Professional Documents

Culture Documents

978 0 7844 1329 6.001

Uploaded by

Manuel MartinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

978 0 7844 1329 6.001

Uploaded by

Manuel MartinCopyright:

Available Formats

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

Sustainability in an era of increasing energy demand: challenges for offshore

geotechnics

Mark J. Cassidy1, Conleth OLoughlin2, Christophe Gaudin3, Melissa Landon

Maynard4

1

Professor, Centre for Offshore Foundation Systems and ARC CoE for Geotechnical Science and

Engineering, Uni. of Western Australia, Perth, Australia; mark.cassidy@uwa.edu.au

2

Associate Professor, Centre for Offshore Foundation Systems and ARC CoE for Geotechnical

Science and Engineering, Uni. of Western Australia, Perth, Australia; conleth.oloughlin@uwa.edu.au

3

Professor, Centre for Offshore Foundation Systems and ARC CoE for Geotechnical Science and

Engineering, Uni. of Western Australia, Perth, Australia; christophe.gaudin@uwa.edu.au

4

Assistant Professor, Civil & Environmental Engineering, University of Maine, Orono, Maine, USA,

melissa.L.maynard@maine.edu

ABSTRACT: The worlds escalating demand for energy, combined with the

depletion of oil reserves in shallow waters and traditional regions, is resulting in the

move of offshore developments into deeper waters, new development regions and

transformation to cleaner natural gas and renewable energy sources. Summarized in

this paper are the geotechnical challenges facing the offshore industry as it attempts to

sustain the worlds expanding energy demands. Representative examples of new

methodologies being used in engineering design are provided, including deep water

anchoring and mudmat systems, installation of mobile jack-up platforms in the stratified

soils that are often encountered in new development regions around Australasia, and the

potential use of caissons for floating wind farms.

INTRODUCTION

In an era of escalating energy demand, securing long-term resources is one of the

major challenges of our generation. Together with a need to mitigate increasing CO2

emissions and climate change, engineers are faced with the additional challenge of

conversion to low-emission energy sources. The worlds oceans hold significant

potential for solutions. However, discovery of these reserves of cleaner natural gas

and offshore renewables requires new approaches. Geotechnical engineering has

significantly contributed to the development of offshore energy reserves in the past.

However, significant challenges remain, with safe and efficient technologies required

to unlock future energy resources in our extensive marine environment.

This paper provides an analysis of current energy trends and the potential role of

geotechnical engineering in providing novel solutions in the offshore environment.

The paper also discusses examples of applications in which practical analytical and

calculation methods have been developed to move offshore energy recovery into

deep waters, new regions, and for technology transfer to cleaner sources. The focus

of the paper, rather than a comprehensive review of all areas, is on critical examples

of possible solutions and challenges to offshore geotechnics applications.

Page 1

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

AN ERA OF ESCALATING ENERGY DEMAND

The worlds demand for energy continues to increase unabated, with the total

supply doubling from ~5 600 MTOE in 1971 to over 12 700 MTOE in 2010 (Figure

1, after IEA, 2012a). This energy demand is causing an infrastructure and resource

boom in many developing offshore regions. For instance, US$120 billion worth of

infrastructure projects are currently under construction off the coast of Australia

(RBA 2011). Although low-emission renewable energy is highly desirable, it still

only accounts for a little over 3% of the world energy supply, with the majority of

that being a 2.3% contribution from hydroelectricity (2010 IEA data, 2012a).

14000

Energy Supply (Mtoe)

12000

10000

8000

Proportions in 2010

Oil

32.4%

Coal/Peat

27.3%

Natural gas

21.4%

Biofuel/waste 10.0%

Nuclear

5.7%

Hydro

2.3%

Geothermal/solar/wind

0.9%

6000

4000

2000

0

1970 1973 1976 1979 1982 1985 1988 1991 1994 1997 2000 2003 2006 2009 2012

Year

Figure 1. Total primary energy supply (from IEA, 2012a)

Governments worldwide are instituting carbon emission reduction strategies, and

several have set targets for a mix of renewably generated electricity. For instance, the

UK and China have set targets of 15% renewably generated electricity by 2015,

whereas Australia and Europe (averaged across the union) have a target of 20% by

2020. Thirty states of the USA have ambitious targets, such as 30% by 2015 (New

York), 30 and 33% by 2020 (Colorado and California) and 40% by 2030 (Hawaii).

Building offshore developments in deep water, remote locations, and for

renewables necessitates paradigm shifts in geotechnical design. The characteristics of

these frontiers and the geotechnical challenges and examples of solutions are

summarized in Table 1. These challenges are expanded in the following sections,

with examples of solutions and challenges for each provided.

ULTRA-DEEP WATER

Challenges off the continental shelf

The depletion of known hydrocarbon reserves in traditional regions and in shallow

waters is resulting in the movement of exploration and development to deeper waters

and often into untested environments. Internationally, in the Gulf of Mexico, West

Africa and offshore Brazil, developments have proceeded off the continental slope

into water depths approaching 3000 m, with prospects beyond 4000 m currently

considered by Total in West Africa. These deep water environments are typically

characterized by soft, lightly overconsolidated, fine-grained sediments.

Page 2

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

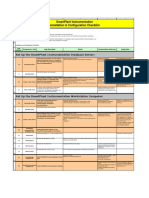

Table 1. Challenges for offshore geotechnics due to increasing energy demand

Deep water

New regions

Characteristic > 1000 m; Typically soft, lightly

Australasia: often highly stratified

environment overconsolidated fine-grained sediments seabeds, carbonates and sensitive silts

Example

challenges

Example

geotechnical

solutions

In-situ characterization (strength, upper

1-2 m layer, wide spatial area,

sensitivity)

Mobility of infrastructure:

- disturbance/healing of soil

- changes in seabed topography

Transformation in soil properties

- under episodic cyclic loading

Fatigue based design (such as risers,

SCRs, pipelines)

Uplift capacity

Geohazard risk assessment

Larger reservoir (50x50 km), requiring

more extensive soil characterization

Improved in-situ technology (largediameter piston coring, continuous Tbar and ball penetrometers)

Failure envelopes written directly in

VHM load space

Improved large deformation analysis

capabilities

New anchor configurations (such as

torpedo and OMNI-max)

SCR-soil interaction models that

account for soil stiffness and erosion

Renewables

Waters < 200 m, close to shore for

connection to the grid, high energy sites,

higher prevalence of sandy soils

Less offshore experience

Large site area to characterize (often

Can be remote with long distances (for

with variable geological features)

example, > 300 km pipelines in Aust.) Light vertical loads with large horizontal

Prediction of drainage and rate effects

and moment loads

Partial drainage conditions

Stringent serviceability requirements

High compressibility

Cyclic loading:

Occasional cementation

- non-coherent wind/wave

Large changes of strength with cyclic

- accumulative rotations and stiffness

loading

degradation

Long pipeline tied back to shore:

Cost pressures

crossing of high scarp

High monitoring and servicing costs

Foundations represent ~15-30% of total

cost (increase with depth).

Needs cheaper site-investigation

Improved numerical methods that

Utilizing previous experience from the

account for rate effects, soil softening

oil and gas industry

through shearing, high sensitivity and Statistical methods for site

strength gain through reconsolidation

characterization with integrated

Improved pipeline stability models

geophysical/geological data

Increased emphasis on direct prediction Testing under large numbers of cycles

methods from CPT-penetrometers

and multidirectional loading

Punch-through models that account for Purpose-built installation vessels

soil dilatancy

Deployable for maintenance at shore

(for example, floating wind)

Shared anchor points

Page 3

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

The nature of geotechnical design has been radically changed by the unique

conditions in deep water environments. Developments usually consist of a moored

floating facility and pipes called risers for transmitting oil or gas to/from the seabed,

often to a flowline or pipeline system (Figure 2). There is a reduced emphasis in the

traditional areas of piles and large gravity-base foundations, in which designs are

focused on ultimate capacity and lack of foundation movement. New infrastructure is

being designed for mobility, whether during installation or service, and the challenge

for geotechnical engineering is to evolve to incorporate transformations in geometry

and soil material properties. There has been a rapid evolution of new anchoring

systems, such as suction caissons, plate anchors (either suction embedded or dragged

in) and dynamically embedded torpedo anchors. These systems can require long

installation paths and face challenges of cyclic and sustained loading capacity over

many years of service. There also has been a parallel demand for efficiently designed

shallow foundations for pipeline terminations and manifolds.

