Professional Documents

Culture Documents

Reuperacion SC (OTf) 3

Uploaded by

Tony Torrez Gonzalez0 ratings0% found this document useful (0 votes)

10 views3 pagesScandium triflate [Sc(OTf)3] has been found to be a recyclable catalyst for mild highly efficient methoxymethylation of alcohols using formaldehyde dimethyl acetal (FDMA). FDMA is an inexpensive reagent.

Original Description:

Original Title

Reuperacion Sc(OTf)3

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentScandium triflate [Sc(OTf)3] has been found to be a recyclable catalyst for mild highly efficient methoxymethylation of alcohols using formaldehyde dimethyl acetal (FDMA). FDMA is an inexpensive reagent.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views3 pagesReuperacion SC (OTf) 3

Uploaded by

Tony Torrez GonzalezScandium triflate [Sc(OTf)3] has been found to be a recyclable catalyst for mild highly efficient methoxymethylation of alcohols using formaldehyde dimethyl acetal (FDMA). FDMA is an inexpensive reagent.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

TETRAHEDRON

LETTERS

Pergamon

Tetrahedron Letters 44 (2003) 60516053

Scandium trifluoromethanesulfonate as a recyclable catalyst for

efficient methoxymethylation of alcohols

Babak Karimi* and Leyla Mamani

Department of Chemistry, Institute for Advanced Studies in Basic Sciences (IASBS), PO Box 45195 -159, Gava Zang,

Zanjan, Iran

Received 31 January 2003; revised 2 June 2003; accepted 13 June 2003

AbstractScandium triflate [Sc(OTf)3] has been found to be a recyclable catalyst for mild highly efficient methoxymethylation of

a variety of alcohols using formaldehyde dimethyl acetal (FDMA).

2003 Published by Elsevier Ltd.

Although tetrahydropyranylation is a commonly used

method for the protection of hydroxy functions,1

methoxymethylation has the advantage over tetrahydropyranylation in many instances because the latter

involves the formation of a new asymmetric center,

thus forming diastereomers when it is used for chiral

alcohols.2 Methoxymethyl (MOM) derivatives are frequently prepared by alkylation of alcohols with an

excess of chloromethyl methyl ether in alkaline solution.1,3 Because of the potent carcinogenic properties of

chloromethyl methyl ether,4 efforts were undertaken to

find an alternative safe method for the preparation of

MOM ethers. A few reports based on formaldehyde

dimethyl acetal (FDMA), an inexpensive reagent, have

appeared in the literature utilizing various catalysts

such as P2O5,5 p-toluenesulfonic acid,6 Nafion-H,7

TMSI,8 molybdenum(VI) acetyl acetonate,9 BF3,10

Envirocat,11 sulfated zirconia,12 expansive graphite,13

and FeCl3 dispersed on molecular sieves 3 A, .14 Very

recently, it has also been shown that methoxymethyl-2pyridyl sulfide (MOM-ON) is an efficient and neutral

methoxymethylating reagent when used in conjunction

with AgOTf, NaOAc and THF.15 However, although

these methods have shown an improvement in many

instances, many of them suffer from drawbacks such as

using stoichiometric amounts of expensive reagents,15

strong protic acid conditions or destruction of the

catalyst during the work-up procedure. Recently, scandium triflate has been introduced as a promising mild

and selective reagent for a variety of functional group

transformations.16 While most Lewis acids are decom-

* Corresponding author. Tel.: +98-241-4248013; fax: +98-2414249023; e-mail: karimi@iasbs.ac.ir

0040-4039/$ - see front matter 2003 Published by Elsevier Ltd.

