Professional Documents

Culture Documents

Sa 299

Uploaded by

Web LogueandoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sa 299

Uploaded by

Web LogueandoCopyright:

Available Formats

SPECIFICATION FOR PRESSURE VESSEL PLATES,

CARBON STEEL,

MANGANESE-SILICON

SA-299/SA-299M

(Identical with ASTM Specification A 299/A 299M-90.)

1.

Scope

3.

1.1 This specification covers manganese-silicon carbon steel plates for use in welded boilers and other

pressure vessels.

3.1 Material supplied to this material specification

shall conform to Specification A 20/A 20M. These

requirements outline the testing and retesting methods

and procedures, permissible variations in dimensions,

and mass, quality and repair of defects, marking, loading, etc.

1.2 Plates under this specification are produced in

one grade only; however, the yield strength decreases

on thicknesses over 1 in. [25 mm]:

Thickness

Up to 1 in.

[25 mm]

Over 1 in.

[25 mm]

Tensile Strength,

ksi [MPa]

Yield Strength,

ksi [MPa]

7595 [515655]

42 [290]

7595 [515655

40 [275]

3.2 Specification A 20/A 20M also establishes the

rules for the basis of purchase that should be complied

with when purchasing material to this specification.

3.3 In addition to the basic requirements of this

specification, certain supplementary requirements are

available when additional control, testing, or examination is required to meet end use requirements. These

include:

1.3 The maximum thickness of plates is limited only

by the capacity of the composition to meet the specified

mechanical property requirements; however, current

practice normally limit, the maximum thickness of plates

furnished under this specification to 8 in. [200 mm].

3.3.1 Vacuum treatment,

1.4 The values stated in either inch-pound units or

SI units are to be regarded separately as standard.

Within the text, the SI units are shown in brackets. The

values stated in each system are not exact equivalents;

therefore, each system must be used independently of

the other. Combining values from the two systems may

result in nonconformance with the specification.

2.

General Requirements and Ordering

Information

3.3.2 Additional or special tension testing,

3.3.3 Impact testing, and

3.3.4 Nondestructive examination.

3.4 The purchaser is referred to the listed supplementary requirements in this specification and to the detailed

requirements in Specification A 20/A 20M.

Applicable Document

3.5 If the requirements of this specification are in

conflict with the requirements of Specification A 20/

A 20M, the requirements of this specification shall

prevail.

2.1 ASTM Standard:

A 20/A 20M Specification for General Requirements for

Steel Plates for Pressure Vessels

455

98

SA-299/SA-299M

4.

1998 SECTION II

Manufacture

6.

4.1 Steelmaking PracticeThe steel shall be killed.

5.

Chemical Requirements

6.1 The steel shall conform to the requirements as

to chemical composition as shown in Table 1 unless

otherwise modified in accordance with Supplementary

Requirement S17, Vacuum Carbon-Deoxidized Steel,

in Specification A 20/A 20M.

Heat Treatment

5.1 Plates 2 in. [50 mm] and under in thickness are

normally supplied in the as-rolled condition. Plates may

be ordered normalized or stress relieved, or both.

7.

Mechanical Requirements

7.1 Tension Test RequirementsThe material as represented by the tension-test specimens shall conform

to the requirements shown in Table 2.

5.2 Plates over 2 in. [50 mm] in thickness shall be

normalized.

TABLE 1

CHEMICAL REQUIREMENTS

Elements

Composition, %

max A:

Carbon,

1 in. [25 mm] and under

Over 1 in. [25 mm]

0.28

0.30

Manganese:

1 in. [25 mm] and under

Heat analysis

Product analysis

Over 1 in. [25 mm]

Heat analysis

Product analysis

Phosphorus, max A

Sulfur, max A

0.90 to 1.40

0.84 to 1.52

0.90 to 1.50

0.84 to 1.62

0.035

0.040

Silicon:

Heat analysis

Product analysis

A

0.15 to 0.40

0.13 to 0.45

Applies to both heat and product analysis.

TABLE 2

TENSILE REQUIREMENTS

Tensile strength, ksi [MPa]

Yield strength, min, A ksi [MPa]:

1 in. [25 mm] and under

Over 1 in. [25 mm]

Elongation in 8 in. [200 mm], min, %

Elongation in 2 in. [50 mm], min, %

7595 [515655]

42 [290]

40 [275]

16 B

19 B

A Determined by either the 0.2% offset method or the 0.5% extension-under-load method.

B See Specification A 20/A 20M.

456

PART A FERROUS MATERIAL SPECIFICATIONS

SUPPLEMENTARY REQUIREMENTS

Supplementary requirements shall not apply unless specified in the order.

