Professional Documents

Culture Documents

Deflection Control in Composite Building by Using Belt Truss and Outriggers Systems

Uploaded by

Tiberiu CotoiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Deflection Control in Composite Building by Using Belt Truss and Outriggers Systems

Uploaded by

Tiberiu CotoiCopyright:

Available Formats

World Academy of Science, Engineering and Technology

Vol:4 2010-12-22

Deflection Control in Composite Building by

Using Belt Truss and Outriggers Systems

S. Fawzia and T. Fatima

International Science Index Vol:4, No:12, 2010 waset.org/Publication/9029

AbstractThe design of high-rise building is more often dictated

by its serviceability rather than strength. Structural Engineers are

always striving to overcome challenge of controlling lateral

deflection and storey drifts as well as self weight of structure

imposed on foundation.

One of the most effective techniques is the use of outrigger and

belt truss system in Composite structures that can astutely solve the

above two issues in High-rise constructions.

This paper investigates deflection control by effective utilisation

of belt truss and outrigger system on a 60-storey composite building

subjected to wind loads. A three dimensional Finite Element Analysis

is performed with one, two and three outrigger levels. The reductions

in lateral deflection are 34%, 42% and 51% respectively as compared

to a model without any outrigger system. There is an appreciable

decline in the storey drifts with the introduction of these stiffer

arrangements.

KeywordsComposite building, belt truss, deflection, FE model,

outrigger truss, 3D analysis.

I. INTRODUCTION

the last few decades several buildings have been

built utilizing belt truss and outrigger system for the

lateral loads transfer (throughout the world). This system is

very effective when used in conjunction with the composite

structures especially in tall buildings (Fig 1).

URING

Fig. 1 Multi-level belt truss and outrigger

S. Fawzia is with Department of Urban Development, Faculty of Built

Environment and Engineering, Queensland University of Technology,

Brisbane 4000, Australia. (Phone: 617-31381012; fax: 617-3138 1170; email: sabrina.fawzia@qut.edu.au).

Tabassum Fatima is with Department of Urban Development, Faculty of

Built Environment and Engineering, Queensland University of Technology,

Brisbane 4000, Australia. (e-mail: tabassum.fatima@qut.edu.au).

International Scholarly and Scientific Research & Innovation 4(12) 2010

Taranath, [1], states that apart from economy of material

and speed of construction, composite structures due to being

light weight inflict less severe foundation conditions hence

results in greater cost savings. Moreover; stiffness of concrete

is more effective in controlling the drifts caused by lateral

loads.

An example is 53 storeys Chifley tower, constructed in

1992 Sydney, Australia. This building exploits the composite

construction along with the use of belt truss and outrigger

system for deflection control. It has central steel braced frame

core and outriggers placed at two levels along the building

height.

Gunel and Ilgin [2], documented that belt truss and

outrigger is basically an evolution of braced frame or shear

wall framed system.

The belt truss tied the peripheral column of building while

the outriggers engage them with main or central shear wall.

Therefore; exterior columns restrained the core wall from free

rotation through outrigger arms. This system is also effective

in the control of differential settlement of columns.

Iyengar [3], demonstrated the deflection control on a two

dimensional model with the use of outriggers trusses. A 25%

reduction is achieved by the use of this system as well as 32%

reduction is attained with steel exterior column.

Kian and Siahaan [4], has studied effectiveness of belt truss

and outrigger in concrete high rise building. They have shown

that deflections can be controlled effectively by the efficient

use of this arrangement.

The effectiveness of belt truss and outrigger arrangement is

an established fact, though; there is always argument on the

reduction of operational space at the outrigger level. This

however; can be minimized by the use of diagonal cross

bracing mostly in line with columns as well as use of

horizontal truss that can be embedded in the false ceiling.

Nair, [5], proposed the concept of virtual outrigger

system where floor diaphragms, which are typically very stiff

and strong in their own plane, transfer moment in the form of

a horizontal couple from the core to trusses or walls that are

not connected directly to the core.

