Professional Documents

Culture Documents

65 45 12 - Spec

Uploaded by

pichirOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

65 45 12 - Spec

Uploaded by

pichirCopyright:

Available Formats

65-45-12 Ductile Iron

Color

Code

Iron Family: Ductile Iron

65-45-12 Ductile Iron contains nodular graphite in a matrix of ferrite with small

amounts of pearlite. The ferritic structure gives excellent machinability with good

surface finishes along with optimal impact strengths, fatigue properties, electrical

conductivity and high magnetic permeability. This iron has approximately the

same tensile and yield strengths as AISI 1020 Steel in the as-rolled condition. This

specification conforms to ASTM A536 grade 65-45-12. The microstructure consists

of Types I & II nodular graphite as defined in ASTM A247. The matrix is ferrite with

approximately 5-25% pearlite. The rim will have a higher nodular count and will be

mostly ferrite. Chill carbides will be less than 5% in any field at 100x and will be well

dispersed.

Available from stock

at Morgan Bronze in:

Equivalent Specifications

ASTM A536

Rounds

65-45-12 Ductile Iron

Equivalent specifications are verified and updated annually.

Specifications shown are current as of May 4, 2010.

Chemical Composition (%)*

Carbon

Silicon

Manganese

Sulfur

Phosphorus

3.50 3.90

2.25 3.00

0.15 0.35

0.025 MAX

0.05 MAX

Mechanical Properties**

English

Metric

Tensile Strength, min.

65,000

448

Yield Strength, min.

45,000

310

12%

12%

Elongation in 2 in. or 50 mm, min.

Hardness Properties*

Size Range

Inches

BHN

Millimeters

MIN

MAX

1.000 - 2.000

25 - 51

156

217

2.001 - 3.000

51 - 76

153

207

3.001 - 6.000

76 - 152

143

207

6.001 - 20.000

152 - 508

131

207

* Values shown are reference. It is the intent of ASTM A536 to subordinate chemical composition to mechanical properties.

** Values shown pertain to ASTM A536.

Phone: 847-526-6000

Toll Free: 800-445-9970

Fax: 847-526-3960

Email: info@morganbronze.com

Rectangles

65-45-12 Ductile Iron

Color

Code

Iron Family: Ductile Iron

(continued)

Heat Treat Response

65-45-12 Ductile Iron can be oil quench hardened from 1600 F (885 C) to

Rockwell C 50 minimum on the outside of the bar. Hardness in the core will be

less than the hardness on the outside surfaces. This grade also responds well

to surface hardening methods such as flame or induction heat treating. It is well

suited for austempering because of the low residual alloy content, and the highly

ferritic matrix provides predictable growth with minimal heat distortion.

Typical Applications

Automotive:

Gears

Fluid Power:

Cylinder blocks, End Caps, Gear Rack Housings, Gerotors,

Glands, Manifolds, Pistons, Rotors, Valves

Glass Mold:

Bank Molds, Plungers

Machinery:

Bushings, Chuck Bodies, Die Blocks, Flywheels, Gears,

Housings, Journals, Pulleys, Rams, Rotary Tables, Side

Frames, Spindle Housings, Tie Rod Nuts

Miscellaneous:

Plunger Pin

Power Transmission:

Coupling Hubs, Gears, Pulleys, Sprockets

Pump & Compressor:

Gears, Housings, Pistons, Rotary Screws, Rotors

Transportation:

Coupling Hubs, Gears, Pulleys, Rail Spacers, Sprockets

www.morganbronze.com

You might also like

- Iso 1083 2018Document13 pagesIso 1083 2018Kerem ErtemNo ratings yet

- Lamellar Graphite Cast Irons FGL 175HB - FGL 215HB - FGL 240HB Technical SpecificationsDocument4 pagesLamellar Graphite Cast Irons FGL 175HB - FGL 215HB - FGL 240HB Technical Specificationsyusuf tolga öksüz100% (1)

- Sweeney 503 Assembly Paste Now in IndiaDocument1 pageSweeney 503 Assembly Paste Now in IndiaProject Sales CorpNo ratings yet

- HR - Meehanite MetalDocument3 pagesHR - Meehanite MetalzamporpsNo ratings yet

- Welding Metallurgy of Stainless Steels During Resistance Spot Welding Part I - Fusion Zone PDFDocument11 pagesWelding Metallurgy of Stainless Steels During Resistance Spot Welding Part I - Fusion Zone PDFKhalid HafezNo ratings yet

- ARC Welding PowARC Welding Power Sources - Pdfer SourcesDocument42 pagesARC Welding PowARC Welding Power Sources - Pdfer SourcesDanielNo ratings yet

- Astm A204 A204m PDFDocument3 pagesAstm A204 A204m PDFKaterynaNo ratings yet

- Super Duplex Stainless Steel: Excellent Engineering SolutionsDocument4 pagesSuper Duplex Stainless Steel: Excellent Engineering SolutionsTXUSNo ratings yet

- 516 Vs 515Document2 pages516 Vs 515Madan YadavNo ratings yet

- Asme Sa 106 Grade A PipesDocument1 pageAsme Sa 106 Grade A PipesFerroPipENo ratings yet

