Professional Documents

Culture Documents

P1064-00-M05-119-R0 Painting Work

Uploaded by

Narayana MugalurCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P1064-00-M05-119-R0 Painting Work

Uploaded by

Narayana MugalurCopyright:

Available Formats

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 1 of 29

TENDER DOCUMENT

FOR

PAINTING WORK

Revision

Date

R0

14-05-2013

Prepared By

Faisal Farooqui

Checked By

K C Sanjay Kumar

Approved By

Jagdish Pathak

Status

Comments / Approval

R1

R2

R3

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 2 of 29

INDEX

1.0

GENERAL INFORMATION: ..................................................................................................................... 3

2.0

TECHNICAL SPECIFICATION FOR PAINTING ............................................................................................ 4

2.1

GENERAL ............................................................................................................................................................. 4

2.2

SCOPE ................................................................................................................................................................. 4

2.3

CODES & STANDARDS .............................................................................................................................................. 5

2.4

EQUIPMENT .......................................................................................................................................................... 7

2.5

RECEIPT AND STORAGE............................................................................................................................................. 7

2.6

SURFACE PREPARATION, COATING APPLICATION .............................................................................................................. 7

2.7

PROTECTIVE COATING & PAINTING MATERIAL .............................................................................................................. 14

2.8

PAINTING SYSTEM ................................................................................................................................................ 14

2.9

PAINTING COLOUR CODES ....................................................................................................................................... 14

2.10

IDENTIFICATION OF EQUIPMENT, PIPING ETC. ............................................................................................................... 14

2.11

INSPECTION & TESTING .......................................................................................................................................... 16

2.12

FIELD SAFETY AND HYGIENE ..................................................................................................................................... 17

2.13

GUARANTEE........................................................................................................................................................ 18

2.14

QUALIFICATION CRITERIA OF PAINTING CONTRACTOR ...................................................................................................... 18

2.15

DOCUMENTATION: ............................................................................................................................................... 18

ANNEXURE I - PAINTING MATERIAL INDEX ............................................................................................................................ 21

ANNEXURE II PAINTING SYSTEM SCHEDULE .......................................................................................................................... 21

ANNEXURE III COLOUR CODE ......................................................................................................................................... 22

SKETCH 1 - WITH PRIMARY COLOUR BAND ........................................................................................................................... 25

SKETCH 2 -WITH PRIMARY & SECONDARY COLOUR BAND......................................................................................................... 26

SKETCH 3 - WITH PRIMARY & SECONDARY COLOUR BAND WITH DIRECTION BY ARROWS .................................................................. 27

SKETCH 4 - COLOUR BANDS WITH HAZARD MARKINGS............................................................................................................. 28

3.0

PAINTING PROGRAMME .................................................................................................................... 29

4.0

SCHEDULE OF QUANTITIES & RATES .................................................................................................... 29

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

1.0

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 3 of 29

GENERAL INFORMATION:

M/s. Carlsberg India Pvt. Ltd.

5th Floor, Paras Twin Towers, Tower B,

: Sector-54, Gurgaon,

Harayana-122 002

1.0

Client

2.0

Plant location

3.0

Project

: Green Field Bihar

M/s. Carlsberg India Pvt. Ltd.

Patna , Bihar

4.0

5.0

Site data

Access to Site

Ambient data

(As per ISHARE)

DBT ( C)

WBT ( C)

RH (%)

Summer

42.2

25.6

26

Monsoon

32.2

28.3

78

Winter

10.0

6.7

60

By Road

: Patna

Railway Station

: Patna

Nearest Airport

: Patna

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 4 of 29

2.0

TECHNICAL SPECIFICATION FOR PAINTING

2.1

General

This engineering standard specification covers the requirements for painting including surface preparation,

method of application, inspection of paints / coating and painted surface for equipment, piping, structures,

electrical, instrumentation equipment for the plants engineered by KCPL

Building / Concrete Painting is not covered under this Specification. For Building / concrete Protection

Painting refer Civil Specification.

2.2

Scope

a.

Scope of work covered in the specification shall include, but not limited to the following:

This specification defines the requirements for surface preparation, selecting and method of application of

paints on external surfaces of equipment, vessels, machinery, piping, ducts, steel structure, electrical and

instrument items. In general all shop fabricated/manufactured equipment will be delivered to job site with

painting in accordance with the requirements of this Specification.

The entire painting job shall be done as per the paint materials specification and apply as per the

specifications for surface preparation, paint system and application method given in the specification.

b.

Extent of Work

All un-insulated CS and SS equipment like columns, vessels, drums, storage tanks, heat exchangers, pump

etc.

All un-insulated carbon and low alloy steel piping, fittings, flanges and valves (Including painting

identification marks), furnaces, ducts and stacks.

Equipment and piping contained in a package unit as necessary.

All structural steel work, pipe structural steel work, walkways, handrails, ladders, platforms etc.

Identification colour bands on all piping as required including insulated aluminium / galvanised clad,

galvanised, SS and non-ferrous piping.

Identification lettering/ numbering on all painted surfaces of equipment/ piping insulated aluminium /

galvanized clad galvanized, SS and non-ferrous piping.

Hazardous content marking/identification signs on painted surfaces of equipment/piping.

Supply of all primers, paints and all other materials required for painting other than owners supply.

Painting under insulation for carbon steel and stainless steel piping, vessels, storage tanks etc, if required.

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 5 of 29

Equipment, piping inside pits or trenches.

Repair and repainting of damaged and defective painting of shop applied items as per the instructions of

engineer in charge of site.

All galvanised piping, structural and equipment to be repaired on damaged at site with suitable coating

materials as per the instruction of engineer in charge at site.

c.

The standard specification excludes the following

Painting of equipment, piping, mechanical structures or package items based on manufacturer

recommendation. (All package items shall be painted in accordance with this Spec.)