Figure 2. Geotechnical infrastructure development in deep water

Example geotechnical solution: suction embedded plate anchors

An important deep water solution that responds to the need for anchors to

withstand significant vertical loading is the Suction Embedded PLate Anchor

(SEPLA). The concept combines the advantage of quick installation at a known

penetration depth and location through use of a suction caisson with the efficiency

and low cost of a plate anchor (Dove et al., 1998). SEPLAs can resist a high vertical

load component in a taut or semi-taut leg mooring configuration; therefore, they can

avoid the large offshore installation spread associated with alternate suction piles.

The plate anchor is housed initially within a slot at the tip of a suction caisson

(Figure 3). The anchor is embedded by pumping out the water inside the suction

caisson. When the targeted depth is reached, the pump flow is reversed, and the

caisson is retrieved, leaving the SEPLA in place in a vertical orientation. The slack

mooring chain attached to the anchor padeye is then tensioned, causing the SEPLA

to rotate to an inclination that is, for a symmetric anchor, approximately normal to

the local chain orientation. This process is known as keying and is conducted

Page 4

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

offshore with minimal delay after installation. During the keying process, the anchor

moves vertically upwards in the soil. As most deep water seabeds have a profile of

increasing strength with depth, keying results in a detrimental loss of capacity.

Although SEPLAs are established technology in the temporary mooring of floating

offshore structures, their application to permanent mooring has only been considered

recently because of uncertainties related to their performance:

(i) during keying - how to predict movement and loss of embedment;

(ii) under sustained loading - how to determine the loss or gain in capacity

associated with the combined effects of consolidation and strain softening;

(iii) under cyclic loading - how to predict degradation under different cyclic levels.

These issues have been recently addressed through an integrated program of

physical model tests in a geotechnical centrifuge, large deformation finite element

modeling and analytical developments (Randolph et al., 2010; Cassidy et al., 2012;

Wong et al., 2012).

suction installation

caisson retrieval

anchor keying

mobilized (sustained/cyclic)

Figure 3. Typical SEPLA used in deep water (after Gaudin et al., 2006)

The bearing capacity of a deeply embedded rectangular anchor is well established

(see Randolph et al, 2010 for example). The challenge of estimating the final anchor

capacity is prediction of the loss of embedment during the keying behavior (the final

depth to consider the undrained shear strength).

Loss of embedment has been investigated both experimentally (OLoughlin et al.,

2006; Gaudin et al., 2009, 2010; Song et al., 2009) and numerically with large

deformation finite element analysis (Wang et al., 2010, 2011; Tian et al., 2013). The

results show the importance of load eccentricity (defined by padeye location, see ep

in Figure 4), anchor thickness and weight. Loss of embedment has been summarized

for relevant non-dimensional groups in a non-dimensional equation by Wang et al.

(2011). However, more recently, a macroelement force-resultant approach has been

used to provide predictive capabilities of the keying process (Lowmass, 2006;

Cassidy et al., 2012; Yang et al., 2012). The entire anchor and surrounding soil is

considered as one element, with behavior expressed directly in terms of the anchors

loads and displacements within a plasticity framework. A yield surface represents the

capacity of the anchor at a certain embedment. Small strain finite element analyses

have been used to define the surface (square and rectangular plates: ONeill et al.,

2003; Elkhatib and Randolph, 2005; an anchor with shank: Wei et al. 2013). By

assuming perfect plasticity and associated flow, the load-displacement path is

predicted through simple differentiation of the yield surface by a conventional

plasticity approach (see Cassidy et al. 2012 for numerical implementation). Example

Page 5

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

trajectories calculated for a 4.64 m high SEPLA anchor are shown in Figure 4 for

various padeye offsets. The anchor was predicted to eventually dive for padeye

locations approximately 0.25 m below the center of the anchor.

These experimental, numerical and analytical developments also highlighted that

the keying flap found on most SEPLA anchors does not open during the initial stages

of keying, as SEPLAs slide backwards with soil resisting the hinge (Figure 4). The

flap does not perform the function for which it was intended: discouraging vertical

motion and loss of embedment. Furthermore, the flap eventually opens during the

subsequent translational phase as the anchor approaches its ultimate capacity, thus

reducing the final capacity with a dog-leg in the anchor. An improved design that

initially opens (reducing sliding and loss of embedment) and then closes (maximum

holding capacity) can be achieved by simply swapping the hinge location to the other

side of the anchor (the back), as shown by Tian et al. (2013).

0.8

Loss of embedmentz/B

0.7

direction of movement

post-keying

ep = 0.246 m

0.6

ep = 0 m

0.5

ep = -0.246 m

0.4

ep = -0.492 m

0.3

0.2

ep = -1.1 m

0.1

0

-0.2

-0.1

0.1

0.2

0.3

0.4

0.5

Horizontal displacementx/B

Figure 4. Prediction of anchor trajectory for a plate anchor loaded at 40 to the

horizontal with various padeye offsets (after Cassidy et al., 2012)

Centrifuge experiments have also evaluate the capacity of a plate anchor under

sustained and cyclic loading during operation (details in Randolph et al., 2010 and

Wong et al., 2012). In a series of six sustained load tests, the reduction in capacity

with uplifting displacements and slow displacement rate were balanced by the

increase in shear strength due to consolidation of the soil in front of the anchor. For

sustained loads at less than ~80% of the peak monotonic load, the increase in

capacity resulting from consolidation compensated for any reduction in capacity due

to low strain rates within the soil (Wong et al., 2012), as shown in the summary

results presented in Figure 5. At the point of 100% consolidation, the maximum

anchor displacement (measured in the experiments as the chain displacement) was

4.5 mm (or 15% of the total model anchor height of 30.9 mm). However, for the two

tests where the sustained load was above 80% of the monotonic capacity, the anchor

showed accelerating displacements, with the anchor no longer able to hold the load

after 5 to 18 days of prototype operations (25 to 70 s in the model centrifuge tests at

150 g). In summary, the two opposing phenomena of (i) strength gain due to

consolidation and dissipation of pore pressures ahead of the anchor and (ii) reduction

in operative shear strength due to slow displacement rates are balanced, for a

sustained loading of approximately 85% of the monotonic capacity (Wong et al.,

2012). Any sustained loading above this level led to an anchor failure.

Page 6

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

It was argued by Wong et al. (2012) that similar mechanisms occur, though with

additional damage, under cyclic loading. For any loading where the cyclic peak

loaded exceeded 75% of the monotonic capacity, anchor failure was measured. This

limit was suggested as a design basis and corresponds to an equivalent monotonic

bearing capacity factor of 7.

Peak load ratio, T m ax-sus /T m ax (-)

Peak load ratio, T max-sus/T max (-)

2

1.8

1.6

1.4

1.2

1

0.8

2

1.8

1.6

1.4

1.2

1

0.8

10

20

30

40

50

60

70

80

90

100

Level of sustained loading, T sus/T max (%)

10

20

30

40

50

60

70

80

90

100

Consolidation degree, U (%)

Figure 5. Increase in anchor capacity, followed by sustained loading (after

Wong et al., 2012)

Example geotechnical solution: torpedo anchors

Dynamically installed anchors (Figure 6) are torpedo-shaped and are designed so

that, after release from a designated height above the seafloor, they will penetrate to

a target depth in the seabed by the kinetic energy gained through free-fall and

through the self-weight of the anchor. The ease of installation makes them an

attractive anchoring solution in deep water, particularly for mobile drilling units. The

majority of installations have been in Brazilian waters with anchors that are 12 m

long and 422 kN in weight for temporary facilities and 17 m long and 961 kN in

weight for permanent installations (Araujo et al., 2004). Anchor impact velocities

depend on anchor release height but are typically between 20 and 30 m/s, with

anchor tip embedment depths of up to 3 times the anchor length.

