Professional Documents

Culture Documents

Ventilation PDF

Uploaded by

Karim Abd ElazizOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ventilation PDF

Uploaded by

Karim Abd ElazizCopyright:

Available Formats

Ven

ntilation

n

An ocean-going

o

g ship is req

quired to operate in a variety of very differe

ent climatess.

o

o

Air te

emperature

es may rang

ge from -15

5 C to 50 C and sea water

w

tempe

eratures ma

ay

o

o

range from 0 C to 38 C. The moisture

e content of

o the air will vary conssiderably.

The air from th

he air-conditioning and ventilatio

on plants iss therefore required to

t

proviide an acce

eptable clim

mate for the crew to live and wo

ork in, suffficient air fo

or

mach

hinery use and to maiintain temp

perature and

d humidity at acceptable levels to

t

the cargo.

c

The design of suitable

s

sysstems will th

herefore req

quire inform

mation abou

ut

the ships

s

trade routes, typ

pes of cargo

o and mach

hinery installation.

Type

es of Syste

ems

Therre are two basic

b

typess of ventilattion system

ms; natural and

a mecha

anical. In th

he

naturral ventilattion system

m, air mo

ovement iss created by the difference in

i

temp

perature an

nd density of

o inside an

nd outside air and the

e trimming of cowls or

o

scoo

ops towards

s the wind.

Mostt modern ships utilize mecha

anical ven

ntilation forr reliabilityy, improve

ed

perfo

ormance an

nd the reducced size of cowls nece

essary.

The mechanical ventilation

n system may be eithe

er:

e, or

a- Mechanical-supply / natural-exxhaust type

b- Mechanical- exhausst / natural-- supply typ

pe, or

c-- Mechanical-supply / mechaniccal- exhaustt type

Marin

neOutfittingss

Prof.Dr.YousriWelayya

Depe

ending upon the locatiion of the fa

an or fans within

w

the system.

s

In general

g

typ

pe

(a) will

w maintain

n a slight po

ositive presssure within

n the space

es served. Type

T

(b) will

main

ntain a sligh

ht negative pressure within

w

the space serve

ed. This typ

pe of system

m

is ussed in space

es such as galleys, toilets, and pantries

p

whe

ere a positiive pressurre

migh

ht dispel the heat and

d odors into

o adjacent spaces. Type

T

(c) may

m producce

eithe

er a slight positive

p

or negative

n

prressure within the spa

aces served

d dependin

ng

on th

he relative ratings

r

of th

he supply and exhaustt fans.

Mech

hanical ven

ntilation can

n also be cla

assified as open or clo

osed system

m. The ope

en

syste

em uses axial

a

flow fa

ans fitted in

i the inlett and exha

aust trunks. The air is

i

supp

plied along trunking

t

an

nd ducts to the

t bottom of the hold

d.

n from the top of the hold

h

just be

elow the de

ecks. The exhaust

e

fan

ns

The air is drawn

can be

b reversed

d if condensation is likkely near th

he deck hea

ads, for exa

ample with a

low outside

o

air temperature

t

e.

The closed sys

stem recircu

ulates air and

a

a contrrolled amou

unt of fresh

h air can be

b

admiitted. The ventilation

v

a is distrib

air

buted aroun

nd the hold and cargo, forming an

a

insulating wall or

o curtain between

b

the

e two. Exha

aust air is drawn

d

from

m the bottom

m

e hold.

of the

Marin

neOutfittingss

Prof.Dr.YousriWelayya

Ventilation of Refrigerated Cargo Holds

These require a carefully controlled air-replacing system for each individual

space. Cooled air is supplied to the refrigerated hold where it gains heat from

ripening cargoes and entrains the gases produced. This air is then exhausted

and a careful balance must be maintained between inlet and exhaust gas

quantities, regardless of the outside climatic conditions.

In figure this is achieved by drawing outside air down to a bank of cooler tubes

via a central unit. The dehumidified air then passes into the cargo holds. The

exhaust gases are drawn from the hold through ducts to the central unit and then

returned to the outside atmosphere.

MarineOutfittings

Prof.Dr.YousriWelaya

Mach

hinery Spa

aces

The machinery

y space re

equires an

n air supply for the operation of boilerss,

bustion eng

gines, comp

pressors, etc., and to maintain a satisfactoryy climate fo

or

comb

the operating

o

sttaff to work in.

