Professional Documents

Culture Documents

RA 002 - HFO Line Pressure Test

Uploaded by

dassi99Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RA 002 - HFO Line Pressure Test

Uploaded by

dassi99Copyright:

Available Formats

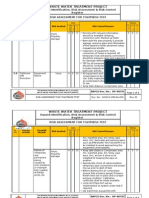

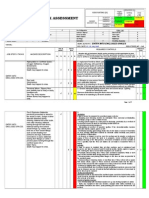

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

RISK MANAGEMENT

Operation / Work activity being assessed:

Generated by: Vessel

RA Code number:

Pressure test of HFO Line

Routine

Non-routine

Office

(record the name)

ALTERNATIVE WAYS TO CONDUCT THE WORK (Prior to deciding to proceed with the work always ensure that all other alternatives methods

for carrying out the job have been identified and documented )

No alternative way available to conduct the task.

FREQUENCY CATEGORY

CONSEQUENCE CATEGORY

Frequent - Possibility of

repeated incidents

Probable - Possibility of

isolated incidents

More often than

once per voyage

Once per year

Occasional- Possibility of

occurring sometime

Once per 5 years

Remote- Not likely to occur

Once per 10 years

Very unlikely- Practically

impossible

Once per 30 years

or more

CECONSEQUEN

1

2

3

4

Human losses / fatalities

Major pollution /

Full scale response

Serious injury to

personnel

Moderate pollution/

Significant resources commitment

Number of minor

injuries / Medical

treatment for personnel

Little pollution /

Limited response of short duration

Little cost or damage

($10000 $ 100000)

Slight impact

Few minor injuries

Minimum pollution /

Little or no response needed

Minimum cost /

damage

< $10000

Zero impact

1

L (1)

L (2)

RISK MATRIX

FREQUENCY

2

3

L (2)

L (3)

M(4)

M(6)

4

M (4)

H(8)

5

M (5)

H(10)

L(3)

M(6)

H(9)

H(12)

H(15)

M(4)

H(8)

H(12)

H(16)

H(20)

Excessive/ high cost

damage >$1000000

Moderate cost or

damage

(100000 1000000$)

Major national &

international impact

Considerable

impact

High=Intolerable Risk Medium=Tolerable Risk Low=Negligible Risk

Risk Assessment

Risk Identification

No

Hazard

Lack or no adequate plan for the work

H.F.O spill through a blind flanges/sensor

connections, manometer / Uncontrolled leakage of oil

Issue No. / Date: 1 / 02.07

Risk Analysis

Potential

hazardous event

Delays, confusion,

Crew injury, Pollution

Pollution

Existing control measures

- The working plan will be

communicated prior the job

commences to the participants.

- The hazards identified by the JHA

/P004 and RA ,will be discussed and

analyzed to the persons involved in

the job

- SMPEP/SOPEP equipment will be

available and personnel at every

manifold, at both passageways,

Forward pump room, Engine room,

during the test. All the drain plugs

around the ship will be rechecked/

plugged. St/by person at engine

control room for opening the filling

Revision No. / Date: 2 / 05.14

Initial risk

evaluation

F

Page 1 of 4

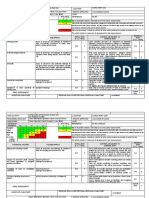

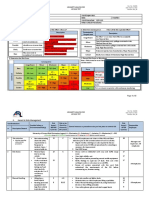

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

Risk Assessment

Risk Identification

No

Hazard

Risk Analysis

Potential

hazardous event

Fire, due to FO leakage and static electricity

4.

During air release through the vent valves sudden FO

splash on the face/eyes of the stby person

Pollution

A drain line pipe broke and a small capacity of HFO

dropped overboard

Pollution

Air pocket in the pipe pressurized air

Pressurized media/overpressure

Adverse weather / sea condition

Inaccurate pressure gauge readings

Issue No. / Date: 1 / 02.07

Crew member injury

Hammer effect

/Pollution

Pollution

Pollution / crew

member injury

Pollution / crew

member injury

Existing control measures

valve and release of pressure.

If a leakage has been identified ,then,

following the necessary repairs the

pressure testing should be repeated

Portable & Fixed fire fighting system

equipment stby and readily available

Glasses and all required PPE in use

according PPE matrix

- Crew will respond as per SMPEP

plan.

