Professional Documents

Culture Documents

Hazard Sheet 12: Lifting Operations

Uploaded by

ThiênSứBanPhúcOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hazard Sheet 12: Lifting Operations

Uploaded by

ThiênSứBanPhúcCopyright:

Available Formats

Hazard Sheet 12

Lifting Operations

Lifting Operations

Typical problems

Lifting operations are high risk if they are not planned and executed properly. Typical causes of lifting failures include:

persons involved are not competent

equipment is in a poor state of repair

incorrect equipment being used

general misuse of equipment

lack of accurate information about the load characteristics

unstable ground where mobile cranes are used

poor weather conditions

poor slinging of the load

production pressure to get the job done on time.

Planning the lift

Confirm the size of the load to be lifted and identify its centre of gravity.

Ensure that the appropriate size of crane is obtained with a sufficient safety margin.

Check on competence of crane supplier and the operator, slinger and signaller to be provided.

Ensure that a lifting risk assessment has been carried out and has taken into account the load, ground conditions and any adjacent

structures.

Check on ground conditions.

If not suitable for the load a special base may need to be provided to position the crane and its out riggers.

Loading in

Chain Leg

Horizontal Force

Horizontal Force

10 tonnes

600 mm min

Fig 1 Safe use of Mobile Crane

Executing the lift

Ensure that when the crane arrives on site it has its documentation in respect of its last inspection/examination, at least

within the last 12 months.

Check lifting slings to be used and that they have also been inspected within the last 6 months and there is an inspection

record.

Check competence evidence of driver, slinger and signaller if provided.

Hazard_12.doc

Page 1 of 6

Hazard Sheet 12

Lifting Operations

Lifting Operations Cont

Signalling

LEFT

RIGHT

LOWER

DANGER

STOP

RAISE

Fig 2 Signalling

Ensure that the crane is located on solid ground and that the outriggers and spreader plates are fully deployed.

The crane must be level and tyres correctly pressurised.

Crane shall be positioned so that there is a min of 600mm distance between it and any fixed structure to prevent any person

becoming trapped.

Check also for any overhead power lines or other structures.

The crane shall have a fully operational automatic safe working load indicator, and overwind protection.

Ensure that all unauthorised persons are kept out of the area in which the lift is being conducted.

Ensure that the crane hook is positioned over the centre of gravity of the load.

UNSTABLE

Centre of gravity is

higher than lift points

UNSTABLE

Hook is not over

centre of gravity

Fig 3 Unstable Load

Load will shift until centre

of gravity is below hook

STABLE

Hook is over centre of gravity

Fig 4 Stable Load

Slinging

Typical problems

Whilst lifting failures can occur with the use of cranes and similar lifting machines many failures arise as a result of incorrect methods or use of

slinging equipment which include:

Slinging operatives not trained or competent;

Slings and other lifting tackle not maintained and therefore not fit for purpose;

Lifting equipment misused or incorrectly used;

Poor knowledge of the load characteristics;

Hazard_12.doc

Page 2 of 6

Hazard Sheet 12

Lifting Operations

Lifting Operations Cont

Notes on Safe Working

1.

All wire ropes, chains and other lifting tackle must never be overloaded and must be inspected and examined by a competent person at

least once every 6 months or earlier as determined by conditions. Useful to have a coloured tag to indicate the last time it was examined.

2. It is advisable to visually check the lifting sling before to ensure that it looks in reasonable condition i.e. it has not suffered significant

wear or damage since it was last inspected or examined.

3. Slings should always be attached correctly to the lifting equipment either by securing the ring directly onto the hook or by using a suitable

shackle, fitted so that the pin of the shackle is located on the load and the hook on the bow section.

4. When handling long or large loads suitable lines (tag lines) should be attached to enable the load to be controlled into its correct position

and also prevent it from spinning.

5. Multiple legged slings must be connected by means of a suitable ring or shackle and load correctly distributed so that no one leg is

overloaded.

6. The angle between sling legs shall not exceed 90 as the load increases substantially.

7. Wire rope slings can be affected by sharp corners which

will reduce their efficiency. Use some form of packing or

lagging to minimise this effect.

Loading in

8. Avoid dragging slings along a hard floor.

Chain Leg

9. Never use a wire rope sling if it has kinks in it.

10. No lifting sling or other lifting equipment shall be used on

site unless it has a certificate that confirms its safe working

load (SWL) and there is a report of its last examination.