A list of standardized supplementary requirements for use at the option of the

purchaser are included in Specification A 20/A 20M. Those which are considered

suitable for use with this specification are listed below by title.

S1.

Vacuum Treatment,

S2.

Product Analysis,

S3.

Simulated Post-Weld Heat Treatment of

Mechanical Test Coupons,

S4.1 Additional Tension Test,

S5.

Charpy V-Notch Impact Test,

S6.

Drop Weight Test,

S7.

High-Temperature Tension Test,

S8.

Ultrasonic Examination in accordance with

Specification A 435/A 435M,

S9.

Magnetic Particle Examination,

S11. Ultrasonic Examination in accordance with

Specification A 577/A 577M,

S12. Ultrasonic Examination in accordance with

Specification A 578/A 578M,

S14. Bend Test, and

S17. Vacuum Carbon-Deoxidized Steel.

457

SA-299/SA-299M

You might also like

- Sa 283Document3 pagesSa 283AnilNo ratings yet

- Installation Guidelines for Integrally Reinforced Branch FittingsDocument7 pagesInstallation Guidelines for Integrally Reinforced Branch FittingsrodofgodNo ratings yet

- 316/316L Stainless Steel Spec SheetDocument3 pages316/316L Stainless Steel Spec SheetLinnie McleodNo ratings yet

- Ab 536 Requirements For The Integrity Management of Grade 91 Steel Used Above Currently Permitted Allowable StressesDocument17 pagesAb 536 Requirements For The Integrity Management of Grade 91 Steel Used Above Currently Permitted Allowable StressesCarlos Maldonado SalazarNo ratings yet

- Is 210Document16 pagesIs 210Debopriyo GhoshNo ratings yet

- Astm A216Document3 pagesAstm A216Ruth Sarai YañezNo ratings yet

- Trading JournalDocument34 pagesTrading JournaltianNo ratings yet

- Astm A192 Asme Sa192 PDFDocument4 pagesAstm A192 Asme Sa192 PDFWil Vasquez C100% (1)

- PED 2014-68-EU Guidelines EN v4Document235 pagesPED 2014-68-EU Guidelines EN v4Nav TalukdarNo ratings yet

- BS 5500 Appendix K and DDocument14 pagesBS 5500 Appendix K and DCRISTIAN SILVIU IANUCNo ratings yet

- Astm A234-A234m-06Document8 pagesAstm A234-A234m-06NadhiraNo ratings yet

- Astm B705Document4 pagesAstm B705Maram NasraweenNo ratings yet

- ASTM F1545 Plastic Lined Pipe 0803Document6 pagesASTM F1545 Plastic Lined Pipe 0803JabranYounasNo ratings yet

- Storage Tank Design GuidelinesDocument6 pagesStorage Tank Design GuidelinespaaryNo ratings yet

- Afnor 28 CDV 5-08 SteelDocument1 pageAfnor 28 CDV 5-08 SteelMagoroku D. YudhoNo ratings yet

- Seamless Carbon Steel Boiler Tubes For High-Pressure ServiceDocument2 pagesSeamless Carbon Steel Boiler Tubes For High-Pressure ServiceChandra ClarkNo ratings yet

- SMAW Electrode IdentificationDocument2 pagesSMAW Electrode IdentificationAsim AliNo ratings yet

- Stillwell Pipe ArrangementDocument1 pageStillwell Pipe ArrangementVishalDhimanNo ratings yet

- Needle ValveDocument8 pagesNeedle ValveMuhammad Chilmi100% (1)

- Astm F436.04 PDFDocument6 pagesAstm F436.04 PDFWelington Volpatto MoraisNo ratings yet

- Astm B 729 - 2000 PDFDocument2 pagesAstm B 729 - 2000 PDFLemir LopezNo ratings yet

- BHEL TDC For FittingsDocument9 pagesBHEL TDC For FittingsGuru KguruNo ratings yet

- Low Temperature and Cryogenic Ball ValvesDocument4 pagesLow Temperature and Cryogenic Ball Valves윤병택100% (1)

- Corrosion Resistance TablesDocument9 pagesCorrosion Resistance TablesManoj BNo ratings yet

- Engineering Data Chapter Provides Specifications for Valve MaterialsDocument9 pagesEngineering Data Chapter Provides Specifications for Valve MaterialsVu Tung LinhNo ratings yet

- 2.2. Allowable Stress Range For Self-Limiting LoadsDocument328 pages2.2. Allowable Stress Range For Self-Limiting LoadsDarshan PanchalNo ratings yet

