Professional Documents

Culture Documents

Surface Bonded Cmu Construction

Uploaded by

rickbmayCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Surface Bonded Cmu Construction

Uploaded by

rickbmayCopyright:

Available Formats

NCMA TEK

SEE RED BOX ON P. 2 FOR BLOCK SPECIFICATION

National Concrete Masonry Association

an information series from the national authority on concrete masonry technology

SURFACE BONDED

CONCRETE MASONRY CONSTRUCTION

TEK 3-5A

Structural

Keywords: construction techniques, mortar, surface bonding

INTRODUCTION

porated into the surface bonding mortar to produce a

finished surface without the need to paint.

Surface bonded concrete masonry construction offers all

of the benefits and advantages of conventional concrete

masonry construction, such as:

fire safety

acoustic insulation

energy efficiency

lasting durability and beauty

Surface bonding is an economical construction technique

which was first introduced in the late sixties by the U. S.

Department of Agriculture for use in low cost housing. In

surface bonded construction, concrete masonry units are laid

dry and stacked, without mortar, to form walls. Walls are

constructed with units that have been precision ground or

honed to achieve a uniform bearing surface, or with shims

DESIGN STRENGTH

placed periodically to maintain a level and plumb condition.

Both sides of the wall are then coated with a thin layer of

Many structural and nonstructural tests have been perreinforced surface bonding mortar. The synthetic fibers

formed on surface bonded walls to establish design paramwhich reinforce the surface bonding mortar impart a tensile

eters for the system.

strength of about 1500 psi (10.3 MPa), producing a strong wall

The nonstructural properties, such as sound transmission

despite the relatively thin thickness of material on each side.

class, fire resistance period, and energy efficiency, of surface

The surface coating on each side of the wall bonds the concrete

bonded concrete masonry can be considered equivalent to a

masonry units together in a strong composite construction,

conventional mortared concrete masonry wall.

and serves as a protective water resistant shield.

There are a few differences between the structural propSurface bonded concrete masonry has a number of advantages:

erties of the two types of construction. These differences are

Less time and skill are required for wall construction. In

discussed in the following paragraphs, and are illustrated in

a 1972 study of mason productivity sponsored by the U.

Figure 1 for ungrouted, unreinforced walls. Although national

S. Department of Housing and Urban Development and

building codes, such as the BOCA National Building Code

other interested organizations, it

was found that surface bonded

concrete masonry construction

resulted in 70 percent greater

productivity than that achievable with conventional construction.

The surface bonding mortar provides excellent resistance to water penetration in addition to its

function of holding the units together. Tests of surface bonded

walls have repeatedly shown

their resistance to wind driven

rain to be excellent even with

wind velocities as great as 100

mph (161 km/h), and over test

periods of 8 hours.

Figure 1Surface Bonded and Mortared Concrete Masonry Wall Strengths

Colored pigment can be incorTEK 3-5A 1998 National Concrete Masonry Association (replaces TEK 3-5)

(1998)

and the Standard Building Code (refs. 1, 3) do not specifically

address reinforced or grouted surface bonded walls, manufacturers of surface bonding mortars may have code-approved

criteria for their products.

Compressive Loads

Resistance to vertical compressive loads depends primarily on the compressive strength of the concrete block used in

the wall construction. Stronger units make stronger walls.

With mortared construction, a rule of thumb is that the wall

strength will generally be about seventy percent of the unit

strength. In comparison, surface bonded walls built with

unground concrete masonry units develop approximately

thirty percent of the strength of the individual block. This

reduced wall strength is depicted in Figure 1 for walls constructed with unground concrete masonry units.

The lower value obtained with the unground units is due

to a lack of solid bearing contact between units, due to the

natural roughness of the concrete units. The mortar bed used

in conventional construction compensates for this roughness

and provides a uniform bearing between units. If the masonry

unit bearing surfaces are ground flat and smooth before the

wall is erected, results similar to those for a mortared wall can

be expected. In Figure 1, note that surface bonded walls built

with precision ground concrete masonry units are equally as

strong in compression as the conventional construction.