Non Ferrous materials like Aluminium.

Austenitic stainless steel & Galvanised iron.

Plastic and plastic coated materials.

Application of paints using methods other than brushing or spraying.

Painting for temporary installation.

Coating and lining

d.

2.3

Pipes and equipment shall be painted only after the mechanical completion, testing on systems are

completed including hydro testing as well as after completion of steam purging wherever required.

Codes & Standards

a.

The latest edition of the following standards including all revisions and addendum shall be applicable.

Works shall also be in accordance with the Paint Manufacturers recommendations.

IS-5

IS-101 Method of test for ready mixed paints and enamels.

IS-158 Spec. for ready mix paints.

IS-161 Heat resistant Paint

IS-2074 Specification for ready mixed paints, red oxide zinc chrome primer.

IS-2339 Aluminium paint for general purposes in dual container

IS-2379 Colour code for identification of pipelines

Colours for ready mixed paints and enamels.

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 6 of 29

IS-2932 Specification for enamel, synthetic, exterior (a) undercoating (b) finishing

A 13.1 American standard scheme for identification of piping by colour coding.

BS-729, 1981 Hot Dip Galvanised Coatings on Iron and Steel Articles

BS-4800, 1981 Paint Colours for Building Purposes

b.

Surface Preparation Standards:

Steel Structure Painting Council (SSPC-SP)

Swedish Standards Institution (SIS) (SIS 05 5900-1967)

International Organisation for Standard (ISO) (ISO 8501-1) : 1988

NACE National Association for Corrosion Engineers

BS-4232 Surface finish of blast cleaned surface for painting.

IS 1477 Part I Code of Practice for Painting of Ferrous metal in building (Pre Treatment)

If there is any conflict between the requirements of the above mentioned codes and standards and this

engineering specification, the requirements of the specification shall prevail. All conflicts shall be referred

to KCPL/Owner for clarification before proceeding for the work.

c.

The paint manufacturers latest approved published instruction shall be followed as far as practicable at all

times. Particular attention shall be paid to the following.

Proper Attention to avoid exposure as well extremes of temperature

Surface preparation prior to painting

Mixing & thinning

Application of paints and recommend limit on time intervals between coats.

The paint materials for any paint system including primer, intermediate coating, finished coating and

thinner shall be from a single approved manufacturer.

d.

Any painting work (Including surface preparation) on piping or equivalent shall commence only after the

system tests have been completed and clearance for taking up painting work is given by the engineer in

charge in writing.

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

2.4

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 7 of 29

Equipment

a.

All tools, brushes, rollers, spray guns, abrasive materials, solvent, hand/power tools for cleaning,

scaffolding materials, shot/wet abrasive blasting, water blasting equipment, air compressors, industrial

vacuum cleaners etc. required to be used shall be suitable for the work and all in good order and shall be

arrange by the contractor at site and insufficient quantity.

b.

Mechanical mixing shall be used for paint mixing operations in case of two-pack system except engineer in

charge may allow the hand mixing of small quantity at his discretion.

2.5

Receipt and Storage

a.

Painting material shall be received, unloaded and stored in a room, which is well ventilated.

b.

In cases where paints are stored outside, adequate protection shall be provided to prevent damage to the

drums.

c.

Warning signboards shall be displayed at places where paints and solvents are stored.

d.

Paints shall not be stored in plant area where there is a fire risk.

e.

Paints and solvents shall be stored and records shall be maintained to ensure their usage before expiry

date.

f.

Containers shall be handled with care. Container of Paint, catalyst and thinners shall not be opened prior

to use except for spot inspection.

g.

Adequate number of fire extinguishers shall be provided in the stores where paint and solvents are stored.

h.

Adequate ventilation and gas masks shall be provided while painting in confined areas.

2.6

Surface Preparation, Coating Application

a.

Preparatory Work:

i.

The agency undertaking work shall estimate quantity of primer and paint required for the job and

arrange to procure the same prior to commencement of the job.

ii.

Approved brands of paints shall only be used (shall be mentioned supplier wise)

iii.

Check, verify the year of manufacture, Batch No. and expiry date of the paint before starting the work.

iv.

Read the paint manufacturers instruction regarding applications, Incase of conflicting requirement with

this specification, Engineer in charge shall be consulted.

v.

Necessary steel scaffolding, landing mats, etc. required to carry out the job is to be arranged.

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 8 of 29

vi.

All workmen deployed on the job shall have personal protection gear such as safety shoes, helmets,

safety belts and goggles.

vii.

Paint shall not be mixed near electrical panels.

viii.

Arranged adequate quantities of consumables such as sand papers, wire brushes, paint brushes and

cloth.

ix.

Arrange sufficient number of air compressor of adequate capacities with spray guns and other

accessories.

x.

Ensure that calibrated DFT (Dry Film Thickness) tester/ elcometer is available at shop/ site.

xi.

Maintain testing and calibration certificate for elcometer.

xii.

Arrange to provide abrasive blasting equipment with all necessary accessories.

xiii.

Ensure that all electrical appliances are tested and properly earthed.

xiv.

Provide galvanised sheets, tarpaulins etc. to protect equipment and men during abrasive blasting

operation.

xv.

Provide adequate gas masks, goggles, hand gloves and other personal protection gear to the workmen

undertaking abrasive blasting.

b.

Surface Preparation:

In order to achieve maximum durability one or more of following methods of surface preparation shall be

followed, depending on the condition of steel surface and as instructed by engineer in charge. Adhesion of

the paint film to surface depends largely on the degree of cleanliness of the metal surface. Proper surface

preparation contributes more to the success of the paint protective system.

Manual or hand tool cleaning

Mechanical or Power tool cleaning

Blast cleaning

For the adequate performance of the painting system, it is absolutely essential that the surfaces to be

painted are adequately prepared. The surface should be dry and free from oil and grease, dust, weld

splatter, burrs, flux, rust, loose scale, dirt and any other foreign matter before any coating is applied.

