Professional Documents

Culture Documents

Esr 3187

Uploaded by

Marcelo ElguetaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Esr 3187

Uploaded by

Marcelo ElguetaCopyright:

Available Formats

ICC-ES Evaluation Report

ESR-3187*

Issued March 1, 2013

This report is subject to renewal March 1, 2014.

www.icc-es.org | (800) 423-6587 | (562) 699-0543

A Subsidiary of the International Code Council

DIVISION: 03 00 00CONCRETE

Section: 03 16 00Concrete Anchors

Adhesive mixing and dispensing equipment

DIVISION: 05 00 00METALS

Section: 05 05 19Post-installed Concrete Anchors

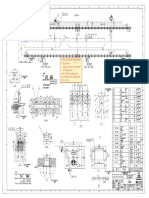

The Hilti HIT-HY 200 Adhesive Anchoring System may

be used with continuously threaded rod, Hilti HIT-Z(-R)

anchor rods, Hilti HIS-(R)N internally threaded inserts

or deformed steel reinforcing bars as depicted in Figure 1.

The primary components of the Hilti Adhesive Anchoring

System, including the Hilti HIT-HY 200 Adhesive,

HIT-RE-M static mixing nozzle and steel anchoring

elements, are shown in Figure 4 of this report.

Equipment for hole cleaning and adhesive injection

REPORT HOLDER:

HILTI, INC.

5400 SOUTH 122ND EAST AVENUE

TULSA, OKLAHOMA 74146

(800) 879-8000

www.us.hilti.com

HiltiTechEng@us.hilti.com

Installation information and parameters, as included with

each adhesive unit package, are replicated as Figure 6.

3.2 Materials:

EVALUATION SUBJECT:

HILTI HIT-HY 200 ADHESIVE ANCHORS IN CONCRETE

1.0 EVALUATION SCOPE

Compliance with the following codes:

2009, 2006, and 2003 International Building Code

(IBC)

2009, 2006, and 2003 International Residential Code

(IRC)

Property evaluated:

Structural

2.0 USES

The Hilti HIT-HY 200 Adhesive Anchoring System is used

to resist static, wind and seismic (Seismic Design

Categories A through F) tension and shear loads in

cracked and uncracked normal-weight concrete having a

specified compressive strength, fc, of 2,500 psi to

8,500 psi (17.2 MPa to 58.6 MPa). The anchor system is

an alternative to anchors described in Sections 1911 and

1912 of the 2009 and 2006 IBC, and Sections 1912 and

1913 of the 2003 IBC. The anchor systems may also be

used where an engineered design is submitted in

accordance with Section R301.1.3 of the 2009, 2006 and

2003 IRC.

3.2.1 Hilti HIT-HY 200

Adhesive:

Hilti HIT-HY 200

Adhesive is an injectable, two-component hybrid adhesive.

The two components are separated by means of a dualcylinder foil pack attached to a manifold. The two

components combine and react when dispensed through

a static mixing nozzle attached to the manifold.

Hilti HIT-HY 200 is available in 11.1-ounce (330 mL) and

16.9-ounce (500 mL) foil packs. The manifold attached to

each foil pack is stamped with the adhesive expiration

date. The shelf life, as indicated by the expiration date,

applies to an unopened foil pack stored in a dry, dark

environment and in accordance with Figure 6.

Hilti HIT-HY 200 Adhesive is available in two options,

Hilti HIT-HY 200-A and Hilti HIT-HY 200-R. Both options

are subject to the same technical data as set forth in this

report. Hilti HIT-HY 200-A will have shorter working times

and curing times than Hilti HIT-HY 200-R. The packaging

for each option employs a different color, which helps the

user distinguish between the two adhesives.

3.2.2 Hole Cleaning Equipment:

3.2.2.1 Standard Equipment: Standard hole cleaning

equipment, comprised of steel wire brushes and air

nozzles, is described in Figure 6 of this report.

3.2.2.2 Hilti Safe-Set System: The Hilti Safe-Set

with Hilti HIT-HY 200 consists of one of the following:

For the Hilti HIT-Z and HIT-Z-R anchor rods, hole

cleaning is not required after drilling the hole, except if

the hole is drilled with a diamond core drill bit.

3.0 DESCRIPTION

3.1 General:

The Hilti HIT-HY 200 Adhesive Anchoring System is

comprised of the following components:

Hilti HIT-HY 200 adhesive packaged in foil packs (either

Hilti HIT-HY 200-A or Hilti HIT-HY 200-R)

For the elements described in Sections 3.2.4.2 through

3.2.4.4, the Hilti TE-CD or TE-YD hollow carbide drill bit

with a carbide drilling head conforming to ANSI

B212.15. Used in conjunction with a Hilti VC 20/40

*Corrected October 2013

ICC-ES Evaluation Reports are not to be construed as representing aesthetics or any other attributes not specifically addressed, nor are they to be construed

as an endorsement of the subject of the report or a recommendation for its use. There is no warranty by ICC Evaluation Service, LLC, express or implied, as

to any finding or other matter in this report, or as to any product covered by the report.

1000

Copyright 2013

Page 1 of 38

ESR-3187 | Most Widely Accepted and Trusted

vacuum, the Hilti TE-CD or TE-YD drill bit will remove

the drilling dust, automatically cleaning the hole.

3.2.3 Dispensers: Hilti HIT-HY 200 must be dispensed

with manual or electric dispensers provided by Hilti.

3.2.4 Anchor Elements:

3.2.4.1 Hilti HIT-Z and HIT-Z-R Anchor Rods: Hilti HIT-Z

and HIT-Z-R anchor rods have a conical shape on the

embedded section and a threaded section above the

concrete surface. Mechanical properties for the Hilti HIT-Z

and HIT-Z-R anchor rods are provided in Table 2. The

rods are available in diameters as shown in Table 7 and

Figure 1. Hilti HIT-Z anchor rods are produced from carbon

steel and furnished with a 0.005-millimeter-thick (5 m)

zinc electroplated coating. Hilti HIT-Z-R anchor rods are

fabricated from grade 316 stainless steel.

3.2.4.2 Threaded Steel Rods: Threaded steel rods must

be clean, continuously threaded rods (all-thread) in

diameters as described in Tables 11 and 15 and Figure 1

of this report. Steel design information for common grades

of threaded rods is provided in Table 3. Carbon steel

threaded rods must be furnished with a 0.0002-inch-thick

(0.005 mm) zinc electroplated coating complying with

ASTM B633 SC 1 or must be hot-dipped galvanized

complying with ASTM A153, Class C or D. Stainless steel

threaded rods must comply with ASTM F593 or ISO 3506

A4. Threaded steel rods must be straight and free of

indentations or other defects along their length. The ends

may be stamped with identifying marks and the embedded

end may be blunt cut or cut on the bias to a chisel point.

3.2.4.3 Steel Reinforcing Bars: Steel reinforcing bars

are deformed bars (rebar). Tables 11, 15, and 19 and

Figure 1 summarize reinforcing bar size ranges. Table 4

summarizes specifications of common reinforcing bar

types and grades. The embedded portions of reinforcing

bars must be straight, and free of mill scale, rust, debris

and other coatings (other than zinc) that may impair the

bond with the adhesive. Reinforcing bars must not be bent

after installation except as set forth in Section 7.3.2 of ACI

318, with the additional condition that the bars must be

bent cold, and heating of reinforcing bars to facilitate field

bending is not permitted.

3.2.4.4 Hilti HIS-N and HIS-RN Inserts: Hilti HIS-N and

HIS-RN inserts have a profile on the external surface and

are internally threaded. Mechanical properties for Hilti

HIS-N and HIS-RN inserts are provided in Table 5. The

inserts are available in diameters and lengths as shown in

Table 22 and Figure 1. Hilti HIS-N inserts are produced

from carbon steel and furnished with a 0.005-millimeterthick (5 m) zinc electroplated coating complying with

ASTM B633 SC 1. The stainless steel Hilti HIS-RN

inserts are fabricated from X5CrNiMo17122 K700 steel

conforming to DIN 17440. Specifications for common bolt

types that may be used in conjunction with Hilti HIS-N and

HIS-RN inserts are provided in Table 6. Bolt grade and

material type (carbon, stainless) must be matched to the

insert. Strength reduction factors, , corresponding to

brittle steel elements must be used for Hilti HIS-N and HISRN inserts.

3.2.4.5 Ductility: In accordance with ACI 318 Appendix

D, for a steel element to be considered ductile, the tested

elongation must be at least 14 percent and reduction of

area must be at least 30 percent. Steel elements with a

tested elongation of less than 14 percent or a reduction of

area of less than 30 percent, or both, are considered

brittle. Values for various steel materials are provided in

Tables 2, 3, 4, and 6 of this report. Where values are

Page 2 of 38

nonconforming or unstated, the steel must be considered

brittle.

3.3 Concrete:

Normal-weight concrete must comply with Sections 1903

and 1905 of the IBC, as applicable. The specified

compressive strength of the concrete must be from

2,500 psi to 8,500 psi (17.2 MPa to 58.6 MPa).