- Trading Journal: "Buat Sampai Profit, Tuhan Jangan Lupa" "Buat Sampai Profit, Tuhan Jangan Lupa"Document2 pagesTrading Journal: "Buat Sampai Profit, Tuhan Jangan Lupa" "Buat Sampai Profit, Tuhan Jangan Lupa"Nuryusri AimanNo ratings yet

- Swagelok Needle ValvesDocument12 pagesSwagelok Needle Valvesnegg 348No ratings yet

- Es7 PDFDocument4 pagesEs7 PDFayoungaNo ratings yet

- Pipe Fittings To BS1740 150lbDocument7 pagesPipe Fittings To BS1740 150lbKiko Ruiz AhedoNo ratings yet

- Piping Class - AC11Document2 pagesPiping Class - AC11Дмитрий РыбаковNo ratings yet

- Asme Section I: Section - Iii Code ExtractionDocument3 pagesAsme Section I: Section - Iii Code ExtractionReadersmo100% (1)

- Asme Section Ii A-2 Sa-592 Sa-592m PDFDocument4 pagesAsme Section Ii A-2 Sa-592 Sa-592m PDFAnonymous GhPzn1xNo ratings yet

- API602 Forged Steel Gate & Globe ValvesDocument4 pagesAPI602 Forged Steel Gate & Globe ValvesThomasFrenchNo ratings yet

- Boq For AS BoilerDocument1 pageBoq For AS BoilerGayan ChathurangaNo ratings yet

- Materials Selection For Seawater Cooled Heat ExchangerDocument12 pagesMaterials Selection For Seawater Cooled Heat ExchangerGreg Agullana Cañares Jr.No ratings yet

- Car Washer CatalogueDocument24 pagesCar Washer Cataloguesra electricalsNo ratings yet

- A 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFDocument16 pagesA 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFshakeelahmadjsrNo ratings yet

- EN 12070 EN 12070 EN 12070 EN 12070: Exam Exam Exam Example Ple Ple Ple:::: TG 215 TG 215 TG 215 TG 215Document2 pagesEN 12070 EN 12070 EN 12070 EN 12070: Exam Exam Exam Example Ple Ple Ple:::: TG 215 TG 215 TG 215 TG 215spaljeniNo ratings yet

- Arcelormittal Pressure VesselDocument10 pagesArcelormittal Pressure VesselkokopirokoNo ratings yet

- ASCE 7-05 Table 15-4-2Document1 pageASCE 7-05 Table 15-4-2barouniamineNo ratings yet

- ASME 193 and 193MDocument4 pagesASME 193 and 193MGauravNo ratings yet

- SA/AS1548 - 7 - 460R: XlerplateDocument3 pagesSA/AS1548 - 7 - 460R: XlerplatenavNo ratings yet

- Metal Foundry Materials GuideDocument1 pageMetal Foundry Materials Guiderush_oceanNo ratings yet

- 163 Dimensions of Large Male Female and Small Tongue and Groove Flange Facing Ansi b165 StandardDocument6 pages163 Dimensions of Large Male Female and Small Tongue and Groove Flange Facing Ansi b165 StandardQiuniuNo ratings yet

- B Jack Nos For Cs Ss MaterialDocument12 pagesB Jack Nos For Cs Ss MaterialfahadfiazNo ratings yet

- Sensitization of Inconel 625Document9 pagesSensitization of Inconel 625nantha kumarNo ratings yet

- BP Variable Catalog 09VDocument52 pagesBP Variable Catalog 09VPetros IosifidisNo ratings yet

- Standards Scope PDFDocument6 pagesStandards Scope PDFaravindhcamNo ratings yet

- Product Categories: Fittings, Valves, Clamps & Accessories For Hose, Pipe and TubeDocument35 pagesProduct Categories: Fittings, Valves, Clamps & Accessories For Hose, Pipe and TubeRaj DomadiyaNo ratings yet

- S275JR PDFDocument1 pageS275JR PDFEmrahCayboylu100% (1)

- Global Marketing For Tube & Pipe: JIS G3457 Arc Welded Carbon Steel PipesDocument7 pagesGlobal Marketing For Tube & Pipe: JIS G3457 Arc Welded Carbon Steel PipesNurzed MunkhbayarNo ratings yet

- Api600 Valve Trim ChartDocument2 pagesApi600 Valve Trim ChartBoankNo ratings yet

- Astm A 515Document5 pagesAstm A 515rameshdatta100% (1)

- Asme Section II A Sa-202 Sa-202mDocument4 pagesAsme Section II A Sa-202 Sa-202mAnonymous GhPzn1xNo ratings yet

