaton error

occurred again?

Terminate the service.

NO

YES

Exchange the outdoor unit PBA.

YES

Is the power is normal?

(check the LED Lamp)

Exchange the PBA of no power unit

NO

YES

12-3

12-2-2.Indoor temperature sensor error

Indoor display

Indoor room temp sensor

error

1.Checklist :

1) Is the indoor units temperature sensor connected correctly?

2) Is the sensor placed correctly?

3) Does the both terminal of sensor satisfy the resistance value in accordance with temperature?

2. Troubleshooting procedure

Is the sensor resistance value #1-#2

10kohm3% at the room

temperature

of 25

Detach the assembled sensor from the PBA sensor

connector and measure the sensor resistance with

ohmmeter(tester)

Sensor Replace

Sensor resistance value : 20- 12.09kohm

30- 8.31kohm

35- 6.94kohm

40- 5.83kohm

Below0.5V or Over 4.5V?

Connect the sensor to PBA connector (4piin)

supply power and measure the voltage of #1-#2 in

the connector

Exchange the indoor PBA

NO

YES

NO

YES

Micomerror or connector check

Exchange the indoor PBA

YES

12-4

12-2-3.Indoor Eva-in temperature sensor error

Indoor display

Indoor Eva-in temp sensor

error

1.Checklist :

1) Is the indoor units temperature sensor connected correctly?

2) Is the sensor placed correctly?

3) Does the both terminal of sensor satisfy the resistance value in accordance with temperature?

2. Troubleshooting procedure

Isthe sensor resistance value #3 -#4

10kohm 3% at the room

temperature

of 25

Detachthe assembled sensor from the PBA sensor

connector and measure the sensor resistance with

ohmmeter(tester)

Sensor Replace

Sensorresistance value : 20 -12.09kohm

30-8.31kohm

35-6.94kohm

40-5.83kohm

Below 0.5V or Over 4.5V?

Connectthe sensor to PBA connector (4piin)

supply power and measure the voltage of #3 -#4 in

the connector

Exchangethe indoor PBA

NO

YES

NO

YES

Micom error or connector check

Exchangethe indoor PBA

YES

12-5

12-2-4.When the Up/Down louver motor does not operate (Initial Diagnosis)

(Not displayed)

1.Checklist :

1) Is the input power voltage normal?

2) Is the Up/Down louver motor properly connected with the connector? (CN61)

2. Troubleshooting procedure

Is the lamp blinking?

Unplug the power cord and plug it afer 30seconds

later.

Check the as in the procedure.

No power.

NO

Is the connected louver wire? Connect the wire PBA to louver motor

NO

YES

Is the voltage changeable at the

pin#2~#5 of CN61(louver

connector)?

Exchange the PBA

NO

YES

Up/Down louver motor is faulty.

YES

Does operaton start when swing

buton of the remote control unit

pushed?

Normal

YES

NO

12-6

12-2-5.When the remote control is not receiving

1.Checklist :

1) Check if the connector was normally assembled.

2) Check the battery in remote control

3) All the lights out and check again : Change electronic typed to a fluorescent light

4) Put the set in operation and check the voltage of display PBA

5) Replace the display PBA

12-7

12-2-6.Indoor fan motor speed detecting error (BLDC fan)

Indoor display Indoor fan error

1.Checklist :

1) Is the indoor units fan motor properly connected with the connector(CN72)?

2) Is the AC voltage correct?

2. Troubleshooting procedure

Does the fan rotate?

Power offand Separatethe Fan motor wire from

CN72 on Indoor PBA

NO

YES

Isthe fan error appeared again?

Reassemble the fan wire and input the power again

YES

Isthe voltage of CN72 #3 -#5 and

#3-#6 with in 1Vdc~15Vdc during

the operation?

YES

Exchange the Indoor PBA

Terminate the

service

NO

NO

PBA problem or Motor problem

Change the PBA first and check the operation

Exchangethe Fan motor

Isthere short among each pin

#1~#6

YES

Exchangethe Fan

motor

Isthe voltage of CN72 #1 -#3 over

250Vdc

NO

Followthe check procedure of Indoor unit power

supply error check

NO

YES

Restart after power off.

12-8

12-2-7.Outdoor temperature sensor error

Indoor display Outdoor error

Outdoor display

Outdoor temperature sensor

error

1.Checklist :

1) Is the sensor connected correctly?

2) Is the sensor placed correctly?

3) Does the both terminal of sensor satisfy the resistance value in accordance with temperature?

4) Is the resistance value of sensor connection pull-up correct?

2-1. Troubleshooting procedure (ASV18P**)

2-2. Troubleshooting procedure (ASV24P**)

Isthe sensor resistance value #1 -#2

10kohm 3% at the room

temperature

of 25

Sensor Replace

Sensorresistance value : 20 -12.09kohm

30-8.31kohm

35-6.94kohm

40-5.83kohm

NO

YES

YES

YES

Isthe sensor connector(CN251)

connected correctly in accordance

with a color(BLU,6PIN)?