Flexural Resistance

The flexural strength of a surface bonded wall is about the

same as that of a conventional mortared wall, as shown in

Figure 1. When walls are tested in the vertical span (i.e., a

horizontal force, such as wind, is applied to a wall that is

supported at the top and bottom) surfaced bonded walls and

mortared walls have about the same average strength; failure

occurs in the surface bonded coating due to tensile stress at or

near one of the horizontal joints. With mortared construction,

failure occurs at a horizontal joint with bond failure between

the mortar and the masonry units. The data from numerous

tests on surface bonded constructions led to an allowable

stress of 18 psi (0.12 MPa) based on the gross area.

When walls are laid in a running bond pattern, either with

mortar joints or with surface bonding, and tested in the

horizontal span, (i.e., a wall supported at each end is subjected

to a horizontal wind force) the strength in bending depends

primarily on the strength of the units. This is due to the

interlocking of the masonry units laid when in a running bond

configuration. In such tests in the horizontal span, the wall

strength of the surface bonded wall is exactly the same as the

conventional construction. In Table 1, an allowable flexural

stress of 30 psi (0.21 MPa) is recommended for horizontal

span when the units have been laid in running bond.

Shear Strength

The shear resistance of surface bonded construction is the

same as that of conventional walls. With face shell mortar

bedding, conventional concrete masonry walls averaged 42

psi (0.29 MPa) shear resistance, based on gross area. Nine

surface bonded walls, 8 in. (203 mm) in thickness, had an

Table 1Allowable Stress, Gross Cross-Sectional Area,

Dry-Stacked, Surface-Bonded Concrete Masonry Walls a

Compression:

45 psi (0.31 MPa)

Shear:

10 psi (0.07 MPa)

Flexural Tension:

Horizontal span: 30 psi (0.21 MPa)

Vertical span: 18 psi (0.12 MPa)

References 1 & 3

average shear resistance of 39 psi (0.27 MPa), and three 6 in.

(152 mm) thick surface bonded walls averaged 40 psi (0.28

MPa). These data are compared in Figure 1, and led to a

recommended allowable shear stress of 10 psi (0.07 MPa) on

the gross area (see Table 1).

CONSTRUCTION

The construction procedure for surface bonded walls is

similar to that of conventional, except that mortar is not placed

between the masonry units. Standard Practice for Construction of Dry-Stacked, Surface-Bonded Walls, ASTM C 946

(ref. 4), governs the construction methods. Care should be

taken to ensure uncoated walls are adequately braced.

Because the walls are constructed without mortar joints,

surface bonded wall dimensions do not conform to the standard 4 in. (102 mm) design module. Wall and opening

dimensions should be based on actual unit dimensions, which

are typically 75/8 in. high by 155/8 in. long (194 by 397 mm).

Materials

Surface bonding mortar should comply with Standard

Specification for Packaged, Dry, Combined Materials for

Surface Bonding Mortar, ASTM C 887 (ref. 6), which governs flexural and compressive strength, sampling, and testing.

ASTM C 946 requires Type I, moisture-controlled, concrete masonry units be used for surface bonded construction.

Type I units must be in a dry condition when delivered to the

job site. Walls laid using dry units will undergo less drying

shrinkage after construction, hence minimizing cracks. Standard Specification for Loadbearing Concrete Masonry Units,

ASTM C 90 (ref. 5) governs these requirements.

As for mortared masonry construction, materials should

be properly stored on site to prevent contamination by rain,

ground water, mud, and other materials likely to cause staining or to have other deleterious effects.

If the bearing surfaces of the concrete masonry units are

unground, metal or plastic shims or mortar may occasionally

be required between units to maintain the wall level and

plumb. Shims must have a minimum compressive strength of

2000 psi (13.8 MPa) to ensure their long term durability after

the wall is loaded. Metal shims, if used, should be corrosion

resistant to reduce the possibility that they will corrode and

bleed through the finished masonry at a later time.

Leveling

Because the footing is not typically level enough to lay up

the dry units without additional leveling, the first course of

masonry units is laid in a mortar bed or set in the fresh footing

concrete to obtain a level base for the remainder of the wall.

Vertical head joints should not be mortared, even when the

first course is mortar bedded, since mortar in the head joints

will misalign the coursing along the wall length.

When required, additional leveling courses are constructed

in the wall. Leveling courses should be placed when:

the wall is out of level by more than 1/2 in. (13 mm) in 10 ft,

at each floor level, and

at a horizontal change in wall thickness (see Figure 2).

