Professional Documents

Culture Documents

AET2114 Ch6 PDF

Uploaded by

Memyah AlOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AET2114 Ch6 PDF

Uploaded by

Memyah AlCopyright:

Available Formats

AET 2114

11/23/2014

CHAPTER 6:

MECHANICAL PROPERTIES

ISSUES TO ADDRESS...

Stress and strain: What are they and why are

they used instead of load and deformation?

Elastic behavior: When loads are small, how much

deformation occurs? What materials deform least?

Plastic behavior: At what point do dislocations

cause permanent deformation? What materials are

most resistant to permanent deformation?

Toughness and ductility: What are they and how

do we measure them?

1

Chapter 6: Mechanical Properties of Metals

6.1 Introduction

Why Study the Mechanical Properties of Metals ?

It is important for engineers to understand

How the various mechanical properties are measured, and

What these properties represent

The role of structural engineers is to determine stresses and

stress distributions within members that are subjected to welldefined loads

By experimental testing

Theoretical and mathematical stress analysis.

Design structures/components using predetermined materials

such that unacceptable levels of deformation and/or failure will

not occur.

2

By: Dr. Tariq Darabseh

AET 2114

11/23/2014

6.2 Concepts of

Stress and Strain

Static load changes

relatively slowly with

time

Applied uniformly

over a cross-section or

surface of a member.

Tension

Compression

Shear

Torsion

6.2 Concepts of Stress and Strain (Contd.)

TENSION TEST

Most common mechanical stress-strain test

Used to ascertain several mechanical properties that are important in design

A specimen is deformed, usually to fracture, with a gradually increasing

tensile load that is applied uniaxially along the long axis of the specimen.

A standard specimen is shown in Figure 6-2.

By: Dr. Tariq Darabseh

AET 2114

11/23/2014

6.2 Concepts of Stress and Strain (Contd.)

The specimen is mounted by its ends

into the holding grips of the testing

apparatus (Figure 6-3).

Tensile testing machine

To elongate the specimen at a

constant rate

To continuously and

simultaneously measure the

instantaneous load and the

resulting extension

Load using load cell

Extension using extensometer

Takes few minutes and is destructive.

5

6.2 Concepts of Stress and Strain (Contd.)

Engineering Stress () = Instantaneous applied

load (F) / Original Area (Ao)

F

A0

Unit: MPa, GPa, psi

Engineering strain ()

l

l l

li = instantaneous length

i 0

l0

l0

lo = original length

COMPRESSION TESTS

Similar to tensile test, compressive load

Sign convention, compressive force is taken negative

stress negative

Since lo > li , negative strain

By: Dr. Tariq Darabseh

AET 2114

11/23/2014

6.2 Concepts of Stress and Strain (Contd.)

SHEAR AND TORSIONAL TESTS

Shear stress : = F / Ao

F: Load or force imposed

parallel to the upper and

lower faces

Ao: shear or parallel area

Shear strain () is defined as the

tangent of the strain angle .

7

6.2 Concepts of Stress and Strain (Contd.)

GEOMETRIC CONSIDERATIONS OF

THE STRESS STATE

Stress is a function of orientations of the

planes

1 cos 2

)

2

sin 2

sin cos (

)

2

cos 2 (

By: Dr. Tariq Darabseh

AET 2114

11/23/2014

ELASTIC DEFORMATION

1. Initial

2. Small load

3. Unload

bonds

stretch

return to

initial

Linearelastic

Elastic means reversible!

Non-Linearelastic

ELASTIC DEFORMATION

6.3 Stress-Strain Behavior

By: Dr. Tariq Darabseh

Elastic deformation:

Non-permanent,

completely reversible,

conservative

Follow same loading and

unloading path

Linear elastic deformation

Hookes Law

Modulus of elasticity or

Youngs Modulus

stiffness or a materials

resistance to elastic

deformation

10

AET 2114

11/23/2014

6.3 Stress-Strain Behavior (Contd.)

11

Nonlinear Elastic

Behavior

Gray cast iron,

concrete, many

polymers

Not possible to

determine a

modulus of

elasticity

Either tangent

or secant

modulus is

normally used.

12

By: Dr. Tariq Darabseh

AET 2114

11/23/2014

6.3 Stress-Strain Behavior

(Contd.)

On an atomic scale, macroscopic

elastic strain is manifested as

small changes in the interatomic

spacing and the stretching of

interatomic bonds.