Horizontal Force

Horizontal Force

10 tonnes

Fig 5 Safe Working Loads

Wind strengths

Lifting operations can only be carried out when the conditions are safe to do so. The manufacturer of the carne or other lifting machine will have

specified the wind strength at which lifting should not be carried out.

Windforce

No

Speed mph

Speed

m/sec

Calm, smoke rises vertically

1-6

0-1

Light air

Direction of wind shown by smoke drift, but not by weather vanes

1-8

1-2

Light breeze

Wind felt on face. leaves rustle and wind vanes move

6.5 -11.0

2-3

Gentle breeze

Leaves and small twigs in constant motion. Wind extends light

flags

13 - 19

3-5

Moderate breeze

Wind raises dust and loose paper. Small branches move.

21 - 29

5 -8

Fresh breeze

Small trees in leaf begin to sway. Little crested wavelets form on

inland waters.

30 - 38

8 - 11

Strong breeze

Large branches in motion. Umbrellas used with difficulty.

40 - 50

11 - 14

Near gale

Whole trees in motion. Becoming difficult to walk against the

wind.

51 - 61

14 - 17

Gale

Twigs break off trees. Progress is generally impeded

62 - 74

17 - 21

Strong gale

Chimney pots, slates and tiles may be blown off. Other slight

structural damage may be caused.

75 - 86

21 - 24

Description

Visible effect

Calm

Table 1 - Wind Strengths

Hazard_12.doc

Page 3 of 6

Hazard Sheet 12

Lifting Operations

Lifting Operations Cont

Types of Slinging arrangements

Permitted Slings

Fig 6 Reeving Sling

Lifting short lengths of tube.

Fig 7 Halshing Sling

Method of using a single sling in place of an endless sling

where a bight is required.

Fig 10 Cradle Sling

Lifting coils of steel strip.

Fig 11 Double Wrap Slings

Note how the double wrap grips the load and helps to prevent it

from slipping sideways out of the slings

A stirrup fitted temporarily in the bight will minimise damage

to the sling.

Fig 8 Reeving Slings

Lifting tubes, bars and rods.

Fig 9 Combination Slings

Concrete beams, steel joists, etc.

Hazard_12.doc

Fig 12 Cradle Slings

Lifting boilers and packing cases.

Fig 13

Timber, steel sheets and packing cases.

Page 4 of 6

Hazard Sheet 12

Lifting Operations

Lifting Operations Cont

Bad Practice

Fig 14

Hooking back to the leg of a sling is not recommended.

Fig 18

A sling which has been doubled around a shackle has a Safe

Working Load equivalent only to that of a single part of the rope.

Max 90 Degrees

Fig 15

Avoid using single slings in this manner.

Fig 19

Crane hooks shall not be loaded up to the full Safe Working

Load at an angle exceeding 90 degrees since there is a risk of

spraining the hook.

Max 90 Degrees

Fig 16

Eyebolts are not designed to be used with a hook. Instead, use a

shackle.

Fig 20

Dee and Bow shackles shall not be loaded at an angle exceeding

90 degrees.

Max 120

Degrees

Fig 17

When using a halshing sling or reeving sling do not force the bight

down on to the load.

Fig 21

Do not use a sling which contains a severe kink,

or with loose or damaged strands.

The included angle formed by the bight should not exceed 120

degrees.

Hazard_12.doc

Page 5 of 6

Hazard Sheet 12

Lifting Operations

Lifting Operations Cont

Gin wheels

A gin wheel is a simple lifting device often used to lift tools and small loads up to the working platform that might be on a scaffold.

all poles and hooks should be of suitable strength to withstand the loads

being lifted and be secured.

Max. 750 mm

all ropes used shall fit the wheel correctly and have a safe working load

greater than the load s being lifted and should be tagged or identified

accordingly.

the gin wheel should be attached with proper hooks.

gin wheels should be suspended not more than 750mm from the outer

support.

hooks used for supporting materials should be safety hooks and spliced

into the rope.

the maximum loading should be no more than 50kg at 750mm from the

Moused or

outer support.

Safety hook

gin wheels should be subject to the usual inspection and test before use

and thereafter every 6 months.

if scaffolds are not available then other suitable anchorages should be

used.

a safety factor of 3 should be used in calculating the weight of the

counterweight.

Fig 22 Gin Wheel Assembly

T (Tail length