All surface preparation will be carried out in accordance with the requirement set out in ISO 8501-1: 1988

Preparation of Steel Substrates before Application of Paints and Related Products Visual Assessment

for surface cleanliness

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 9 of 29

Manual of hand tool cleaning

Manual or hand tool cleaning is used only where safety problems limit the application of other surface

preparation procedure and hence does not appear in the tables of paint systems

Hand tool cleaning normally consist of the following.

Hand descaling and /or hammering

Hand scraping

Hand wire brushing

On completion of cleaning, loose material shall be removed from the surface by clean rags and the

surface shall be brushed, swept dedusted and blow off with compressed air / steam to remove all

loose matter. Finally the surface may be washed with water and dried for effective cleaning.

Mechanical or Power tool cleaning (As per SSPC-SP3)

Power tool cleaning shall be done by non-sparking type brass mechanical striking tools, chipping

hammers, grinding wheels, rotating brass wire brushes. On completion of cleaning the detached rust,

mill scale etc. shall be removed by clean rag and/or washed by water or steam and thoroughly dried

with compressed air jet before application of paint.

Blast Cleaning (NOT APPLICABLE)

Surface Preparation prior to blast cleaning.

Prior to abrasive blast cleaning the surface shall be free from moisture, oil greases and heavy

deposits of rust. Excessive deposits of rust shall be removed using impact cleaning tools prior to

the commencement of abrasive blast cleaning.

Oil and grease shall be removed using an emulsifying solvent, and the surface shall be washed with

clean water and allowed to get dried completely prior to the commencement of abrasive blast

cleaning. Wiping with a rag soaked in solvent for the removal of oil and grease from the

contaminated surfaces shall not be accepted as adequate.

Equipment for Abrasive Blast Cleaning

The compressed air to be used for abrasive blast cleaning shall be dry and free from oil. Adequate

separators and traps shall be installed in the coolest part of the system; they shall be regularly

emptied to prevent the carry over of oil and water.

Accumulations of oil and water shall be removed from air received by regular purging. Blasting

nozzles shall be replaced when wear reaches 50%. Air compressors shall not deliver air at

temperatures in excess of 110oC.

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 10 of 29

Abrasives to be used in Blast Cleaning

The abrasive used for abrasive blast cleaning may be selected from the following:

Steel grit

Steel shot

Malleable iron shot

Crushed or chilled iron grit

Chopped steel wire

Aluminium oxide

Blast furnace slag

Copper Slag

Vasilgrit (a proprietary grade based on inert aluminium silicate)

Sand: Should sand be considered as the blasting medium, it shall be delivered to site in

sealed bags. Each bag shall be identified against a Batch No. and each batch has a third party

certificate. The test certificate shall confirm that the blast medium conforms to the

requirements of US-MIL-S-22262 with a maximum chloride level of 0.03%.

Abrasive Blast Cleaning

The surface shall be blast cleaned using the abrasives at pressure of 7 kg/cm2 (g) at appropriate

angle and distance depending on nozzle size maintaining constant velocity and pressure.

Abrasive Blast Cleaning shall remove all mill scale, rust and other corrosion products, paint and any

other foreign matter to achieve a surface cleanliness of SA 2, accordance with ISO 8501-I with a

surface roughness not exceeding

Surfaces, which become wet due to rain or moisture, shall be re-blasted prior to application of the

primer. Abrasive blast cleaning shall overlap by at least 25 mm on any adjacent painted surface.

Environmental Conditions for Surface Preparation

Surface preparation by abrasive blast cleaning shall not be carried out when the following

conditions prevail:

The surface temperature of the substrate is less than 3oC above the ambient dew point and

when the relative humidity is greater than 85%. Or the substrate temperature is more than

60oC.

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 11 of 29

Abrasive blast cleaning shall not be carried out during the hours of darkness unless

adequately equipped facility for the purpose is available.

Surface preparation after abrasive blast cleaning: All surfaces that have been prepared using

abrasive blast cleaning will normally have traces of blast debris and dust removed from the

surface. The surface including all pockets and corners shall be cleaned by vacuum cleaning, blowing

with dry oil free compressed air, or brushing with a clean brush made from hair, bristle or fiber.

Surface preparation for hot dipped galvanised steel, stainless steel and non-ferrous metals.

Generally these surfaces are not painted.

If, however painting is required on these surfaces, they shall be lightly abrasive blast cleaned using

aluminium oxide or inert aluminium silicate. Copper from furnace slag shall not be used on

stainless steel. Any zinc salts that have formed on galvanised surfaces shall be removed using clean

water or a solvent wash and thoroughly dried before the abrasive cleaning is undertaken.

Surface Preparation of Concrete Surfaces (NOT APPLICABLE):

Concrete surfaces that require painting shall be clean, dry and free from laitance and have a

degree of roughness to ensure proper adhesive of the paint. The surface shall be blast cleaned or

power wire brushed to obtain the degree of roughness required.

Etching with dilute hydrochloric acid and washing with excess water shall be accepted as a last

choice only. Painting shall not commence on concrete surfaces until the surface has dried to

humidity of 4% by wt or less.

Surface preparation classification is indicated in Table-I below

Surface prepared shall be compared with relevant standard using a comparator.

After surface preparation and prior to any coating application the substrate shall be checked for

soluble salt contamination using a suitable salt contamination meter. Maximum allowable is 5

gm/cm2

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 12 of 29

Table I

Surface Preparation Classification

Method of

Cleaning

Solvent Cleaning

Through Hand

Tool Cleaning

Classification

Cleaning with solvents, vapour alkali, emulsion or

steam to remove oil, grease, soil, salts.

