Professional Documents

Culture Documents

CBE 461L 1 Multistage Distillation

Uploaded by

Aubrey LuttrellCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CBE 461L 1 Multistage Distillation

Uploaded by

Aubrey LuttrellCopyright:

Available Formats

Chemical Engineering Laboratory Manual

Multistage Distillation

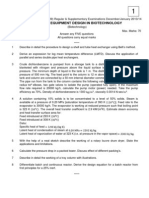

EXPERIMENTNO.51

MULTISTAGEDISTILLATION

OBJECTIVES:

1. Compareobservedcolumntemperatureandcompositionprofileswiththose

predictedbyMcCabeThiele/RADFRAC.

2. Determinetheoverallcolumnefficiencyandcomparewithtypicalefficiencies

fortrayedbubblecapcolumns.

3. Checkmaterialandenergybalancesforthecolumnoperatingatsteadystate.

4. Determinetheoptimumfeedstageforthissystem.

NOTATION:

B

liquidmolarflowrateoftheproductleavingthereboiler(moles/time)

liquidmolarflowrateoftheproductleavingthecondenser(moles/time)

liquidmolarflowratedescendingwithintherectifyingsectionofthetower

(moles/time)

L/

liquidmolarflowratedescendingwithinthestrippingsectionofthetower

(moles/time)

thestrippingsectiontraynumber,wheretraynumberoneisatthetopofthe

tower

thetraynumber,wheretraynumberoneisatthetopofthetower

heatrequiredtoconvert1moleoffeedfromitsconditionasitentersthe

towertoasaturatedvapordividedbythemolallatentheatofthefeed

refluxratio,molepertimeofliquidfromthecondenserreturnedtothetop

trayofthetowerdividedbythemolespertimeofdistillate

molefractionofAintheliquidphase

xB

molefractionofAintheliquidleavingthereboiler

xD

molefractionofAintheliquid(thedistillate,D)leavingthecondensernot

returnedtothetower

xF

molefractionofAinthefeedstream

molefractionofAinthevaporphaseenrichingsection

THEORY:

Distillationisamethodofseparatingthecomponentsofasolution.Itdependsuponthe

distributionofthesubstancesbetweenagasandaliquidphase,appliedtocaseswhere

allcomponentsarepresentinbothphases(2).Itisacommon"unitoperation"found,

forexample,inthepetroleumandchemicalindustries.

5-8

Chemical Engineering Laboratory Manual

Multistage Distillation

Distillationisbasedontheprinciplethatwhensufficientenergyistransmittedtoa

mixturecontainingcomponentsofdifferingvolatilities;themorevolatilecomponents

(i.e.havingahighervaporpressure)willvaporizepreferentiallywithrespecttotheless

volatilecomponents.

Indistillationonlyafractionoftheliquidisvaporized;withrespecttotheoriginal

liquidthevaporisricherinthemorevolatilecomponentsandtheresidualliquidis

richerinthelessvolatilecomponents.Thevaporiscondensedandthenpartially

vaporized,thisprocessisrepeateduntilthevaporhasthedesiredcomposition.The

remainingliquidfromeachpartialvaporizationiscountercurrentlyandintimately

contactedwiththevapor,whichisleanerinthemorevolatilecomponentfromthe

precedingpartialvaporizationstage.Thepointinadistillationtowerwheretheliquid

andvaporcontactiscalledastage.Thecontactingisdonetypicallybyintimatemixing

onsievetrays,inpackedsections,orbybubblecaps,asinthisexperiment.

Whenthestagesarearrangedinaverticalfashionsothatthevaporsevolvingfromone

stagecontactthedescendingliquidfromthestageabove,wehaveadistillation

"column"or"tower",seeFigure188(1),orFigure11.41(6).

Thesectionabovethepointwherethefeedentersthetowerisreferredtoasthe

enrichingorrectifyingsection.Intheenrichingsectionthefallingliquid"washes"the

lessvolatilecomponentsfromtherisingvapor.Thesectionbelowthefeedisreferred

toasthestrippingsection.Inthestrippingsectiontheliquidinthebottomofthetower

ispartiallyvaporized,thevaporthenrisesstrippingthedescendingliquidofthemore

volatilecomponents.

Forliquidtobeprovidedtothetopstage,someofthecondensedvaporsfromthisstage

arereturnedasreflux.Forvaporstobesuppliedtotheloweststage,someliquidfrom

theloweststageisvaporizedinthe"reboiler".

