Professional Documents

Culture Documents

PWM AC Chopper

Uploaded by

ductamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PWM AC Chopper

Uploaded by

ductamCopyright:

Available Formats

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

HANOI UNIVERSITY OF SCIENCE AND TECHNOLOGY

SCHOOL OF ELECTRICAL ENGINEERING

====o0o====

DESIGN REPORT

PROJECT II

PROJECT NAME:

DESIGNING & SIMULATING FULL BRIDGE CONTROLLED

RECTIFIER

CLASS

:

EE.CTTT. K55

INSTRUCTOR :

STUDENTS

CODE

DR. DO MANH CUONG

:

Nguyn c Tm

: 20102119

Hanoi : 07/31/2014

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 1

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

TABLE OF CONTENT

PREFACE

.2

CHATER 1:GENERAL INTRODUCTION TO THYRISTOR.....................................................4

1.The basic theory of thyristor ....

..4

2.Basic principle and state of

thyristor..6

3.Basic parameters of

thyristor

..6

4.Control principle of thyristor.

..7

5.Some advantages and disadvantages of controlled thyristor with other

controlled rectifier..9

CHAPTER 2: CHOOSING AND CALCULATION OF POWER

STAGE..9

1.Requirement for control

stage

.9

2.Choosing and calculating the power

stage..9

CHAPTER 3: DESIGN AND SIMULATING CONTROLLED CIRCUIT AND CONCLUSION.........12

1.Block diagram of controlled

state..12

2.Schematic and simulation

result.17

3.Conclusion

..20

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 2

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

4.References

..20

PREFACE

In the recent years, with the very high development of our country and get many

achivements and make basic premiss for our country go to the new period, the period of

industrialization and modernization of the country and the power electronics of electrical

engineering is the most important part of the development of the country.Especially, with the

application of power electronic in all sector of national economy.In our project related to rectifier

using thysistor control we concern about the method to control safety and and accurately.It is the

mission of sector power electronic is needed to solve.Student of sector automation control

engineering need to have more about knowledge power electronic to apply in factory,

enterpriseto enhance productivity and bring atomatic control technology into manufacturing

process.

The project supplies for our many knowledge about power electronic, specially, in

predictive control algorithm control for PWM AC chopper.To help me to reinforce the

knowledge and have some experiences teacher Dr.Do Manh Cuong help our to do project about

predecitve control.From searching project and some document in internet,specially with the help

of my teacher we now complete the project.The main content of this assignment I concentrate 2

problems: determine,calculate,design parameter of circuit and simulating control circuit..The

assignment give our many new knowledge and help me recognize, design one power electronic

circuit better. Although we attempt to make the good project but with the little experiences so the

project has many mistakes, please forget about it!

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 3

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

Student group: Nguyn c Tm

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 4

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

Chapter 1

GENERAL INTRODUCTION

I. Motivation

One of the great things ever to happened to mankind in the 20nd century was the invention

of a transistor by John Bardeen,Walter Brattain and Wiliam Shockley in 1947 at Bell,USA

and the successful production of the first transistor in 1954.The transistor is the heart of

power electronic and now has become central to our lives.

As the number of transistor on intergrated circuit doubles,computing power is increasing

and online control of complex and faster processes are becoming more commom.This is due

to shrinking transistor size,higher operating speeds and introduction of more power efficient

semiconductor.As the processor die size is decreasing , the processing speed is increasing and

production costs are decreasing.Low power consumption in the devices has been largely

achieved by decreasing the operating voltage,improvement and introduction of new

semiconductor technology and manufacturing methods.

One of the other side of semiconductor technology, is use of semiconductor in high power

and high voltage electronic.To control these power semiconductors is power supply paths

losses .The control should be able to compute online the medium cost with the real time

measurement using complex control algorithm and be able to apply the control law

immediately to achieve the desired the control object.In this research , a finite set model

predictive control algorithm (FS-MPC) that is presented which can be computed by using

DSP

II. Background

The recent developments in the few of power electronics make it possible to improve the

electrical power system ultility interface.Line commutated AC controller can be replaced by

