Professional Documents

Culture Documents

Disclosure To Promote The Right To Information

Uploaded by

Suban MukhopadhyayOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Disclosure To Promote The Right To Information

Uploaded by

Suban MukhopadhyayCopyright:

Available Formats

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

!"#$%&# '(%)

!"# $ %& #' (")* &" +#,-.

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

/0)"1 &2 324 #' 5 *)6

Jawaharlal Nehru

Step Out From the Old to the New

7"#1 &" 8+9&"), 7:1 &" 8+9&")

Mazdoor Kisan Shakti Sangathan

The Right to Information, The Right to Live

!"# %& ;<" =7"#" > 72 &(: ?0)"@" #AB 7" <&*" A*

Bhart+hariN,ti-atakam

Knowledge is such a treasure which cannot be stolen

IS 11494 (1986): Code for construction and maintenance of

surface farm drainage systems [FAD 17: Farm Irrigation and

Drainage Systems]

(Reaffirmed 2000)

IS : 11494 - 1986

I ndian Standard

CODE FOR

CONSTRUCTION AND MAINTENANCE OF

SURFACE FARM DRAINAGE SYSTEMS

Farm Drainage Sectional Committee, AFDC 47

Chairman

DR A. M. MICHAEL

Representing

Indian Agricultural Research Institute ( ICAR ),

New Delhi

Members

DR A. K. BHATTACRARYA ( Alternate to

Dr A. M. Michael )

DR M. C. AGARWAL

DR BHUPAL SIN~H

DR H. S. CHAUIIAN

Haryana Agricultural University, Hissar

Tocklai Experimental Station, Jorhat

G. B. Pant University of Agricultural and

DR SEWA RAX ( Afternate )

CHIEF ENQINEER

SUPERINTENDINQ ENGINEER

DIREC~o~IGNS ) ( Alternate )

Technology, Pantnagar

PWD Irrigation ( North ), Belgaum

Irrigation Research and Development, Pune

EXECUTIVP: ENGINEER ( Alternate )

DIRECTOR ( FCM ) Central Water Commission, New Delhi

SHRI V. S. HEQDE Hulaul Group Cooperative Society. Sirsi

SHRI N. G. JOSHI Indi& Hum6 Pipe-Co Ltd, Bombay

SHRI S. D. KHEPAR Punjab Agricultural University, Ludhiana

DR SITA RAM SINQH ( Alternate )

SRRI V. PATTABHI Hyderabad Industries Ltd, Hyderabad

SHRI A. K. GUPTA ( Alternate )

DR H. PURNAPRA~NACHA~ University of Agricultural Sciences, Bangalore

DR R. K. RAI Rajendra Agricultural University, Patna

DR T. K. SARKAR Damodar Valley Corporation, Calcutta

SHRI G. K. SRINIVASAN Wavin India Limited, Madras

SHI~I K. R. RANQARAJAN ( Alternate )

SHRI V. VASIJDEVAN Khadi and Village Industries Commission, Bombay

SHRI B. P. SRIVASTAVA ( Alternate )

SHRI T. PURNANANDAX, Director General, IS1 ( Ex-ojicio Member )

Director ( Agri & Food )

Secretary

SIZRI R. N. SRARIXA

Joint Director ( Agri & Food ), IS1

@ Copyright 1986

INDIAN STANDARDS INSTITUTION

This publication is protected under the Indian Copyright Act ( XIV of 1957 ) and

reproduction in whole or in part by any means-except with written permission of the

publisher shall be deemed to be an infringement of copyright under the said Act.

IS : 11494 - 1986

I ndian Standard

CODE FOR

CONSTRUCTION AN-D MAINTENANCE OF

SURFACE FARM DRAINAGE SYSTEMS

0. FOREWORD

0.1 This Indian Standard was adopted by the Indian Standards

Institution on 31 January 1986, after the draft finalized by the Farm

Drainage Sectional Committee bad been approved by the Agricultural

and Food Products Division Council.

0.2 Surface drainage is normally required for efficient crop production

on slowly permeable soils with restricted topography. It is not required

when excess water is removed naturally. The objectives of surface

drainage are:

a) To prevent water from ponding on land surface or in surface

drains that are crossed by farm equipment,

b) To remove excess water in time to prevent damage to crops, and

c) To accomplish the above without excess erosion.

0.3 Complete drainage systems shall be planned and designed after

considering a11 aspects. The collection system consisting of the land

surface and shallow drains removes excess surface water from individual

areas within fields. The disposal system consisting of some what larger

ditches receives drainage water from the collection system and removes

it from the farm. Transitions, including structures, that permit drains

to discharge into larger or deeper drains must provide for adequate

erosion control without holding water on field surfaces for excessive

periods of time. The system shall be designed as an integrated com-

ponent of the land and water management activity on the farm.