Certa

ain machinery consum

mes or requ

uires air forr its operatiion and suffficient air at

a

as lo

ow tempera

ature as practically po

ossible sho

ould be pro

ovided. Und

der pressurre

occu

urring in the

e machinerry space will

w affect th

he efficienccy and perfformance of

o

I.C.E

E. Over pre

essure mayy lead to le

eakage of hot air into

o the acco

ommodation

n.

Venttilation is also necessa

ary to remo

ove the hea

at generate

ed within the

e machinerry

spacce and thus

s provide a reasonablle climate for

f the stafff to work in. This verry

difficcult task is

s achieved by the prrovision off ducted supplies of filtered bu

ut

unco

ooled air to as many re

egions as possible.

p

Pa

articular are

eas such ass workshop

ps

and control ro

ooms, being small, may

m

be air condition

ned and more

m

readilly

proviided with an

n acceptab

ble working climate.

Vario

ous system

ms of air supply to the

e machineryy space an

nd casing are

a shown in

i

the fiigure.

Marin

neOutfittingss

Prof.Dr.YousriWelayya

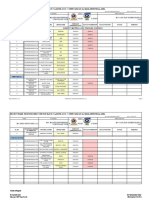

(a)) Machinery

y space

ve

entilation using

g medium

pre

essure axial flow

f

fan

(b) Machinery space

e

ventilation

n using low pressure

p

axial flow

w fan and high

h

pressure centrifugal fa

an

(c) Machine

ery space

ventilation ussing medium

pressure axia

al flow fans an

nd a

through trunkking system

Figurre (a) utilizes a med

dium presssure axial flow fan supplying air down a

trunkking, which

h is proporrtionally released at the variou

us platform levels and

exha

austs throug

gh the top of

o the casin

ng. Figure (b)

( uses a low pressure axial flow

w

fan to

t supply air into the

e casing area.

a

Also a high prressure cen

ntrifugal fa

an

proviides air thrrough ducts to outletss at the va

arious platfforms. Figu

ure (c) use

es

mediium pressu

ure axial flo

ow fans to

o provide a through trunking

t

syystem to the

vario

ous outlets at

a the vario

ous platform

ms. This me

ethod has proved to be

e the best.

Doub

ble-Bottom

m Tanks

Marin

neOutfittingss

Prof.Dr.YousriWelayya

Ventilation of double-bottom tanks is provided by means of an air pipe situated

remote from the filling pipe and usually at the highest point in the tank to avoid

unventilated pockets. The air pipe is led up to the weather deck to a gooseneck

or patent type of head. Air pipes from fuel tanks are positioned in low risk areas

and have flame screen gauzes fitted (see figure).

Cargo Tanks

Ventilation of cargo tanks avoid overpressure or partial pressure conditions which

could occur during loading and unloading of cargo. Temperature fluctuations

during a voyage could have a similar effect. Vapor pipelines from the cargo hatch

are led to pressure/vacuum relief valves which are usually mounted on a

standpipe some distance above the deck. Individual vent lines are fitted for each

tank on large tankers and a common venting line is led up a mast or Sampson

post on smaller vessels.

Design Criteria

The criteria include the recommended ventilation system, the temperature rise

which is the maximum difference between exhaust air and supply air temperature

(6oC for the galley and toilets), and the maximum air change which is the time in

minutes for the supply of a quantity of air equal to the space volume (2 for the

battery room, 10 for the emergency generator room, 1 for the galley, 4 for the

toilets and showers).

In designing a ventilation system, the aim of the designer should be to run the

duct in as nearly a straight line as possible, avoiding sharp bends, abrupt

changes in duct sizes or shapes to minimize excessive pressure losses. Crosssectional areas of ducts should be large enough to permit the air to flow at

moderate velocities to avoid power waste and to reduce noise. Maximum duct

velocity of 10 m/sec for areas where quiet operation is essential and 18 m/sec for

areas where quiet operation is not essential, are good values.

When smaller ducts are taken off the main supply duct to serve individual

spaces, the air quantity is divided in proportion to the area of the duct.

Construction Details

Ducts may be constructed of galvanizes sheet steel in order to withstand

corrosion and vibration, or ducts may be constructed of aluminum in order to

save topside weight. Vertical and horizontal ducts in general cargo holds are

usually constructed of 6.5 mm and 4.8 mm plates respectively.