Reconnect the sensor connector.

NO

Below 0.5V or Over 4.5V?

Connectthe sensor to PBA connector (6pin)

supply power and measure the voltage of #1 -#2 in

the connector

Exchangethe Outdoor PBA

NO

Micom error or connector check

Exchangethe Outdoor PBA

YES

Isthe sensor resistance value #1 -#2

10kohm 3% at the room

temperature of 25

Sensor Replace

Sensorresistance value : 20 -12.09kohm

30-8.31kohm

35-6.94kohm

40-5.83kohm

NO

YES

YES

YES

Isthe sensor connector(CN502)

connected correctly in accordance

with a color(RED,4pin)?

Reconnect the sensor connector.

NO

Below 0.5V or Over 4.5V?

Connectthe sensor to PBA connector(4pin)

supply power and measure the voltage of #1 -#2 in

the connector

Exchangethe Outdoor PBA

NO

Micom error or connector check

Exchangethe Outdoor PBA

YES

12-9

12-2-8.Outdoor Coil temperature sensor error

Indoor display Outdoor error

Outdoor display Outdoor Coil temperature sensor error

1.Checklist :

1) Is the sensor connected correctly?

2) Is the sensor placed correctly?

3) Does the both terminal of sensor satisfy the resistance value in accordance with temperature?

4) Is the resistance value of sensor connection pull-up correct?

2-1. Troubleshooting procedure (ASV18P**)

2-2. Troubleshooting procedure (ASV24P**)

Isthe sensor resistance value #5 -#6

10kohm 3% at the room

temperature

of 25

Sensor Replace

Sensorresistance value : 20 -12.09kohm

30-8.31kohm

35-6.94kohm

40-5.83kohm

NO

YES

YES

YES

Isthe sensor connector(CN251)

connected correctly in accordance

with a color(BLU,6PIN)?

Reconnect the sensor connector.

NO

Below 0.5V or Over 4.5V?

Connectthe sensor to PBA connector (6piin)

supply power and measure the voltage of #5 -#6 in

the connector

Exchangethe Outdoor PBA

NO

Micom error or connector check

Exchangethe Outdoor PBA

YES

Isthe sensor resistance value #3 -#4

(CN501) 10kohm3% at the room

temperature of 25

Sensor Replace

Sensorresistance value : 20 -12.09kohm

30-8.31kohm

35-6.94kohm

40-5.83kohm

NO

YES

YES

YES

Isthe sensor connector(CN501)

connected correctly in accordance

with a color(WHT,4pin)?

Reconnect the sensor connector.

NO

Below 0.5V or Over 4.5V?

Connectthe sensor to PBA connector(4pin)

supply power and measure the voltage of #3 -#4 in

the connector

Exchangethe Outdoor PBA

NO

Micom error or connector check

Exchangethe Outdoor PBA

YES

12-10

12-2-9.Outdoor Discharge temperature sensor error

Indoor display Outdoor error

Outdoor display

Outdoor Discharge temperature sensor

error

1.Checklist :

1) Is the sensor connected correctly?

2) Is the sensor placed correctly?

3) Does the both terminal of sensor satisfy the resistance value in accordance with temperature?

4) Is the resistance value of sensor connection pull-up correct?

2-1. Troubleshooting procedure (ASV18P**)

2-2. Troubleshooting procedure (ASV24P**)

Isthe sensor resistance value #3 -#4

200kohm 3% at the room

temperature

of 25

Sensor Replace

Sensorresistance value : 20 - 242kohm

30- 166ohm

35- 138ohm

40- 115kohm

NO

YES

YES

YES

Isthe sensor connector(CN251)

connected correctly in accordance

with a color(BLU,6PIN)?

Reconnect the sensor connector.

NO

Below 0.5V or Over 4.5V?

Connectthe sensor to PBA connector (6piin)

supply power and measure the voltage of #3 -#4 in

the connector

Exchangethe Outdoor PBA

NO

Micom error or connector check

Exchangethe Outdoor PBA

YES

Isthe sensor resistance value #3 -#4

200kohm 3% at the room

temperature

of 25

Sensor Replace

Sensorresistance value : 20 - 242kohm

30- 166ohm

35- 138ohm

40- 115kohm

NO

YES

YES

YES

Isthe sensor connector(CN502)

connected correctly in accordance

with a color(red,4pin)?

Reconnect the sensor connector.

NO

Below 0.5V or Over 4.5V?

Connectthe sensor to PBA connector(4pin)

supply power and measure the voltage of #3 -#4 in

the connector

Exchangethe Outdoor PBA

NO

Micom error or connector check

Exchangethe Outdoor PBA

YES

12-11

12-2-10.Outdoor Discharge over temperature error

Indoor display Outdoor error

Outdoor display

Outdoor Discharge over temperature

error

1.Checklist :

1) Check the discharge temperature in the outdoor unit

2) Check the compressor locking or gas leak

3) Download the EEPROM data

2. Troubleshooting procedure

Isthe discharge over temperature

sensor error appeared again?