4.0 DESIGN AND INSTALLATION

4.1 Strength Design:

Refer to Table 1 for the design parameters for specific

installed elements, and refer to Figure 2 and Section 4.1.8

for a flowchart to determine the applicable design bond

strength or pullout strength.

4.1.1 General: The design strength of anchors under the

2009 and 2003 IBC, as well as Section 301.1.3 of the 2009

and 2003 IRC, must be determined in accordance with ACI

318-08 Appendix D and this report.

The design strength of anchors under the 2006 IBC, as

well as Section 301.1.3 of the 2006 IRC, must be

determined in accordance with ACI 318-05 Appendix D

and this report.

A design example in accordance with the 2009 IBC is

given in Figure 5 of this report.

Design parameters are based on the 2009 IBC

(ACI 318-08) unless noted otherwise in Sections 4.1.1

through 4.1.12 of this report.

The strength design of anchors must comply with ACI

318 D.4.1, except as required in ACI 318 D.3.3.

Design parameters, including strength reduction factors,

, corresponding to each limit state, are provided in Table

7 through Table 24. Strength reduction factors, , as given

in ACI 318 D.4.4 must be used for load combinations

calculated in accordance with Section 1605.2.1 of the IBC

or Section 9.2 of ACI 318. Strength reduction factors, , as

given in ACI 318 D.4.5 must be used for load combinations

calculated in accordance with ACI 318 Appendix C.

The following section provides amendments to ACI 318

Appendix D as required for the strength design of adhesive

anchors. In conformance with ACI 318, all equations are

expressed in inch-pound units.

Modify ACI 318 D.4.1.2 as follows:

D.4.1.2In Eq. (D-1) and (D-2), Nn and Vn are the

lowest design strengths determined from all appropriate

failure modes. Nn is the lowest design strength in tension

of an anchor or group of anchors as determined from

consideration of Nsa, either Na or Nag, and either Ncb or

Ncbg. Vn is the lowest design strength in shear of an

anchor or a group of anchors as determined from

consideration of Vsa, either Vcb or Vcbg, and either Vcp

or Vcpg. For adhesive anchors subject to tension resulting

from sustained loading, refer to D.4.1.4 for additional

requirements.

Add ACI 318 D.4.1.4 as follows:

D.4.1.4For adhesive anchors subjected to tension

resulting from sustained loading, a supplementary design

analysis shall be performed using Eq. (D-1) whereby Nua is

determined from the sustained load alone, e.g., the dead

load and that portion of the live load acting that may be

considered as sustained and Nn is determined as follows:

D.4.1.4.1For single anchors: Nn = 0.75Na0.

ESR-3187 | Most Widely Accepted and Trusted

Page 3 of 38

D.4.1.4.2For anchor groups, Equation (D-1) shall be

satisfied by taking Nn = 0.75Na0 for that anchor in an

anchor group that resists the highest tension load.

(a) For a single anchor:

D.4.1.4.3Where shear loads act concurrently with the

sustained tension load, interaction of tension and shear

shall be analyzed in accordance with ACI 318 Section

D.4.1.3.

(b) For a group of anchors:

Modify ACI 318 D.4.2.2 in accordance with the 2009 IBC

Section 1908.1.10 as follows:

D.4.2.2The concrete breakout strength requirements

for anchors in tension shall be considered satisfied by the

design procedure of D.5.2 provided Equation D-8 is not

used for anchor embedments exceeding 25 inches. The

concrete breakout strength requirements for anchors in

shear with diameters not exceeding 2 inches shall be

considered satisfied by the design procedure of D.6.2. For

anchors in shear with diameters exceeding 2 inches, shear

anchor reinforcement shall be provided in accordance with

the procedures of D.6.2.9.

Na =

Na =

ANa

ANa0

ANa

ed,Na p,Na Na0

(D-16a)

ed,Na g,Na ec,Na p,Na Na0

ANa0

(D-16b)

where:

ANa is the projected area of the failure surface for the

single anchor or group of anchors that shall be

approximated as the base of the rectilinear geometrical

figure that results from projecting the failure surface

outward a distance ccr,Na from the centerlines of the single

anchor, or in the case of a group of anchors, from a line

through a row of adjacent anchors. ANa shall not exceed

nANa0 where n is the number of anchors in tension in the

group. In ACI 318 Figures RD.5.2.1(a) and RD.5.2.1(b),

the terms 1.5hef and 3.0hef shall be replaced with ccr,Na and

scr,Na, respectively.

4.1.2 Static Steel Strength in Tension: The nominal

strength of an anchor in tension as governed by the steel,

Nsa, in accordance with ACI 318 Section D.5.1.2 and

strength reduction factors, , in accordance with ACI 318

Section D.4.4, are given in the tables outlined in Table 1

for the corresponding anchor steel.

ANa0 is the projected area of the failure surface of a

single anchor without the influence of proximate edges in

accordance with Eq. (D-16c):

4.1.3 Static Concrete Breakout Strength in Tension:

The nominal concrete breakout strength in tension, Ncb or

Ncbg, must be calculated in accordance with ACI 318 D.5.2

with the following addition:

scr,Na

D.5.2.10(2009 IBC) or D.5.2.9 (2006 IBC) The

limiting concrete strength of adhesive anchors in tension

shall be calculated in accordance with D.5.2.1 to D.5.2.9

under the 2009 IBC or D.5.2.1 to D.5.2.8 under the 2006

IBC where the value of kc to be used in Eq. (D-7) shall be:

scr,Na =20 d

kc,cr

= 17

kc,uncr = 24

where analysis indicates cracking at

service load levels in the anchor vicinity

(cracked concrete)

where analysis indicates no cracking at

service load levels in the anchor vicinity

(uncracked concrete)

The basic concrete breakout strength of a single anchor

in tension, Nb, must be calculated in accordance with ACI

318 D.5.2.2 using the values of hef, and kc,cr or kc,uncr as

described in this report . Additional information for the

determination of the nominal concrete breakout strength

(Ncb or Ncbg) is given in the tables outlined in Table 1 for

the corresponding anchor steel. The modification factor

must be taken as 1.0. Anchors must not be installed in

lightweight concrete. The value of fc must be limited to a

maximum of 8,000 psi (55 MPa) in accordance with ACI

318 Section D.3.5.

4.1.4.2 Threaded Rod, Steel Reinforcing Bars, and

Hilti HIS-N and HIS-RN Inserts: In lieu of determining the

nominal pullout strength in accordance with ACI 318 D.5.3,

nominal bond strength in tension must be calculated in

accordance with the following sections added to ACI 318:

D.5.3.7The nominal bond strength of an adhesive

anchor, Na, or group of adhesive anchors, Nag, in tension

shall not exceed:

(D-16c)

with:

=

as given by Eq. (D-16d)

D.5.3.8The critical spacing scr,Na and critical edge

distance ccr,Na shall be calculated as follows:

ccr,Na =

k,uncr

3 hef

1,450

(D-16d)

scr,Na

(D-16e)

D.5.3.9The basic strength of a single adhesive anchor

in tension in cracked concrete shall not exceed:

Na0 = k,cr d hef

(D-16f)

where:

k,cr is the characteristic bond strength in cracked concrete.

D.5.3.10The modification factor for the influence of the

failure surface of a group of adhesive anchors is:

0.5

g,Na = g,Na0 +

1- g,Na0

scr,Na

(D-16g)

where:

g,Na0 = n -

n -1

k,cr

1.5

k,maxr

1.0

(D-16h)

where:

n

the number of tension-loaded adhesive

anchors in a group

spacing of anchors

4.1.4 Static Pullout Strength in Tension:

4.1.4.1 Hilti HIT-Z and HIT-Z-R Anchor Rods: The

nominal pullout strength of a single anchor in accordance

with ACI 318 D.5.3.1 and D.5.3.2 in cracked and

uncracked concrete, Np,cr and Np,uncr, respectively, is given

in Table 10. For all design cases c,P = 1.0.

ANa0 = scr,Na

k,max,cr =

kc,cr

hef f'c

(D-16i)

The value of fc must be limited to maximum of 8,000 psi

(55 MPa) in accordance with ACI 318 Section D.3.5.

D.5.3.11The modification factor

loaded adhesive anchor groups is:

ec,Na =

1

1+

2e'N

scr,Na

1.0

Eq. (D-16j) is valid for

for

eccentrically

(D-16j)

e'N

s

2

ESR-3187 | Most Widely Accepted and Trusted

Page 4 of 38

If the loading on an anchor group is such that only

certain anchors are in tension, only those anchors that are

in tension shall be considered when determining the

eccentricity, eN, for use in Eq. (D-16j).

