Professional Documents

Culture Documents

MD Problems Oct09

Uploaded by

Ironfalcon101Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MD Problems Oct09

Uploaded by

Ironfalcon101Copyright:

Available Formats

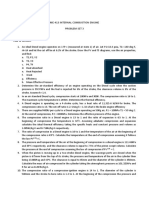

ALCORCON ENGINEERING REVIEW CENTER

Cebu: 4TH Flr. Coast Pacific Downtown Center, Sanciangco St. Cebu City (Tel # 254-33-84)

Manila Branch: 3rd floor JPD Bldg 1955, C M Recto corner N. Reyes St, Sampaloc, Manila Tel # (02) 736-4438

Machine Design Problems DAY 1

MACHINE ELEMENTS

1. PROBLEM (ME Bd. Apr. 97) Two parallel shafts connected by pure rolling turn in the same direction

having a speed ratio of 2.75. What is the distance of the shafts if the smaller cylinder is 22 cm in diameter?

2. Two cylinders rolling in opposite direction has a speed ratio of 3. If center distance is 40 in, find the diameter

of smaller cylinder.

STRESSES

1. PROBLEM (ME Bd. Apr. 96) A steel tie rod on bridge must be made withstand a pull of 5000 lbs. Find the

diameter of the rod assuming a factor of safety of 5 and ultimate stress of 64,000 psi.

2. PROBLEM (ME Bd. Oct. 97) Determine the minimum mean diameter of a taper pin for use to fix a lever to

a shaft, if it is transmit a maximum torque of 700 in-lbs. The shaft diameter is 2 inches and the material

allowable stresses is 15,000 psi. Use factor of safety of 2.

3. PROBLEM (ME Bd. Apr. 97) How many 5/16 inch holes can be punch in one motion in a steel plate made

of SAE 1010 steel, 7/16 inch thick using a force of 55 tons. The ultimate strength for shear is 50 ksi and use 2

factor of safety.

4. PROBLEM (ME Bd. Apr. 97) The shaft whose torque varies from 2000 to 6000 in-lbs has 1 1/2 inches in

diameter and 60,000 psi yield strength. Compute for the shaft mean average stress.

5. In a 2.0 m cantilevered I-beam, a 2 Mton weight is applied at free end. If the allowable stress in beam is 110

Mpa, determine the section modulus.

STRESS AND STRAIN and Poisons Ratio.

1. (ME Bd. Oct. 2000) Compute the induced/compressive stress, in kpa, of a steel solid shafting of 50 mm

diameter and 800 mm in length that is subjected to an increase of temperature by 80 oC.

2. (ME Bd. Oct. 2003) What is the decrease in lateral dimension due to an axial tensile force of 50,000 lbs in a

bar 3 inch on each side and 6 feet long? The material is steel (E = 3.0 x 10 7 psi, = 0.3).

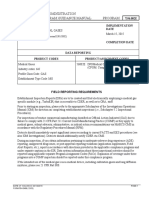

SITUATIONAL PROBLEM (Oct 2003)

An 8 inches long bar is elongate to 8.0065 inches for an applied load of 5000 lbs in which its cross-sectional

area is 0.25 in2.

A. Find the modulus of elasticity, psi.

A. 22.62 x 106 psi

B. 24.62 x 106 psi

B. Find the tensile stress , psi.

A. 20,000 psi B. 15,000 psi

C. Find the strain.

C. 26.62 x 106 psi

C. 20,000 psi

A. 6.309 x 10-4 B. 8.12 x 10-4

D. Find the stress for a load of 5000 kg, kg/cm 2.

A. 2800

B. 2900

C. 3000

D. 28.62 x 106 psi

D. 25,000 psi

C. 10.27 x 10-4 D. 12.09 x 10-4

D. 3100

E. Find the stress if the bar is heated at a temperature change of 80 oF, psi.

A. 15,08.45

B. 10,083.90 C. 5,088.40

D. 12,802.40

ALCORCON ENGINEERING REVIEW CENTER

Cebu: 4TH Flr. Coast Pacific Downtown Center, Sanciangco St. Cebu City (Tel # 254-33-84)

Manila Branch: 3rd floor JPD Bldg 1955, C M Recto corner N. Reyes St, Sampaloc, Manila Tel # (02) 736-4438

Machine Design Problems DAY 2

SHAFT SUBJECTED TO PURE TORSION ONLY

1. (ME Bd. Oct. 1998) What power would a spindle 55 mm in diameter transmit at 480 rpm stress allowed for

short shaft is 59 N/mm2?