Composite structure has long been established itself as a

distinctive construction system which is a blend of structural

steel and reinforced concrete. However; there is a lacking of

detailed investigation on various aspects of this system and

one being the effective utilisation of Belt truss and Outrigger

system in Composite buildings for lateral deflections control.

As contrast to concrete structure composite construction

utilises the use of structural steel section in columns that

results in higher strength but less section size and thereby

646

World Academy of Science, Engineering and Technology

Vol:4 2010-12-22

reducing the stiffness of vertical building elements. In the

same way profiled sheeting serve as sagging reinforcement

increasing the strength and reducing the cross-section areas of

slab. These results in lower self weight, but; their behaviour

to the lateral loads and provision of cross bracings need to be

examined. Therefore; this paper presented the impact of steel

diagonal outriggers and belt truss system when used with a

composite high-rise building.

TABLE I

MODEL STRUCTURAL CONFIGURATION

Element

Slab

Main and Secondary

Beams

Column

Core wall

Belt Truss and

outriggers

International Science Index Vol:4, No:12, 2010 waset.org/Publication/9029

II. MODELLING DESCRIPTION:

The equivalent transformed properties of the structural

elements i.e. composite slab and composite columns have

been used in a three dimensional model to get the maximum

realistic behaviour of the building under dynamic wind loads.

These loads are calculated for 25 years return period based on

the guidelines provided in Australian Standard, Appendix C

[6]. The full advantage of the various structural components is

achieved through three dimensional (3D) analysis of building

in Strand7 [7] software.

Provision of two and more outriggers is desirable in most of

slender and tall structures. This is to provide sufficient

stiffness and avoid undesirable vibrations and discomfort to

the tenants as well as to supply additional stability against the

higher lateral loads. Therefore the option of three outrigger

arrangement is also investigated in this paper.

CTBUH (Council on Tall buildings and Urban Habitat)

provides no specific definition of a tall building and argued

that the defining factors are its location whether it is situated

in Hong Kong or in a provisional European suburb. Therefore

in this case, the criterion of height selection is solely based on

the urban norm of Australia. The floor to floor height chosen

is also being used as a general practice in offices to facilitate

concealment of the service ducts, wiring etc.

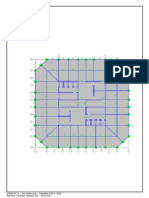

A typical layout has been selected with 5 equal bays (7400

mm) in long direction (X-Axis) and 3 bays of different size in

short direction (Y-direction) as shown in (Fig. 2). Structural

modelling configuration used for modelling is given in Table

1.

Description

Concrete deck with profiled sheeting

Structural Steel Universal Beam

sections.

Steel WC and UC section encased in

reinforced concrete

Reinforced concrete

Structural Steel Universal column

sections

A. Model assumptions:

1) The model is 60 storeys with floor to floor height of 3.5 m

making total height of the building as 210m (Fig. 3).

Belt truss at

different levels

210 m

Fig.3 Strand7 3D building elevation

2) Braced core frame i.e. reinforced concrete core acting in

conjunction with the belt truss and outrigger provides the

resistance to the wind loads (Fig. 4, 5, 6, 7).

Fig. 2 Floor Layout

International Scholarly and Scientific Research & Innovation 4(12) 2010

647

World Academy of Science, Engineering and Technology

Vol:4 2010-12-22

Steel primary and

secondary beams

Reinforced

concrete core

Composite

column

Fig.7 Strand7 3D enlarged view of floor layout

International Science Index Vol:4, No:12, 2010 waset.org/Publication/9029

Fig. 4 Strand7 3D view of floor layout

4) The axial stiffness of the central core and column

decreases linearly with the structural height.

5) Fixed support is provided to the core at the base while

column are pinned (Fig. 8).