In the case where eccentric loading exists about two

orthogonal axes, the modification factor ec,Na shall be

computed for each axis individually and the product of

these factors used as ec,Na in Eq. (D-16b).

for ca,min ccr,Na

(D-16l)

(D-16m)

D.6.3.2The nominal pryout strength of a single

adhesive anchor Vcp or group of adhesive anchors Vcpg

shall not exceed:

or:

ed,Na = 0.7 + 0.3

ca,min

1.0 for ca,min ccr,Na

ccr,Na

D.5.3.13When an adhesive anchor or a group of

adhesive anchors is located in a region of a concrete

member where analysis indicates no cracking at service

load levels, the nominal strength, Na or Nag, of a single

adhesive anchor or a group of adhesive anchors shall be

calculated according to Eq. (D-16a) and Eq. (D-16b) with

k,uncr substituted for k,cr in the calculation of the basic

strength Na0, in accordance with Eq. (D-16f). The factor

g,Na0 shall be calculated in accordance with Eq. (D-16h)

whereby the value of k,max,uncr shall be calculated in

accordance with Eq. (D-16n) and substituted fork,max,cr in

Eq. (D-16h).

k,max,uncr =

kc,uncr

hef f'c

(D-16n)

D.5.3.14When an adhesive anchor or a group of

adhesive anchors is located in a region of a concrete

member where analysis indicates no cracking at service

load levels, the modification factor p,Na shall be taken as:

p,Na = 1.0 for ca,min

cac

(D-16o)

or:

p,Na =

max ca,min ; ccr,Na

cac

for ca,min

cac

4.1.7.1 Hilti HIT-Z and HIT-Z-R Anchor Rods: The

nominal pryout strength of a single anchor or group of

anchors, Vcp or Vcpg, respectively, must be calculated in

accordance with ACI 318 D.6.3, where the value of Ncb or

Ncbg is determined in accordance with section 4.1.3 of this

report.

4.1.7.2 Threaded Rod, Steel Reinforcing Bars, and

Hilti HIS-N and HIS-RN Inserts In lieu of determining the

nominal pryout strength in accordance with ACI 318

D.6.3.1, nominal pryout strength in shear must be

calculated in accordance with the following sections added

to ACI 318 Appendix D:

D.5.3.12The modification factor for the edge effects for

single adhesive anchors or anchor groups loaded in

tension is:

ed,Na =1.0

4.1.7 Static Concrete Pryout Strength in Shear:

(D-16p)

where cac must be determined in accordance with Section

4.1.10 of this report.

For all other cases: p,Na = 1.0

Additional information for the determination of nominal

bond strength in tension is given in Section 4.1.8.

4.1.5 Static Steel Strength in Shear: The nominal static

strength of an anchor in shear as governed by the steel,

Vsa, in accordance with ACI 318 Section D.6.1.2 and the

corresponding strength reduction factors, , are given in

the tables outlined in Table 1 for the corresponding anchor

steel.

4.1.6 Static Concrete Breakout Strength in Shear: The

nominal concrete breakout strength of a single anchor

or group of anchors in shear, Vcb or Vcbg, must be

calculated in accordance with ACI 318 D.6.2 based on

information given in the tables outlined in Table 1 for the

corresponding anchor steel. The basic concrete breakout

strength of a single anchor in shear, Vb, must be calculated

in accordance with ACI 318 D.6.2.2 using the values of d

and hef given in the tables as outlined in Table 1 for the

corresponding anchor steel in lieu of do and le,

respectively. In no case must le exceed 8d. The value of fc

must be limited to a maximum of 8,000 psi (55 MPa) in

accordance with ACI 318 D.3.5.

(a)

For a single adhesive anchor:

Vcp = min kcp Na ; kcp Ncb

(b)

(D-30a)

For a group of anchors:

Vcpg =min kcp Nag ; kcp Ncbg

(D-30b)

where:

kcp

1.0 for hef < 2.5 in. (64 mm)

kcp

2.0 for hef > 2.5 in. (64 mm)

Na shall be calculated in accordance with Eq. (D-16a)

Nag shall be calculated in accordance with Eq. (D-16b)

Ncb and Ncbg are determined in accordance with D.5.2.1 to

D.5.2.9.

4.1.8 Bond Strength/Pullout Strength Determination:

4.1.8.1 Hilti HIT-Z and HIT-Z-R Anchor Rods: Pullout

strength values are a function of the concrete compressive

strength, whether the concrete is cracked or uncracked,

the drilling method (hammer drill, including Hilti hollow drill

bit, diamond core drill) and installation conditions (dry,

water-saturated). The resulting characteristic pullout

strength must be multiplied by the associated strength

reduction factor nn as follows:

HILTI HIT-Z AND HIT-Z-R THREADED RODS

ASSOCIATED

PERMISSIBLE

DRILLING CONCRETE

PULLOUT

STRENGTH

INSTALLATION

METHOD

TYPE

STRENGTH REDUCTION

CONDITIONS

FACTOR

HammerDry

Np,uncr

d

drill

Uncracked

(or Hilti TEWater saturated

Np,uncr

ws

CD or TEYD Hollow

Dry

Np,cr

d

Drill Bit) or

Cracked

Diamond

Water saturated

Np,cr

ws

Core Bit

Figure 2 of this report presents a pullout strength design

selection flowchart. Strength reduction factors for

determination of the bond strength are given in the tables

referenced in Table 1 of this report.

4.1.8.2 Threaded Rod, Steel Reinforcing Bars, and

Hilti HIS-N and HIS-RN Inserts: Bond strength values are

a function of the concrete compressive strength, whether

the concrete is cracked or uncracked, the drilling method

(hammer drill, including Hilti hollow drill bit), the steel

element type, and installation conditions (dry, water

saturated). The resulting characteristic bond strength must

be multiplied by the associated strength reduction factor

nn as follows:

ESR-3187 | Most Widely Accepted and Trusted

PERMISSIBLE

DRILLING CONCRETE

BOND

INSTALLATION

METHOD

TYPE

STRENGTH

CONDITIONS

Hammerdrill

(or Hilti TECD or TEYD Hollow

Drill Bit)

Dry

Uncracked

Water saturated

Dry

Cracked

Water saturated

k,uncr

k,uncr

k,cr

k,cr

Page 5 of 38

ASSOCIATED

STRENGTH

REDUCTION

FACTOR

Linear interpolation is permitted to determine the ratio of

cac/hef for values of h/hef between 2.35 and 1.35 as

illustrated in the graph above.

d

ws

d

ws

4.1.10.2 Threaded Rod, Steel Reinforcing Bars, and

Hilti HIS-N and HIS-RN Inserts: In lieu of ACI 318 D.8.6,

cac must be determined as follows:

Figure 2 of this report presents a bond strength design

flowchart. Strength reduction factors for determination of

the bond strength are given in the tables outlined in Table

1 of this report. Adjustments to the bond strength may also

be taken for increased concrete compressive strength, as

given in the footnotes to the bond strength tables.

k,uncr 0.4

1160

max 3.1-0.7 h ;1.4

Eq. (4-1)

ef

where k,uncr is the characteristic bond strength in

uncracked concrete, h is the member thickness, and hef is

the embedment depth.

k,uncr need not be taken as greater than:

'

kuncr hef fc

4.1.9 Minimum Member Thickness hmin, Minimum

Anchor Spacing smin and Minimum Edge Distance cmin:

k,uncr =

4.1.9.1 Hilti HIT-Z and HIT-Z-R Anchor Rods: In lieu of

ACI 318 Section D.8.3, values of cmin and smin given in

Table 9 of this report must be observed for anchor design

and installation. Likewise, in lieu of ACI 318 Section D.8.5,

the minimum member thickness, hmin, given in Table 9 of

this report must be observed for anchor design and

installation.

4.1.11 Design Strength in Seismic Design Categories

C, D, E and F: In structures assigned to Seismic Design

Category C, D, E or F under the IBC or IRC, the anchor

strength must be determined in accordance with ACI 318

D.3.3, and must be adjusted in accordance with 2009 IBC

Section 1908.1.9 or 2006 IBC Section 1908.1.16. For

brittle steel elements, the anchor strength must be

adjusted in accordance with ACI 318-08 D.3.3.5 or D.3.3.6,

or ACI 318-05 D.3.3.5, as applicable. The nominal steel

shear strength, Vsa, must be adjusted by V,seis as given in

the tables summarized in Table 1 for the corresponding

anchor steel. For tension, the nominal pullout strength Np,cr

or bond strength k,cr must be adjusted by N,seis as given in

the tables summarized in Table 1 for the corresponding

anchor steel.

4.1.9.2 Threaded Rod, Steel Reinforcing Bars, and

Hilti HIS-N and HIS-RN Inserts: In lieu of ACI 318 D.8.1

and D.8.3, values of cmin and smin described in this report

must be observed for anchor design and installation.

Likewise, in lieu of ACI 318 D.8.5, the minimum member

thicknesses, hmin, described in this report must be

observed for anchor design and installation. In determining

minimum edge distance, cmin, the following section must be

added to ACI 318:

D.8.8For adhesive anchors that will remain un-torqued,

the minimum edge distance shall be based on minimum

cover requirements for reinforcement in Section 7.7. For

adhesive anchors that will be torqued, the minimum edge

distance and spacing are given in Tables 12, 16, 20, and

23 of this report.