Terminate the service

NO

after 30min ~ 1Hr

YES

Isthe discharge over temperature

sensor error appeared again?

The condition is too poor for air conditioner to

operate

Waituntil discharge temperature is decreased

Restart after power off

YES

Download the EEPROM data

Isthe discharge over temperature

sensor error appeared again?

YES

Terminate the service

Terminate the service

NO

NO

Exchangethe Outdoor PBA

Exchangedthe Compressor

Restart after power off.

12-12

12-2-11.Outdoor Fan motor error

Indoor display Outdoor error

Outdoor display Outdoor fan error

1.Checklist :

1) Are the input power voltage and the power connection correct?

2) Is the motor wire connected to the outdoor PBA correctly?

3) Is there no assembly error or none-assembly in the terminal of motor wire connector?

4) Is there no obstacle at the surrounding of motor and propeller?

2. Troubleshooting procedure

Does the fan rotate?

Power offand Separatethe Fan motor wire from

CN901 on Outdoor PBA

NO

YES

Isthe fan error appeared again?

Reassemble the fan wire and input the power again

YES

Isthe voltage of CN901 #3 -#5 and

#3-#6 with in 1Vdc~15Vdc during

the operation?

YES

Exchange the Outdoor PBA

Terminate the

service

NO

NO

PBA problem or Motor problem

Change the PBA first and check the operation

Exchangethe Fan motor

Isthere short among each pin

#1~#6

YES

Exchangethe Fan

motor

Isthe voltage of CN901 #1 -#3 over

250Vdc

NO

Followthe check procedure of outdoor unit power

supply error check

NO

YES

Restart after power off.

12-13

12-2-12.Compressor starting error

Indoor display Outdoor error

Outdoor display Comp starting error

1.Checklist :

1) Is the connection of cable for the compressor?

2) Is the compressor wire is connected clockwise? U(RED)-V(BLU)-W(YEL)

3) Is the interphase resistance of compressor normal?

2. Troubleshooting procedure

Is the restart error occurred again? Terminatethe service

NO

YES

Isthe connection of compressor

wire is normal?

YES

Is the compressor body and

interphase resistance insulated?

NO

Exchange the Outdoor PBA

Connectthe comp wire normally

YES

NO

Exchangethe compressor

Is the restart error occurred again? Terminate the service

NO

YES

Restart after power off.

Download the EEPROM data

12-14

12-2-13.Compressor wire missing error/rotation error

Indoor display Outdoor error

Outdoor display

Compressor wire missing error/rotation

error

1.Checklist :

1) Is the connection of cable for the compressor?

2) Is the compressor wire is connected clockwise? U(RED)-V(BLU)-W(YEL)

3) Is the interphase resistance of compressor normal?

2. Troubleshooting procedure

Is the restart error occurred again? Terminatethe service

NO

YES

Isthe connection of compressor

wire is normal? (PBA and

Compressor)

YES

Is the compressor body and

interphase resistance insulated?

NO

Exchange the Outdoor PBA

Connectthe comp wire normally

YES

NO

Exchangethe compressor

Is the restart error occurred again? Terminate the service

NO

YES

Restart after power off.

12-15

12-2-14. O.C(Over Current) error

Indoor display Outdoor error

Outdoor display Comp starting error

1.Checklist :

1) Is the IPM Shunt(ASV18P**:R451,R452,R453,ASV24P**:R413,R414,R415) resistance value correct? Check the resistor is opened

2) Is the condition of surrounding temperature abnormal overload?

3) Is there any problem as like the temperature sensor separation or measurement value error?

4) Is the interphase resistance of compressor normal?

2. Troubleshooting procedure

Is the O.C error occurred? Terminatethe service

NO

YES

Isthe connection of compressor

wire is normal?

YES

Is the compressor body and

interphase resistance insulated?

NO

Exchange the Outdoor PBA

Connectthe comp wire normally

YES

NO

Exchangethe compressor

Is the O.C error occurred again? Terminate the service

NO

YES

Restart after power off.

Is the condition of indoor/outdoor

temperature normal load?

Restart after returning to the normal load

YES

NO

Is the O.C error

occurred again?

Terminatethe

service

YES

NO

Is the position of temperature

sensor and sensing value normal?

Correct the sensor position or exchange the sensor

YES

NO

12-16

12-2-15. DC_link voltage sensor error

Indoor display Outdoor error

Outdoor display DC_link voltage sensor error

1.Checklist :

1) Is the input voltage of outdoor terminal block is normal?

2) Is the reactor wire connected?

