Professional Documents

Culture Documents

Uploads 1 0 8 9 1089833 Lesson5

Uploaded by

Raju ShresthaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uploads 1 0 8 9 1089833 Lesson5

Uploaded by

Raju ShresthaCopyright:

Available Formats

Reinforced Concrete Design to BS8110

Structural Design 1 Lesson 5

Lesson 5: Deflection in reinforced concrete beams

Content

4.1

Introduction

4.2

Definitions

4.2.1 Tension

4.2.2 Compression

4.3

Initial sizing

4.3.1 Worked example

4.4

Reinforcement details

4.5

Anchorage at supports

4.6

Laps in reinforcement

4.1 Introduction to deflection (Cl. 3.4.6. BS8110)

As already mentioned we must remember to check serviceability as well as

ultimate limit states. The SLS for deflection considers the performance of the

structure under Working Loads such that the structure, or part of it under

consideration, does not deflect excessively causing unsightly cracking and loss

of durability.

BS 8110 details how deflections and the accompanying crack widths may be

calculated. But for rectangular beams some simplified procedures may be used to

satisfy the requirements without too much effort. This approximate method for

rectangular beams is based on permissible ratios of span/effective depth.

Reinforced Concrete Design to BS8110

Structural Design 1 Lesson 5

4.2

Definitions:

For span read effective span:

D

A

Here the effective span is the LESSER of:

The distance between centres of bearings, A

OR

The CLEAR span plus the effective depth, D+d

BS8110 Deflection Criteria:

1. Total deflection < span/250

OR

2. For spans up to 10 m, deflection after partitions and finishes <

span/500 or 20 mm, whichever lesser.

These criteria are deemed to be satisfied in the following cases:

Table 3.9 BS8110

Support Conditions

Span/Effective

depth

For Initial design

(rectangular section)

Cantilever

Simply Supported

20

12

Continuous

26

15

The above BASIC ratios apply to spans up to 10 m. For greater spans these

values should be multiplied by 10/span. e.g. for 15m span 10/15 = 0.66666

2

Reinforced Concrete Design to BS8110

Structural Design 1 Lesson 5

These BASIC ratios may be enhanced by provision AND over provision of both

tension and compression reinforcement as shown by the following tables.

4.2.1 Tension

Table 3.10 BS8110

M/bd2

Service

stress

250

460

fs

0.5

0.75

1.00

1.50

2.00

3.00

4.00

5.00

6.00

100

1.86

1.63

1.36

1.19

1.08

1.01

150

1.98

1.69

1.49

1.25

1.11

1.01

.94

156

1.96

1.66

1.47

1.24

1.10

1.00

.94

200

1.95

1.76

1.51

1.35

1.14

1.02

.94

.88

250

1.9

1.7

1.55

1.34

1.20

1.04

.94

.87

.82

288

1.68

1.5

1.38

1.21

1.09

0.95

.87

.82

.78

300

1.6

1.44

1.33

1.16

1.06

0.93

.85

.8

.76

The values in the above table are derived from:

Modification factor 0.55

( 477 fs )

2.0

120(0.9 M 2 )

bd

where:

M = the design ultimate moment

fs design service stress of tension reinforcement

=

5 f y As, req

8 As, prov

1

b

and b = the percentage of moment redistribution

Reinforced Concrete Design to BS8110

Structural Design 1 Lesson 5

4.2.3 Compression

Table 3.11 BS8110

100As,prov/bd

0.0

Factor

1

.15

1.05

.25

1.08

.35

1.1

.5

1.14

.75

1.2

1.0

1.25

1.5

1.33

2.0

1.4

2.5

1.45

>=3.

1.5

Note: deflection is usually more critical in slab design ..

4.3

Initial sizing

All designers develop their own techniques to help them start to tackle the

problem in hand. The following example shows a simple method of sizing a

beam using:

1. Span/Effective depth ratio to estimate a suitable depth for the

section.

2. Limiting the design shear stress (v=V/bd) to say 1.2N/mm2.

As the starting point.