For edge distance cai=1.75 inch (45 mm)and anchor

spacing sai, the maximum torque Tmax must be reduced

according to the table provided below:

Reduced Installation

Distances cai < (5 x d)

Edge

cai

Torque,

Distance, Minimum

Spacing, sai

Tmax,

for

Edge

4.1.12 Interaction of Tensile and Shear Forces: For

designs that include combined tension and shear, the

interaction of tension and shear loads must be calculated

in accordance with ACI 318 Section D.7.

4.2 Allowable Stress Design:

4.2.1 General: For anchors designed using load

combinations in accordance with IBC Section 1605.3

(Allowable Stress Design), allowable loads must be

established using Eq. (4-2) and Eq. (4-3):

Tallowable,ASD =

Nn

Eq. (4-2)

and:

Anchor =>

Maximum

Torque, Tmax

1.75 in. (45 mm) 5 x d < sai < 16 in.

< cai < 5 x d

sai > 16 in. (406 mm)

0.3 x Tmax

0.5 x Tmax

4.1.10 Critical Edge Distance cac:

4.1.10.1 Hilti HIT-Z and HIT-Z-R Anchor Rods: In lieu of

ACI 318 D.8.6, for the calculation of Ncb and Ncbg in

accordance with D.5.2.7 and Section 4.1.3 of this report,

the critical edge distance, cac, must be taken as follows:

i.

cac = 1.5.hef for h/hef 2.35

ii.

cac = 3.5.hef for h/hef 1.35

For definitions of h and hef, see Figure 1.

Vallowable,ASD =

Vn

Eq. (4-3)

where:

Tallowable,ASD = Allowable tension load (lbf or kN)

Vallowable,ASD = Allowable shear load (lbf or kN)

Nn = Lowest design strength of an anchor or anchor

group in tension as determined in accordance with ACI 318

Appendix D with amendments in this report and 2009 IBC

Sections 1908.1.9 and 1908.1.10 and 2006 IBC Section

1908.1.16, as applicable.

Vn = Lowest design strength of an anchor or anchor

group in shear as determined in accordance with ACI 318

Appendix D with amendments in this report, 2009 IBC

Sections 1908.1.9 and 1908.1.10 and 2006 IBC Section

1908.1.16, as applicable.

= Conversion factor calculated as a weighted average

of the load factors for the controlling load combination. In

addition, must include all applicable factors to account

for non-ductile failure modes and required over-strength.

Limits on edge distance, anchor spacing and member

thickness described in this report must apply. Example

ESR-3187 | Most Widely Accepted and Trusted

Page 6 of 38

Allowable Stress Design calculations are provided in

Table 25.

4.2.2 Interaction of Tensile and Shear Forces: In Lieu

of ACI 318 D.7.1, D.7.2, and D.7.3, interaction must be

calculated as follows:

For shear loads V 0.2Vallowable,ASD, the full allowable

load in tension shall be permitted.

For tension loads T 0.2Tallowable,ASD, the full allowable

load in shear shall be permitted.

For all other cases:

T

Tallowable,ASD

V

Vallowable,ASD

1.2

Eq. (4-4)

4.3 Installation:

Installation parameters are illustrated in Figure 1.

Installation of the Hilti HIT-HY 200 Adhesive Anchor

System must conform to the manufacturers published

installation instructions included in each unit package as

provided in Figure 6 of this report. Anchor locations must

comply with this report and the plans and specifications

approved by the code official.

4.4 Special Inspection:

Periodic special inspection must be performed where

required in accordance with Sections 1704.4 and 1704.15

of the 2009 IBC, or Section 1704.13 of the 2006 or 2003

IBC, whereby periodic special inspection is defined in

Section 1702.1 of the IBC and this report. The special

inspector must be on the jobsite initially during anchor

installation to verify anchor type, anchor dimensions,

concrete type, concrete compressive strength, hole

dimensions, hole cleaning procedures, anchor spacing,

edge distances, concrete thickness, anchor embedment,

and tightening torque. The special inspector must verify the

initial installations of each type and size of adhesive

anchor by construction personnel on site. Subsequent

installations of the same anchor type and size by the same

construction personnel may be performed in the absence

of the special inspector. Any change in the anchor product

being installed or the personnel performing the installation

requires an initial inspection. For ongoing installations over

an extended period, the special inspector must make

regular inspections to confirm correct handling and

installation of the product.

Continuous special inspection is required for all cases

where anchors installed overhead (vertical up) are

designed to resist sustained tension loads.

Under the IBC, additional requirements as set forth in

Sections 1705, 1706, and 1707 must be observed, where

applicable.

5.0 CONDITIONS OF USE

The Hilti HIT-HY 200 Adhesive Anchor System described

in this report is a suitable alternative to what is specified in

the codes listed in Section 1.0 of this report, subject to the

following conditions:

5.1 Hilti HIT-HY 200 Adhesive anchors must be installed

in accordance with the manufacturers published

installation instructions as included in the adhesive

packaging and provided in Figure 6 of this report.

5.2 The anchors must be installed in cracked and

uncracked normal-weight concrete having a specified

compressive strength fc = 2,500 psi to 8,500 psi

(17.2 MPa to 58.6 MPa).

5.3 The values of fc used for calculation purposes must

not exceed 8,000 psi (55.1 MPa)

5.4 Anchors must be installed in concrete base materials

in holes predrilled in accordance with the instructions

in Figure 6, using carbide-tipped masonry drill bits

manufactured with the range of maximum and

minimum drill-tip dimensions specified in ANSI

B212.15-1994. The Hilti HIT-Z(-R) anchor rods may

be installed in holes predrilled using diamond core

drill bits.

5.5 Loads applied to the anchors must be adjusted in

accordance with Section 1605.2 of the IBC for

strength design and in accordance with Section

1605.3 of the IBC for allowable stress design.

5.6 Hilti HIT-HY 200 adhesive anchors are recognized for

use to resist short- and long-term loads, including

wind and earthquake, subject to the conditions of this

report.

5.7 In structures assigned to Seismic Design Category C,

D, E or F under the IBC or IRC, anchor strength must

be adjusted in accordance with 2009 IBC Section

1908.1.9 or 2006 IBC Section 1908.1.16.

5.8 Hilti HIT-HY 200 adhesive anchors are permitted to

be installed in concrete that is cracked or that may be

expected to crack during the service life of the anchor,

subject to the conditions of this report.

5.9 Strength design values must be established in

accordance with Section 4.1 of this report.

5.10 Allowable design values must be established in

accordance with Section 4.2 of this report.

5.11 Minimum anchor spacing and edge distance as well

as minimum member thickness must comply with the

values noted in this report.

5.12 Prior to anchor installation, calculations and details

demonstrating compliance with this report must be

submitted to the code official. The calculations and

details must be prepared by a registered design

professional where required by the statutes of the

jurisdiction in which the project is to be constructed.

5.13 Anchors are not permitted to support fire-resistive

construction. Where not otherwise prohibited by

the code, Hilti HIT-HY 200 adhesive anchors are

permitted for installation in fire-resistive construction

provided that at least one of the following conditions is

fulfilled:

Anchors are used to resist wind or seismic forces

only.

Anchors that support gravity loadbearing

structural elements are within a fire-resistive

envelope or a fire-resistive membrane, are

protected by approved fire-resistive materials, or

have been evaluated for resistance to fire exposure

in accordance with recognized standards.

Anchors are

elements.

used

to

support

nonstructural

5.14 Since an ICC-ES acceptance criteria for evaluating

data to determine the performance of adhesive

anchors subjected to fatigue or shock loading is

unavailable at this time, the use of these anchors

under such conditions is beyond the scope of this

report.

5.15 Use of zinc-plated carbon steel threaded rods or steel

reinforcing bars is limited to dry, interior locations.

5.16 Use of hot-dipped galvanized carbon steel threaded

rods with a coating complying with ASTM A153 Class

ESR-3187 | Most Widely Accepted and Trusted

C or D, and stainless steel rods, is permitted for

exterior exposure or damp environments.

5.17 Steel anchor materials in contact with preservativetreated and fire-retardant-treated wood must be of

zinc-coated carbon steel or stainless steel. The

minimum coating weights for zinc-coated steel must

comply with ASTM A153 Class C or D.

5.18 Periodic special inspection must be provided in

accordance with Section 4.4 of this report. Continuous

special inspection for overhead installations (vertical

up) that are designed to resist sustained tension loads

must be provided in accordance with Section 4.4 of

this report.

Page 7 of 38

5.22 Hilti HIS-N and HIS-RN inserts are manufactured by

Hilti (China) Ltd., Guangdong, China, with quality

control inspections by UL LLC (AA-668).

6.0 EVIDENCE SUBMITTED

Data in accordance with the ICC-ES Acceptance Criteria

for Post-installed Adhesive Anchors in Concrete (AC308),

dated February 2013, including but not limited to tests

under freeze/thaw conditions (Table 4.2, test series 6).