Pinned Support

at columns

Belt truss

Fixed Support

at Core

Fig.5 Strand7 3D view of floor slab and belt truss

Belt truss wrapping

the external columns

Outriggers as

cross bracings

Fig. 8 Strand7 3D view showing support conditions

6) One level outrigger is provided in all options.

7) Steel sections are chosen from ASI design capacity tables

for the calculation of column equivalent transformed

properties [9].

8) Lysaght bondek manual is used for the properties of

profiled metal sheeting [10].

To get the maximum effects of composite system equivalent

transformed properties of slabs and columns are calculated for

the model. Slab consists of metal sheeting with concrete

topping while WC and UC sections are used in columns.

Fig.6 Strand7 3D view of Outrigger and belt truss

Transformed Elastic Modulus of composite Section is:

AcEc + ASTEs = AgET

3) Simple construction is adopted for this building based on

definition provided in Australian Standards [8]. Rotation

end releases are provided to all beams to get the pinned

action. Therefore columns only provide the gravity load

path to the base.

Transformed Density of Composite Section is:

Acc + ASTs = AgT

Here:

Ag = Gross area of section

Ac = Area of concrete

AST = Area of steel

Ec = Elastic modulus of concrete

Es = Elastic Modulus of steel

ET= Elastic modulus of transformed section

c =Density of concrete

s = Density of steel

International Scholarly and Scientific Research & Innovation 4(12) 2010

648

World Academy of Science, Engineering and Technology

Vol:4 2010-12-22

T = density of transformed section

The building is analysed for the Dynamic along wind

response applied to the weak axis of the building. The wind

loads are calculated based on Australian standards [11] for

Non-cyclonic region B and terrain category 4. The regional

wind speed of 39 m/s is considered for an annual probability

of exceedance of 1/25. The loads are varied along the height

of the structure (Fig.9).

International Science Index Vol:4, No:12, 2010 waset.org/Publication/9029

Fig. 10 Comparison of various outrigger options

TABLE II

MAXIMUM DISPLACEMENT AND PERCENTAGE REDUCTION IN DEFLECTION

FOR EACH OPTION

Fig. 9 Diagrammatic representation of variable wind loads

B. Basic model arrangements:

1) Model without belt truss and outrigger (MT0).

2) Model with one belt truss and outrigger (MT1).

Various models are run in order to get the optimum

location of the belt truss.

3) Model with double belt truss and out rigger (MT2).

This model has one belt truss and outrigger fixed at top

level, whereas many models has been run to find the

optimum placement of second outrigger.

4) Model with three belt truss and outrigger (MT3).

One location for the belt truss and outrigger is fixed at the

top level whereas the many models have been run to get

the best location of rest of the two cross bracings.

Outrigger Options

MT0

MT1

MT2

MT3

@ Top (mm)

1855.21

1219.4

1073.80

% Reduction in

34%

42%

913.63

51%

There is a sudden fluctuation and change in the gradient of

slope with the addition of outrigger levels as can be seen in

Fig.11. The outrigger levels for MT1and MT2 are level 36,

level 32 respectively whereas outriggers are provided at level

25 and Level 35 for MT3.This variation indicates the higher

stiffness at these levels. This stiffness is helping the structure

to control the inter-storey drift and consequently minimising

the displacements of the building. a similar trend in the

percentage reduction of storey drift is also obtained (Table 3)

as is present in deflection reduction of different outrigger

arrangements.

III. RESULTS

The use of outrigger and the belt truss has improved the

serviceability of the structure. Four options are compared in

Fig.10, including the structure without any outriggers. The

results show appreciable decline in the deflection with the use

of outrigger system. There is 34% reduction by the use of one

outrigger at the effective level. Whereas 41% and 51% drop is

achieved by the use of two and three outrigger levels with

respect to MT0 (Table 2).

