Professional Documents

Culture Documents

1,023,695, Patented Apr. 16, 1912.: G. Walther

Uploaded by

dfdfsdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1,023,695, Patented Apr. 16, 1912.: G. Walther

Uploaded by

dfdfsdCopyright:

Available Formats

G. WALTHER.

DRIVING MECHANISM FOR THBEAD- GUIDE BARS.

APPLICATION FILED MAR. 25, 1911.

1,023,695,

Patented Apr. 16, 1912.

Jnveniars

M212 es: e; -

MW

COLUMBIA PLANOuiiAPI-I 120., WASHINGTON, D c.

TED STATES PATENT OFFTCE.

CARL WAL'II-IER, 0F CHEMNITZ, GERMANY.

DRIVING MECHANISM FOR THREAD-GUIDE BARS.

1,023,695.

Speci?cation of Letters Patent.

Application ?led March 25, 1911.

To all whom it may concern :

Patented Apr. 16, 1912.

Serial No. 616,983.

a variable traverse and to which the thread

Be it known that I, CARL WALTHER, a

25 are ?xed is furnished with a lug

subject of the German Emperor, residing at guides

6. If the bar 5 is shifted in the direction as,

Chemnitz, in the Kingdom of Saxony and the arm or latch It strikes the lug 6 and the

Empire of Germany, have invented certain bar 7 must move therewith in the same di

new and useful Improvements in Driving

60

rection 00. As shown in Fig. 3 the lever

Mechanism for Thread-Guide Bars, of which A can also be thrown upward, so that the

the following is a speci?cation.

'

In many cases in the construction of ma

10

chines it happens that a heavy object con

tinually moves to and fro on a rectilineal

15

way. If this object at the end of its course,

runs against a ?xed body a serious shock

and consequent damage results to one or

both bodies.

The purpose of the present invention is

to avoid this violent contact of parts by

arm or latch 4 and the lug 6 are not in con

tact. The rod 19 is furnished wit-h a head 65

8, and is itself held by a spring 20 in nearly

the same position, as is illustrated in Fig. 2.

The rod 19 generally stands still, and if the

arm or latch 4 is moved in the opposite di

rect-ion, the arm 4 then encounters the oblique

70

face of the head 8 and is turned out as seen

in Fig. 3. Just such a rod as 19 to the right

side is also arranged, 19, to the left side of

retarding the speed of the moving element the

machine. The rod 19' is provided with

in the last moments of its motion.

just such a head 8 and with a spring 20.

75

In the inclosed drawing an instance of the

In the frame of the machine the fashion

construction of the invention in a straight ing screw 15 is mounted. On this screw 15

knitting frame is illustrated.

rests a nut 16. On the nut 16 is arranged a

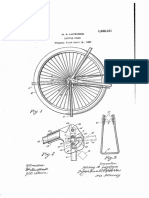

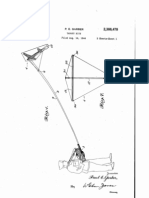

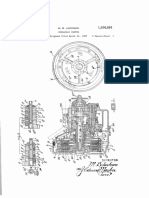

Figure 1 is a front view of the device. bolt 22, which serves as center of motion

Fig. 2 shows enlarged detailed views of

25 parts of the device shown in Fig. 1 when for the crank lever-10, 21. A vertical arm 80

seen from above. Fig. 3 is a vertical cross

section on the line AB of Fig. 1. '

17 is secured on the nut'l6 and carries an

adjusting screw 26 and is, besides, fur

nished with a sloping head 13. The said

The part which is moved to and fro, the crank lever 10, 21 has arranged on its arm

motion of which is to be retarded at the 21 a roller 23, and on the other arm a pawl

30 end of its run, is the rod 7, to which the

1.1 jointed to said arm 10 and with a pin 14,

thread guides 25 are ?xed. As is known the for the purpose of raising the pawl 11.