PWM AC chopper controller which have better overall performance and the above problem can

be improved if there controllers are designed to operate in the chopping mode.In this case ,the

input supply voltage is chopped into segments and the output voltage level is decided by

controlling the duty cycle of the chopping switching function.on easurement using complex

control algorithm and be able to apply the control law immediately to achieve.The growth in

the field of the power electronics has made it possible to improve the performance of electrical

system ultilites through various mean.The solid state power switching devices are employed in

source conditioning by changing either its magnitude or frequency such as inverter,converter,

chopper, regulator.The advantages of using these devices are listed out by Addosweet.They are

below

+ Fast respone

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 5

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

+ Compactness

+ Loss free control

+ Low power demands of control circuitry

Medium,large motor drives and higher power supply inverter in flexible alternate current

transmission system need switching element wich can bear high voltage and current.To

overcome the limitation of semiconductor switches , several new techniques and topologies has

been developed,such as multiple switching elements in one lag of the inverter.

III. Choppers

1.General about DC choppers

A chopper is a static device which is used to obtain a variable dc voltage from a constant dc

voltage source.A chopper is also known as dc-to-dc converter.The thyristor convert offers great

efficiency,faster respone,lower maintenance,small size and smooth control.Choppers are widely

used in trolley cars,control of large number of dc motor,etcThey are also used in regenative

braking of dc motor to return energy back to supply and also as dc voltage regulator.

Choppers are of two types

+ Step-down choppers

+ Step - up choppers

a.Step down choppers

Step down chopper with Resistive load

The thyristor in the circuit acts as a switch.When the thyristor is ON ,supply voltage aprear

across the load and when thyristor is OFF, the voltage across the load will be zero.The output

voltage and current waveform are shown in below

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 6

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

Step down choppers output voltage and current wavform

Vdc = average value of the output or load voltage

Idc = average value of output or load current

tOFF = time interval for which SCR conducts

tON = time interval for which SCR is OFF

T= tOFF +

tON is period of switching or chopping period

Average output voltage

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 7

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

b.Step up choppers

Step up chopper

A step up chopper obtain a load voltage Vo higher than input voltage V.When the choppe is ONN

the inductor L is connected across the supply and when the chooper is OFF the inductor current I

is forced to flow through the diode D and load for a period.Therefore the voltage across load is

given by

When chopper is ON

- Voltage across inductor L=V

Therefore energy store in inductor = V.I.tON

Where TON = ON period of chopper

When chopper is OFF

Energy supplied by inductor L=(V0-V)ItOFF , where tOFF = OFF period of chopper.

Voltage across L = V0 - V

2. The method of control

Pulse Width Modulation is one method of control.The pulse width ( tON) of the output

waveform is varied keeping chopping frequency f varied by varying the ON time.The output

voltage is varied and by varying hence chopping period T constant.Therefore out voltage

waveform for different ON time.

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 8

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

Pulse Width Modulation Control.

3.General about AC choppers.

AC chopper is a static converter which convert AC to AC without changing the frequency and

AC chopper have been widely used to control average load power from a fixed ac source.The

common applictions are industrial heating and ac speed control.

The advantages of AC chopper over DC chopper

+ Simplicity

+ Ability of controlling large amount of power

+ High efficiency

The disadvantages of AC chopper over DC chopper

+ Protection against detrimental switching voltage transients

+ Negative Temperature coefficient

a. Single phase topology

By the supply mode , PWM AC chopper are classified in differential and non-differential .Both

structure are made by two inverter commuanication cells with IGBTs bydirectional in current and

unidirectional in voltage.

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 9

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

Basic single phase PWM AC choppers

Both converter have the same control,depending on the voltage source

b.Three phase topology

In the three phase topology the PWM AC chopper operate like unidirectional voltage chopper.In

the second control depending on the voltage source sign the three phase structure operate like

two independent unidirectional voltage chopper.

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 10

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

In the buck PWM AC chopper for three phase systems the switches with the smallest voltage

source among three voltage source are fully turned on.

Chapter 2

MODEL PRIDECTIVE CONTROL ALGORITHM.

I.

History of model predictive control

The earliest algorithm of Model predictive control was proposed by a French engineer

Richalet in 1978 but the receding horizon principle was proposed as early as 1963 by Propoi in

open loop optimal feedback control

In 1968,Rafal and Stevens presented a control system with a quadratic cost,linear

constraints and moving horizon of one.This was essentially an MPC formulation.MPC later

become popular in the chemical and other slow process industries due to simplicity of the

algorithm and the advent of the computer and the introduction of online optimization.The MPC

control systems was ideal in industrial because of its capability handlding multivariable systems

and constraints

II.