Figure 6. Dynamically installed anchor (after Araujo et al., 2004)

Anchor capacity is governed by the vertical capacity for load inclinations greater

than ~30 relative to the horizontal (Randolph et al., 2011). Vertical capacity may be

predicted adequately using approaches for piles in clay (e.g. Lieng et al., 2000;

Page 7

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

OLoughlin et al., 2004; Richardson et al., 2009), although consideration must be

given to the reduced strength available just after installation. Richardson et al. (2009)

showed that this value was approximately 6% of the long term capacity, compared

with 25-45% for piles and suction caissons in normally consolidated clay (Esrig et al.,

1977; Bogard and Matlock, 1990; Chen and Randolph, 2007) and that the regain in

strength at the anchor interface may be quantified using a cavity expansion model.

It follows that, as for SEPLAs, the key challenge in prediction of anchor capacity is

calculation of the anchor embedment depth and hence the available shear strength in

the vicinity of the embedded anchor. This calculation is complicated by (i) the strain

rates at the anchor-soil interface, which are on the order of 25 s-1, three orders of

magnitude higher than that in a vane test (0.029 s-1; Einav and Randolph, 2006) and

seven orders of magnitude higher that the standard laboratory testing rate of 1%/h

(2.8 10-6 s-1), and (ii) hydrodynamic effects associated with the very soft viscous

clay at shallow penetration and possible entrainment of a boundary layer of water

adjacent to the anchor (OLoughlin et al., 2013).

Approaches to predicting anchor embedment depth (examples in True, 1976;

OLoughlin et al., 2004, 2009, 2013; Audibert et al., 2006) consider Newtons

second law of motion and the forces acting on the anchor during penetration.

OLoughlin et al. (2013) consider such an approach and use a large database of

centrifuge tests on freefall projectiles to calibrate their model:

d 2z

Ws Fb R f (Fbear Ffrict ) Fd

dt 2

(1)

where m is the anchor mass, z is depth, t is time, Ws is the submerged anchor weight

(in water), Fb is the buoyant weight of the displaced soil, Rf is a shear strain rate

function, Fbear is bearing resistance, Ffrict is frictional resistance and Fd is inertial drag

resistance. The important dependence of shear strength on strain rate is generally

quantified using either a power or logarithmic function (Biscontin and Pestana,

2001):

R f 1 log

ref

or R f

ref

(2)

where and are strain rate parameters in the respective formulations, is the

strain rate, which may be approximated as the ratio of the anchor penetration velocity,

v, to the anchor diameter, d, and ref is the reference strain rate associated with the

reference value of undrained shear strength.

There are limited in situ anchor data in the public domain to calibrate Eq. 1.

Calibration has mainly been achieved using centrifuge tests in kaolin clay

(OLoughlin et al., 2004, 2009, 2013; Richardson et al., 2006), as shown by Figure 7.

Figure 7 justifies the inclusion of drag resistance (Fd in Eq. 1), as the predictions that

include Fd are in slightly better agreement with the tests. Whilst Figure 7 indicates

that the magnitude of the strain rate parameter, , used in the power formulation

Page 8

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

increases with anchor impact velocity, the strain rates in the centrifuge tests are

approximately 200 times that in the field, as the velocities are equivalent whilst the

diameters are scaled by 1:200. Hence, the lower bound strain rate parameter, ~0.07,

would be more appropriate for field cases and would therefore be similar to

parameters deduced from variable rate penetrometer tests: = 0.06-0.08 (Lehane et

al., 2009). Despite the very limited field data for dynamically installed anchors in the

public domain, evaluation of a deep ocean nuclear waste disposal option in the 1980s

included a number of field trials in which various projectiles were dynamically

embedded in the seabed in a manner similar to that for dynamically installed anchors.

The most successful and well documented trials took place in the Atlantic Ocean at

Great Meteor East, which is an area at the western extremity of the Madeira Abyssal

Plain (~800 km west of the Canary Islands) in water depths of ~5000 m (Freeman

and Burdett, 1986). The merit of Eq. 1 is demonstrated by Figure 8, which compares

predicted and measured velocity profiles. The parameters adopted for the field

predictions were consistent with the centrifuge study, with the interface friction ratio

taken as the inverse of the soil sensitivity and the rate parameter taken as the lower

bound, = 0.07, as discussed previously. The agreement in Figure 8 is encouraging,

with final embedment depths that are consistently within 4% of the measurements.

Velocity (m/s)

0

10

15

20

25

30

= 0.074

= 0.068

Anchor embedment (mm)

50

= 0.117

= 0.104

100

= 0.090

= 0.079

= 0.120

150

= 0.128

= 0.118

= 0.125

200

Prediction A (drag included)

Prediction B (drag omitted)

A4: m = 5.4 g, 0 mm drop height (drum)

A4: m = 5.4 g, 50 mm drop height (drum)

A4: m = 5.4 g, 200 mm drop height (drum)

A1: m = 14.8 g, 100 mm drop height (beam)

A1: m = 14.3 g, 150 mm drop height (beam)

A1: m = 14.3 g, 200 mm drop height (beam)

= 0.113

= 0.120

250

Figure 7. Predicted and measured velocity profiles from centrifuge tests

(after OLoughlin et al., 2013)

A first-order approximation of anchor embedment depth can be obtained by

considering the total energy of the anchor as it impacts the seabed (OLoughlin et al.

2013). Total energy is defined as the sum of the kinetic and potential energies

(relative to the final embedment depth) of the anchor at the moment of impact:

E total

1

2

mv i2 m' gz e

(3)

where m' is the effective mass of the anchor, vi is the impact velocity, g is Earths

gravitational acceleration and ze is the final embedment depth. Centrifuge and field

data are shown in non-dimensional form (removing the influences of diameter and

soil strength gradient, k) in Figure 9. The collective data form a relatively tight band,

considering the assumptions included shear strength gradients and anchor geometries

for the field data. A conservative fit to the data may be expressed as:

Page 9

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

E

ze

0.1 total

kd 4

d eff

eff

10

1/ 3

(4)

where deff is effective diameter. This relationship harmonizes a very large data set

that encompasses a wide range of anchor masses, geometries and impact velocities.

Figure 8. Predicted and measured velocity profiles from free-fall

penetrometer tests at Great Meteor East (after OLoughlin et al., 2013)

Figure 9. The use of total energy as a means of comparing dynamically

installed anchor embedment data (after OLoughlin et al., 2013).

Example geotechnical solution: mudmats

Subsea mats are used in deep waters as foundations on soft and normally

consolidated (or lightly overconsolidated) clay to support facilities such as pipeline

terminals, jumpers, riser bases and manifolds. They are subjected to combinations of

loading in all six degrees of freedom. In most cases, the mat may not provide

sufficient resistance against sliding or overturning failure. Pinned piles may then be

used in each corner of the mat to increase the capacity of the foundation (Figure 10).

Although mudmats with pinned piles have already been used in-situ, notably by BP

in the Gulf of Mexico, the behavior of the foundation is still uncertain, and their

Page 10

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

11

design remains challenging. The effect of the corner piles on foundation behavior

and capacity have been quantified only recently via a program of centrifuge model

tests (Gaudin et al., 2012), finite element analyses and analytical developments

(Dimmock et al., 2013). The results demonstrated that an increase in capacity is

obtained by supplementing the mat foundation with short piles placed at the corners.

A smaller foundation footprint can then resist the subsea foundation design loads.

The tests showed that the piles significantly increased the size of the yield envelope

in M-H space, notably with respect to the ultimate H, changing the mode of yielding

compared to a conventional mat. Consequently, sliding resistance is increased in a

greater proportion, and overturning moment becomes a more significant mode of

yielding. Based on the experimental and numerical outcomes, a simplified lower

bound design approach was developed, whereby the mat is assumed to carry the

vertical load (as it would prior to installation of the piles); the piles are assumed to

carry the horizontal and torsional loads, and the combined mat and piles resist the

applied moments (Dimmock et al., 2013). The design approach was shown to

provide a conservative estimate of the capacity obtained from numerical analysis.