International Scholarly and Scientific Research & Innovation 4(12) 2010

Fig. 11 Storey drifts comparison of various outrigger options

649

World Academy of Science, Engineering and Technology

Vol:4 2010-12-22

TABLE III

MAXIMUM STOREY DRIFT AND PERCENTAGE REDUCTION IN STOREY

DRIFT () FOR EACH OPTION

International Science Index Vol:4, No:12, 2010 waset.org/Publication/9029

Outrigger Options

Max. drift (mm)

MT0

1.14E-02

MT1

7.23E-03

MT2

6.59E-03

MT3

5.61E-03

% Reduction in

37%

42%

51%

Fig. 12 shows that the best location for one outrigger option

(MT1) is at level 36, i.e. 0.6 times the height of the structure.

The best location for second outrigger of two outrigger system

(MT2) is 0.5 times the structure height while one is fixed at

the top level Fig. 13.

Three outrigger options is run for various arrangements of

levels (see Table 4). The optimum location obtained as can be

seen in Fig.14, is MT3_1 which has outriggers at level 25 and

level 35 while one is provided at the top level. It is noted that

an additional 17% reduction in deflection is obtained by the

introduction of the two outrigger levels at the optimal position

along the structure height.

Fig. 14 Optimum Location of Outrigger for MT3

TABLE IV

VARIOUS ARRANGEMENTS FOR THREE OUTRIGGER

OPTIONS

Type

Outrigger Levels

MT3_1

L60

L25

L35

MT3_2

L60

L30

L40

MT3_3

L60

L30

L45

MT3_4

L60

L30

L50

MT3_5

L60

L35

L45

MT3_6

L60

L15

L45

MT3_7

L60

L40

L50

MT3_8

L60

L20

L40

IV. CONCLUSION

Fig. 12 Optimum Location of Outrigger for MT1

The rigorous three dimensional analyses provided very

approving results in the form of effective deflection control in

somewhat slender and tall structure. The Belt truss and

outrigger system is not only proficient in controlling the

overall lateral displacement but also very capable of reducing

the inter-storey drifts in composite building.

The introduction of two and three outrigger levels results in

a further 8% and 9% deflection reduction respectively. A

comparable fashion can be seen in the reduction of inter-storey

drifts as in displacements.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

Fig. 13 Optimum Location of Outrigger for MT2

[7]

International Scholarly and Scientific Research & Innovation 4(12) 2010

650

B.S. Taranath, Structural Analysis & Design of Tall Buildings. New

York, Mc Graw Hill, 1998.

M. H. Gunel, and H.E. Ilgin, A proposal for the classification of

structural systems of tall buildings. Faculty of Architecture, Middle East

Technical University, Ankara 06531, Turkey, 4 July 2006.

I. Hal, Composite and Steel High Rise Systems. Habitat and The HighRise, Tradition & Innovation. In Proceedings of the Fifth World

Congress. 14-19 May 1995.Amsterdam, The Netherlands, Bethlehem,

Pa : Council on Tall Building and Urban Habitat, Lehigh University

P.S. Kian and F.T.Siahaan, The use of outrigger and belt truss system

for high-rise concrete buildings. Dimensi Teknit Sipil, Volume 3, No1,

Maret 2001, Page 36-41,ISSN1410-9530.

R. S. Nair, Belt Trusses and Basements as Virtual Outriggers for Tall

Buildings. Engineering Journal / Fourth Quarter/ 1998.

Standards Australia/Standards New Zealand, Structural design actions,

Part 0: General principles, Appendix C, Guidelines for Serviceability

Limit State (Informative), AS/NZS 1170.0:2002.

Strand7 Pty Ltd. Strand7, Finite Element Analysis System, Users

Manual 2005, Sydney, Australia.

World Academy of Science, Engineering and Technology

Vol:4 2010-12-22

Standards Australia, Steel Structure, , AS 4100:1998.

Australian Steel Institute (ASI), Design Capacity Tables, Volume 1,

Fourth edition 2009.

[10] BlueScope Lysaght Manual, Using Bondek- design and construction

guide 2003 edition, BlueScope Steel limited, Australia.