3) Is the DC_link capacitor(ASV18P**:CE101,CE102,CE103,ASV24P**:CE001,CE002,CE003,CE004)) assembled in

accordance the specification? (Outdoor PBA)

4) Is the DC_link resistor(ASV18P**:R104,R106,R107,R108,ASV24P**:R004,R005,R006,R007) value is normal? (Outdoor PBA)

Isthe connected of reactor wire?

(PBA-Reactor)

Isthe DC_link sensing voltage(R104

or R004) is normal in operation

mode?

Normal range (0.2Vdc~2.8Vdc)

YES

Exchange the Outdoor PBA

NO

Is the DC_link voltage (CE101 or

CE001) is normal in operation

mode?

Normal range(280Vdc~320Vdc)

Check the powerinput

NO

YES

YES

Connectthe reactor wire

NO

Restart after power off.

Start the operation (cooling mode or heating mode)

Exchangethe Reactor

Is the reactor insulation damaged?

YES

Exchange the Outdoor PBA

NO

12-17

12-2-16. DC_link voltage under/over error, Over voltage protection error/PFC

over load

Indoor display Outdoor error

Outdoor display

DC_link voltage under/over error

Over voltage protection error

PFC over load

1.Checklist :

1) Is the input voltage of outdoor terminal block is normal?

2) Is the input voltage is higher than 300Vac?

3) Is the reactor wire connected?

3) Is the DC_link capacitor(ASV18P**:CE101,CE102,CE103,ASV24P**:CE001,CE002,CE003,CE004)) assembled in

accordance the specification? (Outdoor PBA)

4) Is the DC_link resistor(ASV18P**:R104,R106,R107,R108,ASV24P**:R004,R005,R006,R007) value is normal? (Outdoor PBA)

2. Troubleshooting procedure

Isthe connected of reactor wire?

(PBA-Reactor)

Isthe DC_link sensing voltage(R104

or R004) is normal in operation

mode?

Normal range (0.2Vdc~2.8Vdc)

YES

Exchange the Outdoor PBA

NO

Is the DC_link voltage (CE101 or

CE001) is normal in operation

mode?

Normal range(280Vdc~320Vdc)

Check the input power

NO

YES

YES

Connectthe reactor wire

NO

Restart after power off.

Isthe the input voltage is nomal?

Normal range(180Vac ~ 270Vac)

Restart after power off.

Start the operation (cooling mode or heating mode)

Check the input power in the powercord.

NO

YES

Exchangethe Reactor

Is the reactor insulation damaged?

NO

Exchange the Outdoor PBA

YES

12-18

12-2-17.I_trip error, PFC over current

Indoor display Outdoor error

Outdoor display I_trip error, PFC over current

1.Checklist :

1) Is the PFC Shunt(ASV18P**:R062,R063,ASV24P**:R807,R808,R809) resistance value correct? Check the resistor is opened

2) Is the condition of surrounding temperature abnormal overload?

3) Is there any problem as like the temperature sensor separation or measurement value error?

4) Is the interphase resistance of compressor normal?

2. Troubleshooting procedure

Is the condition of indoor/outdoor

temperature normal load?

Restart after returning to the normal load

YES

YES

Is the connection cable for the

compressor and power terminal

normal?

YES

Correctthe cable connection

Is the I_trip error

occurred again?

NO

NO

Exchangethe Outdoor PBA

Is the position of temperature

sensor and the sensing value

normal?

Correct the sensor position or exchange

the sensor

NO

YES

Restart after power off.

Terminatethe

service

NO

12-19

12-2-18.Current sensor error/Input current sensor error

Indoor display Outdoor error

Outdoor display

Current sensor error/Input current

sensor error

1.Checklist :

1) Is the PFC Shunt(ASV18P**:R062,R063,ASV24P**:R807,R808,R809) resistance value correct? Check the resistor is opened

2) Is the IPM Shunt(ASV18P**:R451,R452,R453,ASV24P**:R413,R414,R415) resistance value correct? Check the resistor is opened

3) Is there no short or open around IC451(ASV18P**) or IC451,IC452(ASV24P**)?

2. Troubleshooting procedure

Is the PFC shunt and IPM shunt

resistance value correct?

Exchangethe Outdoor PBA

Is the current sensor error

appeared again?

YES

Terminate the service

NO

NO

Exchangethe Outdoor PBA

Restart after power off.

YES

12-20

12-2-19.Heatsink sensor error/Heatsink over heat

Indoor display Outdoor error

Outdoor display Heatsink sensor error

Heatsink over heat error

1.Checklist :

1) Are there screws assembly in PBA-heatsink?

2) Is the gap PBA-heatsink

3) Is the fan operation normal?

4) Is the cover assembly in conrol-box normal?

2. Troubleshooting procedure

Are there screws in PBA -heatsink?

(4 screws)

Fasteningthe screw

Is the fan operation normal?

YES

Check the fan connection

Change the Fan motor

NO

NO

Exchangethe Outdoor PBA

Restart after power off.