An alternative to the corner piles, which may prove challenging to install, is the use

of suction caissons installed across the mat. In addition to its self-installation ability,

a mat equipped with a single suction caisson exhibits a horizontal and moment

capacity increase of factors of 2 and 1.2, respectively (Bienen et al., 2012). The

moment capacity can be further enhanced by a caisson of sufficient length to

intercept the rotational mechanism developed by the mudmat. Although it has yet to

be used in the field, such a foundation shows great promise, and research

development is progressing to increase torsion capacity with two suction caissons.

Figure 10. Mudmat reinforced with corner piles (after Gaudin et al., 2012).

NEW REGIONS

Introduction and challenges

Installation of platforms has become challenging in a number of new(er) oil and

gas regions, such as South East Asia, India and Australia, because of the prevalence

of highly stratified seabeds, carbonate soils with high compressibility and occasional

cementation, and sensitive silts that create partial drainage conditions. These

conditions surprised engineers during the installation of the first platform on the

Page 11

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

12

North West Shelf of Australia, the North Rankin A. Installation challenges have

been particularly acute in the operations of mobile jack-up platforms, as discussed by

Osborne et al. (2006) and others, cumulating in the establishment of the InSafe Joint

Industry Project (Osborne et al., 2009, 2010). Although other infrastructure elements,

such as on-bottom pipelines, have specific issues in these soils, this paper will

concentrate on a discussion of jack-ups.

Jack-ups consist of a buoyant triangular hull, three independent truss-work legs

approximately 170 m in length and inverted conical spudcan footings approximately

20 m in diameter. Jack-ups are self-installed by lifting the hull from the water and

pushing the large spudcans into the seabed. This procedure is dangerous, with as

many as five jack-up incidents annually attributable to geotechnical failures (Hunt and

Marsh, 2004; Jack et al., 2007). These events result in rig damage and lost drilling

time, with even temporary loss of serviceability of a rig having major financial

implications. The specific geotechnical challenges to jack-up operations emerging in

these new regions are summarized in Table 2 and illustrated in Figure 11.

Figure 11. Geotechnical challenges for jack-ups encountered in new regions

Table 2. Geotechnical challenges installing jack-ups in new Australasian regions

Installation Issue

Specific Challenge

References for Solutions

Prediction of spudcan

penetration

Risk of punch-through

failures

Offshore operations to

mitigate punch-through

Reinstallation into

seabed footprints

Partial drainage in

sensitive silts

Prevalence of buried sand

layers, multi-layered soils

Use of perforation drilling

Erbrich, 2005; Cassidy, 2012; Osborne et al.,

2010

Edwards and Potts, 2004; Lee et al., 2013a,b; Teh

et al., 2009; Hossain and Randolph, 2009

Brennan et al., 2006; Chan et al., 2008; Hossain et

al., 2010

Dean and Serra, 2004; Leung et al., 2007; Cassidy

et al., 2009; Gan et al., 2012; Kong et al., 2013

Eccentric loading on

spudcans and legs

Example geotechnical solution: prediction of spudcan punch-through failure

The potential for unexpected punch-through failure of a jack-up exists during

installation and pre-loading in layered soils. This failure occurs when the spudcan

uncontrollably pushes a locally strong zone of soil into underlying softer material.

Page 12

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

13

Such failures can lead to buckling of the jack-up leg, effectively temporarily

decommissioning the platform and even toppling the unit.

A thin layer of sand (less than a spudcan diameter) overlaying a weaker stratum of

clay is particularly hazardous, and a new calculation method is discussed below that,

for the first time, takes into account the stress level and dilatant response of sand.

Other soil conditions that can cause rapid leg penetration include stiff-over-soft clay

layers (see Edwards and Potts, 2004 and the new calculation methodology of Hossain

and Randolph, 2009), a thick clay layer whose strength decreases with depth, and a

very soft clay in which the rate of increase of bearing capacity does not match the

loading rate and firm clay with sand or silt pockets (Osborne et al., 2009).

Capturing spudcan failure mechanisms by recording digital images of a halfspudcan installed against a transparent window (analyzed using particle image

velocimetry (PIV) coupled with close-range photogrammetry corrections) has

provided the basis of new analytical models. As shown in Figure 12, Teh et al.

(2008) provided visual evidence that the peak punch-through resistance in sand-overclay cases occurs at a relatively shallow embedment between ~0.12 and 0.15D (also

confirmed by Lee et al., 2013a and Hu et al., 2013) and was caused by a failure

mechanism that consists of a truncated cone of sand being forced vertically into the

underlying clay layer. The truncated cone changes from pure vertical movement

(directly under the spudcan) to radial and small amounts of heave further from the

center line. The outer angle of the sand frustum is forced into the clay and reflects the

dilation of the sand.

qpeak

q0

Sand

z

Hs

' ' s

qclay

Clay

Figure 12. PIV image at punch-though recorded in a centrifuge (after Teh et al.,

2008) and a conceptual mechanism of the recently proposed model

The assumed mechanism at the peak resistance of the conceptual model proposed

by Lee et al. (2013b) is also shown in Figure 12. In this mechanism, a sand frustum

with a dispersion angle equal to the dilation angle is assumed to be pushed into the

underlying clay. The footing pressure and weight of the sand frustum are resisted by

the frictional resistance along the sides of the sand block and in the bearing capacity

of the underlying clay (Lee et al., 2013b).

A design equation for the peak resistance qpeak has been derived by treating the

conceptual sand frustum as a series of infinitesimal horizontal discs and equating

vertical force equilibrium as in a silo analysis. The detailed derivation and final

design equation can be found in Lee et al. (2013b). In the method the stress level and

Page 13

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

14

dilatant response of the sand is calculated using an iterative approach. The

capabilities of this new method to predict results from a database of 47 centrifuge

tests, such as those shown in Figure 13, is provided in Lee et al. (2013b) and Hu et al.

(2013). These provide evidence that the existing punching shear and load spreading

models in current jack-up industry guidelines (such as SNAME, 2008) significantly

and consistently under-predict qpeak. Recent advances reported by Hu et al. (2013)

have extended Eq. 5 to account for the depth of penetration under medium to loose

sand conditions and updated the expression of the distribution factor to account for

different spudcan shapes.

0

200

Depth (m)

Sand

6m diameter

flat foundation

8m dia.

10m dia.

12m dia.

6.2m sand thickness

14m dia.

1000

Clay

8

10

12

Punching shear - SNAME (2002)

800

qpeak,calculated (kPa)

16m dia.

4

6

1200

Equation 1

0

2

Penetration resistance (kPa)

400

600

800

1000

Load spread 1h:5v - SNAME (2002)

600

400

200

14

16

18

0

Series of D1F30a to D1F80a

20

200

400

600

800

1000

qpeak,centrifuge (kPa)

Figure 13. Example results of sand-over-clay penetration of a flat-based footing

and comparison of numerical models (modified after Lee et al., 2013a,b)

MARINE RENEWABLE ENERGY

The challenge of lowering the cost of low-emission, sustainable energy

Regions with significant offshore wind, wave and tidal resources, such as countries

along the western coasts of Europe, Australia, Japan and the USA, have an

opportunity to derive much of their renewably generated electricity from the ocean.

The most rapid development to date has been the installation of offshore wind

turbines, though it remains a fraction of the amount of onshore wind capacity (Figure

14). The International Energy Association (IEA) forecasts that offshore wind will

continue to scale significantly over the next few years to 25.9 GW in 2017, up from

6.1 GW in 2012 (IEA, 2012b). Equivalent projections for offshore wave and tidal

energies are much lower, as these technologies are much less mature.

Most of the installed offshore wind capacity is in European waters, particularly that

of the UK (forecast to grow to 7.4 GW by 2017, Crown Estate, 2013, IEA, 2012b).