Reinforced Concrete Design to BS8110

Structural Design 1 Lesson 5

4.3.1 Worked example

A simply supported beam has an effective span of 9 m and supports loads as

shown. Determine suitable dimensions for the effective depth and width of the

beam.

q k= 20 kN/m

g k= 15 kN/m

9m

From the table of Span/d for initial sizing

Span

12

d

Span 9000

d

750mm

12

12

Total Ultimate Load

(14

. g k 16

. q k ) span (14

. 15 16

. 20)9 477kN

Design Shear Force V

477

238.5kN

2

Limiting v to 1.2 N/mm2. Gives b

V

238.5 103

v 12

.

bd

b 750

238.5 103

b

275mm (to nearest 25 mm)

12

. 750

Hence a beam of width 275 mm and effective depth 750 mm would be suitable to

support the given design loads.

Reinforced Concrete Design to BS8110

Structural Design 1 Lesson 5

4.4

Reinforcement Details

The code (BS8110) requires the final design to pay attention to:

1. Min and Max reinforcement as a percentage of the gross CSA. (Cl.

3.12.5.3. & 3.12.6.1) - This will on the one hand, help the control of

cracking, increase durability, while on the other assist placing and

compaction.

0.24%bh As 4% when f y 250 N / mm2

0.13% bh As 4% when f y 460 N / mm2

2. Min and Max spacing of tension reinforcement (Cl. 3.12.11.1.) - To allow

good compaction and to ensure crack widths do not exceed 0.3 mm

respectively.

hagg 5 mm or bar size s b 300 mm when f y 250 N / mm 2

hagg 5 mm or bar size s b 160 mm when f y 460 N / mm 2

3. Curtailment and (Cl. 3.12.9.) - To allow for the variation in bending

moment decrease towards the supports in a simply supported beam.

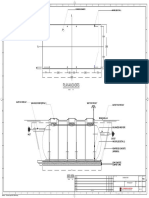

THEORETICALLY - 50% of the bars may be curtailed at points A & B as shown

below.

Reinforced Concrete Design to BS8110

Structural Design 1 Lesson 5

w

x = 0.146 l

As

l

As

As

wl 2

8

A

wl 2

16

B

wl 2

16

PRACTICALLY

However in order to develop any stress in these bars they must be anchored into

the concrete. Except at the end supports the bars are therefore normally extended

beyond this theoretical cut-off point by:

The greater of d OR 12

Also where a bar is stopped in the tension zone FULL anchorage length is

stipulated:

Table 3.29 - FULL Anchorage lengths as bar size multiples

Reinforcement

LA

Type

Plain

Deformed (1)

Deformed (2)

25

30

35

>=40

Tension

39

36

33

31

Compression

32

29

27

25

Tension

51

46

43

40

Compression

41

37

34

32

Tension

41

37

34

32

Compression

32

29

27

26

Reinforced Concrete Design to BS8110

Structural Design 1 Lesson 5

Simplified Rules for SS Beams and Cantilevers (Cl. 3.12.10.2.)

Cut-off 50% of bars

0.08 l

0.08 l

l

2 OR 45

Cut-off 50% of bars

4.5

Anchorage at Supports

Each tension bar will be deemed properly anchored if they extend:

a)

12 beyond C-L of support

b)

12 + d/2 from face of support

12

2 + 12

CL

Reinforced Concrete Design to BS8110

Structural Design 1 Lesson 5

Hooks and bends may be used where necessary to provide adequate anchorage

lengths but they must not begin before the centre of support when used to meet

condition a) OR before d/2 from the face for condition b).

For Mild Steel

rmin = 2

For High Yield Steel

rmin = 3OR 4 for >=25 mm.

For 90 bend LA = 4r < 12

For Hook

4.6

LA = 8r < 24

Laps In Reinforcement

To enable continuity of reinforcement at construction joints and to enable bar

lengths to be man-handled lapped bars are normally detailed.

