Professional Documents

Culture Documents

T12513-Purge Air CHK VLV

Uploaded by

JEORJEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T12513-Purge Air CHK VLV

Uploaded by

JEORJECopyright:

Available Formats

g

TIL 1251-3

GE ENERGY SERVICES

PRODUCT SERVICE

October 23, 1998

TECHNICAL INFORMATION LETTER

IMPROVED PURGE AIR CHECK VALVE

DESIGN

APPLICABLE TO

MS5000, MS6000, MS7000, MS9000 including

frame sizes B, E, EC, F, FA that are liquid fuel

capable.

PURPOSE

Advise that redesigned purge air check valves are

available. The new design check valves

supersede older design part number

354A1909P004, 354A1909P005 and

354A1909P006.

BACKGROUND / DISCUSSION

Field reports indicate purge air check valves

354A1909 have developed leaks on some units.

Studies of returned check valves by GE and the

manufacturer determined that the side of the

check valve poppet was worn. If the worn poppet

is not corrected, the sealing surface may then

also start to wear. Wearing of the sealing surface

will result in valve leakage. It was further

determined that such wearing can occur in

situations where the poppet wobbles during gas

operation.

To reduce the poppet wobble and the potential for

wearing of the seating surfaces, the purge air

check valve has been redesigned to incorporate

changes to the poppet. In the design which had

leaked (354A1909), the poppet was restrained

with a stamped "cage". The new design

(361A2923) employs a poppet which is guided

through the use of machined clearances at the

front and back. This results in a poppet which is

free to move back and forth, but which can not

wobble.

In addition, the sealing surface of the redesigned

check valve was upgraded from a metal-to-metal

seat to a metal-to-polymer seat. This provides a

seal with minimal initial leakage and one which is

more resistant to contamination. The polymer is

a durable polymide material that is capable of 900

deg F transient exposure.

RECOMMENDATIONS

Remove and inspect purge air check valves for

leaks at the first opportunity when the turbine is

shut down for maintenance and at each

combustion inspection.

For users experiencing back flow leakage

problems, replace existing check valves with new

design check valves. Refer to Table 1 for a listing

of old design check valves and corresponding

new design check valves.

Table 1

PURGE AIR CHECK VALVE

Old Part 354A1909

New Part 361A2923

P004

P001

P005

P002

P006

P003

Notes:

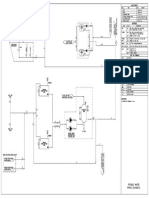

The old and new Purge Air check valves have the same end

connections. No fitting adapters are required for the new check

valves (refer to ML 0918 Purge Arrangement drawing).

Replace O-Ring seals at the end connections as required.

Contact your local GE representative for

assistance and for any additional information on

this subject.

Printed on recycled paper.

TIL Category: D, E, F, G, H, I,

J

COPYRIGHT 1998, GE

The information published in this Technical Information Letter is offered to you by GE in consideration of its ongoing sales and service

relationship with your organization. However, since the operation of your plant involves many factors not within our knowledge, and since

operation of the plant is in your control and ultimate responsibility for its continuing successful operation rests with you, GE specifically

disclaims any responsibility for liability based on claims for damage of any type, i.e. direct, consequential or special that may be alleged to

have been incurred as result of applying this information regardless of whether it is claimed that GE is strictly liable, in breach of contract,

in breach of warranty, negligent, or is in other respects responsible for any alleged injury or damage sustained by your organization as a

result of applying this information.