35

thread guide 25 must be continually shifted A head 12 is formed at the end of the rod

to and fro in the two directions w and g]. In 7 , with which the pawl 11 engages. An

the last moment of its motion, the right oblique wedge 24 is ?xed to the bar 1.

end of the bar 7 encounters the cap 9 of the

The operationeof the device is as follows:

screw 26, and in its return movement the If the parts 1, 2, 3, 5 move in the direction

left end of the rod 7 encounters the cap 9 of the arrow 00 and have got then near the

of the screw 26. But because, as is known, extreme point of their motion, the arm or

90

a knitting frame is very long, the left end latch 4 strikes the end of the bar 19, and 95

of the mechanism could not be fully illus the head 12 snaps under the pawl 11. Con

trated in the drawing.

sequently the bars are positioned as in Fig.

I will now describe the device in detail.

3, that is to say, the arm or latch 4 is lifted

As shown in the drawing the bar 1 is oif from the lug 6 and cannot take the rod

mounted on the stationary frame of the ma

45

chine and can be reciprocated in its longi

tudinal direction as shown by the two ar

rows m and y.

The posts 3 are fixed to the

bar 1, of which in the drawing only one is

illustrated. The bar 5 is fixed to the post

3. The bar 5 must therefore make exactly

the same motions (w,

as the bar 1, whose

movement is constant.

The arm or latch 4 is rotatably mounted

on the bar 5. The two rings 18 ?xed to the

" bar 5 prevent longitudinal movement of the

lever A on the bar 5. The rod 7, which has

7 along with it. In the same moment how 100

ever the wedge 24 also reaches the roller 23

and the lever 10, 21 is consequently turned,

so that the pawl 11 draws the head 12 to

the right. The motion which the rod 7 gets

by the pawl 11 is a much slower motion 105

than that which the rod 7 has got by the

arm or latch 4. The bar 7 is not so freely

movable-in its bearings or driven at such a

rate by its direct connection, to the slur bar

1, as to cause its momentum to carry it be 110

yond the point to which it is positively

moved. In the last moment of this motion

1,023,695

the end of the rod 7 will therefore only run. nisIn for, straight knitting machines a pri

with very slow speed against the cap 9 of mary bar on the machine frame having a

the screw 26. This is the purpose of the in

constant reciprocating movement, a post on 25

vention as it has already been explained said bar, a bar 5 carried by said post, an

arm 4 rotatable on said bar 5, a thread guide

above more particularly.

Having now described my invention and bar having a lug thereon by which said

in what manner the same is operated, what arm drives said thread guide bar, a head

near the end of said thread guide bar, a 30

I claim is:

1. In a thread guide bar traverse mecha frame carrying a fashioning screw, a crank

lever fulcrumed on a nut carried by said

mary bar having a constant reciprocating screw, an 1ncl1ne on said prlmary bar en

movement, a thread guide bar, a latch 4: on gaged by a roller on the lower arm of said

' said primary bar to contact with and drive crank lever, a catch pivoted on the upper 35

the thread guide bar, a stop for the thread arm of said crank lever, adapted to engage

15 guide bar and means to vary the position of behind the head of said thread guide bar

said stop, and a second step 19 carried by and an adjustable stop for said thread guide

said means to unlock the latch before the bar also carried by said nut.

thread guide bar encounters its stop, and

CARL VVALTI-IER.

10

nism for straight knitting machines, a pri

20

means to engage and move the thread guide

a device carried by said stop positioning

bar against the stop.

2. In a thread guide bar traverse mecha

Witnesses :

WM. WVAsHINcToN BnUNswIoK,

KURT SINGER.

Gonies of this patent may be obtained for ?ve cents each, by addressing the Commissioner of Patents,

Washington, D. G.

You might also like

- June 24, 1969 R, Manterhelq 3,451,532: Med March 28, 1967 ', Sheet I OfaDocument5 pagesJune 24, 1969 R, Manterhelq 3,451,532: Med March 28, 1967 ', Sheet I OfabakkaNo ratings yet

- 1895 - Us570025Document5 pages1895 - Us570025Enrico Bruce GioloNo ratings yet

- %WWMD%WM: J. H. Vanderslig-E. Flanging MachineDocument4 pages%WWMD%WM: J. H. Vanderslig-E. Flanging MachineOO G-sus OoNo ratings yet