0.4 This standard is intended to serve as a guide for proper construction

and maintenance of surface drainage systems in the farms.

0.5 In preparation of this standard, assistance has been derived from

ASAE EP 302 : 2-1973 Design and construction of surface drainage

systems on farms in humid areas, published by the American Society of

Agricultural Engineers, USA.

2

IS: 11494=1986

0.6 For the purpose of deciding whether a particular requirement of this

standard is complied with, the final value, observed or calculated,

expressing the result of a test or analysis, shall be rounded off in

accordance with IS : 2-1960. The number of significant places retained

in the rounded off value should be the same as that of the specified

value in this standard.

1. SCOPE

1.1 This standard covers the recommended practice for construction and

maintenance of surface farm drainage systems.

2, TERMINOLOGY

2.1 For the purpose of this standard definitions given in IS : 11495-1986 7

shall apply.

3. DESIGN

3.1 Design of the surface drainage system shall be done in accordance

with IS : 11495-19867.

4. CONSTRUCTION

4.1 Good quality construction is essential for adequate drainage.

Qualified engineers should be responsible for surveys, designs, layouts

and checking to guarantee that construction meets specifications.

Land

owners and contractors shall be provided with complete information

necessary for construction.

4.1.1 Land smoothing will provide adequate drainage only if

depressions are eliminated by smoothing the laud surface. ROW drains,

field drains, and/ or laterals shall be installed in the remaining low areas.

4.1.2 Land grading is hampered by trash and vegetation which shall

be destroyed or removed prior to construction and kept under control

while the work is being done. Ploughing trash under the land surface

is not recommended.

4.1.2.1 Fields shall be scarified prior to construction if there are

hard pans. The field surface shall be firm when surveyed so that staff

readings taken at stakes will reflect the true elevations. Fields shall not

be graded when wet, because this impairs the physical condition of

the soil.

*Rules for rounding off numerical values ( mid ).

*Code for design of surface drainage system.

3

IS : 11494 - 1986

4.1.2.2 Grading shall be checked prior to and following the finishing

operations. A tolerance of 30 mm may be allowed in checking, provided

there are no reverse grades in row direction.

4.1.2.3 Land smoothers shall be passed over the field surface at

least three times as a finishing operation. The first two passes shall be

on opposite diagonals to the stake lines, and the last pass shall be in the

row ~direction.

4.1.2.4 Fields shall be scarified either before or after the final land

smoothing operations to loosen the cut surfaces and to blend the fill

material with the underlying soil.

4.1.3 The slope in the direction of drainage shall usually be 02 to

O-4 percent.

4.1.4 Field drains shall be constructed to facilitate quick disposal of

runoff water from the cultivated areas. These may be shallow and

crossable by farm equipment.

4.1.5 Field drains shall be located along the lowest edge of the field.

If the fields are long in the direction of drainage, there may be more

than one field drain.

4.1.6 Collector drains shall be constructed as per the hydraulic design

and with variation in cross section if required. Such variation may be

made at the point of road crossing where a permanent structure exists.

4.1.6.1 Runoff water from the field may be allowed to fall in the

collector if it is not feasible to have field drains.

However, such entry

points shall be planted and burried pipe outlets shall be provided from

the field into the collector.

4.1.6.2 In the event of constructing culverts at road and collector

junctions, the culvert capacity should be more than the maximum

designed discharge. This will ensure that the culvert will not act as a

bottleneck at any time during the drainage.

4.1.6.3 The productive soil dug out during the construction of

collector drain shall be uniformly spread over the cultivated areas if

possible. Otherwise, all the soil material dug out shall be used to

construct farm road after the drain and to make a protective levee along

the edge of the field adjacent to the drain. The loose soil shall be put at

least 50 cm away from the edge of the drain to avoid falling back of the

soil into the drain during monsoon.

5. CONSTRUCTION EQUIPMENT

5.1 Proper construction equipment and skilled operators are required

for good quality work.

4

IS : 11494 - 1986

5.1.1 Tractor and scraper combinations are used for excavating for

hauling excavated material to fill areas, and for spreading excavated

material. Tractors and scrapers are used for land grading, and to

construct and maintain field drains and diversions. Under favourable

conditions, they are used to construct~and maintain field laterals with

flat side slopes. Wheel type tractors have been used with scrapers for

levelling when lead length is over 50 m. Self-loading ( carry all )

scrapers operated by tractors are used for short lead length when earth

movement is heavy. Animal drawn scrapers are suitable for levelling

small holding.