Branches of predictive control

Many control schemes has been proposed and are used power electronics the most common

controller being the linear controller with pulse width modulation.

Converter control method

Predective control further be broken into several control schemes

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 11

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

Deadbeat control and MPC with a continuous control set require modulators such as pulse width

modulation which results in fixed switching frequency while hysteresis, trajectory and MPC with

finite set control

Moded predictive control is further divided into two kind: MPC with a continuous control set

MPC with a finite set control

+ MPC with continuous control set requires a modulator.

In an MPC with a finite set control ,the switches position form part of the optimization

process

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 12

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

III.

Model predictive control theory

Predective thinking is nautral for people for example during driving the car ,the driver look

ahead and observer the shape of the road and possible obstacles.

The discrete time model of the system can be given by the following equation

Which describe the future state vector

current input vector

as a function of the current state vector and the

Model predictive control refer to a class of control algorithm in which a plant or process dynamic

model is used to control a process or plant by minimizing an objective function.MPC uses

mathematical function model of system to predict the future behavior.MPC process can be

summarized as follow

To take a measurement of a system state and output

Compute a finite horizon sequence

Carry out on-line optimization using a cost function

Apply the vector control variable with the least cos on the controlled plant

A model of plant is necessary for the controller

The success of the controller depend on the accuracy of the model

State and process measurement provide feedback for the system

Acorrding to the component of model predictive control are

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 13

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

1.Influence of predictions on actions

MPC in constrast computer the affect of the current actions over a finite horizon

2.Prediction are based on model

3.Selecting input

The advantages of MPC

rding to the Volt-Ampere characteristic of Thyristor, the width of control pulse is required that

current through Thyristor increase from 0 to Ith_max . Normally, the width of control pulse is not

smaller than 5ms. If we increase the width if control pulse, the amplitude of control pulse will be

decreased.

3. The raising and falling edge of control pulse

The raising and falling time smaller is better. It will decrease the loss power by heating of

Thyristor especially using many Thyristor in circuit. We try to decrease the value of them to 0,

then the control pulse is look like rectangular pulse.

4. Confidence of circuit

The circuit have to operate exactly in condition having increase of temperature, appear

some noise. The Thyristors are not allow to open when the leakage current appear. The control

pulse is little denpend on heating, oscilation of input voltage, noise ,

IV.

Choosing and calculating the power stage.

1. Calculation and choosing Thyristor

We are consider one phase bridge rectifier using Thyristor, so we have:

-

The maximum reverse voltage of Thyristor is :

URe_max = 2 .U2 = 2 220 = 311(V)

The needed reverse voltage of Thyristor is:

URe_needed = 1.8 UNg_max = 1.8311 = 560(V)

The working current of Thyristor following rated current:

Iv =1/ 3 Irated = 0.577 166 = 95.8(A)

The needed current of Thyristor is:

Ineeded = 3.2 Iv = 3.295.8 = 306.56(A)

From all above parameters, we check in Thyristor parameter table and we choose TF440-06X

with parameters:

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 14

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

- The rated current:

Irated = 400(A)

- The maximum reverse voltage:

URe_max = 600(V)

- The peak current:

Ipeak = 4000(A)

- The drop voltage on Thyristor:

Vdrop = 2(V)

- The gate current:

Ig = 200(mA)

- The gate voltage

Vg = 5(V)

- The leakage current:

Ileak = 25(mA)

- The maximum working temperature:

Tmax = 125(oC)

- The maintain current:

Imaintain = 70(mA)

2. Calculation and choosing transformer

2.1. Choosing cross section of iron core S0

S0 = (0.9 0.93) S (mm2)

With S = ab . Choose

a= 3mm, 5mm.We have S = 35=15 (mm2)

So we get S0 = 0.915 = 13.5 (mm2)

The estimation power with cross section wounding S0 :

Pestimate = U2I2

where U1 = 220(V), f = 50(Hz)

U2 = 24(V)

,I2 = 1(A)

Pestimate = U2I2 = 241 = 24(V)

2.2. Choosing the number of winding per volt W

We choose B = 0.7 ( Tesla), so K = 64.

So W = 64/13.5 = 4.74 ( round per volt)

So we choose W = 5.