Twocommonmethodsusedtocalculatetherelationshipbetweenthenumberoftrays,

liquid/vaporratios,andproductcompositionforabinarymixture(AandB)arethe

PonchonandSavaritmethodandtheMcCabeandThielemethod.Theformerrequires

detailedenthalpydatawhilethelatterdoesnotandisthereforealsolessaccurate.Often

theMcCabeThielemethodisadequatebecausetheenthalpyeffectsarenotlarge.

McCabeThieleMethod

Theprimaryassumptionisthattheoperatinglinesinaxycoordinatesystemplotare

straightforeachtowersection.Thiswillbetrueifenthalpyeffectsarenegligible.

5-8

Chemical Engineering Laboratory Manual

Multistage Distillation

Theoperatinglinefortheenrichingsectioncanbeobtainedfromamaterialbalance

aroundtheenrichingsectionincludingthecondenser,seeFigure188(1).Ifthe

condenserisatotalcondenserthentheoperatinglineequationis

y n 1

L

D

xn

xD

LD

LD

Amaterialbalancearoundthestrippingsectionincludingthereboileryieldsthe

operatinglineforthestrippingsection

y m 1

L/

B

xm /

xB

/

L B

L B

Theoperatinglineforthefeed,theqline,isestablishedfromamaterialandanenthalpy

(energy)balancearoundthefeedstage,yielding

y

q

x

x F

q 1

q 1

Ifthefeedcompositionandthermodynamicstate,xD,xB,andtherefluxratioare

specified,theoperatinglinescanbedrawnonaxycoordinatesystemplot.Fromthe

graphthenumberoftheoreticalstagesforthedesiredseparationcanbedetermined.

Notethatfiveoftheabovementionedvariablesneedtobeknowntodeterminethe

sixth,graphically.

EQUIPMENT:

Asimpleschematicarrangementofadistillationcolumnwithaccessoriesisshownin

Figure188(1).Thedistillationequipmentinthelaboratoryismoreelaborate.Itwas

madebytheBrightonCorporationofCincinnati,Ohio.Thereisasetofdrawings

providedtoaidinunderstandingitsconstructionandarrangement.Thepipingdiagrams

aredrawingsBD20194EL,BC80841ELandBC80842EL(6).Thedistillation

columnitselfcontains20bubblecapplates.Eachplatehas3bubblecaps.Thecolumn

ismadeupof18coppersections,each6incheshigh,eachflangedatbothendsand

boltedtogetherwithaplatebetweeneachpairofadjacentsections.Thetwotop

sections,19&20,areofglass,sobubblecapactionmaybeobserved.The

downcomershaveaninsidediameterofabout1inch(eyeballestimate).Thecolumn

sectionshaveadiameterof8inches;flangediameteris11inches;9l/2inchboltcircle

with12boltspercircle.

Thecolumnisuninsulated;therefore,itwillnotoperateadiabatically.

5-7

Chemical Engineering Laboratory Manual

Multistage Distillation

Akettleisprovidedtofurnishheatedfeed.Afeedpumpisprovided.Acalandria

reboilerislocatedinthebottomofthecolumn.Threewatercooledoverhead

condensersoperateinseriesfortotalcondensationoftheoverheadvapors.Pipingis

suchthatfeedmaybeintroducedtoanyofthelower18platesortothetopofthe

column.Tanksareprovidedforoverheadandbottomproductcollection,butthese

streamsshouldbesampledusingthelinetaps.Instrumentationisprovidedfor

measuringtemperaturesandpressureswithinthesystemandformeasuringflowrates

onthevariousstreams.Samplingcontainersarearrangedalongthecolumntoobtain

liquidsamplesfromalternateplates.

PREPARATION:

Beforecomingtothelaboratorypreparethefollowingaids:

1. Avaporliquidequilibriumdiagram(TxyandXYdiagrams)fortheethanolwater

systemat13.25psia.ASPENPluscanbeusedtogeneratethesediagramsusingthe

properphysicalpropertyset.Youshouldverifytheaccuracyofthegenerated

diagramswithliteraturedata;Perrys6theditiongivesanenthalpyconcentration

diagramfortheethanolwatersystem.