- Presentation: Coefficient of Friction On Threaded Fasteners in The Automotive IndustryDocument20 pagesPresentation: Coefficient of Friction On Threaded Fasteners in The Automotive IndustryAvinashRaiNo ratings yet

- Fluorolined PVDF Series III Horizontal Pump 558434Document14 pagesFluorolined PVDF Series III Horizontal Pump 558434khaled younis100% (1)

- Suggested Modifications To ASTM E477Document14 pagesSuggested Modifications To ASTM E477Jerry LillyNo ratings yet

- SULZER CastMaterials - E00510Document5 pagesSULZER CastMaterials - E00510nhirpara1No ratings yet

- Pc280174 System ADocument50 pagesPc280174 System AMírian Ribeiro100% (1)

- Norma FIAT 52631 - Tubo Acero SoldadoDocument13 pagesNorma FIAT 52631 - Tubo Acero SoldadoZAPSE100% (2)

- Uddeholm Pocket Book PDFDocument80 pagesUddeholm Pocket Book PDFPeter NomikosNo ratings yet

- KE Masterflex RubberDocument4 pagesKE Masterflex RubberBenjamin StricklandNo ratings yet

- Astm A 27 PDFDocument4 pagesAstm A 27 PDFRyan LasacaNo ratings yet

- WELDING CONSUMABLES-Hardfacing PDFDocument18 pagesWELDING CONSUMABLES-Hardfacing PDFmanuel_plfNo ratings yet

- Bray ValvesDocument6 pagesBray ValvesiksajidscribdNo ratings yet

- Boil Out ProceduresDocument11 pagesBoil Out ProceduresJorge DiazNo ratings yet

- TOP WELDING ELECTRODES AND FILLER METALS FOR STAINLESS STEELSDocument5 pagesTOP WELDING ELECTRODES AND FILLER METALS FOR STAINLESS STEELSGil OjedaNo ratings yet

- UHMW-PE (Ultra High Molecular Weight - Polyethylene)Document2 pagesUHMW-PE (Ultra High Molecular Weight - Polyethylene)Gaurav PatilNo ratings yet

- Non-Standardized Prototype Tests of Flexible PipesDocument60 pagesNon-Standardized Prototype Tests of Flexible PipesAcacio VieiraNo ratings yet

- Asme B16.22Document26 pagesAsme B16.22JamesNo ratings yet

- 1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFDocument2 pages1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFrabmusukeNo ratings yet

- Corewire Weldclad 01 PDFDocument31 pagesCorewire Weldclad 01 PDFRaviTeja BhamidiNo ratings yet

- Material Comparison F316L Vs F321Document1 pageMaterial Comparison F316L Vs F321Vivi OktaviantiNo ratings yet

- 16899Document33 pages16899Edson BastoNo ratings yet

- ANSI B16.5 Flange Class 300 - Robert-James Sales, IncDocument2 pagesANSI B16.5 Flange Class 300 - Robert-James Sales, IncLuis SotoNo ratings yet

- Norma 1691 DIN 1691 1985 Flake Graphite Cast Iron Grey Cast Iron PropertiesDocument13 pagesNorma 1691 DIN 1691 1985 Flake Graphite Cast Iron Grey Cast Iron PropertiesJuan Rivera100% (1)

- Din 8555Document1 pageDin 8555Kara WhiteNo ratings yet

- 410 QDT Stainless Steel Bar - AISI 410 StandardDocument7 pages410 QDT Stainless Steel Bar - AISI 410 StandardchamaljsNo ratings yet

- Bray Valve Series 40-41 DimensionsDocument2 pagesBray Valve Series 40-41 DimensionsChandravadanNo ratings yet

- Commercial Pipe Thread Couplings SpecifiedDocument3 pagesCommercial Pipe Thread Couplings Specifiedcvz240159No ratings yet

- Danh Muc Tieu Chuan JIS 2007Document3 pagesDanh Muc Tieu Chuan JIS 2007Nguyeentt TntNo ratings yet

- Deva - BM ENDocument24 pagesDeva - BM ENOscar CruzNo ratings yet

- Caldeiras - Listas de NormasDocument14 pagesCaldeiras - Listas de Normasorea1No ratings yet

- Hydrogen Embrittlement - What It Looks Like PDFDocument2 pagesHydrogen Embrittlement - What It Looks Like PDFAdnan SheikhNo ratings yet

- AnyCasting Software Intro SAND PrintDocument45 pagesAnyCasting Software Intro SAND PrintChuah Chun KitNo ratings yet

- Europa 10TH Edition Catalogue PDFDocument530 pagesEuropa 10TH Edition Catalogue PDFnozzon7No ratings yet

- Difference Between Ac DC WeldingDocument2 pagesDifference Between Ac DC WeldingLokeshwari GopinathNo ratings yet

- Astm A694 F65Document1 pageAstm A694 F65Anonymous oVRvsdWzfB100% (2)

- Držači Osovina DIN 15058 PDFDocument1 pageDržači Osovina DIN 15058 PDFMartin JurmanNo ratings yet