- M. Schwafel: Derrick Safety CageDocument4 pagesM. Schwafel: Derrick Safety CageRodrigoPomaNo ratings yet

- Us 1454454Document3 pagesUs 1454454dfdfsdNo ratings yet

- Us1446763 PDFDocument7 pagesUs1446763 PDFJin SongNo ratings yet

- Patented Nov. I3, 900.: A. V0N Zeke A. K. RédlDocument3 pagesPatented Nov. I3, 900.: A. V0N Zeke A. K. Rédlcll1968No ratings yet

- @VLNNR:: Beretta 3,021,763Document8 pages@VLNNR:: Beretta 3,021,763wererNo ratings yet

- Pistol Nickl Us1427966Document11 pagesPistol Nickl Us1427966cll1968No ratings yet

- United States Patent: Dreve, Jr. (45) May 16, 1972Document6 pagesUnited States Patent: Dreve, Jr. (45) May 16, 1972RodrigoPomaNo ratings yet

- Us965386 PDFDocument6 pagesUs965386 PDFJin SongNo ratings yet

- H.M. Sprague's Folding Pistol Patent from 1912Document4 pagesH.M. Sprague's Folding Pistol Patent from 1912djsfNo ratings yet

- April 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932Document8 pagesApril 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932jojaberiNo ratings yet

- J.B. HALE'S 1920 BRAIDING MACHINE CARRIERDocument5 pagesJ.B. HALE'S 1920 BRAIDING MACHINE CARRIERsebastian escobarNo ratings yet

- Variable-Speed Gearing Patent from 1901Document4 pagesVariable-Speed Gearing Patent from 1901belchior alvaroNo ratings yet

- US1685447Document5 pagesUS1685447Redirecting DecoyNo ratings yet

- Conveyer Screw Stops Bottles for LabelingDocument3 pagesConveyer Screw Stops Bottles for LabelingChristian MavarezNo ratings yet

- Us 3026089Document4 pagesUs 3026089takanobu ouraNo ratings yet

- July 8, 1924. 1,500,672: Y 7%Ale/Éa-Ac6-ÉzazaDocument3 pagesJuly 8, 1924. 1,500,672: Y 7%Ale/Éa-Ac6-Ézazakkd108No ratings yet

- April 2, 1968.: Filed Sept 26, 1966Document7 pagesApril 2, 1968.: Filed Sept 26, 1966Pedja Bekic100% (1)

- Apron MechanismDocument7 pagesApron Mechanismgopalpaul0% (2)

- US2160338 Shuttle Picking Mechanism PDFDocument5 pagesUS2160338 Shuttle Picking Mechanism PDFParikshit PaulNo ratings yet

- Efficient loom let-off mechanism for maintaining even warp tensionDocument6 pagesEfficient loom let-off mechanism for maintaining even warp tensionDavictorNo ratings yet

- Us2765819 PDFDocument8 pagesUs2765819 PDFAzri LunduNo ratings yet

- Us 1001260Document5 pagesUs 1001260mehdi parsNo ratings yet

- Us955823 PDFDocument3 pagesUs955823 PDFSashikant SharmaNo ratings yet

- Anti-Aircraft Fire Control Device (1937)Document10 pagesAnti-Aircraft Fire Control Device (1937)CAP History LibraryNo ratings yet

- US2128620 - Bending MachineDocument5 pagesUS2128620 - Bending MachinedevheadbotNo ratings yet

- Rig-E???': Gill!Document6 pagesRig-E???': Gill!luiscremaschiNo ratings yet

- Braiding MachineDocument7 pagesBraiding Machinejojaberi100% (1)

- No. 60,993. ' Patented Jan. 8, 1867.: F. Bru ADocument2 pagesNo. 60,993. ' Patented Jan. 8, 1867.: F. Bru AasdfasfNo ratings yet

- Mauser's Bolt-Locking Rifle PatentDocument4 pagesMauser's Bolt-Locking Rifle Patentcll1968No ratings yet

- Mannlicher Pistol PatentDocument10 pagesMannlicher Pistol PatentAndrew NicolleNo ratings yet