[11] Standard Australia/Standard New Zealand ,Structural design actions

Part 2: Wind actions, ASNZS 1170.2:2002

International Science Index Vol:4, No:12, 2010 waset.org/Publication/9029

[8]

[9]

International Scholarly and Scientific Research & Innovation 4(12) 2010

651

You might also like

- Anexa CopertinaDocument41 pagesAnexa CopertinaTiberiu CotoiNo ratings yet

- Thesis Final Document Tall BuildingsDocument194 pagesThesis Final Document Tall BuildingsPab Fer Man100% (3)

- Neeraj Agrawal Seminar PresentationDocument27 pagesNeeraj Agrawal Seminar PresentationTiberiu CotoiNo ratings yet

- The Construction of Super High-Rise Composite Structures in Hong KongDocument98 pagesThe Construction of Super High-Rise Composite Structures in Hong KongJevgenijs Kolupajevs100% (2)

- Deflection Control in High Rise Building Using Belt Truss and Outrigger SystemsDocument10 pagesDeflection Control in High Rise Building Using Belt Truss and Outrigger SystemsTiberiu CotoiNo ratings yet

- Dam Engineering GRV BUTTDocument74 pagesDam Engineering GRV BUTTTiberiu CotoiNo ratings yet

- Outrigger PositionDocument14 pagesOutrigger PositionKevinWongNo ratings yet

- AXIALADocument1 pageAXIALATiberiu CotoiNo ratings yet

- SLS (Adm) : OK OK OK OK OK OK OKDocument2 pagesSLS (Adm) : OK OK OK OK OK OK OKTiberiu CotoiNo ratings yet

- Cursuri UrbanismDocument18 pagesCursuri UrbanismTiberiu CotoiNo ratings yet

- ETABS v9.7.4 - File: Proiect Drug - September 2,2014 19:58 Plan View - TERASA - Elevation 125 - KN-M UnitsDocument1 pageETABS v9.7.4 - File: Proiect Drug - September 2,2014 19:58 Plan View - TERASA - Elevation 125 - KN-M UnitsTiberiu CotoiNo ratings yet

- Tall Buildings in Numbers: The Economics of High-Rise (As Per 2 Quarter 2010)Document2 pagesTall Buildings in Numbers: The Economics of High-Rise (As Per 2 Quarter 2010)Tiberiu CotoiNo ratings yet

- ETABS v9.7.4 - File: Proiect Drug - September 2,2014 19:58 Plan View - TERASA - Elevation 125 - KN-M UnitsDocument1 pageETABS v9.7.4 - File: Proiect Drug - September 2,2014 19:58 Plan View - TERASA - Elevation 125 - KN-M UnitsTiberiu CotoiNo ratings yet

- Cover LetterDocument1 pageCover LetterTiberiu CotoiNo ratings yet

- Soil Layers PDFDocument3 pagesSoil Layers PDFAndrei LazarescuNo ratings yet

- Specify Soil Strength Parameters for Pile Group AnalysisDocument2 pagesSpecify Soil Strength Parameters for Pile Group AnalysisVlad GrigoreanNo ratings yet

- ERASMUS - Lista Domenii Acorduri BilateraleDocument2 pagesERASMUS - Lista Domenii Acorduri BilateraleTiberiu CotoiNo ratings yet

- Specify Soil Strength Parameters for Pile Group AnalysisDocument2 pagesSpecify Soil Strength Parameters for Pile Group AnalysisVlad GrigoreanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- XRD Standard Patterns of ZeoliteDocument586 pagesXRD Standard Patterns of ZeoliteVijaykumar MarakattiNo ratings yet

- Blocks CatalogueDocument14 pagesBlocks CatalogueshajbabyNo ratings yet

- Skylab 3 PAO Mission Commentary 3 of 6Document851 pagesSkylab 3 PAO Mission Commentary 3 of 6Bob AndrepontNo ratings yet