After the first course of masonry units is laid level in a

mortar bed, dry stacking proceeds with the remaining courses

beginning with the corners, and followed by stacking, in

running bond, between the corners. As they are dry stacked,

the ends of the concrete masonry units should be butted

together tightly. Small burrs should be removed prior to

placement.

After every fourth course, the wall should be checked for

plumb and level.

Crack Control

Temperature and moisture movements have the potential to cause small vertical cracks in a masonry wall. These

cracks are an aesthetic, rather than a structural, concern. In

exposed concrete masonry, where shrinkage cracks may be

objectionable, horizontal joint reinforcement, control joints,

or bond beams are used to control cracking. The absence of a

mortar bed joint in surface bonded walls means that there is no

space in the wall for joint reinforcement, so control joints or

bond beams are used for crack control.

Control joints should be placed:

1. at wall openings and at changes in wall height and

thickness

2. at wall intersections, at pilasters, chases, and recesses

3. in walls without openings, at intervals of 20 ft (6.1 m)

when there are no bond beams in the construction, and at

intervals of 60 ft (18.3 m) when bond beams are incorporated every 4 ft (1.2 m) vertically.

Control joints for surface bonded walls are similar to

Figure 2Change in Wall Thickness

those for mortared concrete masonry. At the control joint

location, the surface bonding mortar should be raked out and

the joint caulked.

Placing Accessories & Utilities

The absence of a mortar bed joint in the construction also

requires that the face shell and/or the cross web of the concrete

masonry units be notched or depressed whenever wall ties or

anchors must be embedded in the wall. A coarse rasp is

typically used to make small notches, while deeper notches

are cut with a masonry saw. Cores containing anchors or wall

ties should be grouted, or other adequate anchorage should be

provided.

Electrical lines and plumbing are often located in the

cores of concrete masonry units. These lines should be placed

before the surface bonding mortar is applied, so that the

masonry units are visible.

Applying Surface Bonding Mortar

Manufacturers recommendations should be followed

for job site mixing of the premixed surface bonding mortar

and application to the dry stacked concrete masonry wall.

As with mortared masonry construction, clean water and

mixing equipment should be used to prevent foreign materials

from being introduced into the mortar. Batches should be

mixed in full bag multiples only, to compensate for any

segregation of materials within a bag.

All materials should be mixed for 1 to 3 minutes, until the

mixture is creamy, smooth, and easy to apply. Note that

mixing time should be kept to a minimum, as overmixing can

damage the reinforcing fibers.

The stacked concrete masonry units should be clean and

free of any foreign matter which would inhibit bonding of the

plaster. Contrary to recommended practice with conventional

mortared walls, the dry stacked concrete masonry units should

be damp when the surface bonding plaster is applied to

prevent water loss from the mortar due to suction of the units.

Care should be taken to avoid saturating the units.

It is very important that the surface bonding mortar be

applied to both sides of the dry stacked wall since the wall

strength and stability depend entirely on this coating.

Premixed surface bonding mortars are smooth textured

and easily applied by hand with a trowel. The workability is

due to the short 1/2 in. (13 mm) glass fibers which reinforce the

mixture. The mortar should be troweled on smoothly with a

minimum thickness of 1/8 in. (3 mm).

Surface bonding mortar can also be sprayed on. On large

projects, use of a power sprayer greatly increases the coverage

rate of the mortar and further reduces wall costs. As applied,

the sprayed-on surface bonding mortar usually has a rougher

surface texture than a troweled finish, and possesses slightly

less tensile strength due to the lack of fiber orientation in the

plane of the mortar coating. This can be overcome by

troweling, hand or mechanical, following spray application of

the mortar. Hand or mechanical troweling of the sprayed

coating also assures that all gaps and crevices are filled.

When a second coat of surface bonding mortar is applied,

either by trowel or spray, it should be applied after the first coat

is set, but before it is completely hardened or dried out. The

second coat may be textured to achieve a variety of finishes.

Joints in surface bonding mortar are weaker than a

continuous mortar surface, and, for this reason, should not

align with joints between masonry units. If application of the

surface bonding mortar is discontinued for more than one

hour, the first application should be stopped at least 11/4 in. (32

mm) from the horizontal edge of the concrete masonry unit.