YES

12-21

12-2-20.Comp Vlimit error/Comp current limit error

Indoor display Outdoor error

Outdoor display

Comp Vlimit error/Comp current limit

error

1.Checklist :

1) Is the IPM Shunt(ASV18P**:R451,R452,R453,ASV24P**:R413,R414,R415) resistance value correct? Check the resistor is opened

2) Is the condition of surrounding temperature abnormal overload?

3) Is there any problem as like the temperature sensor separation or measurement value error?

4) Is the interphase resistance of compressor normal?

2. Troubleshooting procedure

Is the O.C error occurred? Terminatethe service

NO

YES

Isthe connection of compressor

wire is normal?

YES

Is the compressor body and

interphase resistance insulated?

NO

Exchange the Outdoor PBA

Connectthe comp wire normally

YES

NO

Exchangethe compressor

Is the O.C error occurred again? Terminate the service

NO

YES

Restart after power off.

Is the condition of indoor/outdoor

temperature normal load?

Restart after returning to the normal load

YES

NO

Is the O.C error

occurred again?

Terminatethe

service

YES

NO

Is the position of temperature

sensor and sensing value normal?

Correct the sensor position or exchange the sensor

YES

NO

12-22

12-2-21.EEPROM error/OTP error

Indoor display Outdoor error

Outdoor display EEPROM error

OTP error

1.Checklist :

1) Is there a short around micom?

2) Is there a short around IC202(ASV18P**) or IC701(ASV24P**)?

3) Did you download or insert EEPROM IC, after changing outdoor PBA?

2. Troubleshooting procedure

Restart after power off

Is the error appeared again?

YES

Terminate the service

NO

Exchangethe Outdoor PBA

power off and download EEPROM data

(or. Insert the service EEPROM IC)

12-23

12-2-22.AC zero cross signal error

Indoor display Outdoor error

Outdoor display AC zero cross signal error

1.Checklist :

1) Check the power condition at customer's house (Is there any power noise?)

2) Have been there power failure?

2. Troubleshooting procedure

Is the AC line zero cross signal error

appeared again?

YES

Terminate the service

NO

Exchangethe Outdoor PBA

Restart after power off

12-23

12-2-23.Operation condition secession error

Indoor display Outdoor error

Outdoor display AC zero cross signal error

1.Checklist :

1) Check the temperature around the outdoor unit.

2. Troubleshooting procedure

Is the operation condition secession

error appeared again?

YES

Terminate the service

NO

Restart after power off

The temperature condition is too poor to operate.

Wait until temperature is changed

* Cooling mode *

Is the outdoor temperature under -

-7

* Heating mode *

Is the outdoor temperature over

40or under -30?

YES

12-23

12-2-24.Capacity miss match error

Indoor display Outdoor error

Outdoor display Capacity miss match error

1.Checklist :

1) Check the Btu between indoor and outdoor unit

2) Check the indoor unit option and outdoor unit EEPROM data

2. Troubleshooting procedure

Is the capacity miss match error

appearedagain?

YES

Terminate the service

NO

Exchangethe Outdoor PBA

Exchange the Indoor PBA

YES

Isthe rated Btu between indoor

unit and outdoor unit?

Reset the option code again at indoor unit

Exchange the one of them according to the exact

model spec

NO

Is the capacity miss match error

appearedagain?

Download the EEPROM data

Terminate the service

NO

YES

12-23

12-2-25.Gas leak error

Indoor display Outdoor error

Outdoor display Gas leak error

1.Checklist :

1) Is the position of indoor Eva_in sensor normal?

2) Check the pipe crack

3) Check the EEV valve connection in Outdoor unit

4) Check the refrigerant was charged

2. Troubleshooting procedure

Is the gas leak error appeared

again?

YES

Terminate the service.

NO

YES

Isthe position of indoor eva_in

sensor normal?

Restart after power off

Indoor sensor take the normal position

NO

Is the EEV valve connection

normal?

Checkthe EEV valve operation.

Connect the EEV valve.

NO

YES

after 20minutes later

Is the EEV valve is operation?

Check the sound of EEV valve after

power on.

Change the EEV valve.

NO

Is the pressure of refrigerant

normal?

Check the pipe crack.

Fill up the refrigerant.

YES

NO

YES

Exchange the Indoor PBA

Exchange the Outdoor PBA

12-23

12-2-26.No power indoor (Initial Diagnosis) (Not displayed)

1.Checklist :

1) Is input power normal?

2) Is AC power linked correctly?

3) Is input voltage of DC_link capacitor normal?

4) Is the voltage of DC regulator normal?

2. Troubleshooting procedure

Isthe power cable from outdoor is

correct? (L, N -CN71)

YES

Reconnect the power cord correctly.

NO

YES

Press the power button on the

display board

The remote control signal reciever on the display

PBA is wrong

Check the display board

NO

YES

Is the DC_link voltage normal?

C102(+)-C101(-) :270Vdc~320Vdc

Exchange the PBA

NO

Is the SMPS is normal?