- The stby person at the ECR we will

be immediately informed to open the

filling v/v for pipe pressure release.

- Fill piping with FUEL OIL, by using

the F.O transfer pump, taking care to

eliminate all possible air pockets that

remain in the pipe before raising the

pressure (By air venting).

- After filling the pipelines with the fuel

oil, stop the pump, isolate the end of

piping to be tested and increase

pressure with the hydraulic oil pump.

- The proper operation of the

associated fuel oil valves should be

checked prior to testing.

- Until the maximum pressure is

reached (at 100% of their rated

working pressure), persons should be

at a safe distance form the tested

pipeline, maintaining though visual

contact.

- Monitor the pressure inside the pipe

by using remote pressure indicators.

- When the max. pressure is

reached ,maintain the pressure for

about 10-15 minutes.

- Five minutes after the max pressure

should be reduced to aprox. 2 bar in

the line prior a closer inspection taking

place

The work should be carried out during

day light and under favorable

sea/weather conditions in open sea.

Prior to commence the pressure test

Ch. Eng will confirm that the accuracy

of the pressure gauges ( follows

company procedures for the

Revision No. / Date: 2 / 05.14

Initial risk

evaluation

F

Page 2 of 4

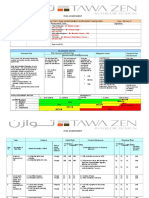

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

Risk Assessment

Risk Identification

No

10

Hazard

Crew fatigue and inexperienced of the persons carry

out the job.

Risk Analysis

Potential

hazardous event

Crew injury, delays.

Initial risk

evaluation

Existing control measures

calibration of all pressure gauges)

a. Only well rested personnel

will participate in the job.

b. Experience personnel will

participate in the job.

Note F: Frequency, C: Consequence, R: Risk

Notes: (1) This Form should be filed onboard in File M27 & E5.

Risk Treatment

Hazard

No.

Additional Risk Control Measures

Residual risk

evaluation

Responsible

*Action

Timeline

Note F: Frequency, C: Consequence, R: Risk

Contingency plans (to facilitate safe management and recovery of the situation in case of any unplanned occurrences)

Emergency case

Contingency Plans

A drain line pipe broke and a small capacity of HFO dropped overboard.

Crew will respond as per SMPEP/SOPEP Plan.

The stand/by person at Engine Control Room we be immediately informed to open the filling

valve.

Risk Assessment reviewed/approved by:

Name

Rank / Title

Signature

Date

Please enter below the persons who will be

involved in the job:

Remarks:

*Action timeline : Ensure the close out of the preventive actions prior to commencement of work.

Verification (Master and the Officer in Charge) that all control measure are fully implemented prior work commencing.

Name

Rank / Title

Signature

Date

Office verification reviewed/approved by:

Name

Issue No. / Date: 1 / 02.07

Rank / Title

Signature

Revision No. / Date: 2 / 05.14

Date

Page 3 of 4

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

*Action timeline : Ensure the close out of the preventive actions prior to commencement of work.

Issue No. / Date: 1 / 02.07

Revision No. / Date: 2 / 05.14

Page 4 of 4

You might also like

- RA 002 - Engine Casing Exhaust Funnel - Hot WorkDocument6 pagesRA 002 - Engine Casing Exhaust Funnel - Hot Workdassi99No ratings yet

- Risk Assessment for LPSG Steam Pipe Hot Work in ERDocument6 pagesRisk Assessment for LPSG Steam Pipe Hot Work in ERdassi99No ratings yet

- DOT TANK INSPECTION RISK ASSESSMENTDocument6 pagesDOT TANK INSPECTION RISK ASSESSMENTdassi99100% (1)

- RA For High Pressure Cleaning Using HPCE 520-330Document3 pagesRA For High Pressure Cleaning Using HPCE 520-330George CristianNo ratings yet

- RA 002 - BunkeringDocument5 pagesRA 002 - Bunkeringdassi99No ratings yet

- Risk Assessment For Tightness TestDocument8 pagesRisk Assessment For Tightness TestAriel Dela Cruz100% (1)

- PTSB (Jsa Form)Document5 pagesPTSB (Jsa Form)hanujaNo ratings yet

- Conversion Table For PressureDocument4 pagesConversion Table For Pressuredassi99No ratings yet

