Professional Documents

Culture Documents

AFFETTI Pumps Series CGV-CGV-N

Uploaded by

Sarmad Ali ShahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AFFETTI Pumps Series CGV-CGV-N

Uploaded by

Sarmad Ali ShahCopyright:

Available Formats

Pumps for corrosive liquids

Pompe centrifughe

verticali con

supporto

e giunto

elastico

Centrifugal sump

pumps with

support

and elastic

coupling

series

CGV

CGV-N

CGV-N

1 Tubo di mandata in termoplastico .

2 Corpo-pompa in PP, PVDF, PEHD ricavato interamente da lavorazione meccanica. Per le macchine

25-125, 32-125, 40-130, 40-160, 50-160, il pezzo viene

stampato ad iniezione solo in PP e PVDF.

3 Girante centrifuga in PP, PVDF, PE-UHMW , (per le

macchine 25-100, 25-125, 32-125, 40-130, 40-160,

50-160, il pezzo realizzato solo in PP e PVDF) ;

versione semi-aperta per liquidi carichi e chiusa

per il pompaggio di soluzioni con temperature

elevate. Autobilanciamento assiale garantito da

contropalettature posteriori, inserto centrale metallico protetto .

4 Bussola di guida statica in PTFE CG (su richiesta

in SiC )

5 Motore elettrico asincrono trifase secondo la

normativa IEC (a richiesta NEMA).

6 Colonna costruita interamente in termoplastico

7 Piastra di elevato spessore in PP rinforzata con

una lamiera dacciaio.

8 Bussola di guida rotante in Al2O3 (su richiesta

in SiC) .

9 Albero bilanciato in acciaio al carbonio 39NiCrMo3,

strutturato per sopportare agevolmente forze torsionali e radiali. Ricavato completamente da barra

piena tramite lavorazione meccanica rivestito

completamente in termoplastico

10 Lanterna in ghisa contiene il supporto dei cuscinetti ed il giunto elastico e distanzia il motore dal

resto della pompa .

11 Supporto in acciaio alloggiano due cuscinetti a

sfere che guidano lalbero

12 Giunto elastico montato per assorbire eventuali disallineamenti dellasse, inoltre consente lo

smontaggio del motore senza dover rimuovere la

pompa

Legenda

PP

PVDF

PEHD

PE-UHMW

EPDM

FPM

FFKM

PTFE-CG

Al2O3

SiC

Legend

PP

PVDF

PEHD

PE-UHMW

EPDM

FPM

FFKM

PTFE-CG

Al2O3

SiC

polipropilene

oruro di polivinilidene

polietilene alto peso molecolare

polietilene ultra alto peso molecolare

etilenpropilene

uoroelastomero

peruoroelastomero

politetrauoruro etilene caricato

carbo-grate

allumina

carburo di silicio

polypropylene

polyvinylidene uoride

high molecular weight polyethylene

extra-high molecular weight

polyethylene

ethyl propylene diene monomer

uoroelastomer

peruoroelastomer

carbon-graphite reinforced

polytetrauoroethylene

alumina

silicon carbide

1 Thermoplastic discharge pipe.

2 Casing made of extra-thick PP, PVDF or PEHD, manufactured using mechanical machining processes.

For pump models 25-125, 32-125, 40-130, 40-160

and 50-160, the part is injection moulded and is

only available in PP or PVDF.

3 Centrifugal impeller in PP, PVDF or PE-UHMW (the

part is only available in PP or PVDF for pump models

25-100, 25-125, 32-125, 40-130, 40-160 and 50-160);

semi-open version for particle-loaded fluids or

closed for pumping solutions at high temperatures.

Axial self-balancing guaranteed by rear counterblades; protected central metal insert.

4 Static guide bushing in PTFE CG (SiC available

on request)

5 Three-phase asynchronous electric motor, in compliance with IEC (NEMA available on request).

6 Column manufactured entirely from thermoplastic

material.

7 Extra-thick PP plate reinforced with a sheet of

steel.

8 Revolving guide bushing in Al2O3 (SiC available

on request).