IC102 : 12Vdc -GND -5Vdc

Exchange the PBA

YES

NO

YES

Exchange the PBA

Check the fuse open or not?

(F701,F702)

Exchange the PBA

NO

Isthe power normal?

Restart after power off.

Check the power source.

Unplug the power cord

12-26

12-3-1 Pre-inspection Notices

1. Check if you pulled out the AC power plug when you eliminate the PCB or front panel

2. Don't hold the PCB side not impose excessive force on it to eliminate the PCB

3. Dont pull the lead wire but hold the whole housing to connect or disconnect a connector to the PCB

4. In case of outdoor PCB disassembly, check first the complete discharge of condenser after 1 minute power off

12-3-2 Inspection procedure

1. Check connector connection and peeling of PCB or bronze coating pattern when you think the PCB is broken

2. The PCB is composed of 3 parts

Indoor Main part : MICOM and surrounding circuit, relay, fan motor sensing and driving circuit, temperature sensing circuit

power circuit of SMPS, buzzer circuit. Communication circuit

Display part : LED lamp, Switch, Remote-control module

Outdoor Main part : MICOM and surround circuit, fan motor sensing and driving circuit, compressor driving circuit

power circuit of SMPS, PFC control circuit, 4way circuit, communication circuit,

OPTION (EEV control circuit, temperature sensing circuit)

12-3-3 Indoor detailed inspection procedure

No procedure Inspection Method Cause

1

Plug out and pull the

PCB out of the control

box

Check the PCB fuse

1) Is 1st fuse disconnected?

2) Is 2nd fuse disconnected?

. Over current

. Indoor Fan motor short

. AC part and pattern short of Indoor PBA

Check the power voltage

1) Is the BD71 input voltage

200Vac~240Vac?

. Power cord is fault, Fuse open, Wrong Power

cable Wiring, AC part is faulty

2) Is the voltage between both

terminal of IC02 pin #1-#2 12Vdc?

. Switching Trans of Power circuit is faulty

3) Is the voltage between both

terminal of IC02 pin #2-#3 5Vdc?

. Power circuit is faulty, Load short

1) Is the voltage over AC 180V being

imposed on terminal #3-#5 of fan motor

connector (CN72)?

. Fan motor of the indoor is faulty

2) The fan motor of the indoor unit

doesn't run

. Fan motor connector(CN72) is faulty

3) The power voltage between terminal

#3-#5 of the connector(CN72) is 0V

. PBA is faulty

Supply power

If the operating lamp

twinkles at this time ,

the above 1)~3) have no

relation

2

3

Press the ON/OFF button

1. Fan speed(high)

2. Continuous Operation

You might also like

- Troubleshooting: 12-1 Items To Be Checked FirstDocument22 pagesTroubleshooting: 12-1 Items To Be Checked FirstZoran19731No ratings yet

- Aprilaire Dehumidifier Troubleshooting Manual Models 1710A 1750A 1770ADocument17 pagesAprilaire Dehumidifier Troubleshooting Manual Models 1710A 1750A 1770AReynaldo FloresNo ratings yet

- Service Manual 6000 SeriesDocument13 pagesService Manual 6000 SeriesKarna PatelNo ratings yet

- 15 - PCC 1302 Troubleshooting TablesDocument15 pages15 - PCC 1302 Troubleshooting TablesAnbuNo ratings yet

- Aprilaire Dehumidifier Troubleshooting Manual Models 1710A 1750A 1770ADocument17 pagesAprilaire Dehumidifier Troubleshooting Manual Models 1710A 1750A 1770AReynaldo FloresNo ratings yet

- Bryant furnace diagnostic codes guideDocument2 pagesBryant furnace diagnostic codes guideJoseph BosterNo ratings yet

- LG Fault Codes For SMS (07 Sept)Document4 pagesLG Fault Codes For SMS (07 Sept)ricardosplitcenter100% (2)

- Testing of Transmitter & SwitchesDocument4 pagesTesting of Transmitter & SwitchesJoost1982No ratings yet

- Payne Furnace Error CodesDocument4 pagesPayne Furnace Error CodesddamitNo ratings yet

- Error Code For BeeDocument4 pagesError Code For BeeMiguel Ruiz TatajeNo ratings yet

- KMHM 20-30-40 Multi Inverter OutdoorDocument15 pagesKMHM 20-30-40 Multi Inverter OutdoorMeselao Meselao MeselaoNo ratings yet

- BMW Motronic Fault CodesDocument4 pagesBMW Motronic Fault CodesChris Palmer100% (1)

- IbisTechManual1Document42 pagesIbisTechManual1sasabarnicNo ratings yet

- Power Supply Testing On Danfos bd35 50 SystemsDocument2 pagesPower Supply Testing On Danfos bd35 50 SystemsMuhammad PandorNo ratings yet

- RHOSS, Tabela AlarmaDocument6 pagesRHOSS, Tabela AlarmaMuhidin KozicaNo ratings yet