2.3. Choosing the number of winding in primary W1 and secondary W2,W3

- The number of primary winding :

W1 = WU1 = 5 220 = 1100 ( round)

- The number of secondary winding :

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 15

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

W2 = W3 = U2 / 2 = 24 / 2 = 12 ( round)

Determine the cross section for winding:

- The cross section of primary winding :

S1 =

P

.U . J

(mm2)

is the effiency of transformer: = 0.85 0.9

J is the current density of winding.

Choosing J = 4 ( A/mm2)

So the cross section of primary core is:

S1 =

24

0.9 220 4

= 0.03 (mm2)

The cross section of secondary windings:

S2 = S3 = I2 / J = 1 / 4 = 0.25 (mm2)

The diameter of a primary winding:

d1 = 1.13 S 1

= 1.13 0.03 = 0.2 ( mm)

The diameter of secondary windings:

d2 = d3 = 1.13 S 2

= 1.13 0.25 = 0.6 ( mm)

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 16

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

Chapter 3

DESIGN AND SIMULATING THE CONTROL CIRCUIT AND

CONCULSION

I.

Block diagram of control stage.

Source

Comparator

Synchronous

PWM

Isolation

Control

voltage

Figure 3.1: Block diagram of control satge

(Source: From internet)

1. Source block

The main function of source block is provide the AC supply power for control stage with

AC current 50Hz. The wave form of source is sinusoidal wave.

2. Synchronous block

The main function of synchronous block is synchonization the width pulse with the

period of AC supply power 50Hz. Firstly, we use 2 diodes to have full-wave rectifier circuit to

obtain DC supply power. Then we use capacitor which can charge and discharge energy to

generate the sawtooth waveform. We have many sample can be choosed to implement this

function, but we choose sample that using transistor to control charge and discharge of capacitor.

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 17

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

Figure 3.2: The synchronous block

( Source: from simulation circuit)

This sample is very useful. We can control the openning and closing of transisor at voltage

approximately to 0 that most other sample can not be performed. So we can easy to control the

charging and discharging of capacitor at region very small value of voltage. This sample control

transistor depending on working principle of Operation Amplifier (OPAM).

Figure 3.3: Control transistor depending on OPAM

(Source : From result simulating)

3. Comparator block

To simplize, we choose OPAM comparator to compare the value of sawtooth wave

voltage and control voltage and then generate the pulse.

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 18

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

Figure 3.4: Comparator block

(Source: From simulation circuit)

In this figure, U1 and U2 are control voltage and sawtooth voltage corresponding. If sawtooth

voltage greater than control voltage, the output voltage will be high level at 5V. Reverstly, the

output voltage of OPAM will be low level at 0V. The advantage of this sample is that it can

generate the control pule very exactly.

Figure 3.5: The voltage control by the comparator block

(Source: Simulation result)

1. Pulse Width Modulation (PWM) block

When circuit operate in reality, the loss power is a big problem. So we have to find how to

reduce the loss power for circuit, how to reduce the raising heat for circuit, We will using

pulse width modulation methods to get it. We devide the control pulse at high level (5V) into

many small period pulse, that mean the frequency of pulse is very big. It is approximately

10KHz.

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 19

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

Figure 3.6:Pulse width modulation block

(Source: From simulation circuit)

This block create the pulse with high frequency.

Figure 3.7:The pulse with high frequency

(Source: result simulating)

Because we consider about bridge rectifier, full-wave rectifier, we have to rectifier at 2-half

period of AC sinusoidal input voltage. We using NOT logical gate to generate invert pulse

serving for negative period.

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 20

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

Figure 3.8: The NOT logical gate

(Source: From simulation circuit)

Finally, we use AND logical gate with 3 inputs to combine and create the openning pulse for 4

Thyristor.

5. Isolation block

The control stage has low power, but power stage has high power. To ensure security, we have

isolate control stage and power stage. Nowday, OPTO coupler is usually used to isolate control

stage and power stage. Moreover, the structure of circuit is not difficult.

Figure 3.9: Isolation block

(Source: From simulating circuit)

Eventually, we connect the output to the input of thyristor corresponding.

II.

Schematic and simulation result

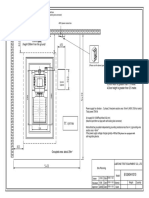

1. Schematic

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 21

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 22

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

Figure 3.10: The schematic

(Source:From internet)

2. Simulation result

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 23

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

Figure 3.11: The simulation result

III.