Hand and

Power Tool

Cleaning

Thorough scrapping and wire brushing machine

brushing- grinding etc. The treatment shall remove

loose mill scale, rust and foreign matter. Finally,

the surface is cleaned with a vacuum cleaner, clean

dry compressed air or a clean brush. It should then

have a faint metallic shine.

Very thorough scrapping and wire brushing,

machine brushing-grinding etc. The treatment shall

remove loose mill scale, rust and foreign matter.

Finally, the surface is cleaned with a vacuum

cleaner, clean dry compressed air or a clean brush.

After removal of dust, the surface shall have a

pronounced metallic shine.

By using oxy acetylene flame dehydrate and

remove rust loose mill scales and tight mill scales

followed by wire brushing

By using wheel or nozzles (dry or wet) using grit or

shot all visible rust, mill scales and foreign matter is

removed.

St 2

Thorough blast cleaning. Almost all mill scale, rust

and foreign matter shall be removed. Finally, the

surface is cleaned with a vacuum cleaner, clean dry

compressed air or a clean brush. It shall then be

grayish in colour.

Blast Cleaning of all except tightly adhered residue

of mill scales rust, coating exposing numerous

flecks of underlying metal

Acid pickling or electrolytic pickling to complete

remove mill scales (may reduce resistance of the

surface to corrosion if not primed immediately)

Weathering to remove all particle of mill scale

followed by blast cleaning to one of the above

method.

Very thorough blast cleaning. Mill scale, rust and

foreign matter shall be removed to the extent that

the only traces remaining are slight stains in the

Sa 2 Nearly

80%

Hand and

Power Tool

Cleaning

Flame Cleaning

of new steel

Blast Cleaning to

usually clean

steel

Through Blast

Cleaning

Reference Standard

SIS / ISO

St 1

Grease and Oil

cleaning

Very thorough

Hand and Power

Tool Cleaning

Procedure & Degree of Steel Surface finish

Removal of

rust, loose mill

scale

Removal of all

visible rust,

mill scales by

blast.

Commercial

Blast Cleaning

Light Blast

Cleaning

Blast Cleaning

Pickling

Pickling

Weathering

followed by

blast cleaning

Very through

blast cleaning

Weathering

Near White

Blast Cleaning

St 3

F1

Sa 3 100% Pure

Surface

Sa 1

Sa 2

95%

Pure

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 13 of 29

Doc. No.

Revision No.

Method of

Cleaning

Classification

Procedure & Degree of Steel Surface finish

form of spots or strips. Finally, the surface is

cleaned with a vacuum cleaner, clean dry

compressed air or a clean brush.

Note :- Nearest equivalent of above can be used

Legends :

SIS :

Swedish Standard Institution SIS 05-5900-1967

ISO :

International Organisation for Standardisation ISO 8501-1:1998(E)

Reference Standard

SIS / ISO

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

2.7

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 14 of 29

Protective Coating & Painting Material

Contractor shall furnish from paint manufacturer, all the characteristics of paint materials on printed

literature, along with test certificate for all the specified characteristics given in this specification for the

supplied batch of material. All paint material shall be first quality and conform to the characteristic

mentioned in this specification.

Refer to Annexure-I

2.8

Painting material index

Painting System

The paint system should vary with the type of environment envisaged in and around plant, the service

temperature and the cost effectiveness. These parameters are defined as part of this specification.

Refer to Annexure II

2.9

Painting System Schedule.

Painting Colour Codes

The colour codes recommended in this specifications as per Indian standards.

Refer to Annexure III: Painting colour codes.

The basic identification colours as indicated in Annexure III are applied to the entire surface of equipment

except on precision-machined surfaces, non-ferrous and threaded parts. On the pipes, the basic colour is

applied over the entire surface of uninsulated pipes and further identification of service, colour bands as

defined in Annexure shall be painted.

2.10

Identification of Equipment, Piping Etc.

Equipment number shall be stenciled in black or white on each equipment after painting.

Line number in Black or White shall be stenciled on all pipelines at more than one location as directed by

engineer in charge.

a.

Flow Direction

Flow direction bands are described in Sketch 1 and 2.

Arrows can also be used to indicate the flow direction as described in Sketch 3

The arrows shall be in white or black colour. Following sizes are recommended:

For pipes diameter 1 to 6 dia., arrow to fit in a 25 mm x 100 mm rectangle.

For pipes diameter 8 dia and above, arrow to fit in a 80 mm x 150 mm rectangle.

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 15 of 29

Doc. No.

Revision No.

b.

In case of flow of fluid is possible in either direction; two arrows shall be indicated one above the other

and both in same colour.

Arrows and band markings shall be made at the unit battery limits and then on convenient location at

the point of use. It is recommended to adopt one method for the entire plant.

Hazardous Mediums

Where the piping system carries a hazardous product, a panel of equal diagonal stripes (black and yellow

colours) shall be superimposed on the pipe on both ends of the basic identification panels as detailed in

Sketch-4.

c.

Details of Code Indications

Colour:

The Line nos. and equipment nos. shall be painted either in white or in black in order to contrast

clearly with the colour of paint on the pipe or equipment. For insulated lines, the code indications

shall be painted over the cladding of the insulation.

Requirements:

The full name or well-known abbreviations of chemical and symbol of fluid flowing (as per Project

Spec.) inside a pipeline shall be indicated. The line number shall also be painted on the pipelines. The

pressure or temperature of the fluid inside the pipeline shall not be indicated.

Location:

The code indication as described above shall be painted at following locations or such other places

where quick identification is deemed necessary.

Pipelines: At all junctions, both sides of valves, both sides of service appliances and at intervals of 25

m on straight pipe lengths.

Note: For long straight lengths of pipelines e.g. transfer lines, the interval of 25 m for code indication

may be varied at the discretion of the Client/KCPL

d.