- Risk Asses 53-GPR Fitting AssemblyDocument6 pagesRisk Asses 53-GPR Fitting AssemblyRochdi BahiriNo ratings yet

- Risk Assessment For Air BlowingDocument8 pagesRisk Assessment For Air BlowingAriel Dela Cruz100% (5)

- PT. SWIBER BERJAYA CHECK PPE & CONTROLS REQUIREDDocument1 pagePT. SWIBER BERJAYA CHECK PPE & CONTROLS REQUIREDDevi Ratna Pratiwi0% (1)

- Risk Assessment for Vessel Approaching InstallationDocument2 pagesRisk Assessment for Vessel Approaching InstallationDevi Ratna PratiwiNo ratings yet

- Crane Operations Risk Assessments For Lift RA4Document2 pagesCrane Operations Risk Assessments For Lift RA4MAB AliNo ratings yet

- Ejemplos de Risk Assessment PDFDocument33 pagesEjemplos de Risk Assessment PDFJhon Oleg Ramos100% (2)

- Risk Assessment No. 39 WELDING IN GENERAL Rev. 02 20.03.09Document2 pagesRisk Assessment No. 39 WELDING IN GENERAL Rev. 02 20.03.09Devi Ratna Pratiwi100% (2)

- Risk Assess - 98-Installation Fuel Oil ConditioniDocument4 pagesRisk Assess - 98-Installation Fuel Oil ConditioniRochdi BahiriNo ratings yet

- Risk Assessment For Pov TestingDocument9 pagesRisk Assessment For Pov TestingvinodhyperNo ratings yet

- Risk Assessment: Pick & Carry CranesDocument36 pagesRisk Assessment: Pick & Carry CranesAbd Ennacer100% (2)

- Risk Assessment - Drain Pipe Connection at MLSDocument8 pagesRisk Assessment - Drain Pipe Connection at MLS逍逾No ratings yet

- Pipelines and Flowlines Cold Cutting ProcedureDocument27 pagesPipelines and Flowlines Cold Cutting ProcedureSuresh Kumar GNo ratings yet

- Confined Space Entry For Painting Inside PontoonDocument4 pagesConfined Space Entry For Painting Inside PontoonAchalere Shekhar KashinathNo ratings yet

- IOGP 577 - Fabrication Site Construction Safety Recommeded PracticesDocument44 pagesIOGP 577 - Fabrication Site Construction Safety Recommeded PracticesTuripno100% (1)

- JSA Pressure TestingDocument1 pageJSA Pressure TestingScott Mills100% (1)

- RISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023Document6 pagesRISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023arabiangulfdoorest2008No ratings yet

- 05.JHA-Site Survey For TR-9702A Transformer Marshalling Box Wiring Verification at Substation EDocument5 pages05.JHA-Site Survey For TR-9702A Transformer Marshalling Box Wiring Verification at Substation EFrancis Enriquez TanNo ratings yet

- STC5 Risk Management and Safe Work ProcedureDocument36 pagesSTC5 Risk Management and Safe Work ProcedureDenise Isebella LeeNo ratings yet

- Confined Space Entry Program 11 2021Document16 pagesConfined Space Entry Program 11 2021zaka ullahNo ratings yet

- Task Risk AssesmentDocument3 pagesTask Risk Assesmentafsalkareem100% (1)

- JSA For BM - To Dry Up at Site, Remove Motor To Workshop For Repair, Re-Install & Perform Run Test-CRMDocument10 pagesJSA For BM - To Dry Up at Site, Remove Motor To Workshop For Repair, Re-Install & Perform Run Test-CRMChung TrịnhNo ratings yet

- Master Hazards Risks RegisterDocument113 pagesMaster Hazards Risks RegisterIvanNo ratings yet

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- Road & Traffic Safety Procedure: Pars Oil & Gas CompanyDocument29 pagesRoad & Traffic Safety Procedure: Pars Oil & Gas CompanyKostan AbdillahNo ratings yet

- HSInspectionsAtWork PDFDocument14 pagesHSInspectionsAtWork PDFMohammed YcfssNo ratings yet

- Loto Implementation Procedure Plan PDFDocument18 pagesLoto Implementation Procedure Plan PDFgilNo ratings yet