- Calibration scope scheduleDocument30 pagesCalibration scope scheduleEjad AfifiNo ratings yet

- Ghali and Megally (1995) - Design For Punching Shear Strength With ACI 318-95Document10 pagesGhali and Megally (1995) - Design For Punching Shear Strength With ACI 318-95Zsuzsa BiróNo ratings yet

- Cotton Dyeing With Natural Dye Extracted From Pomegranate PDFDocument5 pagesCotton Dyeing With Natural Dye Extracted From Pomegranate PDFAmalia RizkaNo ratings yet

- 2.2 Flow Around A Cylinder: The Open Source CFD ToolboxDocument7 pages2.2 Flow Around A Cylinder: The Open Source CFD ToolboxAnand JadoenathmisierNo ratings yet

- Metrology MCQDocument6 pagesMetrology MCQsivakumarNo ratings yet

- DERIVATION OF THE PLASMA DEBYE LENGTHDocument2 pagesDERIVATION OF THE PLASMA DEBYE LENGTHziad0967% (3)

- Nas 107Document498 pagesNas 107lw_ponchNo ratings yet

- Training Report at Structural ConsultancyDocument111 pagesTraining Report at Structural ConsultancyKaushal Patel100% (1)

- Fin FET and Solar CellDocument6 pagesFin FET and Solar CellwixaNo ratings yet

- Masterdrives (Motion Control)Document16 pagesMasterdrives (Motion Control)Abdullah TalibNo ratings yet

- Algorithm For Automated Mapping of Land Surface Temperature Using LANDSAT 8 Satellite DataDocument9 pagesAlgorithm For Automated Mapping of Land Surface Temperature Using LANDSAT 8 Satellite DataNicolas CelisNo ratings yet

- FM Sol Chap12-131Document41 pagesFM Sol Chap12-131CEMONo ratings yet

- Unit 6 WKST 4 Answer Key RevDocument3 pagesUnit 6 WKST 4 Answer Key RevTushar Raj83% (6)

- Stiffness Matrix of Parabolic Beam Element: (Received February 1988)Document8 pagesStiffness Matrix of Parabolic Beam Element: (Received February 1988)Milica BebinaNo ratings yet

- Rolling DefectsDocument6 pagesRolling DefectsAhmed Kaoud Sakr100% (1)

- Cane Cal 12 X 40Document2 pagesCane Cal 12 X 40Herik AziziNo ratings yet

- 04Document267 pages04Jorge David Vallejo EspinozaNo ratings yet

- Thermodynamics & KineticsDocument113 pagesThermodynamics & KineticsAMMASI A SHARAN0% (1)

- Reinforced Earth Bearing CapacityDocument2 pagesReinforced Earth Bearing CapacityAlisha GarzaNo ratings yet

- Aptis Reading TestDocument6 pagesAptis Reading TestRussel80% (5)

- 11-2001-Application of Tabu Search To Optimal Placement of Distributed GeneratorsDocument6 pages11-2001-Application of Tabu Search To Optimal Placement of Distributed GeneratorsAbbas DivianNo ratings yet

- Colloids and Surfaces A: Physicochemical and Engineering AspectsDocument11 pagesColloids and Surfaces A: Physicochemical and Engineering AspectsPpa Gpat AmitNo ratings yet

- Attributes of Technical WritingDocument9 pagesAttributes of Technical WritingJames Mason0% (1)

- r75 Body ElectricsDocument91 pagesr75 Body ElectricsJohnCharlesNo ratings yet

- ANSYS 8.1 - Structural Analysis GuideDocument478 pagesANSYS 8.1 - Structural Analysis GuideMohammed Abd El Rahman100% (19)

- Wedge Wire ScreensDocument5 pagesWedge Wire Screensamolthakur24No ratings yet

- LG Power Supply Reference GuideDocument29 pagesLG Power Supply Reference GuideOrlando Jose PascuaNo ratings yet