E is a measure of the

resistance to separation of

adjacent atoms

Modulus is proportional to the

slope of the interatomic forceseparation curve (Fig 2.8a) at

equilibrium spacing

dF

dr ro

13

6.3 Stress-Strain Behavior (Contd.)

With increasing

temperature, the modulus

of elasticity diminishes

Shear stress and strain

are proportional to each

other:

Shear modulus or

modulus of rigidity (

Table 6.1)

G

14

By: Dr. Tariq Darabseh

AET 2114

11/23/2014

6.4 Anelasticity

Up to this point, it is assumed that

Elastic deformation is time-independent

An applied stress produces an instantaneous elastic strain

Strain remains constant over the period of time the stress is maintained

Upon release of the load, strain is totally recovered (immediately returns

to zero)

In most engineering materials, there will also exist a time-dependent elastic

strain component , i.e.

elastic deformation will continue after stress application

Upon load release some finite time is required for complete recovery

Loading and unloading path are different

Anelasticity : time-dependent elastic behavior

For metals, the anelastic component is normally small and neglected.

For some polymers, it is significant and known as viscoelastic behavior

(Sec. 16.7)

15

6.5 Elastic Properties of Materials

Poissons ratio

lateral strain

axial strain

y

x

z

z

E = 2G(1 + )

Example 6.1

Example 6.2

16

By: Dr. Tariq Darabseh

AET 2114

11/23/2014

17

18

By: Dr. Tariq Darabseh

AET 2114

11/23/2014

19

PLASTIC DEFORMATION

By: Dr. Tariq Darabseh

For most metals, elastic deformation persists only to

strains of about 0.005

Plastic deformation

Stress not proportional to strain (Hookes law cease

to be valid)

Permanent

Nonrecoverable

Non-conservative

Transition from elastic to plastic deformation

Gradual for most metals

Some curvature results at the onset of plastic

deformation

20

10

AET 2114

11/23/2014

PLASTIC DEFORMATION (METALS)

1. Initial

2. Small load

bonds

stretch

& planes

shear

3. Unload

planes

still

sheared

plastic

elastic + plastic

F

Plastic means permanent!

linear

elastic

linear

elastic

plastic

21

3

PLASTIC (PERMANENT) DEFORMATION

(at lower temperatures, T < Tmelt/3)

Simple tension test:

Elastic+Plastic

at larger stress

tensile stress,

Elastic

initially

permanent (plastic)

after load is removed

engineering strain,

plastic strain

22

14

By: Dr. Tariq Darabseh

11

AET 2114

11/23/2014

Plastic deformation (Contd.)

From as atomic perspective

Plastic deformation corresponds to the breaking of bonds

with original atom neighbors

Reforming bonds with new neighbors

Large number of atoms and molecules move relative to one

another

Upon removal of stress, they do not return to their original

position

Mechanism of plastic deformation:

Crystalline Solids:

accomplished by a process called slip

Involves the motion of dislocations (Sec 7.2)

Non-crystalline solids (as well liquids)

23

Occurs by a viscous flow mechanism (Sec 13.9)

YIELD STRENGTH, y

Stress at which noticeable plastic deformation has

occurred.

when p = 0.002

tensile stress,

engineering strain,

p = 0.002

24

15

By: Dr. Tariq Darabseh

12

AET 2114

11/23/2014

6.6 Tensile Properties

YIELDING and YIELD STRESS

Typical stress strain behavior (Figure)

Proportional Limit (P)

Yielding

Yield strength

In most cases, the position of yield

point may not be determined

precisely.

Established convention: a straight

line is constructed parallel to the

elastic portion at some specified

strain offset, usually 0.002 (0.2%)

Fig. 6.10a corresponding

intersection point gives yield

strength.

25

6.6 Tensile Properties (Contd.)

Some steels and other materials exhibit the behavior as

shown in Fig 6.10b

The yield strength is taken as the average stress

that is associate with the lower yield point.

Magnitude of yield strength is a measure of its

resistance to plastic deformation

Range from 35 MPa to 1400 MPa

35 MPa for low-strength aluminum

1400 MPa for high-strength steel

26

By: Dr. Tariq Darabseh

13

AET 2114

11/23/2014

6.6 Tensile Properties (Contd.)

TENSILE STRENGTH

Tensile strength TS (MPa or psi)

is the stress at the maximum on

the engineering stress-strain curve

All deformation up to this point is

uniform.

Onset of necking at this stress at

some point all subsequent

deformation at this neck.