- Aida-StandardsDocument14 pagesAida-StandardsthaivinhtuyNo ratings yet

- Standards Book 2002Document129 pagesStandards Book 2002oliveiralauroNo ratings yet

- Tabela de Flanges ANSIDocument10 pagesTabela de Flanges ANSIJarbas MoraesNo ratings yet

- Achievable perpendicularity tolerances up to 40mm thick materialsDocument1 pageAchievable perpendicularity tolerances up to 40mm thick materialsMihai StanNo ratings yet

- Supply Flange ANSI B16.5 Slip On Flange, SORF Flange, Class 150LBS To 1500LBS - Jinan Hyupshin Flanges Co., LTDDocument3 pagesSupply Flange ANSI B16.5 Slip On Flange, SORF Flange, Class 150LBS To 1500LBS - Jinan Hyupshin Flanges Co., LTDSandipNo ratings yet

- MaterialsDocument1 pageMaterialsakv030011No ratings yet

- MAKO Piping Library Catalogue - Rev CDocument28 pagesMAKO Piping Library Catalogue - Rev Celmfp7774676No ratings yet

- Cast-iron welding guide covers standardsDocument10 pagesCast-iron welding guide covers standardsclnNo ratings yet

- Designing With Ductile IronDocument4 pagesDesigning With Ductile IronCarlos LaoNo ratings yet

- G2 SpecDocument2 pagesG2 SpecSimo PaicNo ratings yet

- Standard Steel PlatesDocument39 pagesStandard Steel PlatesCuong TranHung100% (1)

- Iron AlloysDocument6 pagesIron AlloysHieu NguyenNo ratings yet

- Welding Cast Iron GuideDocument10 pagesWelding Cast Iron GuideRoberto CordovaNo ratings yet

- STANDARD - ASTM A792 - Brief DescriptionDocument3 pagesSTANDARD - ASTM A792 - Brief DescriptionSeyong ParkNo ratings yet

- Analysis & Optimization of Pressure Equipment Swing Check Valve by Using FEA MethodsDocument4 pagesAnalysis & Optimization of Pressure Equipment Swing Check Valve by Using FEA MethodsD_D_76No ratings yet

- Adjust Well Pump Pressure SwitchesDocument1 pageAdjust Well Pump Pressure SwitchesD_D_76No ratings yet

- Monel® Alloy 400: C MN S Si Ni Cu FeDocument2 pagesMonel® Alloy 400: C MN S Si Ni Cu FeD_D_76No ratings yet

- W2420-025-S: Wave Spring Washers: Product DetailsDocument1 pageW2420-025-S: Wave Spring Washers: Product DetailsD_D_76No ratings yet

- ASTM MATERIAL COMPARISON TABLEDocument10 pagesASTM MATERIAL COMPARISON TABLEMardeOpamenNo ratings yet

- Hydro Pnuematic CylinderDocument1 pageHydro Pnuematic CylinderD_D_76No ratings yet

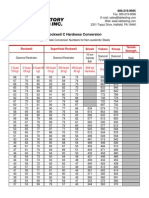

- Chart Hardness CDocument2 pagesChart Hardness CJanaka MangalaNo ratings yet

- Cotter pin specificationsDocument1 pageCotter pin specificationsD_D_76No ratings yet

- Monel® Alloy 400: C MN S Si Ni Cu FeDocument2 pagesMonel® Alloy 400: C MN S Si Ni Cu FeD_D_76No ratings yet

- Surface FinishDocument1 pageSurface FinishD_D_76No ratings yet

- Adjust Well Pump Pressure SwitchesDocument1 pageAdjust Well Pump Pressure SwitchesD_D_76No ratings yet

- Acrylic SheetDocument1 pageAcrylic SheetD_D_76No ratings yet

- Chart Hardness CDocument2 pagesChart Hardness CJanaka MangalaNo ratings yet

- A514 Steel - WikipediaDocument1 pageA514 Steel - WikipediaD_D_76No ratings yet

- Roughness Conversion TableDocument1 pageRoughness Conversion Tabledreamingscientist3393No ratings yet

- ThreadsDocument1 pageThreadsD_D_76No ratings yet

- Drill Size ChartDocument5 pagesDrill Size ChartD_D_76No ratings yet

- BSPT Thread ChartDocument1 pageBSPT Thread ChartAli FikarNo ratings yet

- Thread Hex Head PlugDocument1 pageThread Hex Head PlugD_D_76No ratings yet

- Chapter2 CastingDocument31 pagesChapter2 Castingaghosh704No ratings yet

- Technical Threading Chart 2015Document1 pageTechnical Threading Chart 2015D_D_76No ratings yet

- Art:10.1007/s40033 013 0031 3Document8 pagesArt:10.1007/s40033 013 0031 3D_D_76No ratings yet

- A132 PDFDocument3 pagesA132 PDFD_D_76No ratings yet

- Iso 8062Document1 pageIso 8062Asrar Ahmed100% (2)

- Iso 8062Document1 pageIso 8062Asrar Ahmed100% (2)

- A367 Chill Method PDFDocument4 pagesA367 Chill Method PDFOziel RomeroNo ratings yet