2. (ME Bd. Oct. 2000) Find the torsional deflection, in degrees, of a solid steel shaft, 110 mm OD x 1.4 m long

subject to 3.1 x 106 N-mm torque. The torsional modulus of elasticity is 80,000 N/mm-mm.

3. (ME Bd. Apr. 96) Compute the linear shaft diameter to transmit 12 HP at 180 rpm with torsional deflection of

0.08 degrees per foot length.

4. (ME Bd. Apr. 95) A hollow shaft with outside diameter of 14 cm and wall thickness of 0.8 cm transmits 200

KW at 400 rpm. What must be the angular deflection of the shaft if the length is 5 meters? The material of the

shaft is C4140 steel.

SHAFT WITH ASSUMED ALLOWABLE STRESS & SUBJECTED TO TORSION AND BENDING LOAD

1. (ME Bd. Oct. 95) A short 61 mm diameter shaft transmits 120 Hp. Compute the linear speed of a pulley 55

cm diameter mounted on the shaft.

2. A machine shaft is supported on bearings 1 m apart is to transmit 190 KW at 300 rpm while subjected to

bending load of 500 kg at the center. If maximum shearing stress is 40 Mpa, determine the shaft diameter.

FROM MACHINERIES HANDBOOK

1. (ME Bd. Apr. 98) A 16 ft lineshaft has no bending action except its own weight. What power in Hp can the

shaft deliver at a speed of 200 rpm. Consider that the torsional deflection will not exceed 0.08/ft length.

SITUATIONAL PROBLEMS

(ME Bd. APRIL 2004) A hollow shaft has an outside diameter of 2in. The allowable shearing stress of the shaft

is 7,000 psi and the applied torque is 700 in-lbs. Find:

A. the shaft inside diameter, in

A. 1.95 in

B. 1.93 in

C. 1.91 in

B. the equivalent solid shaft diameter, in

A. 0.788

B. 0.798

C. 0.792

D. 1.97 in

D. 0.790

C. savings in weight if the solid shaft is to be replaced with hollow shaft of the same torsional strength.

A. 76.20%

B. 78.20%

C. 81.29%

D. 85.30%

D. the factor of safety if yield stress is 10,430 psi.

A. 1.49

B. 1.69

C. 1.79

D. 1.99

E. tangential force of the solid shaft, lbs

A. 1754.39

B. 1854.39

C. 1954.39

D. 2054.39

ALCORCON ENGINEERING REVIEW CENTER

Cebu: 4TH Flr. Coast Pacific Downtown Center, Sanciangco St. Cebu City (Tel # 254-33-84)

Manila Branch: 3rd floor JPD Bldg 1955, C M Recto corner N. Reyes St, Sampaloc, Manila Tel # (02) 736-4438

Machine Design Problems DAY 3

KEYS

1. (ME Oct. 1998)

A 76.2 mm diameter shafting of SAE 1040 grade, cold rolled, having a yield point of 50 ksi and with a 3/4 x 3/4 x

5 in key. Compute the minimum yield point in the key in order transmit the torque of the shaft. The factor of

safety to use is 2 and Sys = 0.5 Sy.

2. (ME Bd. Apr. 98)

A keyed gears delivers a torque of 912.4 N-m thru its shaft of 63.5 mm outside diameter. If the key has

thickness of 15.875 mm and width of 11.1125, find the length of the key. Assume the permissible stress values

of 61.2 Mpa for shear and tension at 99.8 Mpa.

COUPLING

1. (ME Bd. Oct. 97)

A flanged bolt coupling has ten (10) steel 25.4 mm diameter bolts evenly tighten around a 415 mm bolt circle.

Determine the torque capacity of the connection if the allowable shearing stress in the bolt is 50 MN/m 2.

2. A flange bolt coupling consist of eight 20 mm diameter steel bolts space evenly around a bolt circle 300 mm

in diameter. If the coupling is subjected to a torque of 15.1 KN-m, determine the maximum shearing stress in

the bolts?