Conclusion

The our project using thyristor to control current and voltage.It are mainly used where

high current and voltage are involved,and often used to control alternating current,

where the change of polarity of the current causes to devices to switch off ,

automatically.This can be said to operate synchronously as, once the device is open,it

conduct current in phase with the voltage applied over its cathode to anode junction

with no further gate modulation being requires to repliable.

IV.

Refereces

1. Trn Trng Minh

Gio trnh in t cng sut.NXB Gio Dc

2.Nguyn Bnh

in t cng sut v ng dng thyristor.NXB i hc v gio dc chuyn nghip

3.Controlled in power electronic

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 24

Project 1&2 of Designing and Simulating full bridge controlled rectifier.

Marian P.Kazmierkowski and Frede Blaabjerg.

Nguyn c Tm. KT.CTTT.K55- 20102119

Page 25

You might also like

- State Space Averaging Model of Boost ConvDocument60 pagesState Space Averaging Model of Boost ConvBharti Thakur100% (1)

- DET 309 Power Electronics Course OutlineDocument27 pagesDET 309 Power Electronics Course Outlinehn317No ratings yet

- EditedDocument55 pagesEditedMeshack LeeNo ratings yet

- 174743t.psu ProjectDocument14 pages174743t.psu ProjectBRIGHT TZZZY CHINGWENANo ratings yet

- Project Report For MLI 7 Level PWMDocument18 pagesProject Report For MLI 7 Level PWMXvasdfr DfgNo ratings yet

- High Step-up DC-DC Converter: 3-Winding Coupled Inductor DesignDocument44 pagesHigh Step-up DC-DC Converter: 3-Winding Coupled Inductor DesignSriramNo ratings yet

- Project (Rubric-1) : March, 2023Document11 pagesProject (Rubric-1) : March, 2023AakankshaNo ratings yet

- Advanced InvertersDocument30 pagesAdvanced InvertersShivam VermaNo ratings yet

- DC DC Buck Converter ThesisDocument7 pagesDC DC Buck Converter Thesisaprilbellhartford100% (2)

- Report On HVDCDocument20 pagesReport On HVDCMk Enterprise JamuriaNo ratings yet

- Power Transformer ThesisDocument4 pagesPower Transformer Thesisnlcnqrgld100% (2)

- Current TransformerDocument16 pagesCurrent TransformerNOV DAVANNNo ratings yet

- Title: Automatic Load Sharing of Transformer: A Synopsis Report OnDocument5 pagesTitle: Automatic Load Sharing of Transformer: A Synopsis Report OnAshish Ghadoje100% (1)

- Variable DC Power Supply Circuit DesignDocument21 pagesVariable DC Power Supply Circuit DesignAbhishek HatagaleNo ratings yet

- Current Mirror 1Document5 pagesCurrent Mirror 1Shaheer DurraniNo ratings yet

- Lab Project ReportDocument11 pagesLab Project ReportMe alag HuNo ratings yet

- Automatic Power Factor Correction Project PresentationDocument23 pagesAutomatic Power Factor Correction Project PresentationAnand BhaskarNo ratings yet

- Important Report File Electricity Theft...Document32 pagesImportant Report File Electricity Theft...Jatinder SainiNo ratings yet

- Report On HVDCDocument18 pagesReport On HVDCBARUN SINGHNo ratings yet

- Android controlled pick and place robotDocument84 pagesAndroid controlled pick and place robotSRL MECHNo ratings yet

- Design and Implementation of ZCS BUCK CONVERTERDocument51 pagesDesign and Implementation of ZCS BUCK CONVERTERAriful Haque100% (1)

- VX Ring Suppression: Current Sensor ADocument2 pagesVX Ring Suppression: Current Sensor AVijyashree IyerNo ratings yet

- Chapter OneDocument28 pagesChapter OneObafemi Samuel0% (1)

- DC-DC Boost Converter With Constant Output Voltage For Grid Connected Photovoltaic Application SystemDocument5 pagesDC-DC Boost Converter With Constant Output Voltage For Grid Connected Photovoltaic Application SystemThamazighth HaddadNo ratings yet

- Microcontroller Based ProjectDocument31 pagesMicrocontroller Based ProjectshashankfruNo ratings yet

- Speed Control of DC Motor Using Pulse Width ModulationDocument5 pagesSpeed Control of DC Motor Using Pulse Width ModulationSyed muhammad zaidi100% (1)