- Viewfinder ProjectDocument4 pagesViewfinder ProjectAndrei PoseaNo ratings yet

- 970,603. ' Patented Sept. 20, 1910.:, Winding Key Fob CamerasDocument4 pages970,603. ' Patented Sept. 20, 1910.:, Winding Key Fob CamerasAndrei PoseaNo ratings yet

- Us2297693 PDFDocument8 pagesUs2297693 PDFJin SongNo ratings yet

- Pa'tentedvvla N. 1, 1867.: H. WatersDocument3 pagesPa'tentedvvla N. 1, 1867.: H. WatersasdfasfNo ratings yet

- GB657382ADocument4 pagesGB657382AOctav IanNo ratings yet

- Sept. 18, 1923. - Bicycle Stand: Original Filed April 16 - 1921'Document3 pagesSept. 18, 1923. - Bicycle Stand: Original Filed April 16 - 1921'Fikri RahimNo ratings yet

- (Patente 1) US1489458Document3 pages(Patente 1) US1489458diegoNo ratings yet

- 1,176,784. Patented Mar, 28, 1916.: Walwe Operating Mechanism For LawatoresDocument5 pages1,176,784. Patented Mar, 28, 1916.: Walwe Operating Mechanism For LawatoresmarlondijiNo ratings yet

- ??????zzzzzzzzzzzzzzzzzzzzzz!é:1: Patented Sept. 24, 1901Document7 pages??????zzzzzzzzzzzzzzzzzzzzzz!é:1: Patented Sept. 24, 1901Слэйтер Строительная компания100% (1)

- Cheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetDocument7 pagesCheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetmephitNo ratings yet

- Mannlicher Us1008162Document6 pagesMannlicher Us1008162cll1968No ratings yet

- Engineering Vol 72 1901-11-29Document31 pagesEngineering Vol 72 1901-11-29ian_newNo ratings yet

- ' Aug. 5, 1930. B. A. Revelli: Filed April' 22, 192sDocument4 pages' Aug. 5, 1930. B. A. Revelli: Filed April' 22, 192sЮрий РуденкоNo ratings yet

- Target Kite (1944)Document7 pagesTarget Kite (1944)CAP History LibraryNo ratings yet

- Us1866891 PDFDocument8 pagesUs1866891 PDFbelchior alvaroNo ratings yet

- 5 - ?lm/"1% Law - (Wee ? Ma : Gssesr Lure-11760745.' Loaf/lb 110072Document2 pages5 - ?lm/"1% Law - (Wee ? Ma : Gssesr Lure-11760745.' Loaf/lb 110072ertsetsetetNo ratings yet

- Tow Target Release Mechanism (1927)Document5 pagesTow Target Release Mechanism (1927)CAP History LibraryNo ratings yet

- Post 6 38604 Reifgraber AutoDocument14 pagesPost 6 38604 Reifgraber AutoAoolf ManNo ratings yet

- Cornely's 1886 Patent for an Embroidering Machine with Cord Attachment MechanismDocument5 pagesCornely's 1886 Patent for an Embroidering Machine with Cord Attachment MechanismIsmail MullaNo ratings yet

- US1952501 Drum WeirDocument12 pagesUS1952501 Drum WeirSlađana RadovanovićNo ratings yet

- A. E. Jones: Filed March 20, 1924 2 Sheets-SheetDocument5 pagesA. E. Jones: Filed March 20, 1924 2 Sheets-SheetRinnoNo ratings yet

- 1.15 The Slider-Crank Chain: Mechanisms and MachinesDocument8 pages1.15 The Slider-Crank Chain: Mechanisms and MachinesNAGU2009No ratings yet

- Lûëîßûäá., Patented July 8, 1913.: C6265 Z1' MEN@ MijnDocument6 pagesLûëîßûäá., Patented July 8, 1913.: C6265 Z1' MEN@ MijnyuehanNo ratings yet

- No. 792,843, PATENTED JUNE 20, 1905, Galwanometer.: E, F, NorthrupDocument6 pagesNo. 792,843, PATENTED JUNE 20, 1905, Galwanometer.: E, F, Northrupmohamed hemdanNo ratings yet