doi:10.1016/S0040-4039(03)01481-3

posed or deactivated in the presence of water or protic

solvents, Sc(OTf)3 is stable and works as a Lewis acid

even in aqueous solutions.17 Thus, unlike other traditional Lewis acids, Sc(OTf)3 does not decompose under

aqueous work-up conditions and its recycling is often

possible. This makes Sc(OTf)3 relatively environmentally acceptable as a catalyst in functional group transformations. This catalyst has been successfully used for

a wide range of synthetic organic reactions,16 especially

as a Lewis acid in aldol condensation reactions,18

DielsAlder reactions,19 FriedelCrafts acylation,20

Michael reactions,21 and Fries rearrangements.22 There

is no report of the application of Sc(OTf)3 as a catalyst

for direct methoxymethylation of alcohols. In this

paper, we wish to disclose an efficient method for

preparing MOM ethers from alcohols by employing

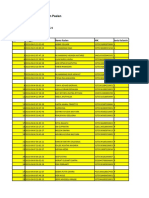

formaldehyde dimethyl acetal (FDMA) using a catalytic amount of Sc(OTf)3.23 Table 1 summarizes the

results and shows the efficiency of the present protocol

for both activated and deactivated benzyl alcohols

including sterically hindered ones such as 2,6dichlorobenzyl alcohol (entries 16).

Primary, as well as secondary alcohols effectively

reacted with an excess of FMDA and 5 mol% of

Sc(OTf)3 in refluxing CHCl3 to afford the corresponding MOM ethers in good to excellent yields (Table 1,

entries 713). It is worth mentioning that by employing

this protocol even hindered tertiary alcohols such as

1-adamantanol and 1-methyl cyclohexanol also furnished the corresponding MOM-ethers in satisfactory

yields (Table 1, entries 14, 15). Neither double bond

migration nor elimination was observed in the case of

either allylic or tertiary alcohols (Table 1, entries 12

6052

B. Karimi, L. Mamani / Tetrahedron Letters 44 (2003) 60516053

Table 1. Methoxymethylation of alcohols using FDMA in

the presence of Sc(OTf)3

In summary, we have demonstrated the use of Sc(OTf)3

for efficient methoxymethylation of a variety of alcohols under mild reaction conditions where the catalyst

could be readily recovered and reused thus making the

procedure environmentally acceptable. Further applications of Sc(OTf)3 especially based upon designing a new

auto-recycling catalytic system are currently underway

in our laboratory.

Acknowledgements

The authors acknowledge the Institute for Advanced

Studies in Basic Sciences (IASBS) Research Council for

support of this work.

References

14). However, our preliminary examination showed

that the method is not applicable for protection of

hydroxy groups in phenols, because mixtures of unidentified products were formed even at room temperature.

In this protocol, we have also found that Sc(OTf)3 can

be effectively recovered from the reaction mixture during the work-up procedure by simple evaporation of the

aqueous phase and drying the solid residue at 90C

overnight. The percentage recovery in most cases was

more than 91%. Moreover, efficient methoxymethylation of 4-nitrobenzyl alcohol using recovered Sc(OTf)3

clearly shows that the reactivity of the recovered catalyst does not change considerably after the work-up

(Table 1, entry 4). This undoubtedly renders the above

protocol environmentally acceptable.

1. (a) Greene, T. W.; Wuts, P. G. M. Protective Groups in

Organic Synthesis, 2nd ed.; Wiley: New York, 1991; (b)

Kocienski, P. J. Protecting Groups; Thieme: Stuttgart,

1994.

2. Reese, C. B.; Saffhill, R.; Sulton, J. E. J. Am. Chem. Soc.

1967, 89, 33663368.

3. Herz, J. E.; Lucero, J.; Santoyo, Y.; Waight, E. S. Can. J.

Chem. 1971, 49, 24182419.

4. Occupational Safety and Health Administration, U.S.

Department of Labor, Federal Register 39 (20); US Government Printing Office: Washington, DC, 1974.

5. Fuji, K.; Nakano, S.; Fujita, E. Synthesis 1975, 276277.

6. Yarley, J. P.; Fletcher, H. Synthesis 1976, 244.

7. Olah, G. A.; Husain, A.; Gupta, B. G. B.; Narang, S. C.

Synthesis 1981, 471472.

8. Olah, G. A.; Husain, A.; Narang, S. C. Synthesis 1983,

896897.

9. Kantam, M. L.; Santhi, P. L. Synlett 1993, 429430.

10. Danheiser, R. L.; Romines, K. R.; Koyama, H.; Gee, S.

K.; Johnson, C. R.; Medich, J. R. Org. Synth. 1992, 71,

133139.

11. Bandgar, B. P.; Hajare, C. T.; Wadgaonkar, P. P. J.

Chem. Res. (S) 1996, 9091.