FLYWHEEL

1. (ME Bd. Apr. 95)

What pressure is required to punch a hole 2 diameter through a 1/4 steel plate?

2. The kinetic energy needed to punch a hole is 5 KJ. What is the maximum thickness of a hole that can be

punch if hole diameter is 25 mm and ultimate shearing stress of plate is 420 Mpa.

3. The energy required to punch a hole is 3 KJ from a flywheel mean diameter of 800 mm that slows down from

3.3 rps to 3 rps during punching. If weight of arm and hub account 10% of rim weight, determine the rim weight.

ALCORCON ENGINEERING REVIEW CENTER

Cebu: 4TH Flr. Coast Pacific Downtown Center, Sanciangco St. Cebu City (Tel # 254-33-84)

Manila Branch: 3rd floor JPD Bldg 1955, C M Recto corner N. Reyes St, Sampaloc, Manila Tel # (02) 736-4438

Machine Design Problems DAY 4

BOLTS AND POWER SCREW

1. (Oct. 1998) Compute the working strength of 1 in bolt is screwed up tightly in packaged joint when the

allowable stress is 13,000 psi.

A. 3,600 lbs

B. 3,700 lbs

C. 3,800 lbs

D. 3,900 lbs

2. (ME Bd. Oct. 97)

An eyebolt is lifting a block weighing 350 lbs. The eyebolt is of SAE C 1040 material with S u = 67 ksi and Sy =

55 ksi, what is the stress area ( in inches square) of the bolt if it is under the unified coarse series thread?

A. 0.1341

B. 0.1134

C. 0.0991

D. 0.1043

3. (ME Bd. Apr. 98)

Compute how many 3/8 inch diameter set screws required to transmit 3 Hp at a shaft speed of 1000 rpm. The

shaft diameter is 1 inch.

A. 1 1/2

B. 2

C. 3

D. 1

4. (ME Bd. Apr. 95)

What is the frictional Hp acting on a collar loaded with 100 kg weight? The collar has an outside diameter of 100

mm and an internal diameter of 40 mm. The collar rotates at 1000 rpm and the coefficient of friction between the

collar and the pivot surface is 0.15.

A. 0.8 Hp

B. 0.3 Hp

C. 0.5 Hp

D. 1.2 Hp

5. A double square thread power screw has a mean radius of 80 mm and a pitch of 10 mm is use to lift a load

of 80 KN. If friction of screw is 0.13 and collar torque is 20% of input torque, determine the input torque required.

A. 830.76 N-m B. 835.76 N-m C. 1246.30 N-m

D. 1365.30 N-m

6. A power screw that has 2 inches mean diameter with two thread per inch is to be used. The frictional

radius of collar is 2 inches and coefficient of friction are 0.10 for the threads and 0.15 for collar. The velocity of

the nut is 10 ft/min. For a lifting load of 5000 lbs, find:

A. the efficiency of the screw for a double square thread.

B. the power output of the screw for a double square thread.

ALCORCON ENGINEERING REVIEW CENTER

Cebu: 4TH Flr. Coast Pacific Downtown Center, Sanciangco St. Cebu City (Tel # 254-33-84)

Manila Branch: 3rd floor JPD Bldg 1955, C M Recto corner N. Reyes St, Sampaloc, Manila Tel # (02) 736-4438

MACHINE DESIGN DAY 5

WORM GEAR

1. (ME Bd. Oct. 97)

A triple thread worm has a pitch diameter of 3 inches. The wheel has 25 teeth and a pitch diameter of 5 inches.

Material for both the worm and the wheel is of phosphor bronze. Compute the helix angle (tan ).

A. 0.20

B. 0.30

C. 0.40

D. 14

2. Two-thread worm gear, rotating at 1200 rpm, drives a 26-tooth worm gear and transmit 10 hp. The worm has

14.5o teeth with 0.5 pitch, 2 in pitch diameter, and an included face angle of 60 o. The coefficient of friction is

0.06. (Assume: y = 0.212)

A. Determine the lead angle of the worm.

B. Determine the speed ratio.

C. Determine the center distance.

BEVEL GEAR

1. A pair of straight-tooth bevel gears are mounted on the shafts that intersect each other at an angle of 70 o.

The velocity ratio is . Determine the angles of the gear and pinion. Also determine the pitch diameter of the

pinion if gear diameter is 15 cm.