China is expected to be the second-largest offshore wind producer by 2017, with a

forecasted 7.0 GW installed capacity by 2017 (IEA, 2012b). Much of the current

growth in offshore wind is driven by government incentives, which are required to

scale the technology but unsustainable in the long term. Future growth beyond the

current IEA projected periods must come from market demand, which will

Page 14

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

15

30

Onshore wind

450

25

400

Offshore wind

350

20

300

15

250

200

10

150

100

50

0

1996

1997

1998

1999

2000

2001

2002

2003

2004

2005

2006

2007

2008

2009

2010

2011

2012

2013

2014

2015

2016

2017

Cummulative onshore capacity (GW)

500

Cummulative offshore capacity (GW)

necessitate technical innovation to drive down the installation and operation costs so

that offshore wind can be competitive with alternative technologies.

Figure 14. Cumulative installed wind capacity (data from IEA and EWEA)

In these offshore wind developments, monopile and gravity-based foundations are

favored due to shallow waters (<30 m), from direct knowledge transferred from the

offshore oil and gas industry. Tripod structures and lattice frames are being

considered within depths of 30-50 m, and floating turbines moored to the seabed are

considered beyond 60 m. There are floating wind turbine concepts at varying stages

of development. The most advanced amongst these include the Hywind spar concept,

which has been in operation in 198 m water depth off the southwest coast of Norway

since 2009 (with advanced plans for small integrated arrays of four of five floating

turbines off the coast of Scotland and the US), and the WindFloat semi-submersible

concept that has been tested in 40 - 50 m water depths off the coast of Portugal since

2011. Various other consortia have planned installations of one or more floating

turbines in Japanese, European and US waters over the coming two to three years.

This increased activity is expected to demonstrate concept feasibility, allowing

attention to turn towards reduction of installation costs for fully commercial farms.

Floating wind turbines are a paradigm shift in technology for the future, even for

shallow water, as they (i) reduce the cost of foundations though anchor arrays, (ii)

significantly reduce the cost for maintenance as turbines can be towed to shore, and

(iii) limit the high cost of scour protection commonly encountered in shallow water.

If floating wind turbines can become economical, access to the worlds best wind

resources can be achieved. For instance, 61% of the USAs offshore wind resources

are in water depths greater than 100 m (estimated resources in Figure 15), almost all

of Japans offshore wind resources are in deep water and the recent Round 3

development sites released by the UK Crown Estate include water depths up to 63 m.

Geotechnical challenges

Current mooring and anchoring technology has been shaped by the offshore oil and

gas industry (O&G), with floating facilities in water depths approaching 3,000 m.

Page 15

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

16

The mooring/anchoring requirements for wind, wave and tidal/current facility will be

different in several ways and pose the following challenges:

1. Economies of Scale: Economic returns for installed floating renewable energy

technologies are much lower than for an O&G installation. The level of platform,

mooring, and anchoring infrastructure required for renewable energy facilities

(especially wave and tidal/current) is prohibitive when using current mooring and

anchoring systems employed by the offshore O&G industry. Anchors and moorings

are a very small proportion of the cost of energy production for O&G platforms. For

instance, 18% of installed wave energy costs are due to moorings and anchors

compared with 2% for an installed floating oil production facility (Fitzgerald, 2009).

There is therefore potential for geotechnical cost savings in the renewable sector and

development of new technologies must be cost driven.

Figure 15. Offshore wind resources in the United States by region and depth

for annual average wind speed sites above 7.0 m/s (after Musial and Ram, 2010)

2. Design Requirements: Currently, many of the design guidance documents being

developed for offshore renewable energy technologies are heavily based on O&G

industry experience and guidance documents. To become economically viable,

however, the offshore renewable energy industry will be motivated to take a much

less conservative approach. This is justified as renewable facilities have lower

consequences of failure due to being unmanned, of lower capital investment and as

they do not carry environmentally hazardous oil and gas.

3. Optimized

Environmental

Interaction:

Floating

renewable

energy

platforms/devices are designed to interact with the wind, wave and currents for

optimized energy extraction. Simultaneously, these devices are designed to maximize

design life under millions of operation environmental loading cycles with minimal

loss of infrastructure during extreme storm events. For instance, a wave energy

converter must be permitted to move relative to the waves so that power can be

extracted, whilst also keeping on station during an extreme storm. Because wave and

tidal/current energy converters will be sited in high energy sea states, cyclic loading

Page 16

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

17

variable in magnitude and spatial orientation will be more prevalent for these

facilities during their operational life than for a floating O&G facility that may only

experience relatively significant cyclic loading during extreme storm events.

Optimized device interaction within its high energy environment requires

investigation of the coupling of cyclic and multi-directional loading. This is a rarely

considered and will present geotechnical challenges, particularly for sands.

4. Mooring System: The choice of a mooring system represents a cost trade-off

between anchoring complexity and device operation. Taut-leg mooring systems have

the advantages of smaller footprints and shorter moorings lines. However, the high

capacity mooring system required for stability under cyclic environmental loading

presents a complex foundation-substructure interaction problem. Taut leg systems

require anchors that can withstand significant components of vertical load and few

anchors that are suitable for sand meet this requirement. The rational against mooring

stabilized designs likely relates to the greater complexity of design required for taut

and tension mooring systems that rely on seafloor sediments for regular device

operation over the full design life as well as during extreme events. This is in direct

contrast to platform stabilized design that rely on anchors mainly for extreme events.

Musial et al. (2006) maintain that floating wind will have lower costs if new drag

embedment and vertically loaded anchors (VLAs) are utilized and mooring line

stabilized designs are avoided. For this, catenary mooring systems typically

comprised of simple, low cost anchors (albeit with long mooring lines) are used.

However, with this system, substructures are subject to greater wave loading and

motion, which increases the complexity and cost of wind turbine design (Butterfield

et al. 2005). However, parametric studies of various floating wind concepts

conducted by Sclavounos et al. (2008) using fully coupled dynamic numerical

simulations found that wind turbine nacelle accelerations (housing covering gearbox

etc) varied as a function of both substructure geometry and mooring configuration.

They found that high nacelle accelerations hasten deterioration of turbine gearbox

and blades, and results showed accelerations were least for tension leg platforms,

greater for slack catenaries, and were greatest for taught catenaries.

While a catenary mooring arrangement appears to be more suitable for floating

renewable energy devices/platforms in order to allow necessary environmental

interaction (e.g., wave, current) and reduce the required contribution from seafloor

sediments to extreme or infrequent loading events, they are not optimal with regard

to long term design and performance of wind and possibly tidal turbines or

minimizing the seabed footprint (which will be discussed).

5. Platform Excursion Limitations: The seabed footprint area covered by the

mooring arrangement for each floating device must be small to avoid the interaction

and abrasion of mooring lines against each other and minimize excursion and

seafloor abrasion of power umbilicals associated with each individual device. This

arrangement is in contrast to typical offshore O&G platforms, where the footprint

area is mostly unrestricted and the maximum allowable excursion is defined by the

allowable movement of the risers.

6. Number of Anchors: A floating O&G facility is a single unit that is typically

positioned using a 12- or 16-point mooring arrangement. A renewable energy facility

Page 17

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

18

could include up to 200 devices, each of which is likely to be positioned using either

three- or four-point mooring systems. Thus, the number of anchor installations is

significantly higher than for an O&G facility, necessitating the need to develop more

efficient anchoring technologies that can also share anchors between multiple

devices/platforms.

The large number of mooring lines will have significant implications for permitting.

Multi-use areas that include fisheries and marine wildlife habitat and migration paths

will be more affected than for seabed fixed renewable energy or O&G facilities.

While anchor sharing will help to reduce cost, development of floating systems

where multiple devices are linked closer to the sea surface with fewer mooring lines

going to the seafloor is a valid option for reducing the impact of the facilities. This is

an approach often taken in aquaculture.

7. Anchor Innovation: Currently, drag embedment anchors are preferred for catenary

moored floating offshore wind platforms (e.g. Hywind and WindFloat) because of

their low cost and simplicity of design and installation. These anchors, however,

cannot be used for anchor sharing or multi-directional loading that will be required

for more cost effective renewable energy facilities. Innovative anchoring systems

have been employed for O&G facilities, e.g., dynamically installed anchors and

SEPLAs. However, these are specifically designed for clay deposits that dominant

deep water O&G fields and there has not been equivalent innovation in anchor

designs for sand. This poses a challenge for both wave and floating wind facilities, as

these are likely to be initially sited in shallower water where the depositional

environment is energetic and coarse-grained seabed deposits are expected.