12. Jin, T. S.; Guo, J. J.; Yin, Y. H.; Zhang, S. L.; Li, T. S.

J. Chem. Res. (S) 2002, 188189.

13. Jin, T. S.; Li, T. S.; Gao, Y. T. Synth. Commun. 1998, 28,

837841.

14. Patney, H. K. Synlett 1992, 567568.

15. Marcune, B. F.; Karady, S.; Dolling, U. H.; Novak, T. J.

J. Org. Chem. 1999, 64, 24462449.

16. For a review, see: Kobayashi, S. Eur. J. Org. Chem. 1999,

1, 1527 and also see: Kobayashi, S.; Sugiura, M.; Kitagawa, H.; Lam, W. W.-L. Chem. Rev. 2002, 102, 2227

2302.

17. Kobayashi, S. Synlett 1994, 689701.

18. Crotti, P.; Bussol, V. D.; Favero, L.; Psero, M. J. Org.

Chem. 1996, 61, 95489552.

19. Kobayashi, S.; Hachiya, I.; Araki, M.; Ishitani, H. Tetrahedron Lett. 1993, 34, 37553758.

20. Kawada, A.; Mitamura, S.; Kobayashi, S. Synlett 1994,

545546.

21. Kobayashi, S.; Hachiya, I.; Ishitani, H.; Araki, M. Synlett 1993, 472474.

B. Karimi, L. Mamani / Tetrahedron Letters 44 (2003) 60516053

22. Kobayashi, S.; Moriwaki, M.; Hachiya, I. J. Chem. Soc.,

Chem. Commun. 1995, 15271528.

23. General procedure for the preparation of MOM ethers:

To a solution of alcohol (2 mmol) and FDMA (100

mmol) in CHCl3, Sc(OTf)3 (0.1 mmol) was added and the

mixture was stirred at reflux until complete disappearance

of starting alcohol (as monitored by TLC). After completion, the reaction was quenched with distilled water (20

mL), and the mixture was extracted with CHCl3 (230

6053

ml). The aqueous layer was separated and evaporated

under reduced pressure to afford the recycled catalyst.

The organic layer was washed successively with a 10%

aqueous solution of NaOH (25 mL) and water (15 ml)

and dried over anhydrous Na2SO4. Evaporation of the

solvent under reduced pressure gave the almost pure

MOM ether. Further purification of products could be

achieved by vacuum distillation or recrystallization to

afford the corresponding pure MOM ethers (Table 1).

You might also like

- M. Curini, F. Epifano, S. Genovese, M.C. Marcotullio, O. Rosati. Ytterbium Triflate-Promoted TandemDocument3 pagesM. Curini, F. Epifano, S. Genovese, M.C. Marcotullio, O. Rosati. Ytterbium Triflate-Promoted TandemMariel MedinaNo ratings yet

- Demethylation With LiCl-DMF (JMolCatA-Chemical2007)Document8 pagesDemethylation With LiCl-DMF (JMolCatA-Chemical2007)Archawin_mooNo ratings yet

- Reaksi PA Dan ButanolDocument5 pagesReaksi PA Dan ButanolUnlucky 2019No ratings yet

- Modification of The Hofmann Rearrangement, Synthesis of Methyl CarbamatesDocument3 pagesModification of The Hofmann Rearrangement, Synthesis of Methyl CarbamatesIsmet KutlukNo ratings yet

- Microwave-Assisted Synthesis of Dihydropyrimidin-2 (1H) - Ones Using Graphite Supported Lanthanum Chloride As A Mild and e Cient CatalystDocument3 pagesMicrowave-Assisted Synthesis of Dihydropyrimidin-2 (1H) - Ones Using Graphite Supported Lanthanum Chloride As A Mild and e Cient CatalystnileshsalunkheNo ratings yet

- Efficient Synthesis of 3-Cyano-6 - (2-Hydroxyphenyl) Pyridines by Multi-Component Condensations On BeadsDocument3 pagesEfficient Synthesis of 3-Cyano-6 - (2-Hydroxyphenyl) Pyridines by Multi-Component Condensations On BeadsBandita DattaNo ratings yet

- Transition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesFrom EverandTransition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesNo ratings yet