HELICAL GEARS:

1. A helical gear has a helix angle of 25o and transverse circular

pinion and gear 15 and 45, respectively.

A) determine the normal circular pitch

B) determine the pitch diameter of the pinion and gear

C) determine the center distance

pitch of /5. The number of teeth for the

2. A steel pinion having a diameter of about 254mm meshes with a helical gear which turns one-fifth the angular

speed of the pinion. The normal diametral pitch to be 4 and the teeth is to be 20 o. Determine the required

number of teeth for the pinion and gear.

ALCORCON ENGINEERING REVIEW CENTER

Cebu: 4TH Flr. Coast Pacific Downtown Center, Sanciangco St. Cebu City (Tel # 254-33-84)

Manila Branch: 3rd floor JPD Bldg 1955, C M Recto corner N. Reyes St, Sampaloc, Manila Tel # (02) 736-4438

MACHINE DESIGN DAY 6

ROLLER CHAIN AND SPROCKETS:

1. A certain farm equipment requires 2,200N-m at 500rpm has a diesel engine to operate at 1500rpm as its

primemover. A no. 60 roller chain with a total length of 60 pitches and small sprocket with 23 teeth are to be

used. Determine

A. the power needed for the farm equipment

B. the required center distance between sprockets in mm.

C. the pitch line velocity in fpm.

BELTS

1. A pulley 610mm in diameter transmits 40kw at 500rpm. The arc of contact between the belt and pulley is

144o, and coefficient of friction is 0,35. The safe working stress of the belt is 2.1Mpa. Calculate:

A. the tangential force at the pulley rim, N

(Ans. 2,505N)

B. the effective belt pull, N

(Ans. 2,505N)

C. the width of the belt if the thickness is 6mm

(Ans. 340mm)

2. Find the belt length at a 72 inches center distance if the pulley diameters are 6in. and 12in., when they are

connected by open and cross belt.

(Ans. 172.4in. ; 173.4in.)

3. A 3/8 in flat leather belt is 12 in wide and is used on a 24 in diameter pulley rotating 600 rpm. The specific

weight of the belt is 0.035 lb/in3. The angle of contact is 150o. If the coefficient of friction is 0.3 and the

allowable stress is 300 psi how much hp can it transmit?

A. 34.5 hp

B. 69.5 hp

C. 78.5 hp

D. 54.5 hp

BEARINGS

1. A 22mm diameter shaft is supported by sleeve bearings at the distance of 0.5m. A load of 2.2KN is applied at

0.2m from the left end. The sleeve bearings have an L/D of 1.5. Find the maximum bearing pressure. (Ans.

1.82Mpa)

2. Determine the life factor of a ball bearing that is use to support for 20 hrs per day for 5 years if catalog rated

life of bearing is 7000 hrs and reliability factor is 3.

A. 3.202

B. 2.202

C. 1.202

D. 0.202

ALCORCON ENGINEERING REVIEW CENTER

Cebu: 4TH Flr. Coast Pacific Downtown Center, Sanciangco St. Cebu City (Tel # 254-33-84)

Manila Branch: 3rd floor JPD Bldg 1955, C M Recto corner N. Reyes St, Sampaloc, Manila Tel # (02) 736-4438

MACHINE DESIGN DAY 7

CLUTCHES:

1. (Board Exam April 97)

If the inertia is 90 lb-ft2 and the speed of the driven shaft is to be increased from 0 to 2500 in 5 seconds, shaft

material is of SAE 4140 with yield strength of 110,000lb/in 2, find the clutch starting torque in ft-lb. (Ans. 146)

2. Assuming uniform wear, find the power capacity of a simple disc clutch with an outside and inside diameter of

200mm and 100mm, respectively. A rotational speed of 1160rpm and coefficient of friction of 0.35 whose axial

operating force is 800N. (Ans. 2.55KW)

3. A cone clutch has cone elements at an angle of 10 o. The clutch transmits 20 hp at a speed of 100 rpm. The

mean diameter of the conical friction sections is 16 in and the coefficient of friction is 0.3. Find the axial force

needed to engage the clutch.