Size:

The recommended size of lettering to be used for code indications on the insulated as well as uninsulated

pipes shall be as per following:

For Pipes

Diameter 2

25 mm letters

For Pipes

Diameter 2 4

40 mm letters

For Pipes

Diameter 6 and above

80 mm letters

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

e.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 16 of 29

Code Indication for Small Diameter Pipes:

Code indication marking by paint may not be done for uninsulated pipelines of nominal diameter 1 and

below and for insulated lines less than 1 diameter. For such pipes, the indication markings shall be

punched on lead tags and then secured to the pipe. Such tags shall be provided at locations as described

earlier. The size of the tag and the method of tying it with pipeline shall be as per advice of Engineer in

charge.

f.

Lettering for Equipment:

Lettering for the equipment should be marked on each equipment at a clearly visible location.

The letters should have following minimum height:

2.11

For Equipment with Diameter 1 m

50 / 80 mm

For Equipment with Diameter 1 m to 5 m

100 mm

For Equipment with Diameter 5 m to 15 m

300 mm

For Equipment with Diameter 15 m to 50 m

600 mm

For Equipment with Diameter more than 50 m

900 mm

Inspection & Testing

a.

Inspection of various stages during painting is essential to ensure quality of painting. Inspection shall be

performed by owner authorized Field Superintendent.

b.

Surface preparation shall be as per specification; the prepared surface shall be compared with standard

comparator charts available in standards such as SIS or ISO. The basis of acceptance shall be based on

visual comparison only.

c.

Standard surface finish comparator specimens are available, which are approved by reputed test house,

these may also be used after obtaining clients or consultant approval.

d.

Visual examination of the painted surface shall be conducted to check for flaws such as unfinished surface,

drips, wrinkles, blisters, peels, cracks, stains, pin holes, crawls, dust settlement and air pockets.

e.

Area where such defects are noticed shall be marked using some paint of different colour.

f.

Areas where there are no such defects shall be accepted after visual examination.

g.

Thickness of primer and finish coats shall be measured using dry film thickness meter or elco-meter or

owners accepted equal. Thickness shall be measured in accordance with specification of SSPC-PA-A-73T.

h.

Location for verifying thickness shall be decided by engineer-in-charge depending on the size and shape of

the item painted.

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 17 of 29

i.

Total three sets of readings shall be carried out at a location, one at the main location and two at the

adjacent points. The average of these three measurements shall be taken as the measured value.

j.

The coating thickness shall be deemed to be accepted if the following conditions are satisfied:

Wet Film Thickness

Use steel type (or disposable type for one day only) each. Wet film thickness measured by using a wet

film gauge of steel or aluminium calibrated to read in mils or microns (25 microns 1 mil).

When using this gauge, the applicator divides the desired dry film thickness by the % volume solids of

the coating as expressed in a decimal (taking into account the amount of thinning done) to yield the

necessary dry film thickness.

Dry Film Thickness:

An Elometer, or mikrotest, or similar approved gauge is used to measure thickness to the nearest

micron. It shall be calibrated against a standard sand blasted surface to SA 2-1/2.

The acceptable tolerance in dry film thickness shall be in accordance with SSPC-PA2.

The Piping Contractors Superintendent shall have in his possession at all times a wet film thickness

gauge for continuous check of the west film as applied.

k.

Consultants/ Client may draw sample of paint before or during application for analysis.

l.

Adhesion test shall be performed after the finish coating has dried up, using a scraper comb with 1 mm gap

between teeth. Adhesion shall exceed 80%.

m.

All painting material including primers and thinners brought to site by contractor for application shall be

procured directly from the manufacturer as per the specification and shall be accompanied by

manufacturers test certificates. Paint formulations without certificates are not acceptable.

n.

Engineer in charge at his discretion, may call for tests of paint formulation. Contractor shall arrange to

have such tests performed including batch wise test of wet paints for physical and chemical analysis. All

cost incurred in carrying out tests shall be borne by the contractor. Defective work shall be corrected by

the Painting/Coating Contractor at his sole expense.

2.12

Field Safety and Hygiene

While performing surface preparation and painting, safety and hygiene conditions shall be observed by the

contractor. Following care shall be observed.

a.

Workmen should be provided with all personal protective gears such as safety shoes, safety goggles/

masks, hand gloves, aprons, safety belts, helmets etc.

b.

Smoking should be totally prohibited in and around painting area and paint storage area.

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 18 of 29

c.

Adequate ventilation and lighting shall be provided while painting in a confined area.

d.

While performing shot blasting activity, the area shall be covered adequately so that no shots fly around.

e.

Proper tubular double scaffolding with metallic clamps and landing mats shall be used while working on

higher elevations.

f.

If painting has to be carried out in an almost airtight environment, workmen shall use gas masks.

2.13

Guarantee

The contractor shall guarantee that the chemical and physical properties of paint materials used are in

accordance with the specifications contained herein / to be provided during job execution. The painting

work shall be guaranteed for at least 2 years without any detrimental failures such as loss of adhesion,

under film corrosion, corrosion spots and blisters etc. under the corrosive conditions prevailing in the

plant.

The contractor shall produce test reports from manufacturer regarding the quality of the particular batch

of painted surface. The Engineer in charge shall have the right to test wet samples of paint at random for

quality as per the paint materials specification given in this specification. Batch test report of the

manufacturer for each batch of paints supplied shall be made available by the contractor.

2.14

Qualification Criteria of Painting Contractor

Painting contractor who is awarded any job under this specification must have necessary equipment,

machinery, tools and tackles for surface preparation, paint application and inspection. All the paint

materials should be supplied from approved manufacturer. The contractor must have qualified, trained,

experienced surface preparator, paint applicator, inspector and supervisors. The contractors supervisor,

inspectors, surface preparators, paint applicators must be conversant with the standards referred in this

specification. The contractors capacity, capability and competency requirement for the job shall be

quantified in the tender document and shall be assessed by Client/ KCPL before awarding contract.