- Transition Metal Compound Mediated Reduction Of In Water: Α-Amino Acids To 1,2-Amino Alcohols With NabhDocument4 pagesTransition Metal Compound Mediated Reduction Of In Water: Α-Amino Acids To 1,2-Amino Alcohols With NabhBandita DattaNo ratings yet

- Microwave Promoted Efficient Synthesis of Substituted Uracils and Thiouracils Under Solvent-Free ConditionsDocument7 pagesMicrowave Promoted Efficient Synthesis of Substituted Uracils and Thiouracils Under Solvent-Free ConditionsCarlos AcevedoNo ratings yet

- qiao2011Document4 pagesqiao2011Isai MarloNo ratings yet

- Akhlaghinia-2009 (Iodacao de Arenos)Document6 pagesAkhlaghinia-2009 (Iodacao de Arenos)tenorio pauloNo ratings yet

- Amantini 2001Document4 pagesAmantini 2001AMNo ratings yet

- Efficient and Convenient Oxidation of AlcoholsDocument5 pagesEfficient and Convenient Oxidation of AlcoholsMedNo ratings yet

- TricicloclavupdfDocument2 pagesTricicloclavupdfOscar Martin OrdoñezNo ratings yet

- Hydrogen Peroxide Oxidation Catalyzed by Heteropoly Acids CombinedDocument7 pagesHydrogen Peroxide Oxidation Catalyzed by Heteropoly Acids Combinedgiordan_13No ratings yet

- Thiols Formation in Presence of K2co3Document5 pagesThiols Formation in Presence of K2co3Harjinder Singh BhatiaNo ratings yet

- Synthesis of Monoacylated Derivatives of 1,2-CyclohexanediamineDocument4 pagesSynthesis of Monoacylated Derivatives of 1,2-CyclohexanediamineDiogo DiasNo ratings yet

- Pivaloyl chloride/DMF reagent converts alcohols to chloridesDocument3 pagesPivaloyl chloride/DMF reagent converts alcohols to chloridesalchymystNo ratings yet

- Jo 0503299Document6 pagesJo 0503299Kyucheol PaikNo ratings yet

- Supramolecular Receptors in Solid Phase For Anionic Radionuclides SeperationDocument10 pagesSupramolecular Receptors in Solid Phase For Anionic Radionuclides SeperationFranx KpdxNo ratings yet

- Thalidomide From Liquid AmmoniaDocument4 pagesThalidomide From Liquid AmmoniaFurphy1No ratings yet

- Influence of Protecting Groups on the Selectivity of Addition of Amines to Vinyl Sulfone-Modified CarbohydratesDocument12 pagesInfluence of Protecting Groups on the Selectivity of Addition of Amines to Vinyl Sulfone-Modified CarbohydratesSilvanaMedhatNo ratings yet

- Highly Selective Methodology For The Direct Conversion of Aromatic Aldehydes To Glycol Monoesters - Sharghi (2003)Document4 pagesHighly Selective Methodology For The Direct Conversion of Aromatic Aldehydes To Glycol Monoesters - Sharghi (2003)marcelw11No ratings yet

- Metathesis of Unsaturated Fatty Acids: Synthesis of Long-Chain Unsaturated-αDocument6 pagesMetathesis of Unsaturated Fatty Acids: Synthesis of Long-Chain Unsaturated-αannisak fitriyanaNo ratings yet

- 4-Hydroxy-3-Methyl-6-Phenylbenzofuran-2-Carboxylic Acid Ethyl Ester Derivatives As Potent Anti-Tumor AgentsDocument4 pages4-Hydroxy-3-Methyl-6-Phenylbenzofuran-2-Carboxylic Acid Ethyl Ester Derivatives As Potent Anti-Tumor AgentsShubham RayNo ratings yet

- SnCll2EsterificationKineticBiodiese CardosoDkk2009Document5 pagesSnCll2EsterificationKineticBiodiese CardosoDkk2009saitama_brahmaNo ratings yet

- Manuscript DraftDocument20 pagesManuscript DraftsadaNo ratings yet

- Efficient Synthesis of 1,5-BenzodiazepinesDocument3 pagesEfficient Synthesis of 1,5-BenzodiazepinesdoubleffectNo ratings yet