Range: 50 - 3000 MPa

50 MPa for aluminum

3000 MPa for high strength steel

27

Tensile Strength, TS

After yielding, the stress necessary to

continue plastic deformation in metals

increases to a maximum point (M) and

then decreases to the eventual fracture

point (F).

All deformation up to the maximum stress

is uniform throughout the tensile sample.

However, at max stress, a small

constriction or neck begins to form.

Subsequent deformation will be confined

to this neck area.

Fracture strength corresponds to the

stress at fracture.

Region between M and F:

Metals: occurs when noticeable necking starts.

Ceramics: occurs when crack propagation starts.

Polymers: occurs when polymer backbones are aligned and about to break.

By: Dr. Tariq Darabseh

28

14

AET 2114

11/23/2014

In an undeformed

thermoplastic polymer

tensile sample,

(a) the polymer chains are

randomly oriented.

(b) When a stress is

applied, a neck

develops as chains

become aligned locally.

The neck continues to

grow until the chains in

the entire gage length

have aligned.

(c) The strength of the

polymer is increased

29

Stress-Strain Diagram

ultimate

tensile

strength

UTS

necking

Strain

Hardening

yield

strength

Fracture

5

2

Elastic region

slope =Youngs (elastic) modulus

yield strength

Plastic region

ultimate tensile strength

strain hardening

fracture

Plastic

Region

Elastic

Region

E

E

By: Dr. Tariq Darabseh

1

E

y

2 1

4

Strain (

) (L/Lo)

15

AET 2114

11/23/2014

Stress-Strain Diagram (cont)

Elastic Region (Point 1 2)

- The material will return to its original shape

after the material is unloaded( like a rubber band).

- The stress is linearly proportional to the strain in

this region.

or

: Stress(psi)

E : Elastic modulus (Youngs Modulus) (psi)

: Strain (in/in)

- Point 2 : Yield Strength : a point where permanent

deformation occurs. ( If it is passed, the material will

no longer return to its original length.)

Stress-Strain Diagram (cont)

Strain Hardening

- If the material is loaded again from Point 4, the

curve will follow back to Point 3 with the same

Elastic Modulus (slope).

- The material now has a higher yield strength of

Point 4.

- Raising the yield strength by permanently straining

the material is called Strain Hardening.

By: Dr. Tariq Darabseh

16

AET 2114

11/23/2014

Stress-Strain Diagram (cont)

Tensile Strength (Point 3)

- The largest value of stress on the diagram is called

Tensile Strength(TS) or Ultimate Tensile Strength

(UTS)

- It is the maximum stress which the material can

support without breaking.

Fracture (Point 5)

- If the material is stretched beyond Point 3, the stress

decreases as necking and non-uniform deformation

occur.

- Fracture will finally occur at Point 5.

VMSE

http://www.wiley.com/college/callister/0470125373/vmse/index.htm

http://www.wiley.com/college/callister/0470125373/vmse/strstr.htm

34

By: Dr. Tariq Darabseh

17

AET 2114

11/23/2014

Example 1

Tensile Testing of Aluminum Alloy

Convert the change in length data in the table to engineering stress

and strain and plot a stress-strain curve.

Example 1 SOLUTION

By: Dr. Tariq Darabseh

18

AET 2114

11/23/2014

DUCTILITY, %EL

%EL

Plastic tensile strain at failure:

Engineering

tensile

stress,

Adapted from Fig. 6.13,

smaller %EL

(brittle if %EL<5%)

L f Lo

x100

Lo

Lo

larg er %EL

(ductile if

%EL>5%)

Ao

Af

Lf

Callister 6e.

Engineering tensile strain,

Another ductility measure:

%AR

Ao Af

x100

Ao

Note: %AR and %EL are often comparable.

--Reason: crystal slip does not change material volume.

--%AR > %EL possible if internal voids form in neck.

37

19

38

By: Dr. Tariq Darabseh

19

AET 2114

11/23/2014

Effect of Temperature

As with modulus of elasticity (E), the magnitudes of both

yield and tensile strengths decline with increasing

temperature

Ductility usually increases with temperature

Figure shown stress-strain behavior of iron

39

RESILIENCE

Resilience is the capacity of a material

to absorb energy when it is deformed

elastically and then, upon unloading, to

have this energy recovered.

Modulus of resilience (Ur)

Associated property

Area under the engineering stressstrain curve

Strain energy per unit volume

required to stress from an unloaded

state to yielding

Mathematically,

1

U r d y y y

2

2E

0

2

40

By: Dr. Tariq Darabseh

20

AET 2114

11/23/2014

Toughness is

the ability to

absorb energy

up to fracture

Toughness

Lower toughness: ceramics

Higher toughness: metals

(energy per unit

volume of material).