- A299 A299m (2001) Standard Specification For Pressure Vessel Plates, Carbon Steel, Manganese-Si PDFDocument2 pagesA299 A299m (2001) Standard Specification For Pressure Vessel Plates, Carbon Steel, Manganese-Si PDFGagan SinghNo ratings yet

- Asme Section II A-2 Sa-455 Sa-455mDocument4 pagesAsme Section II A-2 Sa-455 Sa-455mAnonymous GhPzn1xNo ratings yet

- Sa 612Document5 pagesSa 612Luis MuñozNo ratings yet

- Sa 311Document5 pagesSa 311Web LogueandoNo ratings yet

- Sa 307Document8 pagesSa 307Web LogueandoNo ratings yet

- Statement of PolicyDocument2 pagesStatement of Policyapi-26723112No ratings yet

- Specification For Pressure Vessel Plates, Alloy Steel, Manganese-Molybdenum and Manganese-Molybdenum-NickelDocument4 pagesSpecification For Pressure Vessel Plates, Alloy Steel, Manganese-Molybdenum and Manganese-Molybdenum-NickelmalsttarNo ratings yet

- Summary of Code ChangesDocument4 pagesSummary of Code ChangesAlfredo MedinaNo ratings yet

- Sa 285Document3 pagesSa 285Web LogueandoNo ratings yet

- To Section Iii, Division 2: (A) To Establish Rules in The Form of A Code For TheDocument2 pagesTo Section Iii, Division 2: (A) To Establish Rules in The Form of A Code For TheWeb LogueandoNo ratings yet

- ANSYS Mechanical APDL Material ReferenceDocument220 pagesANSYS Mechanical APDL Material ReferenceWeb Logueando100% (4)

- Industrial Kiln & Dryer Group (IKD) SP: Visit Page Visit Page View Original Image View Original ImageDocument1 pageIndustrial Kiln & Dryer Group (IKD) SP: Visit Page Visit Page View Original Image View Original ImageWeb LogueandoNo ratings yet

- 16.0 ANSYS Quick Start Installation GuideDocument4 pages16.0 ANSYS Quick Start Installation GuidemuomemoNo ratings yet

- Aqwa Theory ManualDocument168 pagesAqwa Theory ManualWeb Logueando100% (3)

- Magnatrol Solenoid ValveDocument34 pagesMagnatrol Solenoid ValveWeb LogueandoNo ratings yet

- Sysreq LinxDocument2 pagesSysreq LinxWeb LogueandoNo ratings yet

- Quick Start LicDocument4 pagesQuick Start LicWeb LogueandoNo ratings yet

- System Requirements For Windows: PrerequisitesDocument2 pagesSystem Requirements For Windows: PrerequisitesWeb LogueandoNo ratings yet

- 11 DDPMDocument13 pages11 DDPMWeb LogueandoNo ratings yet

- Official SAT 2004-2005 Practice Test Answer KeyDocument4 pagesOfficial SAT 2004-2005 Practice Test Answer KeyWeb LogueandoNo ratings yet

- AISC Beam TablesDocument12 pagesAISC Beam Tablesmercab15No ratings yet

- Bubble Column Reactors TutorialDocument14 pagesBubble Column Reactors TutorialAjaykIndauriaNo ratings yet

- 14 Udf FbedDocument14 pages14 Udf Fbedpatmat2009No ratings yet

- 13 Udf ClarifierDocument19 pages13 Udf ClarifierWeb LogueandoNo ratings yet

- 04 DambreakDocument13 pages04 DambreakalbertofgvNo ratings yet

- 08 InkjetDocument15 pages08 InkjetWeb LogueandoNo ratings yet

- 12 DM Ship WaveDocument27 pages12 DM Ship WaveWeb LogueandoNo ratings yet

- 10 Pbed ReactorDocument16 pages10 Pbed ReactorWeb LogueandoNo ratings yet

- 09 SpargerDocument17 pages09 SpargerWeb LogueandoNo ratings yet

- 07 Bubble BreakDocument25 pages07 Bubble BreakWeb LogueandoNo ratings yet

- 03 Nucleate BoilDocument22 pages03 Nucleate BoilWeb LogueandoNo ratings yet

- Tutorial: Fuel Tank SloshingDocument25 pagesTutorial: Fuel Tank Sloshingyeran__xd100% (1)

- Automated Discovery of Custom Instructions for Extensible ProcessorsDocument8 pagesAutomated Discovery of Custom Instructions for Extensible Processorsinr0000zhaNo ratings yet