8. Seafloor Area: The seabed footprint occupied by a typical renewable energy

facility is extremely large compared with an O&G installation, which has significant

implications for site investigations.

9. Subsurface Variability: Spatial variability of seafloor sediments is prevalent in

glacially formed sediments. For instance, glacially affected sediments offshore of the

North Atlantic can include some or all of the following sediments types, in depth

descending sequence (or may be interlayered): 1) recent, soft clays and loose sands,

2) varied marine and fluvial marine sediments of significant and variable thickness,

layering and lateral extent, 3) variable glacial deposits (till, lacustrine, moraine and

outwash) with varied strength, thickness, layering and lateral extent, and 4) bedrock.

An IEA analysis of the experiences from five operational European wind farms (IEA

2005) emphasizes: a) the importance of seabed soils and their relation to design of

foundations, installation method and therefore cost for installation; and b) that site

selection and evaluation of ground conditions and morphology should be considered

from project conception as being critical to technical completion. Additionally,

incomplete and untimely definition of seabed conditions and variability adversely

affected eight offshore wind projects was an important lesson from developments of

offshore wind in northern Europe (Gerdes et al. 2006).

Due to the large footprint areas and inherent variability of seafloor geologic

conditions and engineering properties, there is greater uncertainty in encountering

unanticipated or unknown seabed conditions. This uncertainty directly affects the

Page 18

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

19

costs of the foundation design, fabrication, and installation, and has been shown to

play a pivotal role in the relative success of offshore wind projects.

Random, uniformly-spaced investigations are not an optimum layout for renewable

energy developments. The types, numbers, and depths of investigations depend on

the spatial extent of the planned development, and the properties, layering, and

lateral variability of seabed soils. The anticipated variability of the subsurface needs

to be initially assessed through a desktop study and mapped using geophysical

survey data such that boring and in situ penetration investigations can be optimally

located in typical and critical soil layers. Stuyts et al. (2011) provide an excellent

example of the use of borehole data with geostatistics and reliability methods to

quantify wind turbine risks and costs and to identify areas where additional site

investigation information is required. The ability to identify the presence and scale of

seabed features enables the optimal anchor design(s) for the project because i) it can

eliminate unnecessary conservatism; ii) allows for appropriate choice of methods and

equipment for installation; and iii) reduces operational inefficiencies and

maintenance costs resulting from unanticipated conditions.

10. Site Investigations: The cost and time associated with site investigations

required for the large areas and numbers of turbines associated with commercial

renewable energy projects is significant. Borehole drilling and in situ testing from the

deck of a large ship will no longer be time/cost effective. Additionally, the need to

site wave and tidal/current projects in high energy and possibly shallow water

locations will increase the complexity of site investigations, which will warrant the

use of specialized equipment such as vessels with dynamic positioning, seabed

frames, and high capacity jack-ups.

The use of seabed frames for deep water O&G borings and in situ testing have

been very successful. However, these devices are designed to ensure reliable remote

functionality under extreme conditions. Mini-CPTs deployed from vessels or seabed

frames are currently an option for shallow water site investigations, however, these

are limited to about 10 m of investigation depth in soft clays due to their limited

reaction force. The use of newer generation seabed frames for site investigation of

shallower water renewable energy facilities could represent significant savings.

Newer generation seabed frames would need to address the following challenges for

in situ testing and sample collection: i) penetration into sediments other than soft

clays (e.g., loose and stiff sands, stiff clays) that are likely to exist in geologically

complex nearshore environments; and ii) penetration to depths between 10 m and

50 m. Deeper penetration without the use of a drilling vessel are required for many

anchor types, but especially for drag embedment anchors and VLAs associated with

taut line and high tension mooring lines in order to gain adequate capacity while

keeping anchor size small and installation costs low.

A novel option for site investigations is to bypass the requirement for borings or in

situ tests at each location specified by offshore industry classification agencies, and

develop investigation tools that are more similar to the anchoring devices themselves.

This would allow for characterization of seafloor soil performance directly, instead

of using laboratory or in situ measured sediment parameters to correlate to

anticipated anchor performance.

Page 19

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

20

Example geotechnical solution: foundations for floating wind turbines

Floating wind turbines are classified in three categories that depend on their

method of achieving static stability with respect to pitch and roll. The three concepts

are: 1) the tension leg platform, which maintain stability essentially by the vertical

mooring line taut to the seabed and excess buoyancy; 2) the spar buoy, which

maintains stability by deep draft and a ballast and is anchored to the seabed by taut

inclined mooring lines; and 3) the barge buoy (or semi-submersible), which uses its

large water plane area and shallow draft for stability and is anchored to the seabed

via catenary mooring lines. Suction caissons are favored for all three options because

they are simple to install accurately with respect to location, orientation, and depth,

and they benefit from design and installation procedures that are well-established

after a couple of decades of use in the offshore oil and gas industry.

However, design methods for suction caissons have been established to determine

their ultimate capacity in soft homogeneous sediments. Therefore, their use for

anchoring floating wind turbines in shallow water requires the development of

renewed design methods that focus on serviceability (notably accounting for stiffness

degradation over a large number of cycles) and account for the complex soil

stratigraphy frequently encountered in shallow waters.

Research has been undertaken to address these issues (Foglia et al., 2012; Cermelli

et al., 2012). While such studies will certainly contribute to an optimization of

caisson design and promote the development of floating wind turbines, the potential

cost-savings remains marginal with respect to the total cost of the anchoring system.

Other strategies are to consider 1) a network of interconnected anchors for an array

of floating wind platforms or wave/tidal/current energy devices (Huang and Aggidis

2008; Burns et al. 2014), or 2) multi-turbine platforms that are anchored to the

seafloor with fewer anchors per turbine. These solutions have the potential to reduce

the number of caissons necessary for a floating wind facility, providing cost-savings.

However, the solution also introduces new geotechnical challenges, including more

complex multi-directional loading than encountered in deep water O&G facilities.

The multi-directional loading of suction caissons has recently been investigated by

Burns (2013) and Burns et al. (2014) in experimental and numerical feasibility

studies. Centrifuge model testing was conducted using a 1/150th scale suction caisson

(7.5 m length, 3 m diameter) in normally consolidated kaolin clay to investigate

caisson performance under loading from two orthogonal mooring lines. The caisson

was subject to (i) uni-directional 45 inclined monotonic and cyclic loading and (ii)

monotonic and cyclic loading from two 45 inclined orthogonal mooring lines under

a combination of sustained loading (54% of peak monotonic capacity) and loading to

failure. The experiments also focused on understanding lateral and rotational

stiffness degradation, accumulation of caisson displacement/rotation, and post-peak

ultimate capacity. 3D finite element numerical simulations of the monotonic

orthogonal line centrifuge test found similar trends in increased capacity, but

attributed this to non-optimal pad-eye location in the model caisson for the soil

conditions in the centrifuge tests. Burns (2013) found that numerical simulations of

monotonic orthogonal line loading over a range of mooring line inclination angles

Page 20

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

21

(0 to 90) and various sustained loading vs. loading to failure scenarios that the

resolved load at failure of the two lines was similar to the peak single line capacity at

the equivalent resolved load inclination angle. Cyclic loading also offers interesting

results. Figure 16 illustrates the load versus line displacement for both sustainedcyclic and cyclic-cyclic orthogonal line loading scenarios from Burns et al. (2014).

LMLA: SC S2T06

12

12

8

6

4

2

0

(b)

L1

L2

10

P / (su D L)

10

P / (su D L)

(a)

L1

L2

8

6

4

2

0.5

1.5

/D

0.5

1.5

/D

(c)

(d)

L2

L1

Figure 16. Caisson response under orthogonal loading: initial cyclic loading in

L1 at 35% (mean) and 15% (cyclic) of the peak monotonic capacity, followed by

(a) monotonic load to failure in L2 and (b) cyclic before monotonic load to

failure in L2. (c)/(d) illustration of soil zone of influence (after Burns et al., 2014).

