Professional Documents

Culture Documents

Materials 1

Uploaded by

prasoon_eilCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Materials 1

Uploaded by

prasoon_eilCopyright:

Available Formats

Process plants designed and constructed to the ASME B31.

3 code also

rely on the standardization of the components used for piping systems

and the method of process plant fabrication and construction.

There are numerous standards, many of which are interrelated, and they

must be referred and adhered to by design engineers and manufacturers

in the process industry. These standards cover the following:

. Material chemical composition, mechanical requirements, heat treatment,

etc.

. Dimensions general dimensions and tolerances.

. Fabrication codes welding, threading.

Standards covering the preceding were drawn up by the following major

engineering bodies:

. American Petroleum Institute (API).

. American Society for Testing and Materials (ASTM).

. American Water Works Association (AWWA).

. American Welding Society (AWS).

11

. Manufacturers Standardization Society (MSS).

. National Association of Corrosion Engineers (NACE).

. Society of Automotive Engineers (SAE).

Periodically, these standards are updated to bring them in line with the

latest industry practices. Most of the standards have been in circulation

for a number of years, and the changes are rarely dramatic; however,

such changes must be incorporated into the design. It is essential that the

latest revision is the final reference point.

Other countries publish comprehensive standards containing data on

material, dimensions of components, and construction procedures;

however, for the purpose of this book, the standards mentioned

previously are referenced.

American standards are not superior to other national standards, but

they are the ones most commonly used in the process industry. They are

based on a long track record with a very low failure rate, so there is a

high degree of confidence in these publications. Always refer to the latest

edition of the relevant standards, and if necessary, make sure your

company s library holds the most current version.

The remainder of this chapter is devoted to a listing of the most-used

specifications current at the time of writing (July 2004). Please refer to

the latest revision in the event of any of the specifications becoming

updated.

2. AMERICAN PETROLEUM INSTITUTE

API Spec 5B. Specification for Threading, Gauging and Thread Inspection of

Casing, Tubing and Line Pipe Threads, 14th edition, 1996.

API Spec 5L. Specification for Line Pipe, 42nd edition, 2000.

API Spec 6A. Specification for Wellhead and Christmas Tree Equipment,

18th edition, 2002.

API Bull 6AF. Bulletin on Capabilities of API Flanges under Combinations of

Load, 2nd edition, 1995.

API TR 6AF1. Temperature Derating of API Flanges under Combination of

Loading, 2nd edition, 1998.

API TR 6AF2. Bulletin on Capabilities of API Integral Flanges under

Combination of Loading, 2nd edition, 1999.

API Spec 6D. Specification for Pipeline Valves, 22nd edition, 2002.

API Spec 6FA. Specification for Fire Test Valves, 3rd edition, 1999.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- GD 511a-1 Parts ManualDocument275 pagesGD 511a-1 Parts ManualMachinery Club100% (4)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Teco s310 User ManualDocument10 pagesTeco s310 User ManualEhsan GhanbarzadehNo ratings yet

- Chilled Water Pipe Insulation Method StatementDocument2 pagesChilled Water Pipe Insulation Method StatementGündoğdu Akın75% (4)

- Strudl 1Document1 pageStrudl 1prasoon_eilNo ratings yet

- Design 4Document2 pagesDesign 4prasoon_eilNo ratings yet

- Design 3Document2 pagesDesign 3prasoon_eilNo ratings yet

- Design 5Document2 pagesDesign 5prasoon_eilNo ratings yet

- Design 2Document2 pagesDesign 2prasoon_eilNo ratings yet

- Basic piping stress analysis using CAESAR IIDocument2 pagesBasic piping stress analysis using CAESAR IIprasoon_eilNo ratings yet