Because of headroom requirements, most ducts are rectangular; round ducts

being used only in the smaller sizes. Usually a heavy section of ductwork is

MarineOutfittings

Prof.Dr.YousriWelaya

welded into the penetrated structure where structural compensation is required.

Hand holes, access holes, and portable sections are provided to permit cleaning,

painting, and inspection. Ducts passing over electrical equipment are made

watertight. Ducts are made with either riveted, welded, or hook seams and are

airtight.

To maintain habitable temperature in machinery spaces and for the removal of

fumes, spot cooling with large quantities of air at high terminal velocities, 13-15

m/s, is used at operating stations and other strategic locations. Exhaust terminals

should be located in the vicinity of heat-producing equipment, and on the upper

levels of the machinery space.

Ventilation Components

a) Types of Fans

Axial flow fans are used widely because of compactness and high efficiency and

are well adapted for ventilation of cargo spaces, machinery spaces and other

spaces where noise is not a significant consideration. Centrifugal fans are used

for ventilation where quiet operation is desired and also for galleys, battery room

exhaust, and areas where explosive vapors are removed, where the motor is not

to be located in the air stream. Propeller fans are used in bulkhead installations

and sometimes in a cowl for machinery space supply and exhaust systems

where the pressure is small.

b) Weather-Terminal Openings

MarineOutfittings

Prof.Dr.YousriWelaya

These include cowls, goosenecks, mushrooms, louvers and air lift boxes on deck

or in bulkheads. All of these devices are fitted with wire mesh for rat-proofing.

Weather terminals should be so located that exhaust air or stack gasses do not

contaminate supply air.

c) Interior Terminals

High velocity directional terminals are used in galleys, pantries, laundries,

machinery spaces, and similar heat-producing spaces where spot cooling is

desired. Slotted outlets may be used in front of galleys hoods and switchboards.

Ceiling or wall type diffusers are used for ventilated living spaces, with terminal

MarineOutfittings

Prof.Dr.YousriWelaya

velocities so as to provide diffusion and throw, without objectionable air

movement and air noise in the space.

Terminals for holds and storerooms are merely open-ended ducts or a cut in the

side of the duct fitted with wire-mesh screens for rat proofing.

d) Exhaust Terminals

These are located close to heat sources and are usually an open-ended duct

covered with wire-mesh or grilles where appearance is important. Exhaust inlet

velocities should be about 5-8 m/s in living spaces and up to 10 m/s in other

places.

e) Dampers

They are sometimes used to control the volume of air delivered at terminals.

Manually operated dampers must be provided on passenger ships at the weather

opening in all ventilating systems to shut off the passage of air in the event f fire.

Automatic dampers are required in exhaust ducts over potential sources of fire in

galleys and are required to operate by melting a fusible link.

Air Conditioning Systems

MarineOutfittings

Prof.Dr.YousriWelaya

10

These are used to modify the outside fresh air to improve the ships interior

environment by heating, cooling, dehumidifying, and contaminant removal

processes. Air conditioning is used almost exclusively for living spaces and

sometimes for spaces containing electronic equipment. Conditioning of the air is

accomplished by a cooling medium of chilled water or Freon and a heating

medium of steam, hot water or electricity.

Types of Systems

a) Combination heating and cooling systems.

b) Cooling systems.

c) Dehumidification: for preventing moisture damage or condensation of

moisture on cargo and internal structures of all those portions of holds

suitable for carrying dry cargo.

Design Criteria

Shipboard air conditioning systems are usually designed to maintain inside air

temperatures ranging from 24oC to 29oC dry bulb, and a relative humidity of 50%

with an outside air temperature of 35oC dry bulb and 28oC wet bulb during the

summer season and inside air temperature of 21oC dry bulb with an outside

temperature of -18oC dry bulb during the winter season.

The criteria for cargo hold dehumidification is normally to maintain the dew-point

of atmosphere within the hold at a minimum design depression of 6oC dew-point

below the surface temperature of the cargo or ships structure.