7.0 IDENTIFICATION

7.1 Hilti HIT-HY 200-A and Hilti HIT-HY 200-R adhesive

is identified by packaging labeled with the

manufacturers name (Hilti Corp.) and address,

product name, lot number, expiration date, evaluation

report number (ICC-ES ESR-3187), and the name of

the inspection agency (UL LLC).

5.19 Hilti HIT-HY 200-A adhesive anchors may be used to

resist tension and shear forces in floor, wall, and

overhead installations only if installation is into

concrete with a temperature between 14F and 104F

(-10C and 40C) ) for threaded rods, rebar, and Hilti

HIS-(R)N inserts, or between 41F and 104F (5C

and 40C) for Hilti HIT-Z(-R) anchor rods. Overhead

installations require the use of piston plugs

(HIT-SZ, -IP) during injection, and the anchor must be

supported until fully cured (i.e., with Hilti HIT-OHW

wedges, or other suitable means). Installations in

concrete temperatures below 32F require the

adhesive to be conditioned to a minimum temperature

of 32F.

7.3 Hilti HIS-N and HIS-RN inserts are identified by

packaging labeled with the manufacturer's name

(Hilti Corp.) and address, anchor name and size,

evaluation report number (ICC-ES ESR-3187), and

the name of the inspection agency (UL LLC).

5.20 Hilti HIT-HY 200-A and Hilti HIT-HY 200-R adhesives

are manufactured by Hilti GmbH, Kaufering,

Germany, with quality control inspections by UL LLC

(AA-668).

7.4 Threaded rods, nuts, washers, bolts, cap screws, and

deformed reinforcing bars are standard elements and

must conform to applicable national or international

specifications.

5.21 Hilti HIT-Z and HIT-Z-R rods are manufactured by Hilti

AG, Schaan, Liechtenstein, with quality control

inspections by UL LLC (AA-668).

7.2

Hilti HIT-Z and HIT-Z-R rods are identified by

packaging labeled with the manufacturer's name

(Hilti Corp.) and address, anchor name, evaluation

report number (ICC-ES ESR-3187), and the name of

the inspection agency (UL LLC).

ESR-3187 | Most Widely Accepted and Trusted

Page 8 of 38

HILTI HIT-Z AND HIT-Z-R ANCHOR ROD

Name and Size

lhelix

Anchor Length

Helix Length

in

(mm)

in

(111)

2 /4

(130)

2 /4

(162)

2 /4

(114)

2 /2

6 /2

(165)

7 /4

(197)

(152)

3 /8

(203)

3 /8

(241)

4 /8

5 /8

6 /8

4 /2

HIT-Z(-R) /8'' x 4 /8''

HIT-Z(-R) /8'' x 5 /8''

HIT-Z(-R) /8'' x 6 /8''

HIT-Z(-R) /2'' x 4 /2''

HIT-Z(-R) /2'' x 6 /2''

HIT-Z(-R) /2'' x 7 /4''

5

HIT-Z(-R) /8'' x 6''

5

HIT-Z(-R) /8'' x 8''

9 /2

8 /2

HIT-Z(-R) /8'' x 9 /2''

HIT-Z(-R) /4'' x 8 /2''

HIT-Z(-R) /4'' x 9 /4''

9 /4

HIT-Z(-R) M10x95

3 /4

HIT-Z(-R) M10x115

HIT-Z(-R) M10x135

4 /2

5

5 /16

5

(216)

(mm)

Smooth Shank

Length

in

(mm)

Total Thread

Length

In

(57)

(57)

(57)

(63)

2 /2

(63)

(8)

3 /16

2 /2

(63)

(8)

4 /16

(92)

(11)

1 /16

(92)

(92)

15

3 /8

4

(248)

(95)

2 /8

(115)

2 /8

(135)

2 /8

(160)

2 /8

(105)

2 /8

3

/16

/16

/16

/16

/16

/16

/16

/16

1 /16

(102)

(102)

11

/16

1 /16

(60)

(60)

(60)

(60)

(60)

/16

/16

/16

(8)

(8)

(8)

(11)

(49)

(12)

1 /16

9

2 /16

(mm)

(46)

(65)

13

(97)

11

3 /16

1 /16

in

(33)

(52)

3 /16

(84)

(26)

1 /16

2 /16

(43)

11

(94)

3 /16

(77)

15

(126)

4 /16

(109)

15

(49)

1 /8

(28)

(100)

3 /8

(79)

(100)

(79)

(77)

(77)

15

3 /16

15

3 /16

4

(44)

(8)

1 /8

(8)

1 /8

(8)

2 /8

(8)

3 /8

(8)

1 /2

7

(102)

(102)

(27)

3 /8

3 /16

3 /16

9

/16

(14)

(47)

1 /16

(34)

(67)

2 /8

(54)

(92)

3 /8

(79)

(37)

13

(21)

(72)

(56)

6 /16

HIT-Z(-R) M12x105

4 /8

HIT-Z(-R) M12x140

5 /2

(140)

2 /8

(60)

(8)

2 /8

HIT-Z(-R) M12x155

6 /8

(155)

2 /8

(60)

(8)

3 /8

(87)

2 /16

HIT-Z(-R) M12x196

7 /4

(196)

2 /8

(60)

(8)

(128)

4 /16

HIT-Z(-R) M16x155

6 /8

(155)

3 /16

11

(93)

(11)

(51)

1 /16

HIT-Z(-R) M16x175

(93)

(11)

13

(93)

HIT-Z(-R) M16x205

6 /8

1

8 /16

7

HIT-Z(-R) M16x240

9 /16

HIT-Z(-R) M20x215

HIT-Z(-R) M20x250

8 /2

13

9 /16

(175)

(205)

(240)

(215)

(250)

3 /16

11

3 /16

11

3 /16

15

3 /16

15

3 /16

(93)

(100)

(100)

/16

/16

/16

/16

/16

/16

/16

1

1 /4

1

/2

1 /8

2 /16

(11)

(32)

(13)

(48)

FIGURE 1INSTALLATION PARAMETERS

(mm)

HIT-Z(-R) M10x160

11

/16

(8)

13

Usable Thread

Length

4 /2

4

4

/16

2 /16

13

(71)

(112)

(30)

(71)

15

1 /16

(50)

(101)

(80)

11

(94)

(78)

(78)

(115)

(102)

(102)

3 /8

3 /16

3 /16

3 /16

ESR-3187 | Most Widely Accepted and Trusted

Page 9 of 38

DEFORMED REINFORCMENT

THREADED ROD

h

h

HILTI HIS-N AND HIS-RN THREADED INSERTS

FIGURE 1INSTALLATION PARAMETERS (Continued)

ESR-3187 | Most Widely Accepted and Trusted

Page 10 of 38

TABLE 1-DESIGN TABLE INDEX

Fractional

Design Table

Page

Table

Page

Steel Strength - Nsa, Vsa

13

13

Concrete Breakout - Ncb, Ncbg, Vcb,

Vcbg, Vcp, Vcpg

14

14

Pullout Strength Np

10

18

10

18

Steel Strength - Nsa, Vsa

11

19

15

23

Concrete Breakout - Ncb, Ncbg, Vcb,

Vcbg, Vcp, Vcpg

12

20

16

24

Bond Strength - Na, Nag

14

22

18

26

Steel Strength - Nsa, Vsa

22

29

22

29

Concrete Breakout - Ncb, Ncbg, Vcb,

Vcbg, Vcp, Vcpg

23

30

23

30

Bond Strength - Na, Nag

24

31

24

31

Hilti HIT-Z and HIT-Z-R Anchor Rod

Standard Threaded Rod

Hilti HIS-N and HIS-RN Internally

Threaded Insert

Fractional

Design Table

Steel Reinforcing Bars

Metric

Table

EU Metric

Canadian

Table

Page

Table

Page

Table

Page

Steel Strength - Nsa, Vsa

11

19

15

23

19

27

Concrete Breakout - Ncb, Ncbg, Vcb,

Vcbg, Vcp, Vcpg

12

20

16

24

20

27

Bond Strength - Na, Nag

13

21

17

25

21

28

FIGURE 2FLOWCHART FOR THE ESTABLISHMENT OF DESIGN BOND OR PULLOUT STRENGTH

ESR-3187 | Most Widely Accepted and Trusted

Page 11 of 38

TABLE 2SPECIFICATIONS AND PHYSICAL PROPERTIES OF FRACTIONAL AND METRIC HIT-Z AND HIT-Z-R RODS

Minimum

specified

ultimate

strength, futa

Minimum

specified

yield

strength

0.2 percent

offset, fya

psi

94,200

75,300

(MPa)

(650)

(520)

psi

88,400

71,000

HIT-Z AND HIT-Z-R ROD SPECIFICATION

CARBON STEEL

STAINLESS STEEL

1

2

futa/fya

Elongation,

min.

percent

Reductio

n of Area,

min.

percent

Specification for

2

nuts

1.25

20

ASTM A563

Grade A

1.25

20

ASTM F594

Type 316

/8-in. to /8-in. and M10 to

M12 - AISI 1038

3

/4-in. - AISI 1038 or

18MnV5

M16 - AISI 1038

M20 - AISI 1038 or 18MnV5

3

(MPa)

(610)

(490)

psi

86,200

69,600

(MPa)

(595)

(480)

psi

94,200

75,300

(MPa)

(650)

(520)

psi

88,400

71,000

(MPa)

(610)

(490)

psi

86,200

69,600

(MPa)

(595)

(480)

/8-in. to /4-in. and M10 to

M12

Grade 316 DIN-EN 10263-5

X5CrNiMo 17-12-2+AT

M16

Grade 316 DIN-EN 10263-5

X5CrNiMo 17-12-2+AT

M20

Grade 316 DIN-EN 10263-5

X5CrNiMo 17-12-2+AT

Steel properties are minimum values and maximum values will vary due to the cold forming of the rod.