Min lap length

> 15 OR 300 mm

Tension Laps

Use Anchorage Length L=LA .

where is the diameter of the smaller bar.

Compression Laps Use 1.25 times the compression anchorage length.

You might also like

- BST– 10346 Deflection and cracking limitsDocument15 pagesBST– 10346 Deflection and cracking limitsNelsonDayNo ratings yet

- Unit 8 (SERVICEABILITY LIMIT STATE (SLS) )Document26 pagesUnit 8 (SERVICEABILITY LIMIT STATE (SLS) )Zara Nabilah100% (2)

- Rreinforced Concrete-Beam DesignDocument38 pagesRreinforced Concrete-Beam DesignMohamed AbdNo ratings yet

- Flat SlabsDocument8 pagesFlat Slabsnahzem100% (1)

- How2 Flat SlabsDocument8 pagesHow2 Flat SlabsTim DanNo ratings yet

- Unit 9 (DESIGN OF SHEAR REINFORCEMENT)Document29 pagesUnit 9 (DESIGN OF SHEAR REINFORCEMENT)Zara Nabilah76% (25)

- An Overview of Revisions in Is 456: 2000: Code of Practice For Plain and Reinforced Concrete'Document3 pagesAn Overview of Revisions in Is 456: 2000: Code of Practice For Plain and Reinforced Concrete'Ahmmed MuhseeNo ratings yet

- IS EN 1992 (Eurocode 2) Design of Concrete StructuresDocument64 pagesIS EN 1992 (Eurocode 2) Design of Concrete Structuressanku_cidNo ratings yet

- RCC Lecture Series 4 2018-19Document33 pagesRCC Lecture Series 4 2018-19Mansa ArthurNo ratings yet

- How To Design Concrete Structures Using Eurocode 2 - (3) SlabsDocument8 pagesHow To Design Concrete Structures Using Eurocode 2 - (3) Slabsbobbytirona566100% (1)

- RC Desktop Toolkit v2Document27 pagesRC Desktop Toolkit v2pbharadwaj545No ratings yet

- RCD ObjectivesDocument3 pagesRCD ObjectivesiamcerbzjrNo ratings yet

- Rcc95 Continuous Beams (Tables)Document8 pagesRcc95 Continuous Beams (Tables)Steve JsobNo ratings yet

- Design of ConcreteDocument36 pagesDesign of ConcreteDenden Dermawan100% (3)

- Chapter Three Design Requirements: 3.1.1definition and ConstructionDocument25 pagesChapter Three Design Requirements: 3.1.1definition and ConstructionSTOCK MSOWOYANo ratings yet

- TEK 12-6 Reinforcement & Connectors (2007)Document6 pagesTEK 12-6 Reinforcement & Connectors (2007)B0B_PNo ratings yet

- Reinforced concrete design guide amendmentDocument6 pagesReinforced concrete design guide amendmentstorm7576No ratings yet

- Span Depth RatioDocument11 pagesSpan Depth RatioselinaNo ratings yet

- Beam Design PDFDocument20 pagesBeam Design PDFkabwe ngomaNo ratings yet

- Blue Book' Tables For Bolts, Welds and Webs: TechnicalDocument3 pagesBlue Book' Tables For Bolts, Welds and Webs: TechnicalJacob GrechNo ratings yet

- Dr. Mirvat Bulbul-EnCE335 Fundamentals of Reinforced Concrete Design According ACI 318-05-Birzeit University, Palestinian جامعة بيرزيت هي جامعة فلسطينية (2011-2012)Document41 pagesDr. Mirvat Bulbul-EnCE335 Fundamentals of Reinforced Concrete Design According ACI 318-05-Birzeit University, Palestinian جامعة بيرزيت هي جامعة فلسطينية (2011-2012)Seifeldin Ali MarzoukNo ratings yet

- S 152 ContentDocument22 pagesS 152 ContentIgnatius SamrajNo ratings yet

- Design of Beams To BS 8110Document14 pagesDesign of Beams To BS 8110Kasun Karunaratne99% (76)