- Risk Assessment: Project Manager Project Engineer HSE Officer/engineer First AiderDocument5 pagesRisk Assessment: Project Manager Project Engineer HSE Officer/engineer First AiderOvais FarooqNo ratings yet

- Job Hazard Analysis: Format For JHA WorksheetDocument3 pagesJob Hazard Analysis: Format For JHA WorksheetWaseem AhmadNo ratings yet

- R1937-JSA-003 Job Safety Analysis For TrenchingDocument5 pagesR1937-JSA-003 Job Safety Analysis For TrenchingVineet AgrawalNo ratings yet

- RISK ASSE 110 - Fire Fighting System - F03Document8 pagesRISK ASSE 110 - Fire Fighting System - F03Rochdi BahiriNo ratings yet

- HSE Exception Request Form Rev.1Document1 pageHSE Exception Request Form Rev.1Dhimaz YudiNo ratings yet

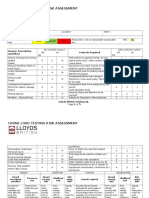

- Crane Load Testing Risk AssessmentDocument5 pagesCrane Load Testing Risk Assessmentdel3333100% (4)

- 7 Hand Held Power ToolsDocument4 pages7 Hand Held Power ToolsGilmar MonteiroNo ratings yet

- A002 C NightclubDocument6 pagesA002 C NightclubBlas de LezoNo ratings yet

- Blinding and De-blinding Safety EssentialsDocument42 pagesBlinding and De-blinding Safety EssentialsMayur NaikNo ratings yet

- PR-1148 - Entry Into A Confined Space ProcedureDocument24 pagesPR-1148 - Entry Into A Confined Space Procedureromedic36No ratings yet

- RA Folder Jan 12Document83 pagesRA Folder Jan 12mouben100% (2)

- Heat Stress ProcedureDocument13 pagesHeat Stress ProcedureKneekEy CastleNo ratings yet

- RA For Hydrostatic Pneumatic-Test and Flushing of Pipeline and Equipment - 17Document9 pagesRA For Hydrostatic Pneumatic-Test and Flushing of Pipeline and Equipment - 17alla malik100% (1)

- Hazard Identification and Risk Assessment FormDocument4 pagesHazard Identification and Risk Assessment FormAli Al-GhamghamNo ratings yet

- Risk Assessment No. 43 ENTRY INTO ENCLOSED SPACES Rev. 02 20Document3 pagesRisk Assessment No. 43 ENTRY INTO ENCLOSED SPACES Rev. 02 20Devi Ratna Pratiwi100% (13)

- RISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The MaterialsDocument6 pagesRISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The Materialsnsadnan100% (5)

- Risk Assessment For Sand Blasting PDFDocument8 pagesRisk Assessment For Sand Blasting PDFOvais FarooqNo ratings yet

- JSA006 - Vacuum Box TestingDocument5 pagesJSA006 - Vacuum Box TestingLaohan LiuNo ratings yet

- Risk Assessment FormDocument8 pagesRisk Assessment FormRochdi BahiriNo ratings yet

- Safety Incident ProcedureDocument15 pagesSafety Incident Proceduresivaguruaks100% (1)

- QA-IMCO-HSE-P-QT-015 Hot Work Procedure PDFDocument16 pagesQA-IMCO-HSE-P-QT-015 Hot Work Procedure PDFFrancis Enriquez TanNo ratings yet

- Risk Assessment Report for Bunkering OperationsDocument2 pagesRisk Assessment Report for Bunkering OperationsNang D. VuNo ratings yet

- L2RA-Personnel TransferDocument10 pagesL2RA-Personnel TransferSam Delo-deloNo ratings yet

- 5.04 - BunkeringDocument8 pages5.04 - BunkeringAnil Kumar Sharma67% (6)

- Royal Commission Risk Assessment Form: Instellation of Water and Fire LineDocument1 pageRoyal Commission Risk Assessment Form: Instellation of Water and Fire Linetousif ahmed100% (1)

- !SIRE Inspection Preparation DocumentDocument4 pages!SIRE Inspection Preparation DocumentKarim Paquiao100% (1)

- Conversion Table For PressureDocument4 pagesConversion Table For Pressuredassi99No ratings yet