As shown for SEPLA plate anchors (Figure 5 and Wong et al., 2012), the cyclic

response of caissons is a direct function of the peak cyclic load with respect to the

monotonic ultimate capacity. Below a critical threshold, cyclic loading results in an

increase in post-cyclic monotonic ultimate capacity. Interestingly, increased

monotonic capacity is also observed, though in a lesser magnitude, if cyclic loading

is undertaken first in the orthogonal direction. This result occurs because the

consolidation occurring during cyclic loading offsets the potential strength

degradation (Matsui et al. 1980), increasing the monotonic caisson capacity.

The response is different if loading is applied simultaneously in both orthogonal

directions. If monotonic loading is sustained in one direction, the post-cyclic

monotonic ultimate capacity is slightly reduced in the orthogonal direction, though

the overall caisson capacity increases when the load resultant is considered. This

result is explained by a larger zone of soil mobilized around the caisson, as illustrated

Page 21

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

22

in Figure 16. The size of the mobilized zone is shown to be a function of the caisson

geometry and soil properties but also of the mean and peak cyclic loads.

For the relatively low level of peak cyclic load considered, limited stiffness

degradation was observed during cycling loading on the subsequent monotonic to

failure load. Caisson rotations were also limited, although greater accumulated

rotation was observed for higher cyclic load amplitudes and when cycles are applied

on both orthogonal directions.

Further research is required to extrapolate these results to a wider range of caisson

geometries, soil conditions, and cyclic amplitudes, but these preliminary results are

promising and indicate that interconnected caissons are a viable solution as

anchoring systems for arrays of floating wind turbines.

CONCLUSIONS

In an era of increasing energy demands, geotechnical engineering is rapidly evolving to

meet challenges in energy extraction from water depths exceeding 1000 m and new and

remote regions with challenging soil conditions and translation of novel solutions to more

economically develop wind, wave and tidal renewable energies from the worlds oceans.

This paper endeavored to summarize the current geotechnical challenges and provide

relevant examples of geotechnical solutions. Though not an exhaustive list, these examples

included new design methods for suction installed plate anchors, torpedo anchors, subsea

mudmats and caissons subjected to orthogonal cyclic loading, and a new formula was

presented for predicting the peak capacity as a mobile jack-up spudcan foundation punches

a strong sand layer into a weaker underlying clay layer.

ACKNOWLEDGEMENTS

This work forms part of the activities of the Centre for Offshore Foundation

Systems, currently supported as a node of the Australian Research Council Centre of

Excellence for Geotechnical Science and Engineering and as a Centre of Excellence

by the Lloyd's Register Foundation. Lloyds Register Foundation invests in science,

engineering and technology for public benefit, worldwide. The authors acknowledge

and thank their colleagues Mark Randolph, Kok Kuen Lee, Yinghui Tian, Dong

Wang, Sam Stanier, and Pan Hu for their contributions to the research discussed.

REFERENCES

Araujo, J.B., Machado, R.D., Medeiros, C.J. (2004). "High holding power torpedo

pile results from the first long term application." Proc. Int. Conf. on Offshore

Mechanics and Arctic Engng, Vancouver, Canada, OMAE2004-51201.

Audibert, J.M.E., Movant, M.N., Won, J-Y. Gilbert, R.B. (2006). "Torpedo piles:

laboratory and field research." Proc. Int. Polar and Offshore Engng Conf., San

Francisco, USA, 462-468.

Page 22

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

23

Bienen, B., Raush, L., Gaudin, C., Cassidy, M.J., Purwana, O.A. (2012). Numerical

modelling of the undrained capacity of a hybrid skirted foundation under

combined loading. Int. Journal of Offshore and Polar Engng. 22(3): 1-7.

Biscontin, G. and Pestana, J.M. (2001). "Influence of peripheral velocity on vane

shear strength of an artificial clay." ASTM Geotechnical Testing Journal,

24(4):423-429.

Bogard, D. and Matlock, H. (1990)."Application of model pile tests to axial pile

design." Offshore Technology Conf., Houston, USA, OTC 6376.

Bolton, M.D. (1986). "The strength and dilatancy of sands." Gotechnique 36(1):6578.

Brennan, R., Diana, H., Stonor, R.W.P., Hoyle, M.J.R., Cheng, C.-P., Martin, D.,

Roper, R. (2006). "Installing jackups in punch-through-sensitive clays." Offshore

Technology Conference, Houston, OTC 18268.

Burns, M, Landon-Meynard, M., Davids, W.G., Chung, J., Gaudin, C. (2014).

"Centrifuge modelling of suction caissons under orthogonal double line loading."

Proc. 8th Int. Conf. on Physical Modelling in Geotechnics, Perth, Australia.

Butterfield, S., Musial, W., Jonkman, J., Sclavounos, P., and Wayman, L. (2005).

"Engineering challenges for floating offshore wind turbines," Proc. Copenhagen

Offshore Wind Conference, Copenhagen, DK: 1-10.

Cassidy, M.J. (2012). "Experimental observations of the penetration of spudcan

footings in silt." Gotechnique, 62(8): 727-732.

Cassidy, M.J., Gaudin, C., Randolph, M.F., Wong, P.C., Wang, D., Tian, Y. (2012).

"A plasticity model to assess the keying behaviour and performance of plate

anchors." Gotechnique 62(9): 825-836.

Cassidy, M.J., Quah, C.K., Foo, K.S. (2009). "Experimental investigation of the

reinstallation of spudcan footings close to existing footprints." Journal of

Geotechnical and Geoenvironmental Engineering, ASCE 135(4): 474-486.

Cermelli C.A., Rodier D.G., Weinstein A. (2012). "Implementation of a 2MW

floating wind turbine prototype offshore Portugal." Offshore Technology

Conference, Houston, USA, paper OTC23492.

Chan, N. H. C., Paisley, J. M., Holloway, G. L. (2008). "Characterization of soils

affected by rig emplacement and Swiss cheese operations - Natuna Sea, Indonesia,

a case study. " Proc. Jack-up Asia Conf. and Exhibition, Singapore.

Chen, W. and Randolph, M. F. (2007). "External radial stress changes and axial

capacity for suction caissons in soft clay." Gotechnique, 57(6):499511.

Crown Estate (2013). "Offshore wind operational report." www.

thecrownestate.co.uk/media/418869/offshore-wind-operational-report-2013.pdf

Dean, E.T.R. and Serra, H. (2004). "Concepts for mitigation of spudcan-footprint

interaction in normally consolidated clay." Proc. Int. Symp. Offshore and Polar

Engng, Toulon, France.

Dimmock, P., Clukey, E., Randolph, M.F., Murff, D., Gaudin, C. (2013). "Hybrid

subsea foundations for subsea equipment." Journal of Geotechnical and

Geoenvironmental Engineering. In Press.

Dove, P., Treu, H., Wilde, B. (1998). "Suction embedded plate anchor (SEPLA): a

new anchoring solution for ultra-deepwater mooring." Proc. Deep Offshore

Technology Conference, New Orleans, USA.

Page 23

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

24

Edwards, D.H. and Potts, D.M. (2004). "The bearing capacity of a circular footing

under punch through failure." Proc. Int. Symp. Num. Models in Geomech.,

(NUMOG), Ottawa, 493-498.

Einav, I. and Randolph, M.F. (2006). "Effect of strain rate on mobilised strength and

thickness of curved shear bands." Gotechnique, 56(7):501-504.

Elkhatib, S. and Randolph, M.F. (2005). "The effect of interface friction on the

performance of drag-in plate anchors." Proc. Int. Symp. on Frontiers in Offshore

Geotechnics (ISFOG), Perth, Australia, 171-177.

Erbrich, C.T. (2005). "Australian frontiers spudcans on the edge." Proc. Int. Symp.

Frontiers in Offshore Geotechnics (ISFOG), Perth, Australia, 4974.

Esrig, M.I., Kirby, R.C., Bea, R.G., Murphy, B.S. (1977). "Initial development of a

general effective stress method for the prediction of axial capacity for driven piles

in clay." Offshore Technology Conf., Houston, USA, OTC 2943.

Fitzgerald, J. (2009). "Position mooring of wave energy converters." PhD Thesis,

Chalmers University of Technology.