5.1.2 Land smoothers, commonly known as land leviers or land planes

operated by tractors are used for land smoothening or to finish land

grading. They will automatically fill small low areas and remove small

high areas when traversing a field. They cannot accomplish the major

grading operations done by tractors and scrapers. Land smoothers are

used periodically to maintain the surface of land that has previously

been graded or smoothened. Animal drawn wooden Rat are suitable

for land smoothening in small scale operations.

5.1.3 Motor graders and animal and tractor drawn V ditchers are

used to excavate re!atively small channels, such as field drains or field

laterals, where the excavated material can be spread or shaped along

one or both sides of the channels.

5.1.4 Draglines and beckhoes are used to construct and maintain large

size drainage channels.

6. EROSION CONTROL

6.1 Erosion of deep productive soils in fields that require surface drainage

may be of little direct economic importance. On shallow soils, erosion

may over a period of time result in irreparable losses in productivity.

Sedimentation that results from erosion obstructs nearby channels. The

justifiable intensity of erosion control measures on field surfaces is, there-

fore, dependent on the depths of productive soils and the relative costs

of preventing erosion and maintaining channels.

6.1.1 Erosion control on land surfaces is norma!ly required only where

land grades exceed 10 percent or where there are reverse row grades.

By concentratimg water and causing it to overflow row beds, reverse row

grades are a major contributing cause of erosion across rows. Graded

rows, precisely constructed so that there are no reverse row grades and

that each row carries its own water, are an effective erosion control

practice.

6.1.2 Field drain side slopes and the row middles immediately above

the field drains are subject to riil erosion with resultant sedimentation in

5

IS : 11494 - 1986

the field drains. To control this erosion, portions of field drains that

are 0.15 m below field level or below row middles shall be vegetated

except vegetation is not necessary for field drains re-established yearly.

6.1.3 Field drains witch grades of about O-3 percent and steeper shall

be vegetated to prevent channel erosion. The initial erosive grades

vary somewhat with~soils.

6.1.4 Field laterals are subject to serious erosion in some areas where

they are located on erodible soils and steeper grades. There laterals

should be vegetated. Where there is a doubt, the maximum permissible

grade for unvegetated channels should be checked. Permissible grades

are dependent on the scour conditions which are likely to occur in the

channels.

6.1.5 Sedimentation in field laterals is usually expected. In areas

where sedimentation is anticipated, field laterals should be overcut 0.1 m

or more to provide for sedimentation.

6.1.6 Inlets to field laterals for surface water shall be constructed only

at planned points. -Continuous low levees, spread spoil or spoil banks

shall prevent entry except at planned inlets.

6.1.7 The outlets of field drains and field laterals shall be checked for

erosiveness. In some cases the depths of channels can be controlled by

design to reduce or eliminate erosion. In other cases the water level in the

larger channels may reduce velocities sufficiently to effectively control

erosion. Where additional erosion control measures are indicated, graded

channel transitions shall be considered. Such transitions may be grass

waterways or non-vegetated channels, depending on the erosion potential.

When graded transitions are not adequate for erosion control, pipe drops,

chutes, drop structures or other suitable erosion control structures

shall be used.

6.1.8 Pipe drops are relatively inexpensive, usually have long lives,

and provide crossings for field roads. Pipe drops shall have design

capacities of 1.25 to 1.5 times the rate of flow indicated on the drainage

curves. Small diameter pipe drops are subject to blockage by debrish.

Hydraulic radius of the pipe line of the range 0.25 to O-4 percent

depending upon the size and overfall at the drain junction O-15 to 0.3

below design grades shall be provided.

6.1.9 AI1 uncultivated field laterals, side slopes and spoil banks shall be

vegetated as soon as practical after cunstruction. Vegetative plants shall

be selected for their erosion resistance, wildlife habitat and beautification

values.

6

IS% 11494 - 1986

7. MAINTENANCE

7.1 Timely maintenance is essential for continued adequate performance

of a drainage system. Maintenance operations shall be planned when

the system is designed. Inspection of the entire drainage system should

be made following heavy rainfall, and at least once each year. Tillage

operations should retain the shape of field surfaces as initially constructed.

The two-way plough is desirable for primary tillage because dead

furrows and back furrows can be eliminated or located to meet the needs

of the drainage system. Where the one-way plough is used, dead

furrows and back furrows shall be kept to a minimum, and shall be

located so they will not restrict water flow. Unless dead and back

furrows are parts of the drainage systems as in bedding, their locations

shall be alternated annually.