- StrudlDocument1 pageStrudlprasoon_eilNo ratings yet

- Design 1Document1 pageDesign 1prasoon_eilNo ratings yet

- Stress PDocument1 pageStress Pprasoon_eilNo ratings yet

- Rivalry 12Document1 pageRivalry 12prasoon_eilNo ratings yet

- IsorefDocument402 pagesIsorefprasoon_eilNo ratings yet

- Asme 4Document4 pagesAsme 4prasoon_eilNo ratings yet

- Asme 3Document4 pagesAsme 3prasoon_eilNo ratings yet

- Asme 2Document4 pagesAsme 2prasoon_eilNo ratings yet

- Rivalry 21Document1 pageRivalry 21prasoon_eilNo ratings yet

- Asme 1Document5 pagesAsme 1prasoon_eilNo ratings yet

- Rivalry 12Document1 pageRivalry 12prasoon_eilNo ratings yet

- Rivalry 16Document1 pageRivalry 16prasoon_eilNo ratings yet

- Rivalry 26Document1 pageRivalry 26prasoon_eilNo ratings yet

- Rivalry 23Document1 pageRivalry 23prasoon_eilNo ratings yet

- Rivalry 22Document1 pageRivalry 22prasoon_eilNo ratings yet

- Rivalry 21Document1 pageRivalry 21prasoon_eilNo ratings yet

- Rivalry 18Document1 pageRivalry 18prasoon_eilNo ratings yet

- Rivalry 24Document1 pageRivalry 24prasoon_eilNo ratings yet

- Rivalry 17Document1 pageRivalry 17prasoon_eilNo ratings yet

- Rivalry byDocument1 pageRivalry byprasoon_eilNo ratings yet

- Rivalry 25Document1 pageRivalry 25prasoon_eilNo ratings yet

- Rivalry 21Document1 pageRivalry 21prasoon_eilNo ratings yet

- Rivalry 20Document1 pageRivalry 20prasoon_eilNo ratings yet

- Rivalry 20Document1 pageRivalry 20prasoon_eilNo ratings yet

- ABB Terminal BlocksDocument236 pagesABB Terminal BlocksBenoit LefebvreNo ratings yet

- cg-600 p2Document1 pagecg-600 p2mdishong27No ratings yet

- 1SDA081063R1 t5n 630 Ekip e Lsig in 630a 3p F FDocument3 pages1SDA081063R1 t5n 630 Ekip e Lsig in 630a 3p F FBolivar MartinezNo ratings yet

- Kalina Cycle and Cement IndustryDocument8 pagesKalina Cycle and Cement IndustryEhab SabryNo ratings yet

- PPTs ON BONTON CABLESDocument10 pagesPPTs ON BONTON CABLESShaishav Anand100% (1)

- Elective 4 Module1Document27 pagesElective 4 Module1kentong compraNo ratings yet

- EnergySRP Forms MatchingDocument2 pagesEnergySRP Forms Matchingeiad-mahmoudNo ratings yet

- Syllabus of Diploma in Electrical EngineeringDocument17 pagesSyllabus of Diploma in Electrical EngineeringJoson Chan100% (1)

- Principle Heat TransferDocument34 pagesPrinciple Heat TransferZick HaziqNo ratings yet

- Motor (ABB Type)Document50 pagesMotor (ABB Type)Rolando Nunez del Prado B.No ratings yet

- Germany and Japan's Remarkable Post-WWII Economic ComebackDocument5 pagesGermany and Japan's Remarkable Post-WWII Economic ComebackHANNALEENo ratings yet

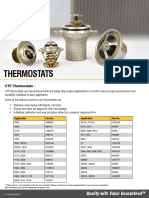

- TERMOSTATOSDocument1 pageTERMOSTATOSSERGIOEDWARDONo ratings yet

- DG Set SelectionDocument12 pagesDG Set SelectionDr. R. SharmaNo ratings yet

- Brazil's ratification adds momentum to Paris climate agreementDocument3 pagesBrazil's ratification adds momentum to Paris climate agreementlauro sNo ratings yet

- 908 PM Expertise and Equipment Contribute To CHP Success at Sodra Cell VaroDocument2 pages908 PM Expertise and Equipment Contribute To CHP Success at Sodra Cell Varoshashikanth79No ratings yet

- YM80SA Abrasive Belt Polishing Machine-Operation ManualDocument7 pagesYM80SA Abrasive Belt Polishing Machine-Operation ManualAgha Ali KhanNo ratings yet

- SOF National Science Olympiad 2018-19 GuidelinesDocument7 pagesSOF National Science Olympiad 2018-19 GuidelinesRahul SinhaNo ratings yet

- New Tutorial 2 Solution On ThermodynamicsDocument7 pagesNew Tutorial 2 Solution On ThermodynamicsNaveed AhmadNo ratings yet

- Wet Steam Washing SystemDocument7 pagesWet Steam Washing SystemPrudhvi Raj100% (1)

- CZ-RTC4 - Service ManualDocument68 pagesCZ-RTC4 - Service ManualAnonymous 31Airw50% (2)

- Water Level IndicatorDocument5 pagesWater Level IndicatorRahul JadhavNo ratings yet

- EDM Technologies: Electrical Discharge Machining ServicesDocument8 pagesEDM Technologies: Electrical Discharge Machining Servicesfarahin_selamatNo ratings yet

- Chlorosorb Ultra Case StudiesDocument5 pagesChlorosorb Ultra Case StudiesWitta Kartika RestuNo ratings yet

- IPM 200 Series: Internal Permanent Magnet MotorsDocument7 pagesIPM 200 Series: Internal Permanent Magnet MotorsLuu JosNo ratings yet

- APC Back-Ups 350Document2 pagesAPC Back-Ups 350Justin EndacottNo ratings yet

- Mechatronics Handbook - 02 - Mechatronic Design Approach PDFDocument16 pagesMechatronics Handbook - 02 - Mechatronic Design Approach PDFJosé Fernando TerronesNo ratings yet

- Inspection GalleryDocument4 pagesInspection GalleryrajmohapatraNo ratings yet