A tough

material has

strength and

ductility.

Approximated

by the area

under the

stress-strain

curve.

41

TOUGHNESS

Energy to break a unit volume of material

Approximate by the area under the stress-strain

curve.

Engineering

tensile

stress,

smaller toughness (ceramics)

larg er toughness

(metals, PMCs)

smaller toughnessunreinforced

polymers

Engineering tensile strain,

42

20

By: Dr. Tariq Darabseh

21

AET 2114

11/23/2014

TOUGHNESS

A measure of the ability of a material to absorb energy up to

fracture.

Specimen geometry and the manner of load application are

important in toughness determination:

Notch toughness: dynamic (high strain rate) loading, specimen

with notch (or point of stress concentration) (Sec 8.6)

Fracture toughness: property indicative of a materials resistance

to fracture when crack is present (Sec 8.5)

For static (low strain rate) condition, modulus of toughness is equal

to the total area under the stress-strain curve (up to fracture ):

For Ductile Material :

For Brittle Material:

U T u f

1

y (0.2%) u f

2

2

U T u f

3

43

6.7 True Stress and Strain

Engineering stress-strain curve

beyond maximum point (M) seems

to indicate that the material is

becoming weaker.

Not true, rather it becomes

stronger.

Since cross-sectional area is

decreasing at the neck reduces

load bearing capacity of the

F

T

material

Ai

True stress: Actual or current or

l

instantaneous force divided by the

l

A

D

dl

T

l li i ln l0i ln A0i 2 ln D0i

instantaneous cross-sectional area.

True Strain: Change in length per

Ai li A0l0

44

unit instantaneous length

i

By: Dr. Tariq Darabseh

22

AET 2114

11/23/2014

6.7 True Stress and Strain (Contd.)

Relation between two

definitions

Above equations are valid

only to the onset of necking;

beyond this point true stress

and strain should be

computed from actual load,

area and gauge length.

Schematic comparison in Figure

6.16

Corrected takes into

account complex stress

state with in neck region.

T ln(1 )

T (1 )

45

6.7 True Stress and Strain (Contd.)

For some metals and alloys, the true stressstrain curve is approximated as

Parameter n

strain-hardening exponent

A value less than unity

Slope on log-log plot

Parameter K

Known as strength coefficient

True stress at unit true strain

T K Tn

46

By: Dr. Tariq Darabseh

23

AET 2114

11/23/2014

47

6.8 Elastic Recovery During Plastic Deformation

Upon release of load,

some fraction of total

strain is recovered as

elastic strain

During unloading,

straight path parallel to

elastic loading

Reloading

Yielding at new yield

strength

48

By: Dr. Tariq Darabseh

24

AET 2114

11/23/2014

Strain Hardening

An increase in y due to

plastic deformation.

large hardening

y

1

y

small hardening

unloa

d

reload

T C T

true stress (F/A)

hardening exponent:

n= 0.15 (some steels)

to n= 0.5 (some copper)

true strain: ln(L/L o )

Strain Hardening (n, K or C values)

T C T

true stress (F/A)

By: Dr. Tariq Darabseh

hardening exponent:

n= 0.15 (some steels)

to n= 0.5 (some copper)

true strain: ln(L/L o )

50

25

AET 2114

11/23/2014

Example 2:

Youngs

Modulus - Aluminum Alloy

From the data in Example 1, calculate the modulus of elasticity

of the aluminum alloy.

Example 2: Youngs Modulus - Aluminum Alloy - continued

Use the modulus to determine the length after deformation of

a bar of initial length of 50 in.

Assume that a level of stress of 30,000 psi is applied.

By: Dr. Tariq Darabseh

26

AET 2114

11/23/2014

Example 3: True Stress and True Strain

Calculation

Compare engineering stress and strain with true stress and

strain for the aluminum alloy in Example 1 at (a) the maximum

load. The diameter at maximum load is 0.497 in. and at fracture

is 0.398 in.

Example 3 SOLUTION

Hardness

Hardness is a measure of a materials resistance to

localized plastic deformation (a small dent or scratch).

Quantitative hardness techniques have been

developed where a small indenter is forced into the

surface of a material.

The depth or size of the indentation is measured, and

corresponds to a hardness number.

The softer the material, the larger and deeper the

indentation (and lower hardness number).