Nuts of other grades and styles having specified proof load stresses greater than the specified grade and style are also suitable. Nuts must

have specified proof load stresses equal to or greater than the minimum tensile strength of the specified threaded rod.

TABLE 3SPECIFICATIONS AND PHYSICAL PROPERTIES OF COMMON

1

CARBON AND STAINLESS STEEL THREADED ROD MATERIALS

Minimum

Minimum

specified

specified

yield strength

ultimate

0.2 percent

strength, futa

offset, fya

THREADED ROD SPECIFICATION

CARBON STEEL

ASTM A193 Grade B7

1

2 /2 in. ( 64 mm)

3

ASTM F568M Class 5.8

1

M5 ( /4 in.) to M24 (1 in.)

(equivalent to ISO 898-1)

4

ISO 898-1 Class 5.8

4

ISO 898-1 Class 8.8

STAINLESS STEEL

ASTM F593 CW1 (316)

1

5

/4-in. to /8-in.

5

ASTM F593 CW2 (316)

3

1

/4-in. to 1 /2-in.

6

ISO 3506-1 A4-70

M8 M24

6

ISO 3506-1 A4-50

M27 M30

psi

125,000

105,000

(MPa)

(862)

(724)

psi

72,500

58,000

(MPa)

(500)

futa/fya

Elongation,

min.

7

percent

Reduction

of Area,

min.

percent

Specification for nuts

1.19

16

50

ASTM A563 Grade DH

1.25

10

35

ASTM A563 Grade DH

(400)

MPa

500

400

(psi)

(72,500)

(58,000)

MPa

800

640

(psi)

(116,000)

(92,800)

psi

100,000

65,000

(MPa)

(689)

(448)

psi

85,000

45,000

(MPa)

(586)

(310)

MPa

700

450

(psi)

(101,500)

(65,250)

MPa

500

210

(psi)

(72,500)

(30,450)

DIN 934 (8-A2K)

1.25

22

DIN 934 Grade 6

1.25

12

52

DIN 934 Grade 8

1.54

20

ASTM F594

1.89

25

ASTM F594

1.56

40

ISO 4032

2.38

40

ISO 4032

Hilti HIT-HY 200 adhesive may be used in conjunction with all grades of continuously threaded carbon or stainless steel rod (all-thread) that

comply with the code reference standards and that have thread characteristics comparable with ANSI B1.1 UNC Coarse Thread Series or

ANSI B1.13M M Profile Metric Thread Series. Values for threaded rod types and associated nuts supplied by Hilti are provided here.

2

Standard Specification for Alloy-Steel and Stainless Steel Bolting Materials for High-Temperature Service

3

Standard Specification for Carbon and Alloy Steel Externally Threaded Metric Fasteners

4

Mechanical properties of fasteners made of carbon steel and alloy steel Part 1: Bolts, screws and studs

5

Standard Steel Specification for Stainless Steel Bolts, Hex Cap Screws, and Studs

6

Mechanical properties of corrosion-resistant stainless steel fasteners Part 1: Bolts, screws and studs

7

Based on 2-in. (50 mm) gauge length except for A 193, which are based on a gauge length of 4d and ISO 898, which is based on 5d.

8

Nuts of other grades and styles having specified proof load stresses greater than the specified grade and style are also suitable. Nuts must

have specified proof load stresses equal to or greater than the minimum tensile strength of the specified threaded rod.

9

Nuts for fractional rods.

ESR-3187 | Most Widely Accepted and Trusted

Page 12 of 38

TABLE 4SPECIFICATIONS AND PHYSICAL PROPERTIES OF COMMON STEEL REINFORCING BARS

REINFORCING BAR SPECIFICATION

ASTM A615 Gr. 60

1

ASTM A615 Gr. 40

2

ASTM A706 Gr. 60

3

DIN 488 BSt 500

4

CAN/CSA-G30.18 Gr. 400

Minimum specified ultimate

strength, futa

Minimum specified yield

strength, fya

60,000

psi

90,000

(MPa)

(620)

(414)

psi

60,000

40,000

(MPa)

(414)

(276)

psi

80,000

60,000

(MPa)

(550)

(414)

MPa

550

500

(psi)

(79,750)

(72,500)

MPa

540

400

(psi)

(78,300)

(58,000)

Standard Specification for Deformed and Plain Carbon Steel Bars for Concrete Reinforcement

Standard Specification for Low Alloy Steel Deformed and Plain Bars for Concrete Reinforcement

3

Reinforcing steel; reinforcing steel bars; dimensions and masses

4

Billet-Steel Bars for Concrete Reinforcement

2

TABLE 5SPECIFICATIONS AND PHYSICAL PROPERTIES OF FRACTIONAL AND METRIC HIS-N AND HIS-RN INSERTS

HILTI HIS-N AND HIS-RN INSERTS

Carbon Steel

DIN EN 10277-3 11SMnPb30+c or DIN

1561 9SMnPb28K

3

/8-in. and M8 to M10

Carbon Steel

DIN EN 10277-3 11SMnPb30+c or DIN

1561 9SMnPb28K

1

3

/2 to /4-in. and M12 to M20

Stainless Steel

EN 10088-3 X5CrNiMo 17-12-2

Minimum specified ultimate

strength, futa

Minimum specified yield strength, fya

psi

71,050

59,450

(MPa)

(490)

(410)

psi

66,700

54,375

(MPa)

(460)

(375)

psi

101,500

50,750

(MPa)

(700)

(350)

TABLE 6SPECIFICATIONS AND PHYSICAL PROPERTIES OF COMMON BOLTS, CAP

1,2

SCREWS AND STUDS FOR USE WITH HIS-N AND HIS-RN INSERTS

BOLT, CAP SCREW OR STUD

SPECIFICATION

Minimum

specified

ultimate

strength futa

Minimum

specified

yield strength

0.2 percent

offset fya

psi

120,000

92,000

(MPa)

(828)

(634)

psi

120,000

92,000

(MPa)

(828)

(634)

psi

110,000

95,000

SAE J429 Grade 5

4 1

ASTM A325 /2 to 1-in.

5

ASTM A193 Grade B8M (AISI

316) for use with HIS-RN

5

ASTM A193 Grade B8T (AISI

321) for use with HIS-RN

1

(MPa)

(759)

(655)

psi

125,000

100,000

(MPa)

(862)

(690)

futa/fya

Elongation,

min.

Reduction

of Area,

min.

Specification for nuts

1.30

14

35

SAE J995

1.30

14

35

A 563 C, C3, D, DH,

DH3 Heavy Hex

1.16

15

45

ASTM F594

Alloy Group 1, 2 or 3

1.25

12

35

ASTM F594

Alloy Group 1, 2 or 3

Minimum Grade 5 bolts, cap screws or studs must be used with carbon steel HIS inserts.

Only stainless steel bolts, cap screws or studs must be used with HIS-RN inserts.

3

Mechanical and Material Requirements for Externally Threaded Fasteners

4

Standard Specification for Structural Bolts, Steel, Heat Treated, 120/105 ksi Minimum Tensile Strength

5

Standard Specification for Alloy-Steel and Stainless Steel Bolting Materials for High-Temperature Service

6

Nuts must have specified minimum proof load stress equal to or greater than the specified minimum full-size tensile strength of the specified

stud.

7

Nuts for stainless steel studs must be of the same alloy group as the specified bolt, cap screw, or stud.

2

ESR-3187 | Most Widely Accepted and Trusted

Page 13 of 38

Fractional and Metric HIT-Z and HIT-Z-R

Anchor Rod

Steel Strength

TABLE 7STEEL DESIGN INFORMATION FOR FRACTIONAL AND METRIC HIT-Z AND HIT-Z-R ANCHOR RODS

DESIGN

INFORMATION

Rod O.D.

STAINLESS STEEL

CARBON STEEL

Rod effective crosssectional area

Nominal Rod Dia. (in.) Fractional

Symbol

Units

/8

Ase

/2

/8

Nominal Rod Dia. (mm) Metric

Units

/4

10

16

20

in.

0.375

0.5

0.625

0.75

mm

10

12

16

20

(mm)

(9.5)

(12.7)

(15.9)

(19.1)

(in.)