At the foundation, the surface bonding mortar should

either form a cove between the wall and the footer or, for a slab

on grade, should extend below the masonry onto the slab

edge, as shown in Figure 3. These details help prevent water

penetration at the wall/footer interface.

windy weather accelerates the water evaporation from the

mortarrequiring more frequent fog spraying.

At the end of the day, tops of walls should be covered to

prevent moisture from entering the wall until the top is

permanently protected. Typically, a tarp is placed over the

wall, extending at least 2 ft (0.6 m) down both sides of the wall,

and weighted down with lumber or masonry units.

Curing

After surface bonding application, the wall must be

properly cured by providing sufficient water for full hydration

of the mortar, to ensure full strength development. The wall

should be dampened with a water mist between 8 and 24 hours

after surface bonding mortar application. In addition, the wall

should be fog sprayed twice within the first 24 hours, although

with pigmented mortar, this may be extended to 48 hours.

The recommendations above may need to be modified for

either cold or hot weather conditions. For example, dry, warm,

REFERENCES

1. BOCA National Building Code. Country Club Hills, IL:

Building Officials and Code Administrators International,

Inc. (BOCA), 1996.

2. Building Code Requirements for Masonry Structures, ACI

530-95/ASCE 5-95/TMS 402-95. Reported by the Masonry

Standards Joint Committee, 1995.

3. Standard Building Code. Birmingham, AL: Southern Building Code Congress International, Inc. (SBCCI), 1997.

4. Standard Practice for Construction for Dry-Stacked, Surface-Bonded Walls, ASTM C 946-91 (1996)e1. American

Society for Testing and Materials, 1996.

5. Standard Specification for Loadbearing Concrete Masonry Units,

ASTM C 90-97. American Society for Testing and Materials, 1997.

6. Standard Specification for Packaged, Dry, Combined Materials for Surface Bonding Mortar, ASTM C 887-79a (1996)e1.

American Society for Testing and Materials, 1996.

wall-footing

wall-slab on grade

Figure 3Wall/Footing Interface

NATIONAL CONCRETE MASONRY ASSOCIATION

2302 Horse Pen Road, Herndon, Virginia 20171-3499

www.ncma.org

To order a complete TEK Manual or TEK Index,

contact NCMA Publications (703) 713-1900

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Dry Stack Manual & Reference Tek 14-22Document6 pagesDry Stack Manual & Reference Tek 14-22rickbmayNo ratings yet

- CV Hl2240d Usaeng Usr CDocument0 pagesCV Hl2240d Usaeng Usr Cbigbigbig90003270No ratings yet

- Swedish Heat Pump StudyDocument10 pagesSwedish Heat Pump StudyrickbmayNo ratings yet

- VACUUM PUMP TESTING 1980s Mercedes DieselDocument3 pagesVACUUM PUMP TESTING 1980s Mercedes DieselrickbmayNo ratings yet

- Silent Subliminal Presentation System Us Patent 5,159,703Document7 pagesSilent Subliminal Presentation System Us Patent 5,159,703rickbmayNo ratings yet

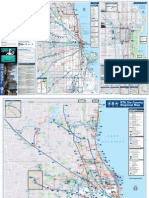

- Rta System Map ChicagoDocument2 pagesRta System Map ChicagorickbmayNo ratings yet

- Inspiron 14r 5420 Owner's Manual en UsDocument110 pagesInspiron 14r 5420 Owner's Manual en UsrickbmayNo ratings yet

- Rta System Map ChicagoDocument2 pagesRta System Map ChicagorickbmayNo ratings yet

- Soc Sec and Spousal BenefitsDocument20 pagesSoc Sec and Spousal BenefitsrickbmayNo ratings yet

- Asparagus With Bread CrumbsDocument1 pageAsparagus With Bread CrumbsrickbmayNo ratings yet

- Social Security GuideDocument20 pagesSocial Security Guiderickbmay100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Cable Care Best ParcticeDocument4 pagesCable Care Best ParcticeHariomNo ratings yet

- Townsends Theory of Conduction and Breakdown in GasesDocument8 pagesTownsends Theory of Conduction and Breakdown in GasesDeepak VapraniNo ratings yet