9 Balanced shaft made of 39NiCrMo3 carbon steel,

structured to easily support torsional and radial

forces. Made exclusively from solid bar stock using

mechanical machining processes and fully coated

in thermoplastic material.

10 Intermediate adaptor in cast iron contains the

support for the bearings and the elastic coupling and

distances the motor from the rest of the pump.

11 Steel support houses two ball bearings

that guide the shaft.

12 Elastic coupling tted to absorb any axial misalignment and allow the motor to be disassembled

without having to remove the pump

12

11

7

9

6

CGV CGV-N

10

Caratteristiche

generali

Adatta al pompaggio

di liquidi corrosivi in

Costruzione solida

Albero collegato

al motore tramite

giunto elastico e

guidato da bussole in

Al2O3 PTFE-CG

Motore e piastra

distanziati da una

lanterna

Facile manutenzione

Lunghezza della

colonna da 500 a

3000 mm

Verniciatura motore

e parti metalliche

primer epossidico

50/80 m pi strato

poliuretanico 70/80

m rosso RAL 3001

Materiali

Parti a contatto con

il liquido pompato

in PP PVDF PEHD

PE-UHMW

O-rings e guarnizioni

in EPDM FPM

FFKM

Albero in acciaio

39NiCrMo3 rivestito

in termoplastico

Temperature

desercizio

PP

0 C + 80 C

PVDF -10 C +100 C

PEHD -5 C + 70 C

Accessori

Attacco angiato in

mandata

Tettuccio parapioggia

motore

Filtro montato in

aspirazione

Tubo di prolunga

montato in

aspirazione

Raccordo di lavaggio

bussole di guida

General

characteristics

Suitable for pumping

corrosive uids

Solid construction

Shaft attached to the

motor with an elastic

coupling and guided

by Al2O3 - PTFE-CG

bushings

Motor and plate

distanced by an

intermediate adaptor

Easy to maintain

Column length from

500 to 3000 mm

Painting of motor and

metallic parts: 50/80

m epoxy primer

plus 70/80 m coat

of polyurethane RAL

3001 red

Materials

Parts in contact with

the uid pumped

made of PP PVDF

PEHD PE-UHMW

O-rings and seals in

EPDM FPM FFKM

Shaft in

thermoplastic-coated

39NiCrMo3 steel

Working

temperatures

PP

0 C + 80 C

PVDF -10 C +100 C

PEHD -5 C + 70 C

Accessories

Flanged connection

on discharge line

Motor rain guard

Filter on suction line

Extension pipe on

suction line

Guide bushing

washing tting

La bocca di mandata pu montare di serie ange

ISO (a richiesta ANSI o JIS). I motori installati sono

asincroni trifase e selezionati in base alle prestazioni

richieste e rispondono alle normative IEC (a richiesta

NEMA). Le frequenze disponibili sono 50 e 60 Hz

The discharge outlet is supplied with ISO ange

connections (ANSI or JIS connections are available

on request). The pumps are tted with three-phase

asynchronous motors, manufactured in accordance

with the IEC standard (NEMA available on request),

and selected according to the performance required.

50 and 60 Hz frequencies are available

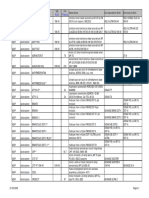

Dimensioni dingombro Overall dimensions

Type

32-125

32-200

40-130

40-160

40-200

50-160

50-200

50-250

50-315

65-125

65-160

65-200

65-250

80-200

80-250

80-315

100-250

150-250

150-315

Motor

min/max

80

132

90

160

80

132

80

160

80

160

80

160

90

200

100

225

100

160

90

160

90

160

90

180

90

160

90

225

112

180

112

200

100

180

132

225

160

280

480 400

710 540

530 450

610 500

710 540

610 500

715 550

720 565

870 550

670 500

670 500

710 540

750 570

710 534

760 570

950 550

864 570

930 600

1145 620

500-750-1000-1250-1500-1750-2000-2250-2500-2750-3000 (5)