A. 246.37 lbs B. 212.56 lbs C. 234.56 lbs D. 346.78 lbs

4. The angle of contact of a band clutch is 250 degrees. The cross section of the band is 1/16 in x 1.5 in. The

design stress for the band material is 8,000 psi. If the drum is 16 inches in diameter and rotates at 350 rpm,

what is the horsepower capacity of the clutch? The coefficient of friction is 0.4.

A. 20.34 hp

B. 15.23 hp

C. 22.34 hp

D. 27.50 hp

BRAKES:

1. The band brake of a band brake has 210 degrees of contact with its drum. By laboratory tests, it is found

that the pull on the tight side is 800 lbs and the pull on the slack side is 285 lb. What is the coefficient of friction?

A. 0.281

B. 0.753

C. 0.186

D. 0.453

2. A band brake is to operate on a 650mm diameter drum rotating at 250rpm. The coefficient of friction between

band and drum is 0.25. The band brake has an angle of contact of 1.5 radians and band width is 65mm. One

end of the band is fastened to the fixed end pin at the end of the lever while the other end on the brake arm

120mm from the fixed pin and is placed perpendicular to the diameter bisecting the angle of contact. The brake

arm length is 750mm.

Calculate the following:

A. torque capacity if the band pressure is not to exceed 290kpa

B. what is the minimum pull necessary at the end of the lever arm in order to absorb the

torque?

C. how much power can be handled at the given speed?

D. tensile stress in the band if the band thickness is 15mm.

ALCORCON ENGINEERING REVIEW CENTER

Cebu: 4TH Flr. Coast Pacific Downtown Center, Sanciangco St. Cebu City (Tel # 254-33-84)

Manila Branch: 3rd floor JPD Bldg 1955, C M Recto corner N. Reyes St, Sampaloc, Manila Tel # (02) 736-4438

MACHINE DESIGN DAY 8

WELDED JOINTS

1. A 16mm plate is lapped over and secured by fillet weld on the inside and outside to form a penstock

1.5m in diameter. Determine the safe internal pressure, assuming an allowable stress of 140Mpa on the

plate and allowable shear stress of 90Mpa on the throat side of the 14mm fillet weld. (Ans. 2375.76 kpa)

RIVETED JOINTS

1. Consider a section of 304.8mm of a single-riveted lap joint made with plates of 6.35mm thickness and 6

rivets, 15.87mm in diameter. Assume that rivet holes are 1.58mm larger in diameter than the rivets. In

this joint, the entire load is transmitted from one plate to the other by means of rivets. Each plate and the

six rivets carries the entire load. The design stresses are:

for shear = 589 kg/cm2

for bearing = 1,406 kg/cm2

for tension = 703 kg/cm2

Calculate the following:

a) force that can be carried by un punched plate

(Ans. 13,606.4 kg)

b) force that cause tensile stress on plate between rivets (Ans. 8,932.6 kg)

c) force that cause shearing stress on rivets

(Ans. 8,580.90 kg)

d) force that cause bearing stress in the rivets

(Ans. 9,347.7 kg)

e) rivet efficiency

(Ans. 63.1%)

WIRE ROPES

What is the factor of safety when a in diameter rope, 6 x 19 MPS wire rope carrying 4000 lb load is bent

around an 18 in sheave. If the load

You might also like

- 2019 PreboarsuejeDocument11 pages2019 PreboarsuejeImmanuel Conrey0% (1)

- Machine Design, Materials and Shop Practice Multiple ChoiceDocument7 pagesMachine Design, Materials and Shop Practice Multiple ChoiceNeil SequioNo ratings yet

- PipeDocument489 pagesPipeShantle Taciana P. Fabico67% (18)

- Past Mechanical Engineering Board Exam Question Set 3Document2 pagesPast Mechanical Engineering Board Exam Question Set 3Creation YourNo ratings yet

- MDSP Set 2Document9 pagesMDSP Set 2iaton77100% (2)

- ReviewerDocument7 pagesReviewerAriel Mark Pilotin50% (2)

- ReviewerDocument35 pagesReviewerAriel Mark Pilotin78% (9)

- Pipe PreboardDocument3 pagesPipe Preboardlawrence catipayNo ratings yet

- Elements in Power Plant and Industrial Plant EngineeringDocument19 pagesElements in Power Plant and Industrial Plant EngineeringRc Tuppal75% (8)