(0.39)

(0.47)

(0.63)

(0.79)

0.0775

0.1419

0.2260

0.3340

mm

58.0

84.3

157.0

245.0

in.

2

2

(mm )

(50)

(92)

(146)

(216)

(in. )

(0.090)

(0.131)

(0.243)

(0.380)

lb

7,306

13,377

21,306

31,472

kN

37.7

54.8

95.8

145.8

(kN)

(32.5)

(59.5)

(94.8)

(140.0)

(lb)

(8,475)

(12,318)

(21,529)

(32,770)

lb

3,215

5,886

9,375

13,848

kN

16.6

24.1

42.2

64.2

(kN)

(14.3)

(26.2)

(41.7)

(61.6)

(lb)

(3,729)

(5,420)

(9,476)

(14,421)

V,seis

1.0

1.0

Strength reduction

2

factor for tension

0.65

0.65

Strength reduction

2

factor for shear

0.60

0.60

Nominal strength

as governed by

1

steel strength

Reduction for

seismic shear

Nominal strength

as governed by

1

steel strength

Nsa

Vsa

Nsa

0.65

0.65

lb

7,306

13,377

21,306

31,472

kN

37.7

54.8

95.8

145.8

(kN)

(32.5)

(59.5)

(94.8)

(140.0)

(lb)

(8,475)

(12,318)

(21,529)

(32,770)

lb

4,384

8,026

12,783

18,883

kN

22.6

32.9

57.5

87.5

(kN)

(19.5)

(35.7)

(56.9)

(84.0)

(lb)

(5,085)

(7,391)

(12,922)

(19,666)

V,seis

1.0

0.75

1.0

0.75

Strength reduction

2

factor for tension

0.65

0.65

Strength reduction

2

factor for shear

0.60

0.60

Reduction for

seismic shear

Vsa

0.65

For SI: 1 inch 25.4 mm, 1 lbf = 4.448 N, 1 psi = 0.006897 MPa.

For pound-inch units: 1 mm = 0.03937 inches, 1 N = 0.2248 lbf, 1 MPa = 145.0 psi

1

12

Steel properties are minimum values and maximum values will vary due to the cold forming of the rod.

For use with the load combinations of ACI 318 Section 9.2, as set forth in ACI 318 D.4.4.

0.65

ESR-3187 | Most Widely Accepted and Trusted

Page 14 of 38

Fractional and Metric HIT-Z and HIT-Z-R

Anchor Rod

Concrete Breakout Strength

Carbide Bit or

Hilti Hollow Carbide Bit or

Diamond Core Bit

TABLE 8CONCRETE BREAKOUT DESIGN INFORMATION FOR U.S. CUSTOMARY UNIT HIT-Z AND HIT-Z-R ANCHOR ROD

1

IN HOLES DRILLED WITH A HAMMER DRILL AND CARBIDE BIT (OR HILTI HOLLOW CARBIDE DRILL BIT) OR A CORE DRILL

Nominal Rod Dia. (in.) Fractional

DESIGN

INFORMATION

Symbol

Units

/8

Effectiveness factor for

cracked concrete

kc,cr

Effectiveness factor for

uncracked concrete

kc,uncr

Minimum embedment

3

depth

Maximum embedment

3

depth

hef,min

hef,max

/4

10

12

SI

7.1

(SI)

(7.1)

(in-lb)

(17)

in-lb

24

SI

10

(SI)

(10)

(in-lb)

16

20

(24)

in.

2 /8

2 /4

3 /4

mm

60

70

96

100

(mm)

(60)

(70)

(95)

(102)

(in.)

(2.4)

(2.8)

(3.8)

(3.9)

in.

4 /2

7 /2

8 /2

mm

120

144

192

220

(mm)

(114)

(152)

(190)

(216)

(in.)

(4.7)

(5.7)

(7.6)

(8.7)

Min. edge distance

cmin

hmin,2

/8

Nominal Rod Dia. (mm) Metric

Units

17

smin

hmin,1

/2

in-lb

Min. anchor spacing

Minimum concrete

thickness

3

Hole condition 1

Minimum concrete

thickness

3

Hole condition 2

Critical edge distance

splitting

(for uncracked concrete)

See Section 4.1.9.1 of this report.

Pre-calculated combinations of anchor

spacing and edge distance are given in

Table 9 of this report.

1

See Section 4.1.9.1 of this report.

Pre-calculated combinations of anchor

spacing and edge distance are given in

Table 9 of this report.

in.

hef + 2 /4

hef + 4

mm

hef + 60

hef + 100

(mm)

(hef + 57)

(hef + 102)

(in.)

(hef + 2.4)

(hef + 3.9)

in.

hef + 1 /4 > 4

hef + 1 /4

mm

hef + 30 > 100

hef + 45

(mm)

(hef + 32 > 100)

(hef + 45)

(in.)

(hef + 1.25 > 3.9)

(hef + 1.8)

cac

See Section 4.1.10.1 of this report

See Section 4.1.10.1 of this report

Strength reduction factor

for tension, concrete

failure modes,

2

Condition B

0.65

0.65

Strength reduction factor

for shear, concrete

failure modes,

2

Condition B

0.70

0.70

For SI: 1 inch 25.4 mm, 1 lbf = 4.448 N, 1 psi = 0.006897 MPa.

For pound-inch units: 1 mm = 0.03937 inches, 1 N = 0.2248 lbf, 1 MPa = 145.0 psi

1

Additional setting information is described in Figure 6, Manufacturers Printed Installation Instructions (MPII).

Values provided for post-installed anchors under Condition B without supplementary reinforcement as defined in ACI 318 Section D.4.4.

3

Borehole condition is described in Figure 3 below.

2

Hole Condition 1 non-cleaned hole

Hole Condition 2 drilling dust is completely removed

FIGURE 3-BOREHOLE SETTING CONDITIONS FOR HILTI HIT-Z AND HIT-Z-R ANCHOR RODS

ESR-3187 | Most Widely Accepted and Trusted

Page 15 of 38

TABLE 9PRE-CALCULATED EDGE DISTANCE AND SPACING COMBINATIONS FOR HILTI HIT-Z AND HIT-Z-R RODS

DESIGN INFORMATION

Symbol

Rod O.D.

Effective embedment

hef

Drilled hole condition1

CRACKED

CONCRETE

UNCRACKED

CONCRETE

Minimum concrete thickness

h

cmin,1

Minimum edge and

spacing

Case 1 2

smin,1

cmin,2

Minimum edge and

spacing

Case 2 2

smin,2

cmin,1

Minimum edge and

spacing

Case 1 2

smin,1

cmin,2

Minimum edge and

spacing

Case 2 2

smin,2

DESIGN INFORMATION

Symbol

Rod O.D.

Effective embedment

hef

Drilled hole condition1

CRACKED

CONCRETE

UNCRACKED

CONCRETE

Minimum concrete thickness

h

cmin,1

Minimum edge and

spacing

Case 1 2

smin,1

cmin,2

Minimum edge and

spacing

Case 2 2

smin,2

cmin,1

Minimum edge and

spacing

Case 1 2

smin,1

cmin,2

Minimum edge and

spacing

Case 2 2

smin,2

DESIGN INFORMATION

Symbol

Rod O.D.

Effective embedment

hef

-

Minimum concrete thickness

CRACKED

CONCRETE

UNCRACKED

CONCRETE

Drilled hole condition1

cmin,1

Minimum edge and

spacing

Case 1 2

smin,1

cmin,2

Minimum edge and

spacing

Case 2 2

smin,2

cmin,1

Minimum edge and

spacing

Case 1 2

smin,1

cmin,2

Minimum edge and

spacing

Case 2 2

smin,2

Units

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

Units

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

Units

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

2

4

(102)

31 / 8

(79)

91 / 8

(232)

55 / 8

(143)

17 / 8

(48)

21 / 8

(54)

63 / 8

(162)

35 / 8

(92)

17 / 8

(48)

Nominal Rod Diameter (in.) - Fractional

3

/8

(9.5)

33/8

23 / 8

(60)

(86)

1 or 2

2

1 or 2

2

53/4

45/8

55/8

63/8

53/4

4 5/ 8

(117)

(146)

(117)

(143)

(162)

(146)

23/4

21/4

23/4

21/4

2

21/4

(70)

(57)

(70)

(57)

(51)

(57)

73/4

61/8

73/4

61/2

55/8

61/8

(197)

(156)

(197)

(165)

(143)

(156)

43/4

33/4

43/4

37/8

31/4

33/4

(121)

(95)

(121)

(98)

(83)

(95)

17/8

17/8

17/8

17/8

17/8

17/8

(48)

(48)

(48)

(48)

(48)

(48)

17/8

17/8

17/8

17/8

17/8

17/8

(48)

(48)

(48)

(48)

(48)

(48)

51/2

41/4

51/2

31/2

25/8

31/4

(140)

(108)

(140)

(89)

(67)

(83)

31/8

23/8

31/8

21/2

21/8

23/8

(79)