- Carbon Compounds: Standard/ Class/ Grade - 10 SSC, CBSE - 8 ICSEDocument53 pagesCarbon Compounds: Standard/ Class/ Grade - 10 SSC, CBSE - 8 ICSEsaintEmNo ratings yet

- BS3974 Pipe SupportsDocument20 pagesBS3974 Pipe SupportsTony100% (1)

- GEOtouch®PET NEEDLE-PUNCHED NONWOVEN GEOTEXTILEDocument1 pageGEOtouch®PET NEEDLE-PUNCHED NONWOVEN GEOTEXTILEManas Kumar SamalNo ratings yet

- Nylatron GSM Technical Data SheetDocument1 pageNylatron GSM Technical Data SheetgovindsrNo ratings yet

- Image Similarity Measure Using Color Histogram, Color Coherence Vector, and Sobel MethodDocument6 pagesImage Similarity Measure Using Color Histogram, Color Coherence Vector, and Sobel MethodIjsrnet EditorialNo ratings yet

- 11 Iso 10110Document28 pages11 Iso 10110fmeylanNo ratings yet

- Mazinoor EN Mini G PDFDocument154 pagesMazinoor EN Mini G PDFBalamurugan ArumugamNo ratings yet

- Domino A Series Classic Spares CatalogueDocument137 pagesDomino A Series Classic Spares CatalogueKoos Roets100% (2)

- SSP421 Body BasicsDocument76 pagesSSP421 Body Basicsmamuko100% (3)

- INA FAG Water Pump BearingsDocument31 pagesINA FAG Water Pump Bearings2bjornNo ratings yet

- Best Practices in PL/SQL: Karthikeyan MDocument15 pagesBest Practices in PL/SQL: Karthikeyan MranusofiNo ratings yet

- Accumulation-Mode Varactor Optimization for 200Q RF ICsDocument2 pagesAccumulation-Mode Varactor Optimization for 200Q RF ICsmenguemengueNo ratings yet

- Kinematics equations motion problemsDocument3 pagesKinematics equations motion problemsAhmed HossainNo ratings yet

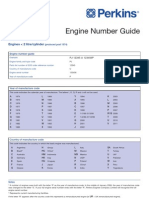

- Perkins Engine Number Guide PP827Document6 pagesPerkins Engine Number Guide PP827Muthu Manikandan100% (1)

- Competency-Check-H e I ADocument20 pagesCompetency-Check-H e I Abaldo yellow4No ratings yet

- Alpha Eritrean Engineers Community's Magazine (October's Issue)Document8 pagesAlpha Eritrean Engineers Community's Magazine (October's Issue)meharigrwNo ratings yet

- List of FEM Documents 2012Document5 pagesList of FEM Documents 2012Gustavo AquinoNo ratings yet

- Caterpillar Cat 336E L Excavator (Prefix YEP) Service Repair Manual (YEP00001 and Up)Document28 pagesCaterpillar Cat 336E L Excavator (Prefix YEP) Service Repair Manual (YEP00001 and Up)kfsmmeNo ratings yet

- Maximum Pressure Rating Schedule 160, Schedule 40 and Schedule 80 - Engineers EdgeDocument5 pagesMaximum Pressure Rating Schedule 160, Schedule 40 and Schedule 80 - Engineers EdgeDevanshu KrNo ratings yet

- Eiac RQ Ib 004Document25 pagesEiac RQ Ib 004esivaks2000100% (1)

- Tobaco VaccDocument19 pagesTobaco VaccSisay KebebeNo ratings yet

- Simulation Instructor WB 2011 ENGDocument57 pagesSimulation Instructor WB 2011 ENGjorgemariovega4910No ratings yet

- Design DocumentDocument10 pagesDesign DocumentLiza WoodsNo ratings yet

- Rotary EvaporatorDocument3 pagesRotary EvaporatorDaryl ChianNo ratings yet

- Slope Stability Then and Now: Professor Emeritus, Virginia Tech, 1600 Carlson DR., Blacksburg, VA, 24060Document20 pagesSlope Stability Then and Now: Professor Emeritus, Virginia Tech, 1600 Carlson DR., Blacksburg, VA, 24060anarNo ratings yet

- Prescolite Akt4 WH Specsheet 13Document2 pagesPrescolite Akt4 WH Specsheet 13James HohensteinNo ratings yet

- Debug 1214Document15 pagesDebug 1214manhlong2009No ratings yet

- Catalogue Cable Tray RevDocument40 pagesCatalogue Cable Tray RevhardiyantodonniNo ratings yet

- Tsi 20040109 PDFDocument2 pagesTsi 20040109 PDFenache_marian0% (1)