2. Youwillbefeedinga~0.12molfractionethanolinwaterstreamtoa20stage

distillationcolumnataflowrateof0.2gpmandatemperatureof60C.Your

targetproductconcentrationis0.70molfractionethanolinthedistillateand97%

recoveryofethanolinthedistillate.UseMcCabeTheile/ASPENRADFRACto

estimatetherefluxratiorequiredandoptimalfeedstageforthisseparationwhenthe

Murphreestageefficiency(Emv)is0.50.Assumethatthereboilerdoesnotcountas

anadditionalequilibriumstage.Useanoverallcolumnmaterialbalanceto

determinethedistillateproductflowrateingallonsperminute.FromASPENusing

NRTL,themolardensityof12mol%ethanolat60Cis2.63lbmol/ft3,andthe

molardensityof70mol%ethanolatthebubblepointis1.26lbmol/ft3.

PROCEDURE:

1. Safety:Hardhatandsafetyglassesrequired.Thesteamlines,feedkettle,

reboiler,andcolumnalloperateatelevatedtemperatures.

2. Familiarizeyourselfwiththedistillationcolumnsystem.KnowtheFeedsystem,

ReboilerCondensate(Bottoms)system,Refluxsystem,UtilitiesPumpsystem,and

Steamsystem.

3. Ensurethatfeedcompositioninkettleisatleast0.12molfractionofethanol.

4. Turn on cooling water supply to the kettle condenser and the top product condensers.

Confirm that condenser vent line to atmosphere is open; this allows non-condensable

gas to exit the column during startup.

5. Open feed valve on desired feed tray, and verify that all other tray valves are closed.

5-8

Chemical Engineering Laboratory Manual

Multistage Distillation

6. Open gate valve for steam coming from header (located on east wall). Make sure ball

valve for the steam condensate is open (going towards the absorber).

7. Verify level in feed kettle and reboiler. Collect a feed sample for GC analysis.

8. Turn on the power supply to the control panel.

9. Startup the computer. On the Desktop, open Distillation Control Strategy. Click

Debug, and then Start Strategy.

10. Put feed kettle temperature control loop in AUTO in PAC Display Runtime Basic

(setpoint at 140 F).

11. With valves open from kettle to pump and then to column, start the feed pump.

Adjust the feed flow rate with the rotameter to achieve 0.1 gpm.

12. Set reboiler temperature in AUTO at 215 F in PAC Display Runtime Basic.

13. Set the Bottoms level to be 80% in PAC Display Runtime Basic.

14. Temperatures for each stage of the column can be viewed in PAC Display Runtime

Basic by opening the Unit Display.

15. Once the overhead temperature reaches 70 C, increase the feed flow rate to 0.2

gpm.

16. Monitor reflux flow rate on display panel. Once the reflux flow rate exceeds 0.1

gpm, start the product flow rate at a value corresponding to your desired reflux ratio.

17. Visually observe the top two stages through the glass wall. Look for flow patterns

that could lower tray efficiency, such as weeping, entrainment, and liquid splashing

down the downcomer.

18. Carefully touch the atmospheric vent line to see if it is hot. If it is hot, increase the

condenser cooling water flow rate and notify the instructor.

19. If level gets too high in Bottoms, Reflux, or Distillate tanks, open valves to drain

tanks and start the Utility Pump to drain tanks into the Kettle.

20. Monitor column temperatures and flow rates (including reflux rotameter) to verify

steady state operation. Verify that all sample jars are empty.

21. Write down all temperatures and flow rates.

22. Sample the overheads distillate and the bottoms product using the needle sample

valves. Open the bottoms sample valve slowly and carefully this sample will

be hot. The person collecting samples should wear rubber gloves.

23. Manually actuate the sample valves with instrument air. Once all the sample jars are

at least half filled, bleed instrument air pressure to close the sample valves.

24. Transfer samples to sample bottles and allow cooling to room temperature.

25. Measure reboiler condensate flow on the display panel labeled Bottoms flow rate.

Whenyouhavecompletedthedistillationrun,observethefollowingproceduresin

shuttingdown.

1. Turn off steam supply manual valves at the column and at the main supply header.

2. Turn off the feed pump.

3. Close out of PAC Display Runtime Basic. In PAC Control Basic, click Stop

Strategy and close out.