- Machine Design/Shop Practice Trivia: Multiple Choice QuestionsDocument9 pagesMachine Design/Shop Practice Trivia: Multiple Choice QuestionsLito Lapid0% (1)

- PipeDocument8 pagesPipeVon A. DamirezNo ratings yet

- Pipe Looksfam - ConfidentialDocument41 pagesPipe Looksfam - ConfidentialJaypes ManzanoNo ratings yet

- Design ProblemsDocument30 pagesDesign ProblemsNelson Naval Cabingas67% (3)

- Elements in Machine Design (J.T.) Module 5Document6 pagesElements in Machine Design (J.T.) Module 5allovid0% (1)

- PDF Machine Design Final Coaching ComprDocument17 pagesPDF Machine Design Final Coaching ComprkilluaNo ratings yet

- Pipe LasonDocument19 pagesPipe LasonMark Pamular0% (1)

- ReviewerDocument12 pagesReviewerAriel Mark Pilotin0% (1)

- Machine Design Problems 1&2 AlcorconDocument68 pagesMachine Design Problems 1&2 AlcorconRuth MontebonNo ratings yet

- Orca Share Media1519993790396 PDFDocument10 pagesOrca Share Media1519993790396 PDFSecret SecretNo ratings yet

- MOI POLARDocument20 pagesMOI POLARAaron Somera SolisNo ratings yet

- Machine Design/Shop Practice Multiple Choice TestDocument10 pagesMachine Design/Shop Practice Multiple Choice TestStephanie ParkNo ratings yet

- Me Preboard MD Mar 2011 Set ADocument11 pagesMe Preboard MD Mar 2011 Set AFrancis AlmiaNo ratings yet

- MD ProbsetDocument27 pagesMD ProbsetRicky AlamoNo ratings yet

- Yes SRDocument5 pagesYes SRSecret SecretNo ratings yet

- PIPE/PROBLEMS FINAL COACHING: HVACR & REFRIGERATION TOPICSDocument95 pagesPIPE/PROBLEMS FINAL COACHING: HVACR & REFRIGERATION TOPICSnathaniel villanuevaNo ratings yet

- Duaso T1-8Document48 pagesDuaso T1-8Nelson Naval Cabingas100% (3)

- Steam Engine Problems & SolutionsDocument10 pagesSteam Engine Problems & SolutionsKristian Taruc100% (2)

- Orca Share Media1530612875778Document9 pagesOrca Share Media1530612875778Victor John PingkianNo ratings yet

- MDMSP#1 stresses types calculationDocument9 pagesMDMSP#1 stresses types calculationJasper EstrellaNo ratings yet

- Deophantine 5 ProblemsDocument60 pagesDeophantine 5 ProblemsCaro Kan LopezNo ratings yet

- Mechanical Engineering Board Exam SubjectsDocument4 pagesMechanical Engineering Board Exam Subjectsbenny narrido100% (1)

- Machine Design ElementsDocument16 pagesMachine Design ElementsRc TuppalNo ratings yet

- PIPE20 PREBOARD202 PDFDocument15 pagesPIPE20 PREBOARD202 PDFJimwell Bobadilla100% (1)

- ME413 ICE Diesel Prob Set 3Document2 pagesME413 ICE Diesel Prob Set 3Rowin Mark Sabornido40% (5)

- Alcorcon Engineering Review Center: Mathematics - AlgebraDocument4 pagesAlcorcon Engineering Review Center: Mathematics - AlgebraChloe OlazoNo ratings yet

- Milling Cutters and Steel Properties CalculationDocument25 pagesMilling Cutters and Steel Properties CalculationAriel Mark Pilotin80% (5)

- Machine Design and Shop Practice Pre BoardDocument7 pagesMachine Design and Shop Practice Pre BoardFrankie NovelaNo ratings yet

- Booklet 2Document7 pagesBooklet 2Jherico Jay SantosNo ratings yet

- ReviewerDocument7 pagesReviewerAriel Mark Pilotin100% (3)

- Pipe 02: by TRC - Tiger's Review CenterDocument119 pagesPipe 02: by TRC - Tiger's Review Centerkristan7No ratings yet