- Chapter 4Document22 pagesChapter 4Nawaf Al-TamimiNo ratings yet

- Standard Test Method For Coefficient of Linear Thermal Expansion of Plastics Between 30°C and 30°C With A Vitreous Silica Dilatometer 1Document6 pagesStandard Test Method For Coefficient of Linear Thermal Expansion of Plastics Between 30°C and 30°C With A Vitreous Silica Dilatometer 1Gaurav KumarNo ratings yet

- 2324 Grade 8 (UAE-GULF) Science Course Revision QuestionsDocument40 pages2324 Grade 8 (UAE-GULF) Science Course Revision Questionswritetome.amjadNo ratings yet

- Anharmonic Crystal InteractionsDocument3 pagesAnharmonic Crystal InteractionsMonika Singh AyamNo ratings yet

- Solu of Assignment 7Document4 pagesSolu of Assignment 7dontstopmeNo ratings yet

- 4 ElectromagnetismDocument38 pages4 ElectromagnetismCart Kartika100% (1)

- DC Motor Characteristics ExperimentDocument7 pagesDC Motor Characteristics Experimentbilalkhan3567No ratings yet

- Nanoindentation-Lecture NotesDocument15 pagesNanoindentation-Lecture NotesAhmad NawazNo ratings yet

- 7.2 Radiaographic Testing ProcedureDocument14 pages7.2 Radiaographic Testing ProcedureMd Anamul HoqueNo ratings yet

- Hoisting SystemDocument42 pagesHoisting SystemBadut Sarkas100% (3)

- QUIRINO GENERAL HIGH SCHOOL HOME LEARNING PLANDocument4 pagesQUIRINO GENERAL HIGH SCHOOL HOME LEARNING PLANPau AbuenaNo ratings yet

- Tutorial-1 Unit 2Document8 pagesTutorial-1 Unit 2Romharsh OliNo ratings yet

- IsomerismDocument57 pagesIsomerismrajeshwariNo ratings yet

- Dekton Technical Manual ENDocument24 pagesDekton Technical Manual ENIzrada FotografijaNo ratings yet

- Effects of Approach Flow ConditionsDocument6 pagesEffects of Approach Flow ConditionsBharath kumarNo ratings yet

- SUDA Fiber Laser Cutting Machine FC1530-1000W 2020.6.2Document15 pagesSUDA Fiber Laser Cutting Machine FC1530-1000W 2020.6.2marceilinus devaluantoNo ratings yet

- Go-Kart Designing ReportDocument56 pagesGo-Kart Designing ReportPraveen Sah84% (25)

- Norma Prueba Acelerada de CorrosionDocument3 pagesNorma Prueba Acelerada de CorrosionVictor FLNo ratings yet

- Bedside Monitor: Service ManualDocument152 pagesBedside Monitor: Service Manualkatabalwa eric100% (1)

- Aircraft Stability and Control PDFDocument1 pageAircraft Stability and Control PDFAGNIDEEP BAIDYANo ratings yet

- Chandigarh University - ApplicationDocument9 pagesChandigarh University - ApplicationNaval Koralkar Chemical Engg. Dept.No ratings yet

- Honor Calculus Min YanDocument632 pagesHonor Calculus Min Yan黃業竣No ratings yet

- Kane 1962Document11 pagesKane 1962Julio César Chinchay QuiñonezNo ratings yet

- Chembio Activity 1Document2 pagesChembio Activity 1Adrian VillanuevaNo ratings yet

- Series and Parallel Circuits Worksheet: Combined Science - Physics - Key Stage 4 - ElectricityDocument18 pagesSeries and Parallel Circuits Worksheet: Combined Science - Physics - Key Stage 4 - ElectricityDhammika JayasingheNo ratings yet

- Types of Sensor and Their ApplicationDocument6 pagesTypes of Sensor and Their Applicationpogisimpatiko0% (1)

- EC - Model Exam QB PH3151Document1 pageEC - Model Exam QB PH3151DharveshNo ratings yet

- J. Hom - Lecture Notes On Heegaard Floer HomologyDocument30 pagesJ. Hom - Lecture Notes On Heegaard Floer HomologyMladen ZekićNo ratings yet