- Patented June 1, 1901. No. 675,999.: L. HellfritzschDocument4 pagesPatented June 1, 1901. No. 675,999.: L. HellfritzschСлэйтер Строительная компанияNo ratings yet

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Axial Movement From Mating Cam Sections Rotating at Different Speeds.-Certain Copper Tubes Used in Connection With Steam-HeatingDocument2 pagesAxial Movement From Mating Cam Sections Rotating at Different Speeds.-Certain Copper Tubes Used in Connection With Steam-Heatingladygaga_pitoNo ratings yet

- Us 5693907Document4 pagesUs 5693907dfdfsdNo ratings yet

- European Patent Specification: For Speed Compensation of A Shaped Charge Jet, and MissileDocument10 pagesEuropean Patent Specification: For Speed Compensation of A Shaped Charge Jet, and MissiledfdfsdNo ratings yet

- United States Patent (191: Beuchat Et Al.vDocument3 pagesUnited States Patent (191: Beuchat Et Al.vdfdfsdNo ratings yet

- Us 4711181Document5 pagesUs 4711181dfdfsdNo ratings yet

- A. Ghuohu.: (No Model.)Document3 pagesA. Ghuohu.: (No Model.)dgfsduuwio100% (1)

- Us 5577431Document4 pagesUs 5577431dfdfsdNo ratings yet

- Us3771455 PDFDocument3 pagesUs3771455 PDFdgfsduuwioNo ratings yet

- Us 4299169Document3 pagesUs 4299169dfdfsdNo ratings yet

- European Patent Specification: Stabilized ShellDocument17 pagesEuropean Patent Specification: Stabilized ShelldfdfsdNo ratings yet

- Witnesses:: No. 628,142. @muted .My 4, - 899Document2 pagesWitnesses:: No. 628,142. @muted .My 4, - 899dgfsduuwioNo ratings yet

- Usd 593635Document5 pagesUsd 593635dgfsduuwioNo ratings yet

- Illlllllllllilllllllllilllllllllli: United States Patent (191Document3 pagesIlllllllllllilllllllllilllllllllli: United States Patent (191dgfsduuwioNo ratings yet

- Us 3715985Document3 pagesUs 3715985dgfsduuwioNo ratings yet

- EP0928948B1Document5 pagesEP0928948B1dfdfsdNo ratings yet

- Us 4004514Document3 pagesUs 4004514dgfsduuwioNo ratings yet

- EP2056060A1Document11 pagesEP2056060A1dgfsduuwioNo ratings yet

- EP0883790B1Document7 pagesEP0883790B1dgfsduuwioNo ratings yet

- United States Design Patent (10) Patent N0.2 US D600,305 SDocument5 pagesUnited States Design Patent (10) Patent N0.2 US D600,305 SdgfsduuwioNo ratings yet

- Us 4715285Document2 pagesUs 4715285dgfsduuwioNo ratings yet

- Us 1608359Document2 pagesUs 1608359dgfsduuwioNo ratings yet

- Unlted States Des1Gn Patent (10) Patent N0.: Us D707,780 SDocument4 pagesUnlted States Des1Gn Patent (10) Patent N0.: Us D707,780 SdgfsduuwioNo ratings yet

- United States Patent (191: Smith (45) Date of Patent: Jul. 8 1997Document2 pagesUnited States Patent (191: Smith (45) Date of Patent: Jul. 8 1997dgfsduuwioNo ratings yet

- ABYIPDocument18 pagesABYIP千住 マリエルNo ratings yet

- Diabetic Safe - One Pager - Version 1.0 - Oct 20Document2 pagesDiabetic Safe - One Pager - Version 1.0 - Oct 20naval730107No ratings yet

- Rotary Gear Pump Manufacturers in India, Pulp Valve Manufacturers IndiaDocument3 pagesRotary Gear Pump Manufacturers in India, Pulp Valve Manufacturers IndiaKirit IndustriesNo ratings yet

- Vertical Jaw Relation Recording MethodsDocument17 pagesVertical Jaw Relation Recording MethodsHarish VsNo ratings yet

- Dell Precision Workstations: The #1 Workstations in The WorldDocument7 pagesDell Precision Workstations: The #1 Workstations in The WorldDiego RodriguezNo ratings yet