54

By: Dr. Tariq Darabseh

27

AET 2114

11/23/2014

Hardness

Resistance to permanently indenting the surface.

Large hardness means:

--resistance to plastic deformation or cracking in

compression.

--better wear properties.

e.g.,

10mm sphere

apply known force

(1 to 1000g)

D

most

plastics

brasses

Al alloys

measure size

of indent after

removing load

Smaller indents

mean larger

hardness.

d

easy to machine

steels

file hard

cutting

tools

nitrided

steels

diamond

increasing hardness

55

Adapted from Fig. 6.18, Callister 6e. (Fig. 6.18 is adapted from G.F. Kinney, Engineering Properties and Applications of Plastics, p. 202, John Wiley and Sons, 1957.)

Hardness Testers

56

By: Dr. Tariq Darabseh

28

AET 2114

11/23/2014

57

Hardness: Measurement

Rockwell Scales

- Prepare surface: cleaning and polishing

No major sample damage (Nondestructive)

Each scale runs to 130 but only useful in range 20-100.

Rockwell Scales

Minor load 10 kg

Major load 60 (A), 100 (B) & 150 (C) kg

A = diamond, B = 1/16 in. ball, C = diamond

Ex: 80 HRB: Means Rockwell hardness of 80 on the B scale.

Chapter 6 -

By: Dr. Tariq Darabseh

58

29

AET 2114

11/23/2014

Hardness: Measurement

Brinell Scale: No major sample damage

HB = Brinell Hardness

TS (psia) = 500 x HB, TS: Tensile strength.

TS (MPa) = 3.45 x HB

Chapter 6 -

59

Chapter 6 -

60

Hardness: Measurement

Knoop and Vickers

No major sample damage

By: Dr. Tariq Darabseh

30

AET 2114

11/23/2014

6.12 DESIGN/SAFETY FACTORS

There will always be uncertainties in characterizing the magnitude of

applied loads and their associated stress levels for in-service

applications; ordinarily load calculations are only approximate

Alternatively, a safe stress or working stress, , is used instead of

design stress. This safe stress is based on the yield strength of the

material and is defined as the yield strength divided by a factor of

safety, N, or

61

62

By: Dr. Tariq Darabseh

31

AET 2114

11/23/2014

63

64

By: Dr. Tariq Darabseh

32

AET 2114

11/23/2014

65

66

By: Dr. Tariq Darabseh

33

AET 2114

11/23/2014

67

By: Dr. Tariq Darabseh

34

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- ACD2501 Day 6 Aircraft StructuresDocument71 pagesACD2501 Day 6 Aircraft StructuresMemyah AlNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Principles of CookingDocument32 pagesPrinciples of CookingMemyah AlNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Aircraft ComponentsDocument6 pagesAircraft ComponentsGeoffrey ArmstrongNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Introduction and Basic Concepts: Mehmet KanogluDocument32 pagesIntroduction and Basic Concepts: Mehmet KanogluRoshan ShanmughanNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Unit 1.1 DescribingGraphsscrambledDocument15 pagesUnit 1.1 DescribingGraphsscrambledhuytnNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Chapter 7 AET 2211Document10 pagesChapter 7 AET 2211Memyah AlNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Isa PDFDocument7 pagesIsa PDFairsorNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Quick Installation Guide: Wireless N Access Point Dap-1360Document40 pagesQuick Installation Guide: Wireless N Access Point Dap-1360Memyah AlNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- How Have Cell Phones Changed Our Life and Behaviors Socially and Mentally?Document5 pagesHow Have Cell Phones Changed Our Life and Behaviors Socially and Mentally?Memyah AlNo ratings yet

- Solution Practice Exam1Document4 pagesSolution Practice Exam1Memyah AlNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Cramer's RuleDocument22 pagesCramer's RuleMemyah AlNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Practice Exam1Document3 pagesPractice Exam1Memyah AlNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- DDDDDDDDD PrereDocument6 pagesDDDDDDDDD PrereMemyah AlNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Properties of The Standard Atmosphere (Metric)Document2 pagesProperties of The Standard Atmosphere (Metric)Memyah AlNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- HelloDocument1 pageHelloMemyah AlNo ratings yet

- Laboratory Experiment 2 (Magnetic Field)Document7 pagesLaboratory Experiment 2 (Magnetic Field)Memyah AlNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- How Have Cell Phones Changed Our Life and Behaviors Socially and Mentally?Document5 pagesHow Have Cell Phones Changed Our Life and Behaviors Socially and Mentally?Memyah AlNo ratings yet