- Qual 002 Evaluation of Supplier - SubcontractorDocument1 pageQual 002 Evaluation of Supplier - Subcontractordassi99No ratings yet

- All About ECDISDocument12 pagesAll About ECDISdassi99No ratings yet

- 06 - Major Alarm& Safety of 50DF With UNIC (DNV)Document16 pages06 - Major Alarm& Safety of 50DF With UNIC (DNV)dassi99100% (1)

- Quick Reference - EnglishDocument44 pagesQuick Reference - Englishdassi99No ratings yet

- Qual 001 Supplier-Subcontractor Quality HistoryDocument1 pageQual 001 Supplier-Subcontractor Quality Historydassi99No ratings yet

- JAN 701B HandoutsDocument22 pagesJAN 701B Handoutsdassi990% (1)

- Piezoelectricity:: Principle Knock SensorsDocument1 pagePiezoelectricity:: Principle Knock Sensorsdassi99No ratings yet

- E1 - Purging & Gas Leakage Test SequencesDocument6 pagesE1 - Purging & Gas Leakage Test Sequencesdassi99No ratings yet

- Final Impa Pilot Ladder PosterDocument1 pageFinal Impa Pilot Ladder Posterdassi99No ratings yet

- Installation Guide EnglishDocument11 pagesInstallation Guide Englishdassi99No ratings yet

- DNV CertificateDocument1 pageDNV Certificatedassi99No ratings yet

- Shipping Law Handbook - Part E CollisionDocument21 pagesShipping Law Handbook - Part E Collisiondassi99No ratings yet

- Cause and Effect Diagram - HHISHI (01-LIST - 1040438Document2 pagesCause and Effect Diagram - HHISHI (01-LIST - 1040438dassi99No ratings yet

- Point Fortin - Umm Bab Port OptimoorDocument7 pagesPoint Fortin - Umm Bab Port Optimoordassi99No ratings yet

- 06 - Major Alarm& Safety of 50DF With UNIC (DNV)Document16 pages06 - Major Alarm& Safety of 50DF With UNIC (DNV)dassi99100% (1)

- Gas System Double WallDocument1 pageGas System Double Walldassi99No ratings yet

- 4.10.1 Ramp Up-Ramp Down Plan-AsclepiusDocument1 page4.10.1 Ramp Up-Ramp Down Plan-Asclepiusdassi99100% (1)

- WISE Cargo User Manual - Ver 6 (A4)Document36 pagesWISE Cargo User Manual - Ver 6 (A4)dassi9950% (2)

- Practical TestDocument4 pagesPractical Testdassi99100% (1)

- The Law of Shipbuilding Contracts - PART 1 The Nature of The Shipbuilding ContractDocument3 pagesThe Law of Shipbuilding Contracts - PART 1 The Nature of The Shipbuilding Contractdassi99No ratings yet

- Calculating Damages by Clive AstonDocument10 pagesCalculating Damages by Clive Astondassi99100% (1)

- LMAA Spring Seminar Owners' Damages for Repudiation Without Available MarketDocument16 pagesLMAA Spring Seminar Owners' Damages for Repudiation Without Available Marketdassi99No ratings yet

- RTCM Auto Acquisition Vs Manual Guard Ring ARPADocument10 pagesRTCM Auto Acquisition Vs Manual Guard Ring ARPAdassi99No ratings yet

- Winch Drum SpoolingDocument2 pagesWinch Drum Spoolingdassi99No ratings yet

- Admission Form BA BSC Composite PDFDocument6 pagesAdmission Form BA BSC Composite PDFKhurram ShahzadNo ratings yet

- The Barber of SevilleDocument1 pageThe Barber of SevilleAine MulveyNo ratings yet

- Module 3 - Subsequent To AcquisitionDocument8 pagesModule 3 - Subsequent To AcquisitionRENZ ALFRED ASTRERONo ratings yet

- Chapter 2 (Teacher)Document19 pagesChapter 2 (Teacher)ajakazNo ratings yet

- Acc121 Exam1 ProblemsDocument4 pagesAcc121 Exam1 ProblemsTia1977No ratings yet

- Urinary: Rachel Neto, DVM, MS, DACVP May 28 2020Document15 pagesUrinary: Rachel Neto, DVM, MS, DACVP May 28 2020Rachel AutranNo ratings yet