- DC-DC Boost Converter Lab ProjectDocument15 pagesDC-DC Boost Converter Lab ProjectAyush MittalNo ratings yet

- DC To DC Usb-C ChargerDocument25 pagesDC To DC Usb-C ChargerNahyanNo ratings yet

- Jeevan AUTOMATIC LOAD SHARING 1Document59 pagesJeevan AUTOMATIC LOAD SHARING 1JEEVAN MANGALAGIRINo ratings yet

- Cta 2701Document25 pagesCta 2701pedroNo ratings yet

- Design, Analysis, and Implementation of Solar Power Optimizer For DC Distribution SystemDocument9 pagesDesign, Analysis, and Implementation of Solar Power Optimizer For DC Distribution SystemraghuaadsNo ratings yet

- H-Bridge DC Motor Direction ControllerDocument7 pagesH-Bridge DC Motor Direction ControllerKhan ElmeNo ratings yet

- DC to AC InverterDocument13 pagesDC to AC Inverterejike123100% (1)

- DC DC Et DC AC Orcad SimDocument23 pagesDC DC Et DC AC Orcad SimabfstbmsodNo ratings yet

- Chapter - 1 Power Electronics ControlDocument0 pagesChapter - 1 Power Electronics Controlwww.bhawesh.com.npNo ratings yet

- Regulated Power Supply Made by - Rajat AggarwalDocument37 pagesRegulated Power Supply Made by - Rajat AggarwalSONUAGGARWAL23338871% (35)

- Adjustable Power SupplyDocument24 pagesAdjustable Power SupplyELLAINE DE CLARONo ratings yet

- Design and Implementation of Multiple Output Switch Mode Power SupplyDocument6 pagesDesign and Implementation of Multiple Output Switch Mode Power SupplyseventhsensegroupNo ratings yet

- BUCK Driver: MicroprocessorDocument9 pagesBUCK Driver: MicroprocessorMehroz KhanNo ratings yet

- BUCK Driver: MicroprocessorDocument9 pagesBUCK Driver: MicroprocessorMehroz KhanNo ratings yet

- Project Report of Buck Boost RegulatorDocument15 pagesProject Report of Buck Boost RegulatorAnshul YadavNo ratings yet

- Design and Implementation of Luo Converter For Electric Vehicle ApplicationsDocument5 pagesDesign and Implementation of Luo Converter For Electric Vehicle ApplicationsseventhsensegroupNo ratings yet

- DC/DC Boost Converter Report: Do Nguyen NghiaDocument34 pagesDC/DC Boost Converter Report: Do Nguyen NghiaNguyên NghĩaNo ratings yet

- A Single Phase, Single Stage Three Level Boost DC - DC ConverterDocument5 pagesA Single Phase, Single Stage Three Level Boost DC - DC Converterijsret100% (1)

- A High Voltage Gain DC To DC Converter For Distributed Generation Systems With MPPT ControllerDocument4 pagesA High Voltage Gain DC To DC Converter For Distributed Generation Systems With MPPT ControllerAfef NejiNo ratings yet

- Tom PPT 2021Document20 pagesTom PPT 2021mebrahtenNo ratings yet

- Design of A Power Converter Based On UC3842 For Blade Electric VehicleDocument6 pagesDesign of A Power Converter Based On UC3842 For Blade Electric VehicleHossam SobhyNo ratings yet

- Design and Simulation of DC-DC Converter Used in Solar Charge ControllersDocument4 pagesDesign and Simulation of DC-DC Converter Used in Solar Charge ControllersInternational Journal of Engineering Inventions (IJEI)No ratings yet

- Regulated Power SupplyDocument15 pagesRegulated Power SupplyAnubhav Yadav100% (4)

- Compact High Voltage Power SupplyDocument69 pagesCompact High Voltage Power SupplyAjith P Shetty100% (1)

- Performance Analysis of Conventional and Interleaved Boost Converters Using MULTISMDocument10 pagesPerformance Analysis of Conventional and Interleaved Boost Converters Using MULTISMIam AbdiwaliNo ratings yet

- DC 12V To 220V Ac Inverter Making by Using Ic CD4047Document19 pagesDC 12V To 220V Ac Inverter Making by Using Ic CD4047Amartya RoyNo ratings yet