- Unit 7 (DESIGN DETAILS OF BEAMS)Document35 pagesUnit 7 (DESIGN DETAILS OF BEAMS)Zara Nabilah94% (16)

- TDS Lec 6Document94 pagesTDS Lec 6YAHAMPATH ARACHCHIGE PASAN MADURA YahampathNo ratings yet

- Chapter 5 Shear, Bond and TorsionDocument82 pagesChapter 5 Shear, Bond and TorsiondavidNo ratings yet

- RC Slab Bridge DecksDocument24 pagesRC Slab Bridge DecksKeyur Patel100% (1)

- Design For RC Flat SlabsDocument70 pagesDesign For RC Flat SlabsAil AafaaqNo ratings yet

- Bs Punching Shear PDFDocument6 pagesBs Punching Shear PDFMrStructuralNo ratings yet

- Watertank GSDocument38 pagesWatertank GSSushobhit ChoudharyNo ratings yet

- DDA 3164 BEAM Shear Deflection and CrackDocument20 pagesDDA 3164 BEAM Shear Deflection and CrackZayyan RomjonNo ratings yet

- Slabs: Designing To Eurocode 2Document8 pagesSlabs: Designing To Eurocode 2way2saleemNo ratings yet

- Ec2ei 12 10 09 PDFDocument64 pagesEc2ei 12 10 09 PDFPYAINo ratings yet

- Limit State of Serviceability in RCCDocument19 pagesLimit State of Serviceability in RCCprashmceNo ratings yet

- RCC BEAM DESIGN AND SERVICEABILITYDocument15 pagesRCC BEAM DESIGN AND SERVICEABILITYprashmceNo ratings yet

- Design For RC Flat SlabsDocument70 pagesDesign For RC Flat SlabsAil Aafaaq100% (3)

- Block Shear Connection Design Checks: (ABN) /ACN (94) 000973 839Document7 pagesBlock Shear Connection Design Checks: (ABN) /ACN (94) 000973 839lutzNo ratings yet

- Shear Wall - BS8110-97-007Document4 pagesShear Wall - BS8110-97-007Kavin TamNo ratings yet

- 2lec3&4 With Assignment 2 Reinf Conc 412Document42 pages2lec3&4 With Assignment 2 Reinf Conc 412Emmanuel MwabaNo ratings yet

- Chapter 1 - FLEXURE - SP-17 - 09-07 PDFDocument36 pagesChapter 1 - FLEXURE - SP-17 - 09-07 PDFYel DGNo ratings yet

- Unrestrained BeamDocument3 pagesUnrestrained BeamGanesh Konar100% (1)

- CSA S16-09 CONNECTION GUIDELINESDocument32 pagesCSA S16-09 CONNECTION GUIDELINESprabhu81100% (2)

- (Eurocode 2) Design of Concrete Structures: Brian O'RourkeDocument20 pages(Eurocode 2) Design of Concrete Structures: Brian O'RourkeselinaNo ratings yet

- 4TH SD-1Document83 pages4TH SD-1Sudeesh M SNo ratings yet

- Bs ClausesDocument3 pagesBs ClausesTobin T Kunnath100% (1)

- Macalloy Bars For Use in Post Tensioning ApplicationDocument21 pagesMacalloy Bars For Use in Post Tensioning Applicationsanusi69No ratings yet

- Pile Caps Guidance PDFDocument7 pagesPile Caps Guidance PDFDeepak Jain100% (1)

- ACI Detailing ManualDocument9 pagesACI Detailing Manualwinard21No ratings yet

- WSM PDFDocument17 pagesWSM PDFSathish SelvaNo ratings yet

- 5 SlimDek Connection - AW 48240Document12 pages5 SlimDek Connection - AW 48240in678No ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- Structural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesFrom EverandStructural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesRating: 3.5 out of 5 stars3.5/5 (13)