MarineOutfittings

Prof.Dr.YousriWelaya

You might also like

- Mooring Systems: Securing Ships to Piers & WharvesDocument12 pagesMooring Systems: Securing Ships to Piers & WharvesKarim Abd Elaziz100% (2)

- HVACDocument9 pagesHVACMailisa FitriaNo ratings yet

- E.5 Engine Room Ventilation SystemDocument5 pagesE.5 Engine Room Ventilation Systemednsmn100% (1)

- Air Distribution System Design and EquipmentDocument36 pagesAir Distribution System Design and EquipmentfekadeNo ratings yet

- Oral and Practical Review: Reflections on the Part 147 CourseFrom EverandOral and Practical Review: Reflections on the Part 147 CourseNo ratings yet

- Design Guide - Humidity ControlDocument2 pagesDesign Guide - Humidity Controldzul92100% (1)

- 10 - Air Distribution SystemDocument7 pages10 - Air Distribution SystemZeeshan HasanNo ratings yet

- Hospital Room Design FundamentalsDocument4 pagesHospital Room Design FundamentalsAbdallah Abu Irmaileh100% (1)

- Cooling Tower DesignDocument11 pagesCooling Tower DesignSmrutiNo ratings yet

- The Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationFrom EverandThe Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationRating: 1 out of 5 stars1/5 (1)

- Mebs6006 1112 10-Airside SystemDocument40 pagesMebs6006 1112 10-Airside Systemsimoncarter313No ratings yet

- Ship Lifesaving Systems GuideDocument15 pagesShip Lifesaving Systems GuideKarim Abd Elaziz100% (1)

- Auxiliary Marine Machinery: Under ConstructionDocument55 pagesAuxiliary Marine Machinery: Under ConstructionAkpojosevbe SamuelNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Sequence of OperationDocument27 pagesSequence of OperationYasser HendyNo ratings yet

- Overall Plot Plan Layout (Design Considerations)Document20 pagesOverall Plot Plan Layout (Design Considerations)rahult19100% (1)

- Section II Equipment Piping and Assembly ApplicationsDocument47 pagesSection II Equipment Piping and Assembly ApplicationsAndy ChongNo ratings yet

- Air Conditioning of Railway CoachesDocument10 pagesAir Conditioning of Railway CoachesEshana JainNo ratings yet

- Design Control Document-MVACDocument48 pagesDesign Control Document-MVACRudivic LumainNo ratings yet

- Ventilation: Types of SystemsDocument10 pagesVentilation: Types of SystemsanangwahjudiNo ratings yet

- Mechanical Ventilation Systems Are Frequently Applied To Commercial BuildingsDocument9 pagesMechanical Ventilation Systems Are Frequently Applied To Commercial BuildingsIbn Shaffee IVNo ratings yet

- DHQC - MVAC - 1&2 - 2020 LOG and TrackDocument13 pagesDHQC - MVAC - 1&2 - 2020 LOG and TrackKumudu PereraNo ratings yet

- Building Services 2 BLD 60503 Case Study PDFDocument88 pagesBuilding Services 2 BLD 60503 Case Study PDFIswadi Bin Zulkarnain100% (3)

- Auxiliary Marine Machinery: Under ConstructionDocument55 pagesAuxiliary Marine Machinery: Under ConstructionAbhinavNo ratings yet

- Fan Coil Units (FCUs) and Air Handling Units (AHUs) Explained <40Document10 pagesFan Coil Units (FCUs) and Air Handling Units (AHUs) Explained <40bandhuarushiNo ratings yet

- Zamil ACDocument40 pagesZamil ACArt James100% (1)

- Ventilation Planning OlDocument97 pagesVentilation Planning Olenjam yasankNo ratings yet

- Confined Space Ventilation TechniquesDocument16 pagesConfined Space Ventilation TechniquesTerry A. WaldropNo ratings yet

- Package Type Air ConditionerDocument20 pagesPackage Type Air ConditionerSohail Wahab100% (1)

- Anchoring SystemsDocument16 pagesAnchoring SystemsKarim Abd ElazizNo ratings yet

- Presentation BoilerDocument24 pagesPresentation BoilerRanjanaWaje100% (1)

- General Exhaust (Dilution) Ventilation Systems General ExhaustDocument5 pagesGeneral Exhaust (Dilution) Ventilation Systems General ExhaustmadbakingNo ratings yet

- Corrosion Control PDFDocument17 pagesCorrosion Control PDFKarim Abd ElazizNo ratings yet

- Laminar Ceiling ALVO Technical DescriptionDocument24 pagesLaminar Ceiling ALVO Technical DescriptionНиколай ШипочкиNo ratings yet

- Ventilation and Air-ConditioningDocument93 pagesVentilation and Air-ConditioningEmmanuel P Dube100% (2)