4. Turn off power supply to display.

5. Turn off the cooling water after the temperature at the top of the column has

5-7

Chemical Engineering Laboratory Manual

Multistage Distillation

dropped to 40 C.

6. Analyze samples for mole fraction ethanol using GC or refractive index.

REPORTING:

Inreportingthisexperimentyoushould:

1. Plottemperatureversusstagenumber.Compareyourmeasuredtemperatureswith

thosepredictedfromyourmeasuredcompositionsviayourTxydiagram.Also

compareyourmeasuredtemperatureprofilewithyourRADFRACgenerated

profile.

2. Plotliquidethanolmolefractionversusstagenumber.Compareyourmeasured

compositionprofilewithprofilesgeneratedbyMcCabeThiele/RADFRAC.

3. Calculatethemolalflowratesofvaporandliquidatthetop.Checkyouroverall

columnmaterialbalance.

4. DetermineyourexperimentalreboilerandcondenserdutiesinBtu/hr.Checkyour

overallcolumnenergybalance.

5. Showthedeterminationoftheoreticalstages(plates)neededtoachievethe

observedseparationbyMcCabeThieleandRADFRAC.

6. Computetheoverallcolumnefficiencyfromyourdata.Comparethiswithtypical

efficienciesreportedintheliteraturefortrayedbubblecapcolumns.

7. Estimatethechangeinmolalvaporflowfromtoptobottomduetocolumnheat

losses.Howwouldthisaffectyourcalculatedcolumnefficiency?

REFERENCES:

1. McCabe,SmithandHarriott,UnitOperationsofChemicalEngineering,Fifth

Edition,McGrawHillBookCo.(1993).

2. Treybal,MassTransferOperations,ThirdEdition,pp.185,342357,371419,

McGrawHillBookCo.(1968).

3. Perry,GreenandMaloney,ChemicalEngineers'Handbook,SixthEdition,pp.18

37to1819,McGrawHillBookCo.(1984).

4.

Perry,Ibid,FourthEdition,pp.132to1310,1817,McGrawHillBookCo.

(1963).

5.

Perry,Ibid,ThirdEdition,p.575(1950).

6.

C.J.Geankoplis,TransportProcessesandUnitOperations,ThirdEdition,

PrenticeHallPTR(1993).

5-8

Chemical Engineering Laboratory Manual

Multistage Distillation

7.

OperatingInstructionsforCompleteModel"A",LaboratoryDistillationUnit,

SDSM&T,SerialNo.4269,BrightonCorporation(1961).

8.

InternationalCriticalTables,Vol.3,p.310.

FORADDITIONALINFORMATION:

9.

Chu,JuChin,etal.,DistillationEquilibriumData,ReinholdPublishingCorp.

(1950).

10.

Chu,JuChin,etal.,VaporLiquidEquilibriumData,J.W.Edwards,Publisher

(1956).

5-7

You might also like

- Experiment No,-3 (A) : Mass Transfer Lab IIT KGPDocument3 pagesExperiment No,-3 (A) : Mass Transfer Lab IIT KGPSiddharth MohapatraNo ratings yet

- Simulation and optimization of a continuous catalytic naphtha reforming processDocument5 pagesSimulation and optimization of a continuous catalytic naphtha reforming processHưng LucaNo ratings yet

- Reactors1 9Document4 pagesReactors1 9Mourad kharbachNo ratings yet

- Distillation Column Design for Ethanol-Water SeparationDocument2 pagesDistillation Column Design for Ethanol-Water Separationafic219473No ratings yet

- Modelling of A Fluidized Catalytic Cracking ProcessDocument7 pagesModelling of A Fluidized Catalytic Cracking ProcessMmediong UdofiaNo ratings yet

- CHE 4613 Radfrac ModelingDocument6 pagesCHE 4613 Radfrac ModelingHuda AlkhouriNo ratings yet

- Bercic-1993-Catalytic Dehydration of MethanolDocument7 pagesBercic-1993-Catalytic Dehydration of MethanolIonut BanuNo ratings yet

- Laboratory AssignmentsDocument44 pagesLaboratory AssignmentsPewdiepaw RockNo ratings yet

- Retrofit of Distillation Columns Using Thermodynamic AnalysisDocument27 pagesRetrofit of Distillation Columns Using Thermodynamic AnalysiskademNo ratings yet

- Reaction Technologies: ThreeDocument31 pagesReaction Technologies: ThreeProcess EngineerNo ratings yet