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- Project: Interior Design of Residence Date: 28 May, 2018 Client: Mr. Pratik AdhikaryDocument1 pageProject: Interior Design of Residence Date: 28 May, 2018 Client: Mr. Pratik AdhikaryRaju ShresthaNo ratings yet

- BIMx Export LogDocument1 pageBIMx Export LogFairus AdhdailamiNo ratings yet

- Understanding Hiatal HerniaDocument37 pagesUnderstanding Hiatal HerniaRaju Shrestha100% (2)

- 4) Using Plugins A4Document12 pages4) Using Plugins A4Raju ShresthaNo ratings yet

- AREA of BARSDocument14 pagesAREA of BARSMuhammad Irfan KhanNo ratings yet

- Road Estimates SheetDocument11 pagesRoad Estimates SheetAmal PremachandranNo ratings yet

- Ties On Column From BeamsDocument1 pageTies On Column From BeamsRaju ShresthaNo ratings yet

- StaadDocument5 pagesStaadRaju ShresthaNo ratings yet

- Architectural Fee Calculator 2015Document12 pagesArchitectural Fee Calculator 2015Raju ShresthaNo ratings yet

- Reinforced Concrete Slab Punching Shear StrengthDocument8 pagesReinforced Concrete Slab Punching Shear StrengthRaju ShresthaNo ratings yet

- Slab in ETABS, Shell or MembraneDocument14 pagesSlab in ETABS, Shell or MembraneNaveen Revanna100% (1)

- ECG Guideline for Using ETABS in Seismic AnalysisDocument25 pagesECG Guideline for Using ETABS in Seismic AnalysisRaju Shrestha100% (1)

- AREA of BARSDocument14 pagesAREA of BARSMuhammad Irfan KhanNo ratings yet

- Checklist For Plastering: Project: Doc. No. Client: Project LocationDocument4 pagesChecklist For Plastering: Project: Doc. No. Client: Project LocationNoorul Mufas MnNo ratings yet

- RCC Thumb RuleDocument7 pagesRCC Thumb RuleRahat ullah100% (6)

- Lesson11 CastUnitDrawing PDFDocument23 pagesLesson11 CastUnitDrawing PDFKadutrisampaNo ratings yet

- Latest Footing DesignDocument7 pagesLatest Footing DesignRaju ShresthaNo ratings yet

- Tekla Structure - Lesson 08 - NumberingAndReports2Document23 pagesTekla Structure - Lesson 08 - NumberingAndReports2Kresno N SoetomoNo ratings yet

- RCC Thumb RuleDocument7 pagesRCC Thumb RuleRahat ullah100% (6)

- 3034.improperly Connected PlatesDocument2 pages3034.improperly Connected PlatesRaju ShresthaNo ratings yet

- Chemistry 2Document9 pagesChemistry 2Suman KarthikNo ratings yet

- Ribed SlabDocument9 pagesRibed SlabEngDbt100% (1)

- Concret Mix Design (M10 To M100)Document65 pagesConcret Mix Design (M10 To M100)Rajesh Kollipara93% (14)

- Field Book Calculation UtilityDocument15 pagesField Book Calculation UtilityRaju Shrestha100% (1)

- Waffle SlabsDocument14 pagesWaffle SlabsRaju Shrestha50% (2)

- Estimating Reinforcing Bars - tcm45-340894Document6 pagesEstimating Reinforcing Bars - tcm45-340894Alvaro Perez LopezNo ratings yet

- Colour byDocument6 pagesColour byRaju ShresthaNo ratings yet

- Flood by Gumbel PDFDocument2 pagesFlood by Gumbel PDFRaju ShresthaNo ratings yet

- Chain AgeDocument5 pagesChain AgeRaju ShresthaNo ratings yet

- Trish UliDocument7 pagesTrish UliRaju ShresthaNo ratings yet

- Joint Oil Analysis Program ManualDocument86 pagesJoint Oil Analysis Program Manualfurious143No ratings yet