2.15

Documentation:

The following documents shall be complied and forwarded to consultant. This shall be equipment wise/

line wise:

a.

Type and Make of primer applied

b.

Type and Make of paint applied (Intermediate & Final)

c.

Batch Certificate Number

d.

Expiry date of paint

e.

Surface Preparation Examination Report

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 19 of 29

Doc. No.

Revision No.

f.

Dry Film Thickness Readings for Primer Coats

g.

Dry Film Thickness Readings for Intermediate & Finish Coats

h.

Check List

i.

Final Acceptance Certificate

j.

Paint Manufacturers QA/ QC Report

k.

Name of the manufacturer

l.

Factory Location

m.

Date of manufacturer

n.

Batch No.

o.

Product Name

p.

Drying Time

q.

Hold up Property

r.

Glossiness

s.

Specific Gravity

t.

Viscosity

u.

Generic Name

v.

Key Composition

Resin

Pigments

Curing Agent

Solvent Name

w.

Density

x.

Fineness

y.

Colour

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 20 of 29

z.

Date of Expiry

aa.

Pot Life

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 21 of 29

Annexure I - Painting Material Index

Application

Type

Dry film

thk.

Description

Max.

Humidity

Temp.

High

Temp. Low

35

85%

45oC

10oC

35

85%

45 C

10 C

PRIMER

01

Zinc Chromate Primer

II

INTERMEDIATE COAT

02

Synthetic Enamel Paint

III

FINAL COAT

03

Synthetic Enamel Paint

35

85%

45oC

10oC

04

High Build Epoxy For SS

100

85%

45oC

10oC

MAKES :- ASIAN PAINTS / BERGER PAINTS

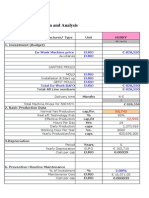

Annexure II Painting System Schedule

I Coat

Sr.

No.

Description of Surface

01

II Coat

III Coat

Final

Coat

Total DFT

(SHOP)

(FIELD)

Structural Steel Work

120

02

Piping System

120

03

Tanks

120

04

Bands for SS Piping

100

Remarks

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 22 of 29

Annexure III Colour Code

1. Colour Code for Equipments & Structural

Sr.

No.

Contents

Tankages

Structural Steel Work

Colour

Light brown

2.1

Frame work, Columns, Beams and Pipe Supports (Unless galvanized)

Light grey

2.2

Stairs, platforms, Floor plates, Kickplates (Unless galvanized)

Light grey

2.3

Ladder, Ladder Cages, Handrails (Unless galvanized)

Black with yellow bands

2. Colour Code for Piping:

Sr.

No.

Contents

Ground Colour

Second Colour

Band

First Colour Band

WATER

1

Cooling

Sea green

French blue

Boiler feed water

Sea green

Gulf red

Condensate

Sea green

Light brown

Drinking

Sea green

French blue

Signal red

Treated

Sea green

Light orange

Fire water

Fire red

Crimson red

Cold water down service from Sea green

storage tanks

French blue

Canary yellow

Domestic, hot

Sea green

Light grey

Sea, river, untreated

Sea green

White

10

Filtered water

Sea green

Light brown

11

Soft water

Sea green

Light brown

Signal red

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 23 of 29

12

Chilled water

Sea green

Black

Canary yellow

13

Sprinkle and hydrant water

Sea green

White

Signal red

14

Waste water

Sea green

Canary yellow

Signal red

AIR

15

Compressed, up

including 15 Kg/cm2

to

and Sky blue

16

Plant air

Sky blue

Silver grey

17

Instrument air

Sky blue

French blue

18

Dry vacuum

White

19

Wet vacuum

White

Dark violet

20

Very high pressure steam

Aluminium to IS 2339

Signal red

21

High pressure steam

Aluminium to IS 2339

French blue

22

Medium pressure steam

Aluminium to IS 2339

Gulf red

23

Low pressure steam

Aluminium to IS 2339

Canary yellow

24

Drainage

Black

OIL

25

Light diesel fuel

Light Brown

Brilliant green

26

High speed diesel fuel

Light Brown

27

Furnace fuel

Light Brown

French blue

OTHERS

28

Ammonia

Canary Yellow

Dark violet

29

Chlorine

Canary Yellow

Dark violet

Light Orange

30

Acetylene

Canary Yellow

Service Brown

31

Freon

Canary Yellow

Light grey

Dark violet

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 24 of 29

32

Nitrogen

Canary Yellow

Black

33

Oxygen

Canary Yellow

White

34

Ethylene Glycol

Dark Admirality grey

Brilliant green

35

Ethylene Di-chloride

Dark Admirality grey

Gulf red

36

Acetone

Dark Admirality grey

Black

37

Methanol

Dark Admirality grey

Deep buff

38

Sulphuric Acid

Dark violet

Brilliant green

Light orange

39

Hydrochloric Acid

Dark violet

Signal red

Light orange

40

Brine

Black

White

41

Mercury

Black

White

Brilliant green

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 25 of 29

Doc. No.

Revision No.

Sketch 1 - With Primary Colour Band

B

Basic Identification Colour

Primary Colour Band

Colour Band B (Same Colour as Band

A) located in the down-stream of band

A indicates the direction of flow.

In case of both direction flow, BandB should be located each side of BandA

Pipe

Size of Letters for

Line No.

100

50

100

25 mm

2 4

100

50

100

40 mm

6 16

D/2

80 mm

For the pipes sizes more than 16

A = 1 x 400 = 400 Max.

B = 400 / 2 = 200 Max.

C = 1 x 400 = 400 Max.