- MD Preboard 2011Document8 pagesMD Preboard 2011Francis Almia100% (1)

- Ice Plant Refrigeration System Performance AnalysisDocument70 pagesIce Plant Refrigeration System Performance AnalysisJohn PingkianNo ratings yet

- Steam Power Reviewer Terms and Problem SolvingDocument9 pagesSteam Power Reviewer Terms and Problem SolvingCherry May Basinang-RamosNo ratings yet

- Machine Design Exam PDFDocument6 pagesMachine Design Exam PDFLanz CruzatNo ratings yet

- LN Tutorial Services - Machine Design, Materials & Shop PracticesDocument4 pagesLN Tutorial Services - Machine Design, Materials & Shop PracticesEngr Amethyst RiegoNo ratings yet

- Exercises On Stresses 2016Document2 pagesExercises On Stresses 2016Santos JustinNo ratings yet

- Bolts, screws, threads and their designDocument8 pagesBolts, screws, threads and their designKen YuNo ratings yet

- Reviewer 6Document7 pagesReviewer 6tiburciomadlangtutaNo ratings yet

- Machine Shop Practices and Lathe Machine Parts GuideDocument33 pagesMachine Shop Practices and Lathe Machine Parts GuideMark AllenNo ratings yet

- Alcorcon Engineering Review Center: STRESS AND STRAIN and Poisons RatioDocument1 pageAlcorcon Engineering Review Center: STRESS AND STRAIN and Poisons RatioKers CelestialNo ratings yet

- Machine Design Problems - DAY 4Document1 pageMachine Design Problems - DAY 4Kers CelestialNo ratings yet

- Machine Design Problems - DAY 3KEYSDocument1 pageMachine Design Problems - DAY 3KEYSKers CelestialNo ratings yet

- UNC Problem SetDocument67 pagesUNC Problem SetjaysamNo ratings yet

- Me2254 QBDocument18 pagesMe2254 QBAinnar Kesavan0% (1)

- Ashok Dmm1Document4 pagesAshok Dmm1Praveen KumarNo ratings yet

- Me-528-Review-3-Md-Problems PlatesDocument37 pagesMe-528-Review-3-Md-Problems PlatesGraceeNo ratings yet

- Stresses & Machine Elements: PROBLEM SET (Topic 1)Document7 pagesStresses & Machine Elements: PROBLEM SET (Topic 1)Elisif DeFairNo ratings yet

- Machine Design Problems - DAY 1MACHINE ELEMENTSDocument1 pageMachine Design Problems - DAY 1MACHINE ELEMENTSKers CelestialNo ratings yet

- Me2254 SM QBDocument15 pagesMe2254 SM QBhodvmkvecautoNo ratings yet

- Engineering Materials Practice Problems in Simple StressesDocument4 pagesEngineering Materials Practice Problems in Simple StressesEu Aumentado100% (1)

- Machine Design Reviewer 2Document14 pagesMachine Design Reviewer 2Ironfalcon101100% (1)

- Day 01 - Algebra 1Document19 pagesDay 01 - Algebra 1Ironfalcon101No ratings yet

- Machine Design Reviewer 2Document14 pagesMachine Design Reviewer 2Ironfalcon101100% (1)

- Day 02 - Algebra 2Document26 pagesDay 02 - Algebra 2Ironfalcon101100% (2)

- EMC Quiz QuestionsDocument3 pagesEMC Quiz QuestionsIronfalcon101No ratings yet

- Algebraans 05Document7 pagesAlgebraans 05Pom SurasakNo ratings yet

- Past Board Exam Questions for Math Teachers (LETDocument5 pagesPast Board Exam Questions for Math Teachers (LETIronfalcon101No ratings yet

- Algebra II Exam with Trigonometry QuestionsDocument7 pagesAlgebra II Exam with Trigonometry QuestionsRuslan AganiNo ratings yet

- Math Module Series 2Document4 pagesMath Module Series 2Ironfalcon101No ratings yet

- Math Module Series 2Document4 pagesMath Module Series 2Ironfalcon101No ratings yet

- Declaration of Denise RohrbacherDocument6 pagesDeclaration of Denise RohrbacherElizabeth Nolan BrownNo ratings yet

- Question & Answers: Certified in Cybersecurity (CC)Document6 pagesQuestion & Answers: Certified in Cybersecurity (CC)ArifNo ratings yet