- Mine Ventilation System PDFDocument22 pagesMine Ventilation System PDFADRIAN NURHADINo ratings yet

- A33 Si - Kitchen VentilationDocument1 pageA33 Si - Kitchen VentilationAhmed NabilNo ratings yet

- Mine Ventilation Systems ExplainedDocument22 pagesMine Ventilation Systems ExplainedMatías Ignacio Fuentes BustamanteNo ratings yet

- 218 LabSystemDocument23 pages218 LabSystemAndryan FebriadiNo ratings yet

- Mine Ventilation Module General.Document19 pagesMine Ventilation Module General.Maxine MukokiNo ratings yet

- E.5Engine Room Ventilation System PDFDocument6 pagesE.5Engine Room Ventilation System PDFSimon LaurentNo ratings yet

- Ventilation SystemsDocument5 pagesVentilation SystemsnualdinNo ratings yet

- Central Air Conditioning Systems ExplainedDocument32 pagesCentral Air Conditioning Systems Explainedjoechengsh100% (1)

- Tutorial - Ku Illyani Nadia BT Ku Aziz 2011478072 BCM5BDocument3 pagesTutorial - Ku Illyani Nadia BT Ku Aziz 2011478072 BCM5Bnadia0109No ratings yet

- Operating Instructions Refrigerated Air Dryers Models D-300 Through D-7500Document13 pagesOperating Instructions Refrigerated Air Dryers Models D-300 Through D-7500janessa ilaganNo ratings yet

- EEMs To Consider 2011-09-15Document12 pagesEEMs To Consider 2011-09-15razali131266No ratings yet

- Cooling TowerDocument13 pagesCooling TowerMuhammad TayyabNo ratings yet

- Requirement of Ships Air Conditioning SystemDocument3 pagesRequirement of Ships Air Conditioning SystemVishu SharmaNo ratings yet

- Air HandlerDocument15 pagesAir HandlerShashank BijweNo ratings yet

- Why Is Forced Mechanical Ventilation Necessary in A Confined BuildingDocument3 pagesWhy Is Forced Mechanical Ventilation Necessary in A Confined BuildingJade Putis100% (1)

- Control and condition air with an air handler unitDocument10 pagesControl and condition air with an air handler unitSreekanth MadakaNo ratings yet

- Central Air ConditioningDocument8 pagesCentral Air ConditioningAditi SharmaNo ratings yet

- Dry Type TransformersDocument12 pagesDry Type Transformersraul_bsuNo ratings yet

- Clean RoomDocument9 pagesClean Roomxyzscribd1988No ratings yet

- DSAIRELIM Air Eliminators SpecsDocument10 pagesDSAIRELIM Air Eliminators SpecsGerman Felipe TorresNo ratings yet

- Fiba Guide To Basketball Facilities - Air DistributionDocument2 pagesFiba Guide To Basketball Facilities - Air DistributionMustafa Onur SarıkayaNo ratings yet

- Understanding mechanical systems and ventilation for buildingsDocument19 pagesUnderstanding mechanical systems and ventilation for buildingsXaira Alexa Mari CastroNo ratings yet

- 9 - Subsurface Ventilation SystemsDocument22 pages9 - Subsurface Ventilation SystemsSude Yağmur ÇalışırNo ratings yet

- Air Handler: Navigation SearchDocument5 pagesAir Handler: Navigation SearchNikhil KallaNo ratings yet

- Tutorial - Underfloor Air-ConditioningDocument8 pagesTutorial - Underfloor Air-ConditioningJasper_HVACNo ratings yet

- Auxiliary Marine Machinery: Under ConstructionDocument55 pagesAuxiliary Marine Machinery: Under ConstructionArunNo ratings yet

- Wind Tunnels PDFDocument4 pagesWind Tunnels PDFPrince RajNo ratings yet

- Hvac 4Document3 pagesHvac 4zolalkkNo ratings yet

- HVAC Equipment Selection GuideDocument4 pagesHVAC Equipment Selection GuideJanakiramNo ratings yet

- Dual Duct Dual FanDocument2 pagesDual Duct Dual FansajuhereNo ratings yet

- What Is Air ConditioningDocument16 pagesWhat Is Air ConditioningCheeragNo ratings yet

- Main Application of Fans and BlowerDocument5 pagesMain Application of Fans and Blowermissy forlajeNo ratings yet