- Air Pollution - Plume RiseDocument15 pagesAir Pollution - Plume RiseAmrut RajkarneNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Ref Compr Process 08 DatumDocument8 pagesRef Compr Process 08 DatumSugeng WahyudiNo ratings yet

- Re Engineering BookDocument117 pagesRe Engineering Bookroscilla100% (1)

- Advances in Concrete TechnologyDocument10 pagesAdvances in Concrete TechnologytusshaarpatilNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Diesel Fuel MSDS 2019Document12 pagesDiesel Fuel MSDS 2019bobNo ratings yet

- MS Notice 3 of 2014 - Bunker Audit PDFDocument12 pagesMS Notice 3 of 2014 - Bunker Audit PDFBala MuruganNo ratings yet

- Dangerous Goods Panel (DGP) : Working PaperDocument50 pagesDangerous Goods Panel (DGP) : Working PaperexpairtiseNo ratings yet

- Wall - Penstock - 200x200 1200x1200Document2 pagesWall - Penstock - 200x200 1200x1200Mohamed RamadanNo ratings yet

- 2 - Shell Momentum BalanceDocument34 pages2 - Shell Momentum BalanceAdheep DasNo ratings yet

- Prepared by Ray Delaforce For Internal Use OnlyDocument20 pagesPrepared by Ray Delaforce For Internal Use OnlyEdwin MariacaNo ratings yet

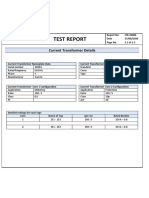

- Test Report: Current Transformer DetailsDocument3 pagesTest Report: Current Transformer DetailsJRC TestingNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Deophantine 6 ProblemsDocument231 pagesDeophantine 6 ProblemsCaro Kan LopezNo ratings yet

- Shaping SUEZ 2030 Presentation 20191002 ENDocument58 pagesShaping SUEZ 2030 Presentation 20191002 ENMohsin ModiNo ratings yet

- NJYB3Document3 pagesNJYB3Prime ProNo ratings yet

- Jordan Toward A 100% Renewable Electricity SystemDocument14 pagesJordan Toward A 100% Renewable Electricity SystemMinh Pháp VũNo ratings yet

- Classical Physics Prof. V. Balakrishnan Department of Physics Indian Institute of Technology, Madras Lecture No. # 38Document27 pagesClassical Physics Prof. V. Balakrishnan Department of Physics Indian Institute of Technology, Madras Lecture No. # 38Anonymous 8f2veZfNo ratings yet

- Bee PPT-1Document309 pagesBee PPT-1wondimagegn debebeNo ratings yet

- .Fabrication of Solar Air Cooler For Remote AreaDocument4 pages.Fabrication of Solar Air Cooler For Remote AreaAnonymous Clyy9NNo ratings yet

- The Harmonic Impact Project - IEEE-1459 Power Definitions Trialed in Revenue MetersDocument5 pagesThe Harmonic Impact Project - IEEE-1459 Power Definitions Trialed in Revenue MetersErika LeonNo ratings yet

- Introduction To The MTS-5000 PDFDocument71 pagesIntroduction To The MTS-5000 PDFJorge Michela ScarlazettaNo ratings yet

- Matlab CodeDocument3 pagesMatlab CodeAbdallAh ALi SmaDi50% (2)

- N 181 enDocument74 pagesN 181 enAbdoNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chapter 42 - Nuclear PhysicsDocument14 pagesChapter 42 - Nuclear PhysicsVV Cephei100% (3)

- Rd125lcii RZ125 Ypvs '86 1GL 1ga 2HKDocument49 pagesRd125lcii RZ125 Ypvs '86 1GL 1ga 2HKMohamad SyukhairiNo ratings yet

- Polymer ProcessingDocument28 pagesPolymer ProcessingMousom SomNo ratings yet

- Electrical Submersible Pumps DesigningDocument17 pagesElectrical Submersible Pumps Designingdhulfikarfadhil100% (1)

- HydrogenDocument38 pagesHydrogenClaudio Ibarra Casanova0% (2)

- Gen2 Otis PDFDocument6 pagesGen2 Otis PDFEng M ElseaidyNo ratings yet

- Schrack RelayDocument4 pagesSchrack RelaydadddooooNo ratings yet

- Hydraulic Fluid PDFDocument6 pagesHydraulic Fluid PDFSarah HayesNo ratings yet