- Barriers To The Teaching of Health Education inDocument23 pagesBarriers To The Teaching of Health Education inbrinda_pratap2779No ratings yet

- Is7 Eng 101201Document305 pagesIs7 Eng 101201محمدحمادNo ratings yet

- Fitjee Paper Class 10 ElectrcityDocument4 pagesFitjee Paper Class 10 ElectrcityKeerthivasav 12No ratings yet

- Control Valve Training July O6Document36 pagesControl Valve Training July O6ecsuperal100% (1)

- Back To TopSkip To Main ContentDocument60 pagesBack To TopSkip To Main ContentandrewNo ratings yet

- Task: My Week AgoDocument2 pagesTask: My Week AgoxioteNo ratings yet

- Combined ADCP Course OutlinesDocument21 pagesCombined ADCP Course OutlinesSundar WajidNo ratings yet

- APG InternalAudit2015 PDFDocument4 pagesAPG InternalAudit2015 PDFBulmaro SanchezNo ratings yet

- History - DR Tony Taylor Monash Uni and Ac History WriterDocument37 pagesHistory - DR Tony Taylor Monash Uni and Ac History Writerapi-290776269No ratings yet

- 1-SablaEVAReportver5.1 0 PDFDocument241 pages1-SablaEVAReportver5.1 0 PDFshaikmanoj100% (1)

- Bedtime Routines For Young ChildrenDocument6 pagesBedtime Routines For Young ChildrenmithaNo ratings yet

- Fischer General-CatalogueDocument108 pagesFischer General-Cataloguebo cephusNo ratings yet

- Anenberg Et Al 2017 NatureDocument17 pagesAnenberg Et Al 2017 NatureJonnathan RamirezNo ratings yet

- Cosnsoles 1Document249 pagesCosnsoles 1Anonymous pmVnncYJNo ratings yet

- Contoh Soalan 14Document4 pagesContoh Soalan 14Rozaiya RamliNo ratings yet

- Challenges of Catholic Doctors in The Changing World - 15th AFCMA Congress 2012Document218 pagesChallenges of Catholic Doctors in The Changing World - 15th AFCMA Congress 2012Komsos - AG et al.No ratings yet

- Compressed Medical Gases PDFDocument34 pagesCompressed Medical Gases PDFRaúl DonosoNo ratings yet

- A Review Article On Edible Pigments Properties and Sources As Natural Biocolorants in Foodstuff and Food IndustryDocument8 pagesA Review Article On Edible Pigments Properties and Sources As Natural Biocolorants in Foodstuff and Food Industrybestread67No ratings yet

- CHEMICAL KINETICS PRACTICE TESTDocument3 pagesCHEMICAL KINETICS PRACTICE TESTlydia21111No ratings yet

- A Practical Guide To TG142Document46 pagesA Practical Guide To TG142Edis ĐedovićNo ratings yet

- Unit 1 - Construction Materials - WWW - Rgpvnotes.inDocument21 pagesUnit 1 - Construction Materials - WWW - Rgpvnotes.inmadhavi likharNo ratings yet

- Reactions of Carbonyl and Non-carbonyl Functional GroupsDocument4 pagesReactions of Carbonyl and Non-carbonyl Functional GroupsKashif AliNo ratings yet

- Compounding With PhlojelDocument29 pagesCompounding With PhlojelMichael SchreiberNo ratings yet

- A Comparison of Assisted, Resisted, and Common Plyometric Training Modes To Enhance Sprint and Agility PerformanceDocument8 pagesA Comparison of Assisted, Resisted, and Common Plyometric Training Modes To Enhance Sprint and Agility Performancegaston9reyNo ratings yet

- Procedure Kimia Fizik Lab 1Document2 pagesProcedure Kimia Fizik Lab 1izz isalahNo ratings yet

- Effectiveness of Pantawid Pamilyang PiliDocument17 pagesEffectiveness of Pantawid Pamilyang PiliDell Asus94% (51)

- Properties of Pure SubstancesDocument36 pagesProperties of Pure SubstancesAhmadFaisalNo ratings yet

- Secretary, NSW HealthDocument30 pagesSecretary, NSW HealthRiku KusanagiNo ratings yet