CGV-N

M

345

420

345

420

345

420

345

420

345

420

345

420

345

435

345

480

345

420

345

420

345

420

345

420

345

420

345

480

345

420

345

435

345

420

345

480

345

480

N

26

36

36

36

36

36

50

50

50

36

36

50

50

50

50

50

50

55

55

0

210

400

250

500

210

400

210

500

210

500

210

500

250

620

300

690

300

500

250

500

250

500

250

570

250

570

250

690

330

570

330

620

300

570

400

690

500

830

dnAdnM A M a

50

32

2" 1" 100 140 18

"

50

32

2"

100 140 18

"

50

40

2"

" 110 150 18

"

65

40 2 " " 110 150 18

"

65

40 2 "

110 150 18

"

65

50 2 " 2" 125 165 18

"

80

50

3"

125 165 18

"

80

50

3"

125 165 18

"

80

50

3"

125 165 18

"

100 65

4"

145 185 18

"

100 65

4"

145 185 18

"

100 65

4"

145 185 18

"

100 65

4"

145 185 18

"

125 80

5"

160 200 18

"

125 80

5"

160 200 18

"

125 80

5"

160 200 18

"

125 100 5"

180 220 18

"

200 150 8"

240 290 22

"

200 150 8"

240 290 22

"

CGV

1 Tubo di mandata in termoplastico .

2 Corpo-pompa in PP, PVDF, PEHD ricavato interamente

da lavorazione meccanica. Per le macchine 25-125, 32125, 40-130, 40-160, 50-160, il pezzo viene stampato ad

iniezione solo in PP e PVDF.

3 Girante centrifuga in PP, PVDF, PE-UHMW, (per le macchine 25-100, 25-125, 32-125, 40-130, 40-160, 50-160, il

pezzo realizzato solo in PP e PVDF) ; versione semi-aperta

per liquidi carichi e chiusa per il pompaggio di soluzioni

con temperature elevate. Autobilanciamento assiale

garantito da contropalettature posteriori, inserto centrale

metallico protetto.

4 Bussola di guida statica in PTFE CG (su richiesta in SiC)

5 Motore elettrico asincrono trifase secondo la normativa

IEC (a richiesta NEMA).

6 Colonna costruita interamente in termoplastico

7 Piastra di elevato spessore in PP.

8 Bussola di guida rotante in Al2O3 (su richiesta in SiC) .

9 Albero bilanciato in acciaio al carbonio 39NiCrMo3,

strutturato per sopportare agevolmente forze torsionali

e radiali. Ricavato completamente da barra piena tramite

lavorazione meccanica rivestito completamente in

termoplastico

10 Lanterna in alluminio contiene il supporto dei cuscinetti ed il giunto elastico e distanzia il motore dal resto

della pompa .

11 Supporto in alluminio alloggiano due cuscinetti a sfere

che guidano lalbero

12 Giunto elastico montato per assorbire eventuali disallineamenti dellasse, inoltre consente lo smontaggio del

motore senza dover rimuovere la pompa.

1 Thermoplastic discharge pipe.

2 Pump-body made of extra-thick PP, PVDF or PEHD,

manufactured using mechanical machining processes.

For pump models 25-125, 32-125, 40-130, 40-160 and

50-160, the part is injection moulded and is only available

in PP or PVDF.

3 Centrifugal impeller in PP, PVDF or PE-UHMW (the part

is only available in PP or PVDF for pump models 25-100,

25-125, 32-125, 40-130, 40-160 and 50-160); semi-open

version for particle-loaded uids or closed for pumping

solutions at high temperatures. Axial self-balancing

guaranteed by rear counterblades; protected central

metal insert.

4 Static guide bushing in PTFE CG (SiC available on

request)

5Three-phase asynchronous electric motor, in compliance

with IEC (NEMA available on request).

6 Column manufactured entirely from thermoplastic

material.

7 Plate in extra-thick PP.

8 Revolving guide bushing in Al2O3 (SiC available on

request).

9 Balanced shaft made of 39NiCrMo3 carbon steel,

structured to easily support torsional and radial forces.

Made exclusively from solid bar stock using mechanical

machining processes and fully coated in thermoplastic

material.

10 Intermediate adaptor in aluminium contains the

support for the bearings and the elastic coupling and

distances the motor from the rest of the pump.

11 Aluminium support houses two ball bearings that

guide the shaft.