- Lanthanide Amides ( (Me Si) N) Ln (μ-Cl) Li (THF) Catalyzed Hydrophosphonylation of Aryl AldehydesDocument4 pagesLanthanide Amides ( (Me Si) N) Ln (μ-Cl) Li (THF) Catalyzed Hydrophosphonylation of Aryl AldehydesDiogomussumNo ratings yet

- A Convenient Modification of The Fischer Indole Synthesis PDFDocument6 pagesA Convenient Modification of The Fischer Indole Synthesis PDFUlises González Martínez100% (1)

- Ylva E. Bergman, Roger Mulder and Patrick Perlmutter - Total Synthesis of 20-Norsalvinorin A. 1. Preparation of A Key IntermediateDocument4 pagesYlva E. Bergman, Roger Mulder and Patrick Perlmutter - Total Synthesis of 20-Norsalvinorin A. 1. Preparation of A Key IntermediateBic0000No ratings yet

- Journal of Molecular Catalysis A: ChemicalDocument10 pagesJournal of Molecular Catalysis A: ChemicalAlina IonNo ratings yet

- Heliyon: Research ArticleDocument8 pagesHeliyon: Research ArticleRicardo AndradeNo ratings yet

- An Easy Microwave-Assisted Synthesis of Sulfonamides Directly From Sulfonic AcidsDocument3 pagesAn Easy Microwave-Assisted Synthesis of Sulfonamides Directly From Sulfonic AcidsVirender KumarNo ratings yet

- Rajguru2013 Article Solvent-freeGreenAndEfficientSDocument6 pagesRajguru2013 Article Solvent-freeGreenAndEfficientSGanesamoorthy ThirunarayananNo ratings yet

- Carrira GlycosideDocument3 pagesCarrira GlycosideYasser SamirNo ratings yet

- 1-s2.0-S0022286023020987-mainDocument9 pages1-s2.0-S0022286023020987-mainbellaoui.batounNo ratings yet

- Recent Advances in The Hydrosilylation of AlkynesDocument4 pagesRecent Advances in The Hydrosilylation of AlkynesjavasoloNo ratings yet

- SEMINARDocument13 pagesSEMINARHamidNo ratings yet

- Photochemical Hydroxylation of 1-Methyl-9,10-Anthraquinones: Synthesis of 9 - Hydroxyaloesaponarin IIDocument5 pagesPhotochemical Hydroxylation of 1-Methyl-9,10-Anthraquinones: Synthesis of 9 - Hydroxyaloesaponarin IISilvanaMedhatNo ratings yet

- Molbank 2014 M819Document3 pagesMolbank 2014 M819Anouar AlamiNo ratings yet

- Diazotazione NaNO2 NaHSO3Document3 pagesDiazotazione NaNO2 NaHSO3leda_prandiNo ratings yet

- Anal. Chem. 2000, 72, 3902-3907Document6 pagesAnal. Chem. 2000, 72, 3902-3907cullen bohannonNo ratings yet

- Enantioselective Intermolecular (2 + 2) - Photocycloaddition Reactions of Alkenes and A 2-Quinolone in SolutionDocument2 pagesEnantioselective Intermolecular (2 + 2) - Photocycloaddition Reactions of Alkenes and A 2-Quinolone in SolutionM PadilNo ratings yet

- Nucleosidic Phosphoramidite Synthesis Via PhosphitylationDocument8 pagesNucleosidic Phosphoramidite Synthesis Via PhosphitylationClarence AG YueNo ratings yet

- TEMPODocument16 pagesTEMPOVirat KohNo ratings yet

- A Mild and Efficient Method For Aromatic Chlorination of Electron-Rich Arylalkyl AminesDocument3 pagesA Mild and Efficient Method For Aromatic Chlorination of Electron-Rich Arylalkyl AmineskispsNo ratings yet

- 1H, 2,4 TriazoleDocument7 pages1H, 2,4 TriazoleStas BulgariNo ratings yet

- Joctamiflu PDFDocument8 pagesJoctamiflu PDFFikriansyah Bin IrmanNo ratings yet

- THE STRUCTURE OF METOPON - J. Am. Chem. Soc., 1953, 75 (17), PP 4373-4374Document2 pagesTHE STRUCTURE OF METOPON - J. Am. Chem. Soc., 1953, 75 (17), PP 4373-4374muopioidreceptorNo ratings yet