- Simulation, Sensitivity Analysis and Optimization of a Continuous Catalytic Naphtha Reforming ProcessDocument5 pagesSimulation, Sensitivity Analysis and Optimization of a Continuous Catalytic Naphtha Reforming Processck19654840No ratings yet

- Fractional Distillation Experiment - ChEDocument6 pagesFractional Distillation Experiment - ChEmutencoNo ratings yet

- Chemcad Cc5 ExampleDocument37 pagesChemcad Cc5 ExampleBabulu BalarkanNo ratings yet

- Distillation Column EfficienciesDocument32 pagesDistillation Column EfficienciesJesus GarcíaNo ratings yet

- Chapter 4 (Process Description)Document6 pagesChapter 4 (Process Description)Jamil WarrenNo ratings yet

- Experiment 5 - Atmospheric DistillationDocument3 pagesExperiment 5 - Atmospheric DistillationMOHD WAHEEDNo ratings yet

- Design of Tubular Reactor for Monochlorobenzene ProductionDocument2 pagesDesign of Tubular Reactor for Monochlorobenzene ProductionRhea Joy C. MoralesNo ratings yet

- Batch Reactive DistillationDocument7 pagesBatch Reactive DistillationChalmer BelaroNo ratings yet

- Mole Balances: Industrial ReactorsDocument3 pagesMole Balances: Industrial Reactorsdina rodianaNo ratings yet

- 1.1.0 Background 1.1.1 Chemical ReactorsDocument5 pages1.1.0 Background 1.1.1 Chemical ReactorsEvan ChinNo ratings yet

- Project Report NewDocument41 pagesProject Report Newrohith reddyNo ratings yet

- Effect of Temperature on CSTR ReactionDocument22 pagesEffect of Temperature on CSTR Reactionafnan_lion94No ratings yet

- LG Chem Terephthaldehyde Reactor OptimisationDocument7 pagesLG Chem Terephthaldehyde Reactor Optimisationnghiemta18No ratings yet

- PFR ReactorDocument19 pagesPFR Reactorkhairi100% (1)

- Hysys Project of Chemical Reaction Engineering: Prepared By: Mahmoud Mohamed ID: 141761Document9 pagesHysys Project of Chemical Reaction Engineering: Prepared By: Mahmoud Mohamed ID: 141761Mahmoud HendawyNo ratings yet

- Batch Distillation Laboratory ReportDocument17 pagesBatch Distillation Laboratory ReportNayantara Soni100% (1)

- Effect of Residence Time on Hydrolysis ReactionDocument8 pagesEffect of Residence Time on Hydrolysis ReactionElaine PuiNo ratings yet

- Delayed Coking UnitDocument27 pagesDelayed Coking Unitstunningmanju50% (2)

- UOP Proper Design NHT Combined Feed Exchanger Equipment PaperDocument9 pagesUOP Proper Design NHT Combined Feed Exchanger Equipment Paperpiolinwalls100% (1)

- Design For A High Temperature Shift ConverterDocument43 pagesDesign For A High Temperature Shift ConverterAaron GyamfiNo ratings yet

- 9A23702 Process Equipment Design in BiotechnologyDocument4 pages9A23702 Process Equipment Design in BiotechnologysivabharathamurthyNo ratings yet

- Plug Flow ReactorDocument28 pagesPlug Flow ReactorNurul AinNo ratings yet

- Improved Reactor Internals For HGO HydrotreatersDocument2 pagesImproved Reactor Internals For HGO HydrotreatersapitbhuNo ratings yet

- Chapter 3 - Equipment Design Part 3 (R-101)Document37 pagesChapter 3 - Equipment Design Part 3 (R-101)aimanrsln0% (1)

- Hydrogenation of hydrocarbons in trickle bed reactorsDocument11 pagesHydrogenation of hydrocarbons in trickle bed reactorsAram Nasih MuhammadNo ratings yet

- Melt Polymerization ReactorDocument9 pagesMelt Polymerization ReactornichkhunieNo ratings yet

- v01 I01 07Document7 pagesv01 I01 07SuperbankNo ratings yet

- CSTR 40L LAB EXPERIMENTDocument18 pagesCSTR 40L LAB EXPERIMENTSaber Minato Azrul100% (2)