12 Elastic coupling tted to absorb any axial misalignment

and allow the motor to be disassembled without having

to remove the pump.

10

12

11

7

9

1

6

8

4

3

2

Legend

PP

polypropylene

PVDF

polyvinylidene uoride

PEHD

high molecular weight polyethylene

PE-UHMW extra-high molecular weight polyethylene

EPDM

ethyl propylene diene monomer

FPM

uoroelastomer

FFKM

peruoroelastomer

PTFE-CG

carbon-graphite reinforced

polytetrauoroethylene

Al2O3

alumina

SiC

silicon carbide

Legenda

PP

PVDF

PEHD

PE-UHMW

EPDM

FPM

FFKM

PTFE-CG

Al2O3

SiC

polipropilene

oruro di polivinilidene

polietilene alto peso molecolare

polietilene ultra alto peso molecolare

etilenpropilene

uoroelastomero

peruoroelastomero

politetrauoruro etilene caricato

carbo-grate

allumina

carburo di silicio

CGV

Dimensioni dingombro Overall dimensions

La bocca di mandata pu montare di serie ange

ISO (a richiesta ANSI o JIS). I motori installati sono

asincroni trifase e selezionati in base alle prestazioni

richieste e rispondono alle normative IEC (a richiesta

NEMA). Le frequenze disponibili sono 50 e 60 Hz

Type

25-100

25-125

32-125

32-200

40-130

40-160

40-200

50-160

50-200

65-125

65-160

Motor

min/max

71

90

80

100

80

112

90

160

80

132

80

160

80

160

80

160

90

200

90

160

90

160

410 350

410 350

480 400

710 540

530 450

610 500

710 540

610 500

710 540

670 500

750 570

500-750-1000-1250-1500-1750-2000-2250-2500-3000

(5)

The discharge outlet is supplied with ISO ange

connections (ANSI or JIS connections are available

on request). The pumps are tted with three-phase

asynchronous motors, manufactured in accordance

with the IEC standard (NEMA available on request),

and selected according to the performance required.

50 and 60 Hz frequencies are available.

170

200

200

226

200

226

200

288

200

268

200

268

200

288

200

288

200

288

200

288

200

288

N

20

20

20

30

30

30

30

30

40

30

30

dnAdnM A M a

176

40 25

226

209

40 25

272

209

50 32

299

226

50 32

455

209

50 40

370

209

65 40

390

209

65 40

390

209

65 50

455

248

80 50

500

248

100 65

455

248

100 65

455

1 " 1"

85 100 14

"

1 " 1"

85 100 14

"

2" 1 " 100 140 18

"

2"

100 140 18

"

2" 1 " 110 150 18

"

1" 110 150 18

"

110 150 18

"

2 " 1 " 125 165 18

"

2"

2 "

3"

125 165 18

"

4"

145 185 18

"

4"

145 185 18

"

2900 RPM/50 Hz

US gpm

1450 RPM/50 Hz

US gpm

3450 RPM/60 Hz

US gpm

1750 RPM/60 Hz

US gpm

Curve caratteristiche

Tutte le macchine prodotte sono sottoposte, una per

una, a tests idromeccanici con acqua a temperatura

di 18C e sono garantite no a PN10.

Characteristic curves

All of the pumps manufactured are subjected to

hydro-mechanical tests, one by one, with water

at a temperature of 18C and are guaranteed up

to PN10.

I dati di questo catalogo sono indicativi ma non

impegnativi e possono subire delle variazioni senza

alcun preavviso.

The data contained in this catalogue is indicative but

not binding and may be subject to change without

any prior warning.