- Quick Healthcare Stencil: SketchDocument2 pagesQuick Healthcare Stencil: SketchNafiz Hannan NabilNo ratings yet

- A Psychologist Explains Why Everyone Is Suddenly On TiktokDocument3 pagesA Psychologist Explains Why Everyone Is Suddenly On TiktokImen ImenNo ratings yet

- Game Informer September 2013Document104 pagesGame Informer September 2013Igor IvkovićNo ratings yet

- Corporate Citizenship, Social Responsibility, Responsiveness, and PerformanceDocument27 pagesCorporate Citizenship, Social Responsibility, Responsiveness, and Performanceguru2k9100% (1)

- Anectodal RecordsDocument10 pagesAnectodal RecordsSchahyda ArleyNo ratings yet

- AbolethDocument3 pagesAbolethjlewis_4No ratings yet

- European Management Journal: Pawel Korzynski, Grzegorz Mazurek, Michael HaenleinDocument9 pagesEuropean Management Journal: Pawel Korzynski, Grzegorz Mazurek, Michael HaenleinkharismaNo ratings yet

- TBEM CII Exim Bank Award ComparisonDocument38 pagesTBEM CII Exim Bank Award ComparisonSamNo ratings yet

- Railway noise source modeling and measurement methodsDocument78 pagesRailway noise source modeling and measurement methodsftyoneyamaNo ratings yet

- Mr. Frank Remedios Certified Career Counselor Authorised Franchise-Brain CheckerDocument24 pagesMr. Frank Remedios Certified Career Counselor Authorised Franchise-Brain Checkerrwf0606No ratings yet

- Sustainability and Design EthicsDocument178 pagesSustainability and Design EthicsAbby SmithNo ratings yet

- DIRECTORS1Document28 pagesDIRECTORS1Ekta ChaudharyNo ratings yet

- Angel FishDocument1 pageAngel FishWilla CrowellNo ratings yet

- Business-Process Integration: Supply-Chain Management 2.0 (SCM 2.0)Document8 pagesBusiness-Process Integration: Supply-Chain Management 2.0 (SCM 2.0)nidayousafzaiNo ratings yet

- ChE 4110 Process Control HW 1Document6 pagesChE 4110 Process Control HW 1MalloryNo ratings yet

- (Macmillan Studies in Marketing Management) Frank Jefkins BSC (Econ), BA (Hons), MCAM, FIPR, MInstM, MAIE, ABC (Auth.) - Public Relations For Marketing Management-Palgrave Macmillan UK (1983)Document193 pages(Macmillan Studies in Marketing Management) Frank Jefkins BSC (Econ), BA (Hons), MCAM, FIPR, MInstM, MAIE, ABC (Auth.) - Public Relations For Marketing Management-Palgrave Macmillan UK (1983)Subhasis DasNo ratings yet

- 28/08/2016 1 Advanced Research Methodology... RU, Bangalore-64Document38 pages28/08/2016 1 Advanced Research Methodology... RU, Bangalore-64Ananthesh RaoNo ratings yet

- The Minecraft Survival Quest ChallengeDocument4 pagesThe Minecraft Survival Quest Challengeapi-269630780100% (1)

- SheeshDocument31 pagesSheeshfrancisco bonaNo ratings yet

- Physics Chapter on Motion and Force EquationsDocument2 pagesPhysics Chapter on Motion and Force EquationsMalikXufyanNo ratings yet

- What Is InterpolDocument5 pagesWhat Is InterpolJimmy Jr Comahig LapeNo ratings yet

- Komatsu PC01-1 (JPN) 14001-Up Shop ManualDocument217 pagesKomatsu PC01-1 (JPN) 14001-Up Shop Manualhaimay118100% (2)

- Fundamental Powers of The State (Police Power) Ynot v. IAC Facts: Ermita Malate v. City of Manila 20 SCRA 849 (1967)Document18 pagesFundamental Powers of The State (Police Power) Ynot v. IAC Facts: Ermita Malate v. City of Manila 20 SCRA 849 (1967)Ella QuiNo ratings yet

- Lista 30 JulioDocument2 pagesLista 30 JulioMax Bike MartinezNo ratings yet