- Ebullated Bed Reactor Modeling For Residue Conversion PDFDocument9 pagesEbullated Bed Reactor Modeling For Residue Conversion PDFMohmmed Abdullah Sanam100% (1)

- Deisel Hydrotreating UnitDocument9 pagesDeisel Hydrotreating UnitRittu Paul100% (1)

- Continuous Distillation Column Lab Report (40Document27 pagesContinuous Distillation Column Lab Report (40JimNo ratings yet

- Lab Report CSTR 40LDocument26 pagesLab Report CSTR 40LAnonymous NyvKBW33% (3)

- Reactors: CHML 404-01 Date: 03/11/2019 Unit Operation: 1 Instructor: Dr. MartinezDocument23 pagesReactors: CHML 404-01 Date: 03/11/2019 Unit Operation: 1 Instructor: Dr. MartinezKevin ThomasNo ratings yet

- Chemical and Mechanical DesignDocument460 pagesChemical and Mechanical DesignNuriman K-monNo ratings yet

- Stirred Tank ReactorDocument32 pagesStirred Tank ReactorChristopher Emeka Ominyi100% (1)

- Modeling and Simulation of Bubble Column ReactorsDocument21 pagesModeling and Simulation of Bubble Column Reactorsjonathan arboledaNo ratings yet

- Batch Distillation: System OverviewDocument2 pagesBatch Distillation: System OverviewMiliani AhmedNo ratings yet

- 1993 - Barreiros Et Al. - Modeling and Simulation of Structured Packing Column Distillation (OCR, Outro)Document8 pages1993 - Barreiros Et Al. - Modeling and Simulation of Structured Packing Column Distillation (OCR, Outro)Manuel Menezes de SequeiraNo ratings yet

- Simulating Methanol Production Using Distillation ColumnDocument8 pagesSimulating Methanol Production Using Distillation ColumnRathika RathikaNo ratings yet

- CSTR in SeriesDocument12 pagesCSTR in Seriesmnizamarzuki0% (2)

- Model Predictive Controller Design of Hydrocracker ReactorsDocument9 pagesModel Predictive Controller Design of Hydrocracker ReactorsM Ahmed LatifNo ratings yet

- FSI-P-CHME Chemical Engineering ExamDocument6 pagesFSI-P-CHME Chemical Engineering ExamAaqib AshrafNo ratings yet

- Distillation ConvergenceDocument4 pagesDistillation ConvergenceSai Pavan100% (1)

- Working Guide to Reservoir Rock Properties and Fluid FlowFrom EverandWorking Guide to Reservoir Rock Properties and Fluid FlowRating: 3 out of 5 stars3/5 (1)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasFrom EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNo ratings yet

- Multiphase Reactor Engineering for Clean and Low-Carbon Energy ApplicationsFrom EverandMultiphase Reactor Engineering for Clean and Low-Carbon Energy ApplicationsYi ChengNo ratings yet

- Multiphase Catalytic Reactors: Theory, Design, Manufacturing, and ApplicationsFrom EverandMultiphase Catalytic Reactors: Theory, Design, Manufacturing, and ApplicationsNo ratings yet

- Lesson Three Environmental Ethics and Equity Howard University, Spring Semester 2015Document18 pagesLesson Three Environmental Ethics and Equity Howard University, Spring Semester 2015Aubrey LuttrellNo ratings yet

- Physics Lab Report Example PDFDocument17 pagesPhysics Lab Report Example PDFFara Diba100% (1)

- Solving Linear Differential Equations with Constant CoefficientsDocument2 pagesSolving Linear Differential Equations with Constant CoefficientsAubrey LuttrellNo ratings yet

- Self ReflectionDocument1 pageSelf ReflectionAubrey LuttrellNo ratings yet

- Interpretations of CirceDocument10 pagesInterpretations of CirceAubrey LuttrellNo ratings yet

- Chemical Engineering PRe Lab 2Document6 pagesChemical Engineering PRe Lab 2Aubrey LuttrellNo ratings yet

- Interpretations of CirceDocument10 pagesInterpretations of CirceAubrey LuttrellNo ratings yet

- The Adventures of HimDocument1 pageThe Adventures of HimAubrey LuttrellNo ratings yet

- Multistage Distilation - Draft ProtocolDocument9 pagesMultistage Distilation - Draft ProtocolAubrey LuttrellNo ratings yet