- Mve 2.oDocument16 pagesMve 2.oOm KaitadeNo ratings yet

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemFrom EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- The Secrets of Examination Technique - Certificate FinalDocument3 pagesThe Secrets of Examination Technique - Certificate FinalSanjai SureshNo ratings yet

- Acronyms IGCDocument2 pagesAcronyms IGCKarim Abd ElazizNo ratings yet

- Cargo Handling PDFDocument12 pagesCargo Handling PDFKarim Abd ElazizNo ratings yet

- M S P P H B: Arine Team Ower Lant EAT AlanceDocument10 pagesM S P P H B: Arine Team Ower Lant EAT AlanceKarim Abd ElazizNo ratings yet

- Air System Sizing Summary for 03-L2-FCU-101-R14Document138 pagesAir System Sizing Summary for 03-L2-FCU-101-R14Jeffy ShannonNo ratings yet

- 132 U-matchAA Inverter Series FDocument164 pages132 U-matchAA Inverter Series FWarlin FortunatoNo ratings yet

- York Absorption Chillers FlyerDocument2 pagesYork Absorption Chillers FlyerEnrique Mejia GamarraNo ratings yet

- Panasonic Sky Series and Aero Series Air ConditionersDocument20 pagesPanasonic Sky Series and Aero Series Air ConditionersAdityo RahmanNo ratings yet

- 2010 CM Engineering Manual Pefy-Nmsu-Nmau-NmhuDocument60 pages2010 CM Engineering Manual Pefy-Nmsu-Nmau-NmhuEli Montano VegaNo ratings yet

- Compact Brazed Plate Heat Exchangers for Refrigeration and HVACDocument1 pageCompact Brazed Plate Heat Exchangers for Refrigeration and HVACGustavo LopezNo ratings yet

- How refrigeration system subcooling impacts control qualityDocument8 pagesHow refrigeration system subcooling impacts control qualitymarjan 01No ratings yet

- Quick Reference Guide: 15 To 25 Tons Packaged Rooftop Units Cooling & Gas/ElectricDocument2 pagesQuick Reference Guide: 15 To 25 Tons Packaged Rooftop Units Cooling & Gas/ElectricJesus HerediaNo ratings yet

- Ducted Exhaust Ventilation Fans: Low Noise, High Performance Air and Moisture ExtractionDocument4 pagesDucted Exhaust Ventilation Fans: Low Noise, High Performance Air and Moisture ExtractionNicolas BaquedanoNo ratings yet

- RACDocument117 pagesRACTsihatesfaNo ratings yet

- Heat Loss CalculationDocument9 pagesHeat Loss CalculationAthanasios AntonopoulosNo ratings yet

- Conversion Table From Inches To MillimetersDocument4 pagesConversion Table From Inches To MillimetersZeljko KukicNo ratings yet

- VRVX BroucherDocument45 pagesVRVX BroucherasdthuNo ratings yet

- R & AcDocument6 pagesR & AcM.ThirunavukkarasuNo ratings yet

- Manual Air Conditioner: SectionDocument76 pagesManual Air Conditioner: SectionEduardo ColinNo ratings yet

- Duct Air Leakage PDFDocument3 pagesDuct Air Leakage PDFWilliam GrecoNo ratings yet

- 52c, P-3ae PtacDocument56 pages52c, P-3ae Ptackennethfbarnes0% (1)

- Calculate air conditioning needs for various roomsDocument8 pagesCalculate air conditioning needs for various roomsFauzi RahmanNo ratings yet

- Aquaforce: Detailed Performance Summary For Untitled1Document3 pagesAquaforce: Detailed Performance Summary For Untitled1RikiNo ratings yet

- Greenstar 30-40 CDi Classic Regular Operating InstructionsDocument16 pagesGreenstar 30-40 CDi Classic Regular Operating InstructionsPbNo ratings yet

- William Munharira: Curriculum VitaeDocument3 pagesWilliam Munharira: Curriculum VitaeWilliamNo ratings yet

- Refrigeration Capacity of Local Compressors PDFDocument3 pagesRefrigeration Capacity of Local Compressors PDFNaqqash SajidNo ratings yet

- Reboiler: Types of ReboilersDocument5 pagesReboiler: Types of ReboilersMigueAngelPFNo ratings yet

- Hvac QuestionDocument12 pagesHvac QuestionMuhamed Elsayed - ZalatNo ratings yet