Professional Documents

Culture Documents

A Study On Effective Replacement of Fine Aggregate Using Copper Slag

Uploaded by

IJSTEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Study On Effective Replacement of Fine Aggregate Using Copper Slag

Uploaded by

IJSTECopyright:

Available Formats

IJSTE - International Journal of Science Technology & Engineering | Volume 1 | Issue 10 | April 2015

ISSN (online): 2349-784X

A Study on Effective Replacement of Fine

Aggregate using Copper Slag

M. R. Amarnaath

UG Student

Department of Civil Engineering

Knowledge Institute of Technology

S. Jaya Pradeep

UG Student

Department of Civil Engineering

Knowledge Institute of Technology

R. A. Kavin

UG Student

Department of Civil Engineering

Knowledge Institute of Technology

P. Dinesh

UG Student

Department of Civil Engineering

Knowledge Institute of Technology

S. Haribaskaran

UG Student

Department of Civil Engineering

Knowledge Institute of Technology

Abstract

In This paper we have experimented and investigate the effect of copper slag by replacing it with the fine aggregates and studied

the properties of concrete. For the experiment we have prepared five mix designs with different proportions of copper slag

ranging from 0% (for the control mix) to 35% and 100%. Concrete mixes were evaluated for density, compressive strength,

tensile strength, exural strength and durability. The results indicate that there is an increase in the concrete density of nearly 5%

with the increase of copper slag content, whereas the workability increased rapidly with increases in copper slag percentage.

Addition of up to 35% of copper slag as sand replacement has a comparable strength with that of the control mix. However,

further additions of copper slag caused reduction in the strength due to an increase of the free water content in the mix. Mixes

with 100% copper slag replacement gave the lowest compressive strength value of approximately 50 MPa, which is almost 16%

lower than the strength of the control mix. The results also demonstrated that the surface water absorption decreased as copper

slag quantity increases up to 35% replacement; beyond that level of replacement, the absorption rate increases rapidly. Therefore,

it is recommended that 40 wt. % of copper slag can used as replacement of sand in order to obtain concrete with good strength

and durability properties.

Keywords: Concrete, Copper slag, Density, Compression strength

________________________________________________________________________________________________________

I. INTRODUCTION

Copper slag is a massive metallurgical residue obtained from the transformation of copper ore concentrates into metallic copper

in the smelters. Slags are deposited in landfills that occupy large areas of land. Their chemical composition is rich in iron, silicon

and aluminum oxides and in their mineralogical composition, the presence of fayalite and magnetite, among other compounds is

common. The main environmental impact produced by slag disposition is a change in land use and the visual pollution of the

landscape. On the other hand, under certain weather conditions, leaching can occur, depending on the characteristics of the

solution, the composition, and the final crystalline structure of the solid slag.

It is estimated that in the copper industry, for every ton of metallic copper production, approximately 2.2 tons of copper slag is

generated and in the world, about 24.6 million tons of slag is produced annually. These metallurgical centers produced 2,360,000

metric tons of copper slag in the year 2002, leaving this waste deposited indefinitely as a hard floor, without current industrial

utility. However, global experiments for the use of copper slag have been going on in various sectors of production and the

results have been published with very good prospects. In particular, there is the use of this metallurgical waste in the construction

industry, where one of the studied applications is its use as a substitute for aggregates, both in cement mortar and concrete. This

paper describes an experimental study performed to determine possibilities for the use of copper slag as a substitute for the sand

in the manufacture of concrete.

Also, copper slag exhibits pozzolanic properties since it contains a low CaO content and other oxide such as Al2O3, SiO2, and

Fe2O3. Use of copper slag in the concrete industry as a replacement for cement and/or ne aggregates can has the benets of

reducing the costs of disposal and helps protecting the environment.

All rights reserved by www.ijste.org

227

A Study on Effective Replacement of Fine Aggregate using Copper Slag

(IJSTE/ Volume 1 / Issue 10 / 045)

II. MATERIALS

1) Cement: Portland Pozzolona cement, 43 Grade conforming to IS: 12269 1987.

2) Fine aggregate: Locally available river sand conforming to Grading zone II of IS: 383 1970.

3) Copper slag: Copper slag is a by-product material produced from the process of manufacturing copper. As the copper

settles down in the smelter, it has a higher density, impurities stay in the top layer and then are transported to a water

basin with a low temperature for solidication. The end product is a solid, hard material that goes to the crusher for

further processing.

4) Coarse aggregate: Locally available crushed blue granite stones conforming to graded aggregate of nominal size 12.5

mm as per IS: 383 1970.