- Faiq ResumeDocument3 pagesFaiq ResumeFoudziah SarinNo ratings yet

- Delivering Success Tesco Case Study On BSCDocument4 pagesDelivering Success Tesco Case Study On BSCWenuri KasturiarachchiNo ratings yet

- A Handbook for Cooperative Fieldworkers in Developing NationsDocument389 pagesA Handbook for Cooperative Fieldworkers in Developing NationsjimborenoNo ratings yet

- Us06-102 841 01 02 02 PDFDocument62 pagesUs06-102 841 01 02 02 PDFF2CANALESNo ratings yet

- The Impact of Time Management on Student Academic AchievementDocument8 pagesThe Impact of Time Management on Student Academic AchievementShyrel siborboroNo ratings yet

- The Marcos Ill-Gotten WealthDocument12 pagesThe Marcos Ill-Gotten WealthAngel Nieto PengsonNo ratings yet

- Deposit SlipDocument1 pageDeposit SlipMansoor RaoNo ratings yet

- Latest JIG Standards issues releasedDocument2 pagesLatest JIG Standards issues releasedPETENo ratings yet

- GMP-Inspection Report 2391Document5 pagesGMP-Inspection Report 2391ajitjoshi950No ratings yet

- Scope and Nature of HotelDocument2 pagesScope and Nature of HotelJan Hidalgo LaroyaNo ratings yet

- Unit 2 - Professional Ethics & Code of ConductDocument97 pagesUnit 2 - Professional Ethics & Code of ConductPradiba Raajkumaar25% (4)

- Computer Masti Level 2Document105 pagesComputer Masti Level 2Rupesh Kumar Shah67% (3)

- Cultural Impacts of Tourism in VietnamDocument4 pagesCultural Impacts of Tourism in VietnamBùi Thanh Ngọc BíchNo ratings yet

- Utah County Attorney Prioritized CrimesDocument9 pagesUtah County Attorney Prioritized CrimesThe Salt Lake TribuneNo ratings yet

- Contribution Collection List: Quarter EndingDocument2 pagesContribution Collection List: Quarter EndingBevs Al-OroNo ratings yet

- CitectSCADA Cicode ReferenceDocument1,355 pagesCitectSCADA Cicode ReferenceSebestyén Béla100% (2)

- ACEA Regulatory Guide 2022Document197 pagesACEA Regulatory Guide 2022Reinaldo RamírezNo ratings yet

- High-Voltage Fuse-LinksDocument11 pagesHigh-Voltage Fuse-LinksSatheesh Kumar NatarajanNo ratings yet

- Defect Life Cycle or A Bug Lifecycle in Software TestingDocument6 pagesDefect Life Cycle or A Bug Lifecycle in Software TestingKrish KumarNo ratings yet

- Educational Leadership and Management: Lecturer: Ms. Janet Au YeungDocument22 pagesEducational Leadership and Management: Lecturer: Ms. Janet Au YeungTamamaNo ratings yet

- Scrum Developer AssessmentDocument11 pagesScrum Developer Assessmentmohannad44% (9)

- UAE HealthcareDocument15 pagesUAE HealthcareUmaira UsmanNo ratings yet

- Model MRP: Samsung B7620Document19 pagesModel MRP: Samsung B7620Rajni MenonNo ratings yet

- Tek Radius ManualDocument42 pagesTek Radius ManualjesusvpctNo ratings yet

- The Risk Management of Medical Device-Related Pressure Ulcers Based On The Australian/ New Zealand StandardDocument11 pagesThe Risk Management of Medical Device-Related Pressure Ulcers Based On The Australian/ New Zealand StandardJugurtha BoutlikhetNo ratings yet

- Ecg EkgDocument3 pagesEcg EkgrochimNo ratings yet

- Bangalisan V Ca G.R. No. 124678 July 31, 1997 Regalado, J.: FactsDocument1 pageBangalisan V Ca G.R. No. 124678 July 31, 1997 Regalado, J.: FactsKate GaroNo ratings yet

- Customer and Banker Relationship MCQDocument13 pagesCustomer and Banker Relationship MCQsn n100% (3)

- Assessement 8 Mitosis Video RubricDocument1 pageAssessement 8 Mitosis Video Rubrictr4lNo ratings yet

- XJ550 Parts ManualDocument121 pagesXJ550 Parts Manualjuan2610100% (5)