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 26 of 29

Sketch 2 -With Primary & Secondary Colour Band

G

Basic Identification Colour

Secondary Colour Band - F

Primary Colour Band - E

Colour Band G (Same

Colour as Band E)

located in the downstream of Band E

indicates the direction

of flow.

In case of both

direction flow, Band-G

should be located each

side

E

Size of Letters for

Line No.

100

50

50

50

25 mm

2 4

100

50

50

50

40 mm

6 16

D/2

D/2

80 mm

Pipe

For the pipes of area > 16

E

400 Max.

200 Max.

G =

200 Max.

400 Max.

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 27 of 29

Sketch 3 - With Primary & Secondary Colour Band With Direction By Arrows

J

Basic Identification Colour

Secondary Colour Band K

Primary Colour Band (J)

For pipes 1 6 arrow size

should be 25 mm x 100 mm

For pipes 8 and above

arrow size should be 80 x

150 mm

Size of Letters for

Line No.

100

50

25 mm

2 4

100

50

40 mm

6 16

D/2

80 mm

Pipe

For the pipes of sizes more than 16 the dimensions

J = 400 Max.

K = 200 Max.

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 28 of 29

Sketch 4 - Colour Bands with Hazard Markings

R

P/2

11-001-16-BBCIH

Hazard Marking Strips of

Black & Yellow B

Secondary Colour Band - M

Primary Colour Band - L

Direction of Flow N as

shown in sketch 1 & 2

(same colour as L)

The colour band N can be

replaced by arrow as shown

in sketch 3

Size of Letters for

Line No.

100

50

50

100

100

25 mm

2 4

100

50

50

100

100

40 mm

6 16

D/2

D/2

80 mm

Pipe

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 91-22 61547800. Fax.: 91-2225111092

Website : www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

TENDER DOCUMENT FOR PAINTING WORK

KCPL:P1064:00:M05:119

Date

14-05-2013

R0

Page No.

Page 29 of 29

3.0

PAINTING PROGRAMME

a.

Equipment and Piping Painting work is required to be completed within the time stipulated in the main

Contract.

b.

Key completion dates of various areas of work shall be specified at the time of award of Contract.

c.

The Site Planning Engineer of the Contractor shall be required to work out detailed erection programme

periodically as per completion requirements indicated by Consultant.

d.

The dates of completion for various milestones will be worked out by the Contractor jointly with the

Consultant. It will be the Contractors responsibility to execute the job totally as per agreed programme.

e.

Bi-monthly review meetings will be held at SITE to assess the progress and revise the schedule to ensure

completion as per Contract.

f.

Contractor mobilization to Site is to suit the completion targets and other than Force Majure, no excuses

for delay in completion is acceptable.

g.

The contract envisages liquidated damages (mentioned elsewhere in this document) for delay in

completion and the Contractor to bear the same in mind.

4.0

SCHEDULE OF QUANTITIES & RATES

a.

Schedule Of Equipment For Painting

- Annexure I

b.

Schedule Of Piping For Painting

- Annexure II

c.

Schedule Of Miscellaneous Items For Painting

- Annexure-III

You might also like

- Precious MetalDocument3 pagesPrecious MetalNarayana MugalurNo ratings yet

- Final Mat Requiement CompDocument20 pagesFinal Mat Requiement CompNarayana MugalurNo ratings yet

- Emergency Acupressure TreatmentDocument39 pagesEmergency Acupressure TreatmentNarayana Mugalur100% (1)

- DocumentsDocument3 pagesDocumentsNarayana MugalurNo ratings yet

- Instrumentation Supply StatusDocument3 pagesInstrumentation Supply StatusNarayana MugalurNo ratings yet

- Payment and IssuesDocument27 pagesPayment and IssuesNarayana Mugalur100% (1)

- GPI cap production Technology Comparison and AnalysisDocument54 pagesGPI cap production Technology Comparison and AnalysisNarayana MugalurNo ratings yet

- No More ExcusesDocument19 pagesNo More ExcusesNarayana MugalurNo ratings yet

- Visakhapatnam Steel Plant: Rashtriya Ispat Nigam Limited (A Government of India Enterprise) Visakhapatnam - 530031Document2 pagesVisakhapatnam Steel Plant: Rashtriya Ispat Nigam Limited (A Government of India Enterprise) Visakhapatnam - 530031Narayana MugalurNo ratings yet

- Wage CalculationDocument60 pagesWage CalculationNarayana MugalurNo ratings yet

- Name of Employee Employee PF NoDocument2 pagesName of Employee Employee PF NoNarayana MugalurNo ratings yet

- Materials Despatched List From Om Industrial Supplier To Carlsberg Patna - STL-13024Document8 pagesMaterials Despatched List From Om Industrial Supplier To Carlsberg Patna - STL-13024Narayana MugalurNo ratings yet

- Hathway Internet billDocument1 pageHathway Internet billNarayana MugalurNo ratings yet

- Ree Microbrewery Business PlanDocument19 pagesRee Microbrewery Business PlanNarayana Mugalur100% (1)

- Comparis I OnDocument8 pagesComparis I OnNarayana MugalurNo ratings yet

- Labour WagesDocument145 pagesLabour WagesNarayana MugalurNo ratings yet

- Erection CostingDocument1 pageErection CostingNarayana MugalurNo ratings yet

- Payment ModesDocument24 pagesPayment ModesNarayana MugalurNo ratings yet

- Pipe FittingsDocument8 pagesPipe FittingsNarayana MugalurNo ratings yet

- Ree Microbrewery Business PlanDocument19 pagesRee Microbrewery Business PlanNarayana Mugalur100% (1)

- Space Pipe Stacking and Stores Container Stores PlacingDocument1 pageSpace Pipe Stacking and Stores Container Stores PlacingNarayana MugalurNo ratings yet