- AQ12FANDocument9 pagesAQ12FANhdave32No ratings yet

- Daco Rwall Oven Diagnostic ManualDocument40 pagesDaco Rwall Oven Diagnostic ManualJaco Pretorius NelNo ratings yet

- Washer Tech Data Sheet: Troubleshoot The Problem by Using Charts On The Pages 3-5. Quick CheckDocument16 pagesWasher Tech Data Sheet: Troubleshoot The Problem by Using Charts On The Pages 3-5. Quick CheckPedro ArceNo ratings yet

- Manual Ec2002mDocument4 pagesManual Ec2002mReinaldo Trindade ProençaNo ratings yet

- Duo Therm TroubleshooterDocument9 pagesDuo Therm TroubleshooterDale LewisNo ratings yet

- 2008 Mariner 2Document11 pages2008 Mariner 2Primer Almacenamiento DriveNo ratings yet

- Frigidaire Affinity Washer Codes Model# AFT6000FS1Document16 pagesFrigidaire Affinity Washer Codes Model# AFT6000FS1brendaestesNo ratings yet

- Panasonic TroubleshootingDocument89 pagesPanasonic Troubleshootingjmarrero_3No ratings yet

- Panasonic AC Troubleshooting GuideDocument5 pagesPanasonic AC Troubleshooting GuideDidi Nurtadi LibraNo ratings yet

- Dometic RM 2612 RV Ref Ridge Rat orDocument20 pagesDometic RM 2612 RV Ref Ridge Rat orgoldminer4No ratings yet

- Haier Air Conditioner DC Invert Product Abnormity SolutionDocument19 pagesHaier Air Conditioner DC Invert Product Abnormity SolutionglobalelektroNo ratings yet

- C2 - Testing The Dulas SDD ControllerDocument7 pagesC2 - Testing The Dulas SDD ControllerDulasNo ratings yet

- LD-B10-10 Temperature Controller User GuideDocument22 pagesLD-B10-10 Temperature Controller User GuideFareh KhanNo ratings yet

- At13 Samsung Laundry Wf317 Fast Track r22012 02 07Document7 pagesAt13 Samsung Laundry Wf317 Fast Track r22012 02 07bigfatbob44100% (1)

- Fault Code 154 Intake Manifold Air Pressure/Temperature Sensor Circuit - Voltage Below Normal or Shorted To Low SourceDocument12 pagesFault Code 154 Intake Manifold Air Pressure/Temperature Sensor Circuit - Voltage Below Normal or Shorted To Low SourceAhmedmahNo ratings yet

- LG Air Conditioning Universal & Multi Split Fault Codes SheetDocument19 pagesLG Air Conditioning Universal & Multi Split Fault Codes Sheettonares100% (1)

- 3gts250 Workshop Manual-3Document109 pages3gts250 Workshop Manual-3Fernando MattinaNo ratings yet

- 7 TroubleshootingDocument10 pages7 Troubleshootingequus43No ratings yet

- P1660Document5 pagesP1660Frank DiblasiNo ratings yet

- 037 - Diagnostic Information and ProceduresDocument332 pages037 - Diagnostic Information and ProceduresGedas GvildysNo ratings yet

- Syl 2372Document8 pagesSyl 2372Ismael 8877No ratings yet

- Rectifier Control Card Test ProcedureDocument5 pagesRectifier Control Card Test Procedurekundan kunalNo ratings yet

- Caterpillar ADEM II 3176C 3406E C10 C12 Completo PDFDocument2 pagesCaterpillar ADEM II 3176C 3406E C10 C12 Completo PDFOmar Garcia Cazares100% (3)

- Dx1000 InstrDocument6 pagesDx1000 InstrcakebuildNo ratings yet

- Tech Sheet for Microwave Oven ServicingDocument8 pagesTech Sheet for Microwave Oven ServicingDouglas A. Joslyn Jr.No ratings yet

- LG Alarm CodeDocument6 pagesLG Alarm CodepaulusNo ratings yet

- LG Split AC Fault Code SheetDocument19 pagesLG Split AC Fault Code SheetGabriel Marian BechmanNo ratings yet

- Manual Version 3.4Document8 pagesManual Version 3.4pjvansandwykNo ratings yet

- Whirlpool SBS 2006 Collection Repair ManualDocument13 pagesWhirlpool SBS 2006 Collection Repair ManualNeil Pound100% (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Digital LED Thermometer with Microcontroller AVR ATtiny13From EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Rating: 5 out of 5 stars5/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Electrical and Electronic Principles: Volume 2From EverandElectrical and Electronic Principles: Volume 2Rating: 4 out of 5 stars4/5 (5)

- The First-Time Homeowner's Survival Guide: A Crash Course in Dealing with Repairs, Renovations, Property Tax Issues, and Other Potential DisastersFrom EverandThe First-Time Homeowner's Survival Guide: A Crash Course in Dealing with Repairs, Renovations, Property Tax Issues, and Other Potential DisastersRating: 2.5 out of 5 stars2.5/5 (3)