- Introduction of A New High Yielding Method For The Synthesis of 1, 8-Dioxo-Octahydroxanthenes Using W-Doped Zno NanocompositeDocument9 pagesIntroduction of A New High Yielding Method For The Synthesis of 1, 8-Dioxo-Octahydroxanthenes Using W-Doped Zno NanocompositeAnaGomezNo ratings yet

- A General Procedure For Mitsunobu Inversion of Sterically Hindered Alcohols - Inversion of Menthol. (1S, 2S, 5R) - 5-Methyl-2 - (1-Methylethyl) Cyclohexyl 4-Nitrobenzoate PDFDocument4 pagesA General Procedure For Mitsunobu Inversion of Sterically Hindered Alcohols - Inversion of Menthol. (1S, 2S, 5R) - 5-Methyl-2 - (1-Methylethyl) Cyclohexyl 4-Nitrobenzoate PDFthamtusieuquayNo ratings yet

- Syntheses of The Enantiomers of 1-Deoxynojirimycin and 1-Deoxyaltronojirimycin Via Chemo-And Diastereoselective Olefinic Oxidation of Unsaturated AminesDocument14 pagesSyntheses of The Enantiomers of 1-Deoxynojirimycin and 1-Deoxyaltronojirimycin Via Chemo-And Diastereoselective Olefinic Oxidation of Unsaturated AminesDiogo DiasNo ratings yet

- A Simple and Straightforward Approach To Quinoxalines by Iron/Sulfur-Catalyzed Redox Condensation of o Nitroanilines and PhenethylaminesDocument4 pagesA Simple and Straightforward Approach To Quinoxalines by Iron/Sulfur-Catalyzed Redox Condensation of o Nitroanilines and PhenethylaminesClaudia BocanegraNo ratings yet

- Efficient Synthesis, Anti-Inflammatory and Antibacterial Properties of 9 - Aryl-6 - (3-Methylphenyl) (1,2,4) Triazolo (4,3-A) QuinolinesDocument8 pagesEfficient Synthesis, Anti-Inflammatory and Antibacterial Properties of 9 - Aryl-6 - (3-Methylphenyl) (1,2,4) Triazolo (4,3-A) QuinolinesIJAR JOURNALNo ratings yet

- Isobe 2005Document7 pagesIsobe 2005Nguyễn Minh ThôngNo ratings yet

- European Polymer Journal: Christian Hahn, Sebastian Wesselbaum, Helmut Keul, Martin MöllerDocument11 pagesEuropean Polymer Journal: Christian Hahn, Sebastian Wesselbaum, Helmut Keul, Martin MöllerShanti Astuti MustafaNo ratings yet

- Batch Salicylic Acid Nitration OPRD2006Document6 pagesBatch Salicylic Acid Nitration OPRD2006Tanushree DebnathNo ratings yet

- Quinon RespiratoryDocument12 pagesQuinon RespiratoryMika MargaretaNo ratings yet

- Carbohydrate Chemistry—8: Plenary Lectures Presented at the Eighth International Symposium on Carbohydrate Chemistry, Kyoto, Japan 16 - 20 August 1976From EverandCarbohydrate Chemistry—8: Plenary Lectures Presented at the Eighth International Symposium on Carbohydrate Chemistry, Kyoto, Japan 16 - 20 August 1976K. OnoderaNo ratings yet

- Travel Guide: Jomalig IslandDocument36 pagesTravel Guide: Jomalig IslandBea RomeroNo ratings yet

- MasterFlow 932 An 010 028Document19 pagesMasterFlow 932 An 010 028nsriitm100% (3)

- Stormwater Management:: What Stormwater Management Is and Why It Is ImportantDocument4 pagesStormwater Management:: What Stormwater Management Is and Why It Is ImportantMeenatchiNo ratings yet

- Wbscte - Gpa SystemDocument39 pagesWbscte - Gpa SystemnurNo ratings yet

- OISD safety standards for oil and gas installations layoutDocument31 pagesOISD safety standards for oil and gas installations layoutहेमंत कुमार मीणाNo ratings yet