- Mat Supply - As On 13112013Document41 pagesMat Supply - As On 13112013Narayana MugalurNo ratings yet

- 7 Avenue de La Paix 1202 Geneva Switzerland Wa License n1Document2 pages7 Avenue de La Paix 1202 Geneva Switzerland Wa License n1Narayana MugalurNo ratings yet

- Senior Analyst Profile - Ashoka B VDocument1 pageSenior Analyst Profile - Ashoka B VNarayana MugalurNo ratings yet

- 7th Mile, Mysore Road, Nayandahalli, Bangaluru - 560 039Document8 pages7th Mile, Mysore Road, Nayandahalli, Bangaluru - 560 039Narayana MugalurNo ratings yet

- Details To Be Printed On First Page Details To Be Printed On Last PageDocument1 pageDetails To Be Printed On First Page Details To Be Printed On Last PageNarayana MugalurNo ratings yet

- Required Details FormDocument9 pagesRequired Details FormNarayana MugalurNo ratings yet

- Invoice A/ctd by Carlsber G Total Invoices Billed As Per SpectraaDocument5 pagesInvoice A/ctd by Carlsber G Total Invoices Billed As Per SpectraaNarayana MugalurNo ratings yet

- KCPL p1064 00 m08 101 (Piping Legend)Document1 pageKCPL p1064 00 m08 101 (Piping Legend)Narayana MugalurNo ratings yet

- Invoice A/ctd by Carlsber G Total Invoices Billed As Per SpectraaDocument5 pagesInvoice A/ctd by Carlsber G Total Invoices Billed As Per SpectraaNarayana MugalurNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Sol ArcDocument26 pagesSol ArcpatilparagossNo ratings yet

- Carbon Steel Forging SpecificationDocument6 pagesCarbon Steel Forging SpecificationAnilNo ratings yet

- Factory Assembled Insulated Sandwich Panels Using Puf: M/s Metecno (India) Pvt. LTDDocument38 pagesFactory Assembled Insulated Sandwich Panels Using Puf: M/s Metecno (India) Pvt. LTDDiya MakanurNo ratings yet

- ARM4 - A Working Guide - Section A - General RulesDocument18 pagesARM4 - A Working Guide - Section A - General RulesdduffyNo ratings yet

- G DHS 1Document22 pagesG DHS 1Sergio Boillos100% (1)

- AX2012 PERIODIC MAINTENANCE: PERIODIC CLEANUP ACTIVITIESDocument72 pagesAX2012 PERIODIC MAINTENANCE: PERIODIC CLEANUP ACTIVITIESMansi0% (1)

- Electrical Engineer CV TemplateDocument2 pagesElectrical Engineer CV TemplateEli NaguitNo ratings yet

- Types of Technical ReportsDocument16 pagesTypes of Technical ReportsaminoacidNo ratings yet

- Technical Solution Design TemplateDocument19 pagesTechnical Solution Design TemplateLuis Arry100% (4)

- Bulletin 142 Testing Water Separation Properties of Jet Fuel Revised MSEP Protocol 04 - 2022Document5 pagesBulletin 142 Testing Water Separation Properties of Jet Fuel Revised MSEP Protocol 04 - 2022ElieNo ratings yet

- P14DZ - MC en 9Document46 pagesP14DZ - MC en 9Panu Mark IINo ratings yet

- Lo3 PDFDocument13 pagesLo3 PDFEsu Rasu EsubalNo ratings yet

- Ranjit Singh. Int.Document4 pagesRanjit Singh. Int.ranjit_sgprNo ratings yet

- Faa G 2100HDocument95 pagesFaa G 2100HAdah AzizNo ratings yet

- D5977 Specification For High Load Rotational Spherical Bearings For Bridges and Structures.Document5 pagesD5977 Specification For High Load Rotational Spherical Bearings For Bridges and Structures.Francis DomingoNo ratings yet

- Awwa D130Document28 pagesAwwa D130Jacques BlueqNo ratings yet

- Specification For Park City-clubhouse-Rev 0Document332 pagesSpecification For Park City-clubhouse-Rev 0ThatnguyentonNo ratings yet

- AUTOSAR SWS C ImplementationRulesDocument45 pagesAUTOSAR SWS C ImplementationRulesYaswanth Sai MuluguruNo ratings yet

- Library Management System SrsDocument10 pagesLibrary Management System SrsHimanshu TiwariNo ratings yet

- Contract PlanningDocument50 pagesContract Planninghannykhawaja88% (8)

- Canteen & Garbage Shed - ReportDocument19 pagesCanteen & Garbage Shed - ReportahnafNo ratings yet

- Specifications - AC SystemDocument15 pagesSpecifications - AC System123agattar100% (1)

- Design For Standard Bridges - General SpecificationsDocument31 pagesDesign For Standard Bridges - General SpecificationsMarc LxmnNo ratings yet

- Method Statement For Chemical AnchorDocument6 pagesMethod Statement For Chemical Anchormohammed faraazNo ratings yet

- Founding - Technical Conditions of Delivery: BSI Standards PublicationDocument28 pagesFounding - Technical Conditions of Delivery: BSI Standards PublicationAditya Pratap100% (1)

- SECTION 03 52 00 Lightweight Concrete Roof InsulationDocument7 pagesSECTION 03 52 00 Lightweight Concrete Roof InsulationJuanPaoloYbañezNo ratings yet

- 01 Samss 012 2014Document10 pages01 Samss 012 2014lhanx2No ratings yet

- 7.1 - Mobile Harbour Crane PDFDocument83 pages7.1 - Mobile Harbour Crane PDFanindya.basu859217No ratings yet

- A459 PDFDocument3 pagesA459 PDFRafael CossolinoNo ratings yet

- Micrel's Quality/Reliability ProgramDocument6 pagesMicrel's Quality/Reliability ProgramKrisztina MkNo ratings yet