You might also like

- Datasheet 2Document28 pagesDatasheet 2JEORJENo ratings yet

- Workshop-II Material 1 - 0Document101 pagesWorkshop-II Material 1 - 0JEORJENo ratings yet

- 213 35667 - 42 Class Symbols PDFDocument17 pages213 35667 - 42 Class Symbols PDFJEORJENo ratings yet

- 2 - Sea Water System ModelDocument1 page2 - Sea Water System ModelJEORJENo ratings yet

- Mooring Test ProcedureDocument2 pagesMooring Test ProcedureJEORJENo ratings yet

- CN72 1Document21 pagesCN72 1amirlove206No ratings yet

- Grontmij's Marine Department Designs Efficient 2300 TEU Container Feeder VesselDocument4 pagesGrontmij's Marine Department Designs Efficient 2300 TEU Container Feeder VesselJEORJENo ratings yet

- 352 Aws 11Document1 page352 Aws 11JEORJENo ratings yet

- Outfitting & Deck MachineryDocument8 pagesOutfitting & Deck MachineryJEORJENo ratings yet

- 6 - Potable Water System ModelDocument1 page6 - Potable Water System ModelJEORJENo ratings yet

- 24 MDocument1 page24 MJEORJENo ratings yet

- Pipe Fitting Symbol Guide Under 40 CharactersDocument5 pagesPipe Fitting Symbol Guide Under 40 CharactersErnalyn ValenciaNo ratings yet

- 19 - Compressed Air System ModelDocument1 page19 - Compressed Air System ModelJEORJENo ratings yet

- DS DLV2000 Rev10 09082012Document3 pagesDS DLV2000 Rev10 09082012JEORJENo ratings yet

- Welding Distortion of A Thin-Plate Panel StructureDocument10 pagesWelding Distortion of A Thin-Plate Panel StructureNegin MalekiNo ratings yet

- Electrical DesignDocument4 pagesElectrical DesignKrishna AdinaNo ratings yet

- OppDocument22 pagesOppKidus Yado GirmaNo ratings yet

- Pipe Stress Analysis Per ASME B31.3Document2 pagesPipe Stress Analysis Per ASME B31.3manickbatsaNo ratings yet

- Stress AnalysisDocument6 pagesStress Analysisapi-3836286100% (4)

- Ansys Transient Thermal ExampleDocument5 pagesAnsys Transient Thermal ExampleMaciejBlokNo ratings yet

- A Design and Analysis of A Morphing Hyper-Elliptic Cambered Span (HECS) WingDocument10 pagesA Design and Analysis of A Morphing Hyper-Elliptic Cambered Span (HECS) WingJEORJENo ratings yet

- ANSYS transient analysis load stepsDocument6 pagesANSYS transient analysis load stepskondalreddyNo ratings yet

- Limit LoadDocument16 pagesLimit Load001tabNo ratings yet

- Tutorial 1 Simple 3D TrussDocument11 pagesTutorial 1 Simple 3D TrussSalma FarooqNo ratings yet

- 16 Guided-Buckling of Euler ColumnDocument10 pages16 Guided-Buckling of Euler ColumnsmartebuNo ratings yet

- Buckling of Hydraulic Cylinder - ANSYSDocument11 pagesBuckling of Hydraulic Cylinder - ANSYSnavsidNo ratings yet

- ANSYS TutorialDocument44 pagesANSYS Tutorialsauravc88No ratings yet

- Lab 10 Tutorial ME442, Spring 2009Document7 pagesLab 10 Tutorial ME442, Spring 2009JEORJENo ratings yet

- Tribon M3 v3.00.0000 Automated Installation Package DefinitionDocument1 pageTribon M3 v3.00.0000 Automated Installation Package DefinitionFirstface LastbookNo ratings yet

- License Server v1.10 InfoDocument2 pagesLicense Server v1.10 InfoK-therine VBNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Instruction Manual: Anchor Darling Swing CheckDocument30 pagesInstruction Manual: Anchor Darling Swing CheckDhananjay ShindeNo ratings yet

- Backflow Prevention Devices: Continuing Education From The American Society of Plumbing EngineersDocument8 pagesBackflow Prevention Devices: Continuing Education From The American Society of Plumbing Engineersexfireex1No ratings yet

- Marine Piping Diagram Graphical SymbolsDocument18 pagesMarine Piping Diagram Graphical SymbolsRudyGunawan100% (2)

- Plumbing Study GuideDocument43 pagesPlumbing Study GuidebillpetrrieNo ratings yet