- Blu VisionDocument8 pagesBlu VisionAnonymous HKuYF6kNo ratings yet

- Question & Answer - Module 1 NACEDocument6 pagesQuestion & Answer - Module 1 NACEraghuvarma0% (1)

- Green Synthesis of Antioxidants Using Ionic Liquid CatalystDocument7 pagesGreen Synthesis of Antioxidants Using Ionic Liquid Catalystchannie_amecaNo ratings yet

- Building a bridge strategy for residual waste managementDocument22 pagesBuilding a bridge strategy for residual waste managementFernanda BenedettiNo ratings yet

- Shell Tellus S2 M 46 MSDSDocument13 pagesShell Tellus S2 M 46 MSDSThomas FungNo ratings yet

- Sanitary Ni Crist PDFDocument1 pageSanitary Ni Crist PDFJun MichaelNo ratings yet

- BCA Green Mark For Districts (Version 2.0)Document24 pagesBCA Green Mark For Districts (Version 2.0)duygu cinar umduNo ratings yet

- SMR System DAO 2003-27 2nd QTR Apr To June 2011Document14 pagesSMR System DAO 2003-27 2nd QTR Apr To June 2011Luis UrzoNo ratings yet

- Manual WIKO BloomDocument236 pagesManual WIKO BloompablocobisaNo ratings yet

- (Doi 10.1002 - 0471238961.0308121518090308.a01) Richey, W. Frank - Kirk-Othmer Encyclopedia of Chemical Technology - Chlorohydrins PDFDocument14 pages(Doi 10.1002 - 0471238961.0308121518090308.a01) Richey, W. Frank - Kirk-Othmer Encyclopedia of Chemical Technology - Chlorohydrins PDFWidya Isti AriantiNo ratings yet

- Background Report For The National Dialogue On PaintDocument82 pagesBackground Report For The National Dialogue On PaintMSCT TrainingNo ratings yet

- Mor Et Al., (2006)Document22 pagesMor Et Al., (2006)Fatin Al-Khuza'iNo ratings yet

- Sanitation Presentation 2.0Document40 pagesSanitation Presentation 2.0rajvie2000No ratings yet

- Eia On Galachipa Bridge Project Bangladesheia On Galachipa Bridge Project BangladeshDocument3 pagesEia On Galachipa Bridge Project Bangladesheia On Galachipa Bridge Project BangladeshropovevNo ratings yet

- Statement-I Consolidated Fund of TamilnaduDocument3 pagesStatement-I Consolidated Fund of TamilnadukanaharajNo ratings yet

- BASIC PLUMBING SKILLSDocument1 pageBASIC PLUMBING SKILLSFREDERICK DELA CRUZNo ratings yet

- PRS Neoloy BrochureDocument12 pagesPRS Neoloy BrochureMulsa KTGNo ratings yet

- Eoa Peg-4000 (En) MsdsDocument7 pagesEoa Peg-4000 (En) MsdsNisa SutopoNo ratings yet

- SSB International School Semester 2 First Preparatory Exam Class X Date and SubjectDocument2 pagesSSB International School Semester 2 First Preparatory Exam Class X Date and Subjectkaran sharmaNo ratings yet

- Bihar State Pollution Control Board: IlleeDocument2 pagesBihar State Pollution Control Board: Illeekrish659No ratings yet

- IELTS Writing Task 2 Model Answer - Disposing of Waste On Streets Has Become A Common Problem in Many Countries These Days - IELTS ONLINE PRACTICEDocument8 pagesIELTS Writing Task 2 Model Answer - Disposing of Waste On Streets Has Become A Common Problem in Many Countries These Days - IELTS ONLINE PRACTICEFotini KalaiNo ratings yet

- Laporan Harian Pasien Puskesmas JatinegaraDocument8 pagesLaporan Harian Pasien Puskesmas JatinegaraanggaNo ratings yet

- It Is An Ornamentation of Textiles and Other Materials With NeedleworkDocument4 pagesIt Is An Ornamentation of Textiles and Other Materials With NeedleworkNiss VillasordaNo ratings yet

- The Audition: An Actress' Solo PerformanceDocument0 pagesThe Audition: An Actress' Solo PerformanceMicky MihalacheNo ratings yet

- Case Study Hotel The OrchidDocument5 pagesCase Study Hotel The Orchidkkarankapoor100% (4)