7.1.1 Field drains may require cleaning following tillage operations.

When the field drains are not cultivated, weed growth shall be kept

under control by mowing, spraying, or burning.

7.1.2 Field laterals require periodic maintenance. Suitable chemical

weed and bush sprays are effective in controlling cattails, williows, and

other undesirable vegetation. Mowing is effective where side slopes are

not steeper than 3 : 1. Controlled grazing of livestock is a good method.

Laterals require clean out where excess deposition has occurred.

7.1.3 Land grading maintenance is critical during the first year or

two after construction. Settlement of the fill areas may make serveral

annua1 land smoothing operations necessary. In some cases, particularly

where deep fills have been made, it may be necessary to ut

d

and fill

again with tractors and scrapers to eliminate depressions an reverse row

grades. It is recommended that the land planning operation be substi-

tuted for one of the secondary tillage operations. The final land main-

tenance operations shall be in the direction of the crop rows.

7.1.4 Transitions shall be checked frequently for restriction of drainage.

Removal of deposition downstream from the transition may be the only

maintenance required.

7.1.5 Pipe drops shall be checked and maintained to see that the flow

is not restricted, that overtopping of the fills is not causing excessive

erosion and that piping is not occurring along the conduits.

7

INTERNATIONAL SYSTEM OF UNITS ( SI UNITS)

Base Units

QUANTITY

Length

Mass

Time

Electric current

Thermodynamic

temperature

Luminous intensity

Amount of substance

Supplementary Units

QUAXTITY

Plane angle

Solid angle

Derived Units

QUANTITY

Force

Energy

Power

Flux

Flux density

Frequency

Electric conductance

Electromotive force

Pressure, stress

UNIT

metre

kilogram

second

ampere

kelvin

candela

mole

UNIT

radian

steradian

UNIT

newton

joule

watt

weber

tesla

hertz

siemens

volt

pasta 1

SYMBOL

m

kg

S

A

K

cd

mol

SYMBOL

rad

sr

SYaaROL

N

J

W

Wb

T

Hz

s

V

Pa

DEFINITION

1 N = 1 kg.m/ss

1 J = 1 N.m

1 W = 1 J/s

1 Wb = 1 V.s

1 T = 1 Wb/m*

1 Hz = 1 c/s (s-l)

1 S = 1 A/V

1 V = 1 W/A

1 Pa w 1 N/m*

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Fidge Louis Primary Foundation Skills Reading Comprehension 2 PDFDocument48 pagesFidge Louis Primary Foundation Skills Reading Comprehension 2 PDFAnonymous LELyuBo100% (1)

- Food Always in The Home - Training ManualDocument18 pagesFood Always in The Home - Training ManualAte MytNo ratings yet

- How Peanut Butter is Made in 40 StepsDocument8 pagesHow Peanut Butter is Made in 40 Stepsnickelas11No ratings yet

- Shear Strength TheoryDocument32 pagesShear Strength TheoryChikkanna TNo ratings yet

- Handbook On Agricultural Cost of Production Statistics PreEGM2015Document124 pagesHandbook On Agricultural Cost of Production Statistics PreEGM2015hodatabaNo ratings yet

- Deforestation Success Stories, 2014Document64 pagesDeforestation Success Stories, 2014Rainforest Connection0% (1)

- Technical DrawingDocument58 pagesTechnical Drawingamacarras95% (21)

- Horse Voc For AdultsDocument11 pagesHorse Voc For Adultssilcab67No ratings yet

- Selection of Site Edited Long A4Document4 pagesSelection of Site Edited Long A4JaideHizoleSapulNo ratings yet

- RDE Digest Vol.11 No.1Document21 pagesRDE Digest Vol.11 No.1UPLB Office of the Vice Chancellor for Research and Extension100% (2)

- CLMD4A HorticultureG9 10Document25 pagesCLMD4A HorticultureG9 10Dianne Abante100% (2)

- Condition DischargeDocument23 pagesCondition DischargeSuban MukhopadhyayNo ratings yet

- Harmony BrochureDocument2 pagesHarmony BrochureSuban MukhopadhyayNo ratings yet

- Odesk Contractor Manual 2013Document22 pagesOdesk Contractor Manual 2013Suban MukhopadhyayNo ratings yet

- Test Insertplate RGDocument2 pagesTest Insertplate RGnsureshbabuNo ratings yet

- 4923 1997Document14 pages4923 1997Jessica DickersonNo ratings yet

- C - Test 5.6.14 PDFDocument5 pagesC - Test 5.6.14 PDFSuban MukhopadhyayNo ratings yet