- AQV18&24VBE Service Manual PDFDocument100 pagesAQV18&24VBE Service Manual PDFstefanovigano8579No ratings yet

- TC 36 TransformerDocument2 pagesTC 36 Transformerstefanovigano8579No ratings yet

- ATmega 8515Document257 pagesATmega 8515stefanovigano8579No ratings yet

- Fender 400-PS SchematicDocument1 pageFender 400-PS Schematicshmuck9995No ratings yet

- Fender 400-PS SchematicDocument1 pageFender 400-PS Schematicshmuck9995No ratings yet

- SmaartLive5 UserManualDocument214 pagesSmaartLive5 UserManualapi-3781771No ratings yet

- LT150X1 151Document22 pagesLT150X1 151stefanovigano8579No ratings yet

- Microcontroller Selection Guide: Factors to ConsiderDocument3 pagesMicrocontroller Selection Guide: Factors to ConsiderVarun Raj NagaNo ratings yet

- Computer Applications in Economics - Unit - 1Document24 pagesComputer Applications in Economics - Unit - 1manimadhavanNo ratings yet

- MAQ20Document4 pagesMAQ20raajitaNo ratings yet

- W27C512 45Z PDFDocument20 pagesW27C512 45Z PDFAbdelkrim RamdaneNo ratings yet

- 9608G IP Deskphone-UC7509 PDFDocument2 pages9608G IP Deskphone-UC7509 PDFFelipe Ignacio Herrera EscobarNo ratings yet

- Keyestudio Smart Small Turtle RobotDocument41 pagesKeyestudio Smart Small Turtle RobotJose PradoNo ratings yet

- MTNL Systems: A Training Report TO Study THEDocument74 pagesMTNL Systems: A Training Report TO Study THEapi-20013961No ratings yet

- Logitech Z3Document16 pagesLogitech Z3bruatiNo ratings yet

- KUBE Electronics AG - Smart SwitchDocument2 pagesKUBE Electronics AG - Smart SwitchdewasuryantoNo ratings yet

- 02 Chipyard BasicsDocument38 pages02 Chipyard Basicsmuhammadakhtar201No ratings yet

- B8 RNE Fundamentals Ed01Document422 pagesB8 RNE Fundamentals Ed01govindjiraiNo ratings yet

- Daewoo SJ-210H DSJ-6000LHMDocument44 pagesDaewoo SJ-210H DSJ-6000LHMMarco Antonio100% (5)

- Electrical Engineer ProfileDocument3 pagesElectrical Engineer ProfileprakashNo ratings yet

- Ortea Orion Plus 3 PhaseDocument2 pagesOrtea Orion Plus 3 PhaseReymart ManablugNo ratings yet

- Siw AntennaDocument8 pagesSiw Antennasayantan100% (1)

- As 110023 Nu-Ep1 Um 952GB GB WW 2020-1Document236 pagesAs 110023 Nu-Ep1 Um 952GB GB WW 2020-1Adrian Barrios CruzNo ratings yet

- Iptv GuideDocument66 pagesIptv GuidemaafkoroNo ratings yet

- Acer Projector X128HDocument2 pagesAcer Projector X128HOmer MesihovićNo ratings yet

- CCNA ProjectDocument27 pagesCCNA ProjectSatnam Singh Mann100% (1)

- Design and Analysis of Yagi-Uda AntennaDocument5 pagesDesign and Analysis of Yagi-Uda AntennaLester Cerojales PadayaoNo ratings yet

- Timer/Counter/ Analyzer: Getting Started ManualDocument32 pagesTimer/Counter/ Analyzer: Getting Started Manualscorpion_l_81No ratings yet

- Manual 9401ADocument28 pagesManual 9401ASANTOS DALLACQUANo ratings yet

- JA M672 385 FichaTecnicaDocument2 pagesJA M672 385 FichaTecnicaEverardo Bracamontes DíazNo ratings yet

- Proceq GPR Live Cue CardsDocument31 pagesProceq GPR Live Cue CardsAlexandre PerrotNo ratings yet

- NH40 DatasheetDocument4 pagesNH40 DatasheetPatricio Rivera LaraNo ratings yet

- bg16df DatasheetDocument2 pagesbg16df DatasheetSamastha Nair SamajamNo ratings yet

- E1005 SpecDocument4 pagesE1005 SpecMakombe RonnyNo ratings yet

- Circuits 2 Lab ManualDocument106 pagesCircuits 2 Lab ManualBJ HaleNo ratings yet

- 10-17 SCR Into, CommutationDocument45 pages10-17 SCR Into, CommutationAdnan MagsiNo ratings yet

- PRBS Generator Using VHDL FinalDocument17 pagesPRBS Generator Using VHDL FinalAlpesh ThesiyaNo ratings yet