- Motorola68k 2Document114 pagesMotorola68k 2SoumyabrataPatraNo ratings yet

- Data Packets Analyzer AND Controller LanDocument7 pagesData Packets Analyzer AND Controller LanMumbai AcademicsNo ratings yet

- Fundamentals of Electric Vehicles Lecture on Vehicle DynamicsDocument15 pagesFundamentals of Electric Vehicles Lecture on Vehicle DynamicsaerovinuNo ratings yet

- Low Band Receiving AntennasDocument50 pagesLow Band Receiving AntennasDavid Bohorquez RamosNo ratings yet

- Midterm Exam Physics General 1 Forces MotionDocument3 pagesMidterm Exam Physics General 1 Forces MotionNam Anh Nguyễn HữuNo ratings yet

- Qs X 4077590Document190 pagesQs X 4077590Vượng UôngNo ratings yet

- Ssis Mock Test FDocument7 pagesSsis Mock Test Fparashuram nNo ratings yet

- Steam Turbine Overspeed-Protection Woodward Protech-GIIDocument4 pagesSteam Turbine Overspeed-Protection Woodward Protech-GIIMarioEnriqueAlcocerÁvilaNo ratings yet

- SikaGrout 3200 PDS (CE)Document3 pagesSikaGrout 3200 PDS (CE)salma karimahNo ratings yet

- jQuery 3 Day CourseDocument6 pagesjQuery 3 Day CourseAmit SharmaNo ratings yet

- Materials System SpecificationDocument10 pagesMaterials System SpecificationMudabbir Hussain100% (1)

- Isolation and Purification of Peroxidase From Shoots of OF TOMATODocument9 pagesIsolation and Purification of Peroxidase From Shoots of OF TOMATOPooja WalkeNo ratings yet

- Lab 1Document8 pagesLab 1Khurram SattarNo ratings yet

- Hall Buttons Car Operating Panel: Standard Hall Call Button & Position IndicatorDocument1 pageHall Buttons Car Operating Panel: Standard Hall Call Button & Position Indicatorsameer hassanNo ratings yet

- GSM R Hlr9820Document0 pagesGSM R Hlr9820futronoNo ratings yet

- Civil Engineering Laboratory DSTDocument6 pagesCivil Engineering Laboratory DSTJuhil ZalavadiyaNo ratings yet

- Yahoo Finance stock data snapshotDocument9 pagesYahoo Finance stock data snapshotsandip_exlNo ratings yet

- Moodle User Manual for UJ StudentsDocument14 pagesMoodle User Manual for UJ StudentsalexNo ratings yet

- Detail Biofile 1Document1 pageDetail Biofile 1Rully SaputraNo ratings yet

- Skin Friction in Shale Results TPDocument6 pagesSkin Friction in Shale Results TPSteven LongNo ratings yet

- Voltage Source Drive Programming Manual SummaryDocument262 pagesVoltage Source Drive Programming Manual SummaryCarolina HuertaNo ratings yet

- GE Lighting Systems Roadway Lighting Catalog 1967Document20 pagesGE Lighting Systems Roadway Lighting Catalog 1967Alan Masters100% (2)

- Engine - Suzuki Spare Part Suzuki IndonesiaDocument1 pageEngine - Suzuki Spare Part Suzuki IndonesiaFuspita KusangNo ratings yet

- Amortiguador Pala 7495Document2 pagesAmortiguador Pala 7495milenko Cortes100% (1)

- Mechanical Properties of MetalsDocument258 pagesMechanical Properties of MetalsIsza Marie N. SocorinNo ratings yet

- Iptc-17413-Ms EspDocument22 pagesIptc-17413-Ms Espamramazon88No ratings yet

- MidDocument92 pagesMidKUNONo ratings yet

- Homemade Solar Food DehydratorDocument6 pagesHomemade Solar Food DehydratorHilion FLAVIO100% (1)

- Sarlink® 3190 (ShA 90)Document4 pagesSarlink® 3190 (ShA 90)Fumel EsquivelNo ratings yet