(60)

(79)

(64)

(54)

(60)

17/8

17/8

17/8

17/8

17/8

17/8

(48)

(48)

(48)

(48)

(48)

(48)

2

4

(102)

51 / 8

(130)

147/8

(378)

91 / 4

(235)

21 / 2

(64)

35 / 8

(92)

107/8

(276)

61 / 2

(165)

21 / 2

(64)

Nominal Rod Diameter (in.) - Fractional

1

/2

(12.7)

1

2-3/4

4 /2

(70)

(114)

1 or 2

2

1 or 2

2

53/4

63/4

81/4

71/4

5

7 1/ 8

(127)

(181)

(146)

(171)

(210)

(184)

41/8

27/8

35/8

3

21 / 2

27/8

(105)

(73)

(92)

(76)

(64)

(73)

117/8

85/8

101/4

9

71 / 4

81/8

(302)

(219)

(260)

(229)

(184)

(206)

71/4

47/8

61/4

51/4

41/8

43/4

(184)

(124)

(159)

(133)

(105)

(121)

21/2

21/2

21/2

21/2

21/2

21/2

(64)

(64)

(64)

(64)

(64)

(64)

3

21 / 2

25/8

21/2

21/2

21/2

(76)

(64)

(67)

(64)

(64)

(64)

81/2

6

73 / 8

51/2

31/8

41/2

(216)

(152)

(187)

(140)

(79)

(114)

5

31 / 4

41/4

31/2

23/4

31/4

(127)

(83)

(108)

(89)

(70)

(83)

21/2

21/2

21/2

21/2

21/2

21/2

(64)

(64)

(64)

(64)

(64)

(64)

2

51/ 2

(140)

61 / 4

(159)

183/8

(467)

113/8

(289)

31 / 8

(79)

45 / 8

(117)

137/8

(352)

81 / 4

(210)

31 / 8

(79)

Nominal Rod Diameter (in.) - Fractional

5

/8

(15.9)

3

5

5 /8

3 /4

(95)

(143)

1 or 2

2

1 or 2

2

73/4

93/8

73/8

95/8

101/2

91/4

(197)

(238)

(187)

(244)

(267)

(235)

41/2

33/4

45/8

35/8

31/4

33/4

(114)

(95)

(117)

(92)

(83)

(95)

127/8

105/8

137/8

103/8

93/4

107/8

(327)

(270)

(352)

(264)

(248)

(276)

73/4

61/4

81/4

61/8

51/2

63/8

(197)

(159)

(210)

(156)

(140)

(162)

31/8

31/8

31/8

31/8

31/8

31/8

(79)

(79)

(79)

(79)

(79)

(79)

33/8

31/8

31/2

31/8

31/8

31/8

(86)

(79)

(89)

(79)

(79)

(79)

91/2

83/4

101/8

61/2

53/8

71/8

(241)

(222)

(257)

(165)

(137)

(181)

51/2

43/8

57/8

41/4

37/8

41/2

(140)

(111)

(149)

(108)

(98)

(114)

31/8

31/8

31/8

31/8

31/8

31/8

(79)

(79)

(79)

(79)

(79)

(79)

41/2

(114)

1 or 2

63/4

(171)

17/8

(48)

53/8

(137)

31/8

(79)

17/8

(48)

17/8

(48)

2

(51)

2

(51)

17/8

(48)

6

(152)

1 or 2

81/4

(210)

21/2

(64)

71/4

(184)

41/8

(105)

21/2

(64)

21/2

(64)

31/8

(79)

23/4

(70)

21/2

(64)

93/4

(248)

21/2

(64)

5

(127)

33/8

(86)

21/2

(64)

21/2

(64)

21/2

(64)

21/2

(64)

21/2

(64)

71/2

(191)

1 or 2

111/2

(292)

31/8

(79)

83/8

(213)

47/8

(124)

31/8

(79)

31/8

(79)

37/8

(98)

33/8

(86)

31/8

(79)

For SI: 1 inch 25.4 mm

1

See Figure 3 for description of drilled hole condition.

2

Linear interpolation is permitted to establish an edge distance and spacing combination between case 1 and case 2.

Linear interpolation for a specific edge distance c, where cmin,1 < c < cmin,2, will determine the permissible spacing, s, as follows:

s

smin,2

s smin,2 min,1

c cmin,2

cmin,1 cmin,2

73/8

(187)

17/8

(48)

41/2

(114)

23/4

(70)

17/8

(48)

17/8

(48)

17/8

(48)

17/8

(48)

17/8

(48)

121/4

(311)

31/8

(79)

73/8

(187)

45/8

(117)

31/8

(79)

31/8

(79)

31/8

(79)

31/8

(79)

31/8

(79)

ESR-3187 | Most Widely Accepted and Trusted

Page 16 of 38

TABLE 9PRE-CALCULATED EDGE DISTANCE AND SPACING COMBINATIONS FOR HILTI HIT-Z AND HIT-Z-R RODS (Continued)

DESIGN INFORMATION

Symbol

Rod O.D.

Effective embedment

hef

Drilled hole condition1

CRACKED

CONCRETE

UNCRACKED

CONCRETE

Minimum concrete thickness

h

cmin,1

Minimum edge and

spacing

Case 1 2

smin,1

cmin,2

Minimum edge and

spacing

Case 2 2

smin,2

cmin,1

Minimum edge and

spacing

Case 1 2

smin,1

cmin,2

Minimum edge and

spacing

Case 2 2

smin,2

DESIGN INFORMATION

Symbol

Rod O.D.

Effective embedment

hef

Drilled hole condition1

CRACKED

CONCRETE

UNCRACKED

CONCRETE

Minimum concrete thickness

h

cmin,1

Minimum edge and

spacing

Case 1 2

smin,1

cmin,2

Minimum edge and

spacing

Case 2 2

smin,2

cmin,1

Minimum edge and

spacing

Case 1 2

smin,1

cmin,2

Minimum edge and

spacing

Case 2 2

smin,2

DESIGN INFORMATION

Symbol

Rod O.D.

Effective embedment

hef

-

Minimum concrete thickness

CRACKED

CONCRETE

UNCRACKED

CONCRETE

Drilled hole condition1

cmin,1

Minimum edge and

spacing

Case 1 2

smin,1

cmin,2

Minimum edge and

spacing

Case 2 2

smin,2

cmin,1

Minimum edge and

spacing

Case 1 2

smin,1

cmin,2

Minimum edge and

spacing

Case 2 2

smin,2

Units

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

in.

(mm)

Units

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

Units

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

2

53/ 4

(146)

93 / 4

(248)

283/4

(730)

181/8

(460)

33 / 4

(95)

71 / 4

(184)

213/4

(552)

131/4

(337)

33 / 4

(95)

Nominal Rod Diameter (in.) - Fractional

3

/4

(19.1)

4

6 3/ 4

(102)

(171)

1 or 2

2

1 or 2

2

8

111/2

81/2

103/4

131/8

101/4

(203)

(292)

(216)

(273)

(333)

(260)

7

5

65 / 8

51/4

41/4

51/2

(178)

(127)

(168)

(133)

(108)

(140)

205/8

14

193/8

151/4

125/8

16

(524)

(356)

(492)

(387)

(321)

(406)

125/8

81/2

117/8

91/8

71/4

95/8

(321)

(216)

(302)

(232)

(184)

(244)

33/4

33/4

33/4

33/4

33/4

33/4

(95)

(95)

(95)

(95)

(95)

(95)

51/4

41/8

5

4

33 / 4

41/8

(133)

(105)

(127)

(102)

(95)

(105)

151/2

121/4

141/2

113/8

9

121/8

(394)

(311)

(368)

(289)

(229)

(308)

91/4

6

85 / 8

65/8

51/8

7

(235)

(152)

(219)

(168)

(130)

(178)

3

3

3

3

3

3 /4

3 /4

3 /4

3 /4

3 /4

33/4

(95)

(95)

(95)

(95)

(95)

(95)

156

(6.14)

64

(2.52)

187

(7.36)

110

(4.33)

50

(1.97)

52

(2.05)

150

(5.91)

74

(2.91)

50

(1.97)

Nominal Rod Diameter (mm) Metric

10

(0.39)

90

(3.54)

2

1 or 2

120

150

176

(4.72)

(5.91)

(6.91)

83

66

57

(3.27)

(2.60)

(2.24)

244

197

166

(9.61)

(7.76)

(6.54)

148

115

96

(5.83)

(4.53)

(3.78)

50

50

50

(1.97)

(1.97)

(1.97)

59

50

50

(2.32)

(1.97)

(1.97)

174

131

106

(6.85)

(5.16)

(4.17)

101

77

64

(3.98)

(3.03)

(2.52)

50

50

50

(1.97)

(1.97)

(1.97)

1 or 2

130

184

(5.12)

(7.24)

107

76

(4.21)

(2.99)

320

225

(12.60)

(8.86)

194

131

(7.64)

(5.16)

60

60

(2.36)

(2.36)

78

62

(3.07)