5) Silica fume: Obtained from ELKEM India (P) Ltd., Navi Mumbai conforming to ASTM C 1240 as mineral admixture

in dry form.

A commercially available Poly Carboxylic Ether based super plasticizer was used as chemical admixture to enhance the

workability of the concrete.

6) Water: potable water.

III. MATERIAL PROPERTIES

A. Cement:

Portland Pozzolona cement (43 Grade) was used for casting all the Specimens. To produce high performance concrete, the

utilization of high strength cements is necessary. Different types of cement have different water requirements to produce pastes

of standard consistence. Different types of cement also will produce concrete have a different rates of strength development.

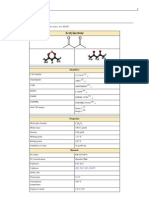

Fig. 3.1: Cement

S. No.

Table -3.1:

Properties of Cement

Property Of Cement Values

Fineness Of Cement

7.5%

2

3

4

5

Grade Of Cement

Specific Gravity

Initial Setting time

Final Setting Time

43

3.15

28 min

600 min

Normal consistency

35%

B. Fine Aggregate:

Clean and dry river sand available locally will be used. Sand passing through IS 4.75mm Sieve will be used for casting all the

specimens.

Fig. 3.2: Fine Aggregate

All rights reserved by www.ijste.org

228

A Study on Effective Replacement of Fine Aggregate using Copper Slag

(IJSTE/ Volume 1 / Issue 10 / 045)

Table -3.2:

Properties of Fine Aggregate

S.No

1

Properties

Specific Gravity

Value

2.65

2

3

Fineness Modulus

Water absorption

2.25

1.5%

C. Copper Slag:

Tests were conducted to determine the chemical composition, specic gravity and water absorption of copper slag and sand.

Results presented in Table 3.3 show that copper slag has a low CaO content compared with ordinary Portland cement,

which indicates that copper slag on its own cannot be used as a cementations material. But copper slag has high concentrations

of silica, alumina and iron oxides, which suggests that copper slag could have the potential to produce high quality pozzolans.

Results from specic gravity and water absorption tests (Table 3) revealed that copper slag has a specic gravity of 3.4 which

is higher than that of sand (2.77), whereas the water absorption values for copper slag and sand were about 0.2% and 1.4%,

respectively. This suggests that concrete produced with large copper slag substitution would have larger density values than

concrete produced with sand alone. On the other hand, due to its low water absorption it is expected that the free water content in

concrete mixtures will increase as copper slag content increases. This will lead to an increase in the workability of concrete

mixtures containing high copper slag percentages

Fig. 3.3: Copper Slag

Table -3.3:

Chemical composition and physical properties of ordinary Portland cement (OPC), copper slag (CS) and sand

Component

OPC (%)

CS (%)

Sand

SiO2

20.85

33.05

Al2O3

4.78

2.79

Fe2O3

3.51

53.45

CaO

63.06

6.06

MgO

2.32

1.56

SO3

2.48

1.89

K2O

0.55

0.61

Na2O

0.24

0.28

TiO2

0.25

Mn2O3

0.05

0.06

Cl

0.01

0.01

Loss on ignition

1.75

IR

0.21

CuO

0.46

Al2O3 + SiO2 + Fe2O3

29.14

89.29

Specific gravity

3.15

3.4

2.77

Absorption(%)

0.17

1.36

All rights reserved by www.ijste.org

229

A Study on Effective Replacement of Fine Aggregate using Copper Slag

(IJSTE/ Volume 1 / Issue 10 / 045)

D. Coarse Aggregate:

Crushed granite aggregate with specific gravity of 2.77 and passing through 4.75 mm sieve and will be used for casting all

specimens. Several investigations concluded that maximum size of coarse aggregate should be restricted in strength of the

composite. In addition to cement paste aggregate ratio, aggregate type has a great influence on concrete dimensional stability.

Fig. 3.4: Coarse Aggregate

Table -3.4:

Properties of Coarse Aggregate

S. No.

Properties

Values

Specific Gravity

2.65

Size Of Aggregates

Passing Through 12.5 mm Sieve

Fineness Modulus

5.96

Water absorption

2.0%

Impact Test

15.2%

Crushing Test

22.5%

E. Super Plasticizer:

The inter particle friction between fibers and aggregates controls the orientation and distribution of thr fibers and consequently

the properties of concrete. Therefore Napthalene-Formaldehyde Sulphonated based super plasticizer is added as a friction

reducing admixture to improve the cohesiveness of mix.