- Segment Distributor PSG 2 DSK0-003-02 - UsDocument24 pagesSegment Distributor PSG 2 DSK0-003-02 - UsCristianNo ratings yet

- Water Heater InstallDocument24 pagesWater Heater Installmcx_usa100% (1)

- Wet Abrasive Blasting System and MethodDocument13 pagesWet Abrasive Blasting System and MethodhainguyenbkvhvNo ratings yet

- Medical Gas Piping SpecDocument22 pagesMedical Gas Piping Specvvg100% (1)

- Catalogue Maximator Valves Fittings and Tubings 05 2011Document62 pagesCatalogue Maximator Valves Fittings and Tubings 05 2011willianNo ratings yet

- N 4.16.5.3 Automated Valves. N 4.16.5.3.1 N 4.16.5.3.2: Installation of Stationary Pumps For Fire ProtectionDocument2 pagesN 4.16.5.3 Automated Valves. N 4.16.5.3.1 N 4.16.5.3.2: Installation of Stationary Pumps For Fire Protectionbhima irabattiNo ratings yet

- Transient - Chapter 11 - Advanced TopicsDocument181 pagesTransient - Chapter 11 - Advanced TopicsPasquale CutriNo ratings yet

- Mandiri Investa Bersama Company ProfileDocument16 pagesMandiri Investa Bersama Company ProfileIrfan FauzieNo ratings yet

- Valve Types and ApplicationsDocument82 pagesValve Types and Applicationsrajeshn1No ratings yet

- Distribuitors Volvo Ec140Document3 pagesDistribuitors Volvo Ec140Michael DavenportNo ratings yet

- Catalogo Bombas Neumaticas Warren Rupp MarathonDocument15 pagesCatalogo Bombas Neumaticas Warren Rupp Marathonjvan migvelNo ratings yet

- FCS CatalogueDocument366 pagesFCS CatalogueMohamed AymanNo ratings yet

- Full Floating Clapper Assembly: Swing Check ValveDocument2 pagesFull Floating Clapper Assembly: Swing Check Valvemubarak aliNo ratings yet

- Fm200 Data SheetDocument10 pagesFm200 Data SheetMahmoud EldusokyNo ratings yet

- Valve - Check - Globe - StopDocument288 pagesValve - Check - Globe - StopveneethgeoNo ratings yet

- SPM Flow Control Products CatalogDocument61 pagesSPM Flow Control Products CatalogCampo Elias QNo ratings yet

- Leakage Acceptance Rates Comparison Metal & Soft Seated Valves Api 598/api 6D/Mss Sp-61/Fci 70-2Document5 pagesLeakage Acceptance Rates Comparison Metal & Soft Seated Valves Api 598/api 6D/Mss Sp-61/Fci 70-2Ashfaq AnwerNo ratings yet

- Walnut Filter IOM RevA2Document12 pagesWalnut Filter IOM RevA2Ledavid Leonel Flores RiveraNo ratings yet

- Voith Retarder 115 E 147 Pag PDFDocument147 pagesVoith Retarder 115 E 147 Pag PDFDardan Husi100% (2)

- FM Global Property Loss Prevention Data SheetsDocument16 pagesFM Global Property Loss Prevention Data SheetsMetal tecNo ratings yet

- Basic Hydraulic SystemDocument142 pagesBasic Hydraulic SystemAlif Aizat Azman100% (1)

- Dynamic Testing of CheckvalveDocument10 pagesDynamic Testing of Checkvalveamirthraj74No ratings yet

- 580L 580 Super L 590 Super L Series Service Manual PDFDocument1,468 pages580L 580 Super L 590 Super L Series Service Manual PDFNever 2Lo91% (11)

- Boiller Types Sabic PDFDocument40 pagesBoiller Types Sabic PDFMuhammad Hamza NaveedNo ratings yet

- Toro RescomDocument144 pagesToro RescomMiodrag ObradovicNo ratings yet