Pumps for corrosive liquids

tel. +39 331 503358 +39 331 505595

fax. +39 331 483007

e-mail for Italy: vendite@aetti

e-mail for others countries : export@aetti.com

web site:www.aetti.com

Distributore autorizzato - Authorized distributor

Graca e stmpa: Real Arti Lego - Il Guado - Corbetta (MI)

AFFETTI GIUSEPPE & C. s.n.c

Via P. Maroncelli , 4

21053 CASTELLANZA (VA) - ITALY

You might also like

- Catalogo Chero PipingDocument28 pagesCatalogo Chero PipingAnonymous JwmreatNo ratings yet

- Esquema Hidraulico 2Document14 pagesEsquema Hidraulico 2israel ruiz gallardoNo ratings yet

- Material ListDocument752 pagesMaterial ListSandip RoutNo ratings yet

- Valve TormeneDocument8 pagesValve TormeneIrvansyah RazadinNo ratings yet

- C01 01 00 Rev 3Document14 pagesC01 01 00 Rev 3Salvatore IgnazziNo ratings yet

- KKS Sistema Identificazione Impianti: 2 0 HAD 10 CL 901Document1,247 pagesKKS Sistema Identificazione Impianti: 2 0 HAD 10 CL 901Mayur Gupta100% (1)

- Catalogo HDPEDocument88 pagesCatalogo HDPEtrifiloNo ratings yet

- Tubo Di Rame Per Impianti ITADocument56 pagesTubo Di Rame Per Impianti ITAAnonymous f3iGLjxNo ratings yet

- ESERCIZITAZIONI Trasporto FluidiDocument44 pagesESERCIZITAZIONI Trasporto FluidiFranco RossiNo ratings yet

- Catalogxxx CXDocument282 pagesCatalogxxx CXCristian Ramos PNo ratings yet

- Manuale PEADDocument155 pagesManuale PEADlollazzoNo ratings yet

- A5678A16-E-030 - 02 Instrument & Control Wiring and Interconnecting DiagramDocument51 pagesA5678A16-E-030 - 02 Instrument & Control Wiring and Interconnecting Diagramwael zakariaNo ratings yet

- Centrifugal Pumps PROMIXDocument16 pagesCentrifugal Pumps PROMIXBenicio Joaquín Ferrero BrebesNo ratings yet

- 5 Mu-L&lds PDFDocument12 pages5 Mu-L&lds PDFMohd NazriNo ratings yet

- SILVERSON Mixer IndustrialiDocument32 pagesSILVERSON Mixer Industrialipippo2378793No ratings yet

- MuroniDocument25 pagesMuronibrujieNo ratings yet

- Pbpnu35322 Gme3780159 Rev C As Built Electrical Load ListDocument9 pagesPbpnu35322 Gme3780159 Rev C As Built Electrical Load ListChampa Jiménez de CostanillasNo ratings yet

- 01 02 Tubazioni - PPHDocument8 pages01 02 Tubazioni - PPHSami ThirunavukkarasuNo ratings yet

- Nuovo Pignone: Dynamic Simulation Study (Feed Gas Service 231-001A/B)Document17 pagesNuovo Pignone: Dynamic Simulation Study (Feed Gas Service 231-001A/B)Noman Abu-FarhaNo ratings yet

- Faro Bearings Catalog PDFDocument36 pagesFaro Bearings Catalog PDFdNo ratings yet

- CSM MotorsDocument85 pagesCSM MotorswazjhebkNo ratings yet

- Progetto Preliminare-Relazione TecnicaDocument38 pagesProgetto Preliminare-Relazione TecnicaMauro MLRNo ratings yet

- DIN2353 Rev19 2 3 PDFDocument161 pagesDIN2353 Rev19 2 3 PDFfabioNo ratings yet

- 10.1 - KSB-Criteri Di Scelta Delle Pompe CentrifugheDocument46 pages10.1 - KSB-Criteri Di Scelta Delle Pompe Centrifughetony995No ratings yet

- Gearbox - BonfiglioliDocument29 pagesGearbox - BonfiglioliKiran Kumar0% (1)

- Uni en 12845 2009 PDFDocument152 pagesUni en 12845 2009 PDFluigicorvaglia100% (1)

- Atti Safap2016Document861 pagesAtti Safap2016Pingu3No ratings yet

- pn16 25Document3 pagespn16 25marpadanNo ratings yet

- Cataloge PumpDocument9 pagesCataloge PumpahmedNo ratings yet

- Udor Man Uso It-En Gen (7202080577)Document20 pagesUdor Man Uso It-En Gen (7202080577)Yipper ShnipperNo ratings yet