- Design of Zeta Converter Based Electronic Ballast For Fluorescent LampsDocument7 pagesDesign of Zeta Converter Based Electronic Ballast For Fluorescent LampscamiloNo ratings yet

- Design & Construction of 220 V Voltage StabilizerDocument46 pagesDesign & Construction of 220 V Voltage StabilizerNitin VermaNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Astor: Test TransformerDocument1 pageAstor: Test TransformermominzadahNo ratings yet

- Precision Junction Boxes: Download Installation GuideDocument46 pagesPrecision Junction Boxes: Download Installation GuideEmanuel Pajares JuárezNo ratings yet

- Neurotherm NT-500 Lesion Generator - User ManualDocument32 pagesNeurotherm NT-500 Lesion Generator - User ManualAferNo ratings yet

- 0-1-DEBRIEFING-Ca'c 1, Cal'c 2 and Fluid-StudentsDocument2 pages0-1-DEBRIEFING-Ca'c 1, Cal'c 2 and Fluid-StudentsPaul Philip LabitoriaNo ratings yet

- Car Pollution BookletDocument12 pagesCar Pollution BookletVianaNo ratings yet

- BV Webinar SlidesDocument64 pagesBV Webinar SlidessuinsasNo ratings yet

- Wave Optics SolutionsDocument26 pagesWave Optics SolutionsAjay AgrawalNo ratings yet

- Sourcing and BioprocessingDocument139 pagesSourcing and BioprocessingMary Grace ProgellaNo ratings yet

- SNP Tanker ReportDocument3 pagesSNP Tanker ReportfikrifadzalNo ratings yet

- A Polyhydron Group Company: DescriptionDocument3 pagesA Polyhydron Group Company: DescriptionHorea CordunianuNo ratings yet

- Plastic Analysis AssignmentDocument6 pagesPlastic Analysis AssignmentLeo DoeNo ratings yet

- Ready Made RC Car SchematicDocument3 pagesReady Made RC Car SchematicybyDgreat jbNo ratings yet

- Sustainable StrategiesDocument26 pagesSustainable StrategiesJhuneil B GermonesNo ratings yet

- Efficient Artificial Lighting Systems For Apparel Stores: Sailee RaisoniDocument3 pagesEfficient Artificial Lighting Systems For Apparel Stores: Sailee RaisoniSailee Raisoni BafnaNo ratings yet

- General Purpose US FusesDocument69 pagesGeneral Purpose US FusesEliasNo ratings yet

- Water Resources EngineeringDocument1,199 pagesWater Resources EngineeringVikaas Jha97% (35)

- Yanmar 3TNV76-DWL Engine Parts CatalogDocument20 pagesYanmar 3TNV76-DWL Engine Parts CatalogDarryl CareyNo ratings yet

- Physics AssignmentDocument41 pagesPhysics AssignmentMustapha KaojeNo ratings yet

- Hatz ManualDocument53 pagesHatz ManualCubi Masinska ObradaNo ratings yet

- Question Bank SMDocument10 pagesQuestion Bank SMamurugan_22No ratings yet

- Physics: Pearson Edexcel GCEDocument24 pagesPhysics: Pearson Edexcel GCERabia HasanNo ratings yet

- Guidelines: Commercial Office SpacesDocument14 pagesGuidelines: Commercial Office SpacesapoyoNo ratings yet

- Me6603 Fea - 2 MarksDocument15 pagesMe6603 Fea - 2 MarksPrabha KaranNo ratings yet

- BetonDocument2 pagesBetonEmily StaffordNo ratings yet

- EEDC DetailDocument21 pagesEEDC DetailAfrian HindrawijayaNo ratings yet

- Pressure Vessel Creep Analysis: RuptureDocument7 pagesPressure Vessel Creep Analysis: RuptureFlorin TrNo ratings yet

- Micro Motion Mass Flow Transmitter Data SheetDocument2 pagesMicro Motion Mass Flow Transmitter Data SheetAhmed ElhoniNo ratings yet

- Hydraulic Institute StandardDocument2 pagesHydraulic Institute StandardCheerag100% (1)

- Alan Electronics' Story of Quality, Consistency and ReliabilityDocument6 pagesAlan Electronics' Story of Quality, Consistency and Reliabilitysathishsutharsan87No ratings yet

- Beam Powered PropulsionDocument19 pagesBeam Powered PropulsionSai Sushma100% (1)