- Self-Balancing Two-Wheeler Using GyroscopeDocument33 pagesSelf-Balancing Two-Wheeler Using Gyroscopemilan mottaNo ratings yet

- Passive Filter vs. Active Filter: DefinitionsDocument3 pagesPassive Filter vs. Active Filter: DefinitionsAmit DebnathNo ratings yet

- Vapour Bar Exchange IMFL PackageDocument4 pagesVapour Bar Exchange IMFL PackageNishank AgarwalNo ratings yet

- Lession Plan - MIDocument21 pagesLession Plan - MINithya SannidhiNo ratings yet

- Refraction Through Lenses & Optical Instruments5Document144 pagesRefraction Through Lenses & Optical Instruments5geniusamahNo ratings yet

- Site Master FileDocument51 pagesSite Master FileMilonhg100% (2)

- Fault Code 155: Intake Manifold Air Temperature High - CriticalDocument3 pagesFault Code 155: Intake Manifold Air Temperature High - Criticalhamilton miranda100% (1)

- Hobby 01: COD. 9942062.01 REV. 00Document9 pagesHobby 01: COD. 9942062.01 REV. 00Alexander SharamiginNo ratings yet

- KTS - Sarao.bakus Temple of Eternal FiireDocument176 pagesKTS - Sarao.bakus Temple of Eternal FiireK.T.S. SaraoNo ratings yet

- Gas Turbine Performance Enhancement Update: GE Energy ServicesDocument45 pagesGas Turbine Performance Enhancement Update: GE Energy Servicesesteban100% (1)

- Mathematics 5 Q1 W10Document31 pagesMathematics 5 Q1 W10Aices Jasmin Melgar BongaoNo ratings yet

- PCS PADDLE SHIFTER INSTALL GUIDEDocument21 pagesPCS PADDLE SHIFTER INSTALL GUIDEAndreas T P ManurungNo ratings yet

- LutensolxpDocument11 pagesLutensolxppkh29No ratings yet

- Procedure - AC Circuits and Signal Modulation - W20Document6 pagesProcedure - AC Circuits and Signal Modulation - W20ChocoNo ratings yet

- Narayana Sukta MeaningDocument4 pagesNarayana Sukta Meaningvinai.20No ratings yet

- Dimensions and Relations of The Dentogingival Junction in Humans. Gargiulo 1961Document7 pagesDimensions and Relations of The Dentogingival Junction in Humans. Gargiulo 1961Linda Garcia PNo ratings yet

- HistorydylaneditDocument6 pagesHistorydylaneditapi-19858424No ratings yet

- MSC Syllabus AllDocument13 pagesMSC Syllabus AllOmSilence2651No ratings yet

- Capacity and Safety Analysis of Hard Shoulder Running HSR A Motorway Case Study 2016 Transportation Research Part A Policy and PracticeDocument22 pagesCapacity and Safety Analysis of Hard Shoulder Running HSR A Motorway Case Study 2016 Transportation Research Part A Policy and PracticeZen ZeeNo ratings yet

- Kirloskar-Oil-Engines DescriptionsDocument8 pagesKirloskar-Oil-Engines Descriptionssinghhardeep760No ratings yet

- TICSA - Diesel Uno Petroleos Guatemala (13.01.23)Document1 pageTICSA - Diesel Uno Petroleos Guatemala (13.01.23)Luis M LópezNo ratings yet

- 322439480MVR Single Page Single Page Booklet - OPTDocument12 pages322439480MVR Single Page Single Page Booklet - OPTlarry vargas bautistaNo ratings yet

- Baby NamesDocument9 pagesBaby Namesppremamca_617705407No ratings yet

- Metric Heavy Hex Nuts: ASME B18.2.4.6M-2010Document16 pagesMetric Heavy Hex Nuts: ASME B18.2.4.6M-2010CarlitosNo ratings yet

- MACRO XII Subhash Dey All Chapters PPTs (Teaching Made Easier)Document2,231 pagesMACRO XII Subhash Dey All Chapters PPTs (Teaching Made Easier)Vatsal HarkarNo ratings yet