- Libretto e Let Tro Pompe at ExDocument40 pagesLibretto e Let Tro Pompe at ExMohammad ElbaghatiNo ratings yet

- Onda C-Rev.-1.1-2016Document20 pagesOnda C-Rev.-1.1-2016Manoj ManivasagamNo ratings yet

- GMT HPDocument2 pagesGMT HPsrinivasan81No ratings yet

- Spe FlexDocument7 pagesSpe FlexmarcopasottiNo ratings yet

- ECM 18 ATEX 2599 CertificateDocument2 pagesECM 18 ATEX 2599 CertificateJawad AziziNo ratings yet

- Specifica 1110Document2 pagesSpecifica 1110tutusNo ratings yet

- Tubazioni ESERCIZIDocument11 pagesTubazioni ESERCIZIEnzoNo ratings yet

- Gasd A.01.20.01.03Document3 pagesGasd A.01.20.01.03ELNA83No ratings yet

- Simbologia Pneumatica PDFDocument4 pagesSimbologia Pneumatica PDFmarioNo ratings yet

- Catalogo Generale CameDocument256 pagesCatalogo Generale CameS.S.I Forniture ProfessionaliNo ratings yet

- Flange APIDocument7 pagesFlange APIPopovici AlexandruNo ratings yet

- Speroni 2015 It GBDocument260 pagesSperoni 2015 It GBFelipe ChNo ratings yet

- Cap 1 SerbatoiDocument9 pagesCap 1 SerbatoiGiulio VezzelliNo ratings yet

- Anti SurgeDocument13 pagesAnti Surgebaheaja1059100% (1)

- NPSH KSBDocument3 pagesNPSH KSBbefana63No ratings yet

- Professione Imballatore PDFDocument522 pagesProfessione Imballatore PDFBrooke CraigNo ratings yet

- Sapitflex Disc Coupling CatalogueDocument50 pagesSapitflex Disc Coupling CatalogueJas SumNo ratings yet

- Catalogo FornaraDocument66 pagesCatalogo FornaraNadaNo ratings yet

- Raggio Critico IsolanteDocument4 pagesRaggio Critico IsolantebearsmordeNo ratings yet

- Dimensionamento Degli Impianti REMIDocument90 pagesDimensionamento Degli Impianti REMIMarco CarrieriNo ratings yet

- Scheda Tecnica Sesalit Plus-GDocument1 pageScheda Tecnica Sesalit Plus-Ganderson añezNo ratings yet

- ABAC CatalogDocument119 pagesABAC CatalogmahdiNo ratings yet

- Garioni Naval - Thermal Oil HeaterDocument9 pagesGarioni Naval - Thermal Oil HeatergarioninavalNo ratings yet

- Air Compressor Chicago PneumaticDocument2 pagesAir Compressor Chicago PneumaticmoisexyNo ratings yet

- L20 Flow Control RBS Maintenance ManualDocument40 pagesL20 Flow Control RBS Maintenance ManualFiq GanuNo ratings yet

- Tabelle CORRISPONDENZA PDFDocument159 pagesTabelle CORRISPONDENZA PDFSara Mayerlin Ramos PáezNo ratings yet

- SPERONI 2020 Rev14Document306 pagesSPERONI 2020 Rev14Ahmed SamirNo ratings yet

- Upa 150 CDocument14 pagesUpa 150 Cajrojas1359No ratings yet

- Ac 09Document8 pagesAc 09yudiltaufikumarNo ratings yet

- FinderPump HCV PDFDocument8 pagesFinderPump HCV PDFGeorge_Wabag_2014No ratings yet

- Catedral de La Habana - CupelloDocument3 pagesCatedral de La Habana - CupelloGreta BrunoNo ratings yet

- Itr PartesDocument117 pagesItr PartesAdrian cota100% (2)

- Istruzioni Di Posa Porta PDFDocument48 pagesIstruzioni Di Posa Porta PDFmizar_10No ratings yet

- Azioni Sulle Costruzioni (Vento Si Capisce QLCS)Document68 pagesAzioni Sulle Costruzioni (Vento Si Capisce QLCS)Claudio PaganiNo ratings yet