- Lattice GirderDocument85 pagesLattice GirderSuban MukhopadhyayNo ratings yet

- SS304 304L Data SheetDocument2 pagesSS304 304L Data SheetPrakash KumarNo ratings yet

- End Semester Question Paper With Model SolutionDocument16 pagesEnd Semester Question Paper With Model SolutionSwapnil RahaneNo ratings yet

- Dow Corning SealantDocument2 pagesDow Corning SealantSuban MukhopadhyayNo ratings yet

- DikhonditoDocument394 pagesDikhonditoSuhan ChowdhuryNo ratings yet

- BCi Unitized Advantage1Document11 pagesBCi Unitized Advantage1Suban MukhopadhyayNo ratings yet

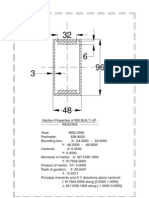

- MS Built UpDocument1 pageMS Built UpSuban MukhopadhyayNo ratings yet

- Gate2014 Brochure PDFDocument81 pagesGate2014 Brochure PDFsurabhidivyaNo ratings yet

- Design & Fabrication of A Motorized Maize Shelling Machine: Conference PaperDocument9 pagesDesign & Fabrication of A Motorized Maize Shelling Machine: Conference PaperGodwin UmoffiaNo ratings yet

- Herb Is The Healing of A Nation, Alcohol Is Destruction - Bob MarleyDocument13 pagesHerb Is The Healing of A Nation, Alcohol Is Destruction - Bob MarleyShameer Fuqaha100% (1)

- 6.4 A Short Monsoon DiaryDocument7 pages6.4 A Short Monsoon DiarySaahil LedwaniNo ratings yet

- Dte June 1 15, 2021 SmallDocument92 pagesDte June 1 15, 2021 SmallChinmai HemaniNo ratings yet

- Fire as a vegetation management tool in rangelandsDocument14 pagesFire as a vegetation management tool in rangelandsAngela AlegnaNo ratings yet

- List of University Open Elective Courses-2022Document2 pagesList of University Open Elective Courses-2022Lucky RajNo ratings yet

- Plant Growth RegulatorsDocument5 pagesPlant Growth RegulatorsNishamolKSNo ratings yet

- Amul FinalDocument8 pagesAmul FinalkhushitmehtaNo ratings yet

- (Studyplan) Combined Defense Services CDS - Booklist, Strategy, Free Study Material, Previous Papers, Cutoffs, Physical Medical - Mrunal PDFDocument24 pages(Studyplan) Combined Defense Services CDS - Booklist, Strategy, Free Study Material, Previous Papers, Cutoffs, Physical Medical - Mrunal PDFAnurag VermaNo ratings yet

- Political Geography: Paul Robbins TDocument6 pagesPolitical Geography: Paul Robbins TIsabela FreitasNo ratings yet

- Swine Artificial Insemination For Beginners - The Insemination ProDocument3 pagesSwine Artificial Insemination For Beginners - The Insemination ProGman00No ratings yet

- Design Automatic Irrigation SystemDocument8 pagesDesign Automatic Irrigation Systempradeepyadav11100% (1)

- Can You Identify The Parts of A Full Size Corn Plant?Document9 pagesCan You Identify The Parts of A Full Size Corn Plant?Mohamad Fitri Mustafa100% (1)

- Effect of Various Levels of Fertilizers On Growth and Yield of Finger MilletDocument4 pagesEffect of Various Levels of Fertilizers On Growth and Yield of Finger MilletIOSRjournalNo ratings yet

- Lesson of The KaibabDocument2 pagesLesson of The Kaibabapi-294565326No ratings yet

- Report on School Garden ProgramDocument5 pagesReport on School Garden ProgramKennedy EscanlarNo ratings yet

- Challenges and Opportunities For Water in Development in The Lowlands of EthiopiaDocument24 pagesChallenges and Opportunities For Water in Development in The Lowlands of EthiopiaAbdusalam IdirisNo ratings yet

- Effect of Age and Cut On The Colour of Turkey, Japanese Quail andDocument3 pagesEffect of Age and Cut On The Colour of Turkey, Japanese Quail andJournal of Environment and Bio-SciencesNo ratings yet

- Value Chain Analysis of Large Cardamom in Taplejung District of NepalDocument19 pagesValue Chain Analysis of Large Cardamom in Taplejung District of NepalIEREKPRESSNo ratings yet

- Abstract Substructure Conc - Frame Westgate RealDocument4 pagesAbstract Substructure Conc - Frame Westgate RealTashamiswa MajachaniNo ratings yet