Foglia A., Ibsen L.B., Andersen L.V., Roesen H.R. (2012). Physical modeling of

bucket foundation under long term cyclic lateral loading. Proc. 22nd Int. Offshore

and Polar Engng Conf., 667-673.

Freeman, T.J. and Burdett, J.R.F. (1986). "Deep ocean model penetrator

experiments." Final report to Commission of European Communities. Report No.

EUR 10502.

Gan, C.T., Leung, C.F., Cassidy, M.J., Gaudin, C., Chow, Y.K. (2012). "Effect of

time on spudcan-footprint interaction in clay." Gotechnique 62(5): 401-413.

Gaudin, C., O'Loughlin C.D., Randolph, M.F., Lowmass, A.C. (2006). "Influence of

the installation process on the performance of suction embedded plate anchors"

Gotechnique 56(6): 381-391.

Gaudin C., Randolph M.F., Clukey E., Dimmock P. (2012). "Centrifuge modelling of

a hybrid subsea foundation for subsea equipment." Proc 7th Int. Conf. of Offshore

Site Investigations and Geotechnics, London, England, 411-420.

Gaudin C., Simkin M., White D.J., OLoughlin, C.D. (2010). Experimental

investigation into the influence of a keying flap on the keying behaviour of plate

anchors. Proc. 20th Int. Offshore and Polar Engng Conf., Beijing, China: 533-540.

Gaudin C., Tham K.H., Ouahsine S. (2009). "Keying of plate anchors in NC clay

under inclined loading." Int. Journal of Offshore and Polar Engng. 19(2):1-8.

Gerdes, G., Tiedemann, A. and Zeelenberg, S. (2006). Case Study: European

Offshore Wind Farms: A Survey to analyse experiences and lessons learnt by

developers of offshore wind farms, Final Report, Deutsche WindGuard GmbH.

Hodder, M.S., White, D.J., Cassidy, M.J. (2009). "Effect of remoulding and

reconsolidation on the touchdown stiffness of a steel catenary riser: observations

from centrifuge modelling." Offshore Technology Conference, Houston, USA.

Paper OTC19871.

Hodder, M.S., White, D.J., Cassidy, M.J. (2013). "An effective stress framework for

the variation in penetration resistance due to episodes of remoulding and

reconsolidation." Gotechnique 63(1):30-43.

Page 24

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

25

Hossain, M.S. and Randolph, M.F. (2009). "New mechanism-based design approach

for spudcan foundations on stiff-over soft-clay." Offshore Technology Conference,

Houston, USA, OTC19907.

Hossain, M.S., Cassidy, M.J., Daley, D., Hannan, R. (2010). "Experimental

investigation of perforation drilling in stiff-over-soft clay." Applied Ocean

Research, 32(1):113-123.

Houlsby, G.T. and Martin, C.M. (2003). "Undrained bearing capacity factors for

conical footings on clay." Gotechnique, 53(5): 513-520.

Hu, P., Stanier, S., Cassidy, M.J., Wang, D. (2013). "Predicting the peak punchthrough penetration resistance of a spudcan penetrating sand overlying clay."

Journal of Geotechnical and Geoenvironmental Engineering, ASCE, In Press.

IEA (2005). "Offshore Wind Experiences," International Energy Agency, France.

IEA (2012a). "2012 Key world energy statistics." International Energy Agency. Paris,

France. www.iea.org

IEA (2012b). "Medium-term renewable energy market report 2012 Market trends

and projections to 2017." International Energy Agency. France.www.iea.org.

Kong, V.W., Cassidy, M.J., Gaudin, C. (2013). "Experimental study of the effect of

geometry on the reinstallation of a jack-up next to a footprint." Canadian

Geotechnical Journal 50(5):557-573.

Lee, K.K., Cassidy, M.J., Randolph, M.F. (2013a). "Bearing capacity on sand

overlying clay soils: Experimental and finite element investigation of potential

punch-through failure." Gotechnique, In press, (doi): 10.1680/geot.12.P.175.

Lee, K.K., Randolph, M.F., Cassidy, M.J. (2013b). "Bearing capacity on sand

overlying clay soils: A simplified conceptual model" Gotechnique, (doi):

10.1680/geot.12.P.176.

Lehane, B.M., OLoughlin, C.D., Gaudin, C., Randolph, M.F. (2009). "Rate effects

on penetrometer resistance in kaolin." Gotechnique, 59(1):41-52.

Leung, C.F., Gan, C.T. and Chow, Y.K. (2007). "Shear strength changes within jackup spudcan footprint." Proc. 7th Int. Offshore and Polar Engng Conf. (ISOPE),

Lisbon, Portugal, 1504-1509.

Lieng, J.T., Kavli, A., Hove, F., Tjelta, T.I. (2000). "Deep Penetrating Anchor:

further development, optimization and capacity clarification." Proc. Int. Offshore

and Polar Engng Conf., Seattle, USA, 410-416.

Lowmass, A.C. (2006). "Installation and keying of follower embedded plate

anchors." Masters of Engineering Thesis, UWA

Matsui, T., Ohara, H., Ito, T. (1980). "Cyclic stress-strain history and shear

characteristics of clay." Journal of the Geotechnical Engineering Division ASCE,

106(10): 1101-1120.

Musial, W., Butterfield, S., and Ram, B. (2006). "Energy from offshore wind," Proc.

2006 Offshore Technology Conference, OTC18355: 11.

Musial, W. and Ram, B. (2010). Large-Scale Offshore Wind Power in the United

States. Assessment of opportunities and barriers. NREL/TP-500-40745,

Retrieved from http://www.nrel.gov/wind/pdfs/40745.pdf

OLoughlin, C.D., Lowmass, A., Gaudin, C., Randolph, M.F. (2006). "Physical

modelling to assess keying characteristics of plate anchors." Proc. 6th Int. Conf.

on Physical Modelling in Geotechnics, Hong Kong, 659-665.

Page 25

Geo-Congress 2014 Keynote Lectures, GSP 235 ASCE 2014

26

O'Loughlin, C.D., Randolph, M.F., Richardson, M.D. (2004). "Experimental and

theoretical studies of Deep Penetrating Anchors." Offshore Technology

Conference, Houston, USA, OTC 16841.

OLoughlin, C.D., Richardson, M.D., Randolph, M.F. (2009). "Centrifuge tests on

dynamically installed anchors." Proc. 28th Int. Conf. on Ocean, Offshore and

Arctic Engng, Honolulu, Hawaii, OMAE2009-80238.

O'Loughlin, C.D., Richardson, M.D., Randolph, M.F., Gaudin, C. (2013).

"Penetration of dynamically installed anchors in clay." Gotechnique, 63, doi:

10.1680/geot.11.P.137.

ONeill, M.P., Bransby, M.F., Randolph, M.F. (2003). "Drag anchor fluke-soil

interaction in clay." Canadian Geotechnical Journal, 40(1):78-94.

Osborne, J.J., Houlsby, G.T., Teh, K.L., Bienen, B., Cassidy, M.J., Randolph, M.F.,

Leung, C.F. (2009). "Improved guidelines for the prediction of geotechnical

performance of spudcan foundations during installation and removal of jack-up

units." Offshore Technology Conference, Houston, OTC-20291.

Osborne, J.J., Pelley, D., Nelson, C., Hunt, R. (2006). Unpredicted jack-up

foundation performance. Proc. 1st Jack-up Asia Conference. Singapore.

Osborne, J.J., Teh, K.L., Houlsby, G.T., Cassidy, M.J., Bienen, B., Leung, C.F.

(2010). "Improved guidelines for the prediction of geotechnical performance of

spudcan foundations during installation and removal of jack-up units." RPS

Energy Report Number EOG0574-Rev1. Final Guidelines of the InSafe Joint

Industry Project, 124p. http://insafe.woking.rpsplc.co.uk/Default.asp

Randolph, M.F., Gaudin, C., Cassidy, M.J., Wang, D., Tian, Y. (2010).

"Qualification of SEPLA for permanent mooring: Interpretation of centrifuge,

finite element and analytical plasticity modelling." Geo: 10519, COFS, UWA.