Fig. 3.5: Super Plasticizer Conplast

Table -3.5:

Properties of Super Plasticizer

PROPERTIES

VALUE

Colour

Specific gravity

Brown

1.22to1.225

Chloride content

Solid content

Nil

40%

All rights reserved by www.ijste.org

230

A Study on Effective Replacement of Fine Aggregate using Copper Slag

(IJSTE/ Volume 1 / Issue 10 / 045)

IV. MIX RATIO AND RESULTS

Table -4.1:

Percentage replacement of copper slag as sand

Mix No

Copper slag

Sand

0%

100%

2

3

35%

100%

65%

0%

Table -4.2:

Compressive strength of concrete after curing

Compressive strength (MPa)

Mix No

7 days

21 days

28 days

1

21.2

21.8

22.6

2

30

37.6

42.7

3

23.2

25.4

26.1

Table- 4.3:

Flexural strength of concrete after curing

Flexural strength (MPa)

Mix No

7 days 21 days 28 days

1

3

5.2

7.7

2

4.1

5.5

7.3

3

3.4

4.6

5.9

V. CONCLUSION

1) Compared to the control mix, there was a slight increase in the concrete density of nearly 5% with the increase Of

copper slag content.

2) Whereas the workability increased rapidly with increases in copper slag percentage.

3) Addition of up to 35% of copper slag as sand replacement yielded comparable strength with that of the control mix.

4) However, further additions of copper slag caused reduction in the strength due to an increase of the free water content in

the mix.

5) Mixtures with 0% and 100% copper slag replacement gave the lowest compressive strength value of Approximately 30

MPa, which was almost 16% lower than the strength of the control mix.

6) There was a decrease in the surface water absorption as copper slag quantity increased up to 35% replacement.

Beyond that level of replacement, the absorption rate increases rapidly.

7) It is recommended that 35 wt. % of copper slag can be used as replacement of sand in order to obtain High strength with

good properties.

8) It should be noted that further research work is needed to explore the effect of copper slag as ne aggregates on the

properties of concrete with different cement types, silica fume sources and the degree of nes.

REFERENCE

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

K. S. Al Jabri, Copper Slag As Fine Aggregate For High Performance Concrete, 10.2495/HPSM060371

Khalifa S. Al-Jabri, Effect of copper slag as a fine aggregate on the properties of cement mortars and concrete, 02/2011; 25(2):933-938.

C. K. Madheswaran ,P. S. Ambily ,J. K. Dattatreya , N. P. Rajamane, Studies on use of Copper Slag as Replacement Material for River Sand in Building

Constructions, J. Inst. Eng. India Ser. A (JulySeptember 2014) 95(3):169177

J. Shahu, S. Patel, A. Senapat, Engineering properties of copper slag-fluash-polime mix and its utilization in base course of flexible pavements, J. Mater

Civ. Eng. (2012) doi:10.1061/(ASCE)MT.1943-5533.0000756

Hassan, H, AI-Jabri, K (2011) Laboratory evaluation of hot-mix asphalt concrete containing copper slag aggregate. J. Mater. Civ. Eng. 23: pp. 879-885

CrossRef

Al-jabri, KS, Al-oraimi, H, Alnuaimi, AS (2012) Copperslag as fine aggregate for high performance concrete. TJER 9: pp. 90-102

K. M. Sharma, P. S. Sharma, D.Yadav, J. M. Sharma, K. Mohan, Technical suitability of Copper Slag for the Manufacture of Cement. for M/s Sterlite

Industries (India) Ltd., Tuticorin (Tamil Nadu) Sponsored Project-1324, July 2005

Supekar, N (2007) Utilisation of Copper Slag for Cement Manufacture Construction Management and Review. Sterilite Industries (I) Ltd, Tuticorin.

All rights reserved by www.ijste.org

231

You might also like

- Optimization of Overall Efficiency Using Facilities Planning in Ropp Cap Making IndustryDocument8 pagesOptimization of Overall Efficiency Using Facilities Planning in Ropp Cap Making IndustryIJSTENo ratings yet

- Design and Analysis of Magneto Repulsive Wind TurbineDocument7 pagesDesign and Analysis of Magneto Repulsive Wind TurbineIJSTENo ratings yet

- Automatic Generation Control in Three-Area Power System Operation by Using "Particle Swarm Optimization Technique"Document8 pagesAutomatic Generation Control in Three-Area Power System Operation by Using "Particle Swarm Optimization Technique"IJSTENo ratings yet

- Multipurpose Scheme of Workshop Exhaust System For Ventilation and Electrical Power GenerationDocument9 pagesMultipurpose Scheme of Workshop Exhaust System For Ventilation and Electrical Power GenerationIJSTENo ratings yet

- The Bicycle As A Mode Choice - A Gendered ApproachDocument4 pagesThe Bicycle As A Mode Choice - A Gendered ApproachIJSTENo ratings yet

- Effect of RIB Orientation in Isogrid Structures: Aerospace ApplicationsDocument9 pagesEffect of RIB Orientation in Isogrid Structures: Aerospace ApplicationsIJSTENo ratings yet

- A Mixture of Experts Model For ExtubationDocument4 pagesA Mixture of Experts Model For ExtubationIJSTENo ratings yet

- FPGA Implementation of High Speed Floating Point Mutliplier Using Log Based DesignDocument4 pagesFPGA Implementation of High Speed Floating Point Mutliplier Using Log Based DesignIJSTENo ratings yet

- Partial Replacement of Fine Aggregate With Iron Ore Tailings and Glass PowderDocument7 pagesPartial Replacement of Fine Aggregate With Iron Ore Tailings and Glass PowderIJSTENo ratings yet

- RFID Based Toll Gate AccessDocument5 pagesRFID Based Toll Gate AccessIJSTENo ratings yet

- A Cloud Based Healthcare Services For Remote PlacesDocument4 pagesA Cloud Based Healthcare Services For Remote PlacesIJSTENo ratings yet

- Enriching Gum Disease Prediction Using Machine LearningDocument6 pagesEnriching Gum Disease Prediction Using Machine LearningIJSTENo ratings yet

- Optimization of Treatability by FACCO For Treatment of Chemical Industry EffluentDocument9 pagesOptimization of Treatability by FACCO For Treatment of Chemical Industry EffluentIJSTENo ratings yet

- A Comprehensive Survey of Techniques/Methods For Content Based Image Retrieval SystemDocument6 pagesA Comprehensive Survey of Techniques/Methods For Content Based Image Retrieval SystemIJSTENo ratings yet

- Development of Relationship Between Saturation Flow and Capacity of Mid Block Section of Urban Road - A Case Study of Ahmedabad CityDocument6 pagesDevelopment of Relationship Between Saturation Flow and Capacity of Mid Block Section of Urban Road - A Case Study of Ahmedabad CityIJSTENo ratings yet

- A Radar Target Generator For Airborne TargetsDocument8 pagesA Radar Target Generator For Airborne TargetsIJSTENo ratings yet

- Comparative Study and Analysis of PCC Beam and Reinforced Concrete Beam Using GeogridDocument7 pagesComparative Study and Analysis of PCC Beam and Reinforced Concrete Beam Using GeogridIJSTENo ratings yet

- Optimum Placement of DG Units Using CPF MethodDocument6 pagesOptimum Placement of DG Units Using CPF MethodIJSTENo ratings yet

- An Implementation and Design A Customized Advanced Image Editor Using Image Processing in MatlabDocument5 pagesAn Implementation and Design A Customized Advanced Image Editor Using Image Processing in MatlabIJSTENo ratings yet

- Wireless Information Process and Power Transfer in Single-User OFDM SystemDocument6 pagesWireless Information Process and Power Transfer in Single-User OFDM SystemIJSTENo ratings yet

- Onerider The Bike TaxiDocument3 pagesOnerider The Bike TaxiIJSTENo ratings yet

- Interstage Construction Techniques For Mass Gain: An OverviewDocument5 pagesInterstage Construction Techniques For Mass Gain: An OverviewIJSTENo ratings yet

- App-Based Water Tanker Booking, Monitoring & Controlling SystemDocument6 pagesApp-Based Water Tanker Booking, Monitoring & Controlling SystemIJSTENo ratings yet

- Research On Storage Privacy Via Black Box and Sanitizable SignatureDocument6 pagesResearch On Storage Privacy Via Black Box and Sanitizable SignatureIJSTENo ratings yet

- Technology Advancement For Abled PersonDocument9 pagesTechnology Advancement For Abled PersonIJSTENo ratings yet

- Using The Touch-Screen Images For Password-Based Authentication of IlliteratesDocument6 pagesUsing The Touch-Screen Images For Password-Based Authentication of IlliteratesIJSTENo ratings yet

- Optimizing Turning Process For EN43 by Taguchi Method Under Various Machining ParametersDocument4 pagesOptimizing Turning Process For EN43 by Taguchi Method Under Various Machining ParametersIJSTENo ratings yet

- An Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemDocument5 pagesAn Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemIJSTENo ratings yet

- Duplicate Detection Using AlgorithmsDocument3 pagesDuplicate Detection Using AlgorithmsIJSTENo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ASTM-A519.pdf - Scribd: Rating: 5 - 1 VoteDocument3 pagesASTM-A519.pdf - Scribd: Rating: 5 - 1 VoteInfoNo ratings yet

- Me 701 Heat and Mass Transfer Dec 2020Document2 pagesMe 701 Heat and Mass Transfer Dec 2020Shyam Sunder PrasadNo ratings yet

- Test For Proteins-ResearchLab4Document8 pagesTest For Proteins-ResearchLab4Mikaela Rome BigayNo ratings yet

- Liquid Soap ProcessDocument3 pagesLiquid Soap ProcessAnnette40% (5)

- SS COCrDocument101 pagesSS COCrsoujanyaNo ratings yet

- Unit 1&2 Exercises Biochemistry 27.10.20Document56 pagesUnit 1&2 Exercises Biochemistry 27.10.20Nguyen Bao TranNo ratings yet

- BioPharming (Molecular Farming)Document57 pagesBioPharming (Molecular Farming)Kuldeep SharmaNo ratings yet

- KPPL CorporateDocument8 pagesKPPL CorporateDeepak PandeyNo ratings yet

- Synthesis and Properties of Soaps From Bidara Leaf: (Ziziphus Mauritania) Via Soft SaponificationDocument5 pagesSynthesis and Properties of Soaps From Bidara Leaf: (Ziziphus Mauritania) Via Soft SaponificationFRANCINNE MARTINNo ratings yet

- Safety Construction IndustriesDocument65 pagesSafety Construction IndustriesAbhishekNo ratings yet

- Requirement For Crown Industrial ParkDocument1 pageRequirement For Crown Industrial ParkAbdul RafaeNo ratings yet

- Tappi Tip 0402-28Document16 pagesTappi Tip 0402-28Haries Bugarin Garcia100% (1)

- Sustainable Environment Research: ReviewDocument9 pagesSustainable Environment Research: ReviewDiana PaipillaNo ratings yet

- Kingdom of Saudi Arabia: Ministry of Interior High Commission For Industrial Security Secretariat GeneralDocument2 pagesKingdom of Saudi Arabia: Ministry of Interior High Commission For Industrial Security Secretariat GeneralVishnudasNo ratings yet

- Quality Improvement of Sintered Ore in Relation To Blast Furnace OperationDocument6 pagesQuality Improvement of Sintered Ore in Relation To Blast Furnace OperationROWHEITNo ratings yet

- Heat TransferDocument28 pagesHeat TransferShusha ShomaliNo ratings yet

- Semiconductor polishing compound for cerium oxide slurry stabilityDocument13 pagesSemiconductor polishing compound for cerium oxide slurry stabilityrat0708No ratings yet

- Useful formula for flat plate solar collector efficiencyDocument3 pagesUseful formula for flat plate solar collector efficiency김동욱No ratings yet

- PresentationDocument13 pagesPresentationAtman WagleNo ratings yet

- 2701 MSDSDocument5 pages2701 MSDSAhmed Emad AhmedNo ratings yet

- Nitocote NT402 UAEDocument4 pagesNitocote NT402 UAEbuitems11No ratings yet

- Human Biology 12th Edition Mader Test BankDocument25 pagesHuman Biology 12th Edition Mader Test BankLauraMitchellfgie98% (52)

- AcetylacetoneDocument5 pagesAcetylacetoneac_76_pxNo ratings yet

- EurekaDocument19 pagesEurekaCalhounHonorsCollegeNo ratings yet

- Electroplating Lab CHEM 401Document10 pagesElectroplating Lab CHEM 401anak gamerNo ratings yet

- Ud He TechnologyDocument16 pagesUd He TechnologyBejavada SureshNo ratings yet

- Multiple Choice QuestionsDocument18 pagesMultiple Choice QuestionsGranpaXNo ratings yet

- API - 510 Training Course 2 PDFDocument2 pagesAPI - 510 Training Course 2 PDFRobin GuNo ratings yet

- Intro To Fluid PropertiesDocument18 pagesIntro To Fluid PropertiesAngela Mae LopezNo ratings yet

- Chemistry 101 Final Exam-B Fall 2014Document13 pagesChemistry 101 Final Exam-B Fall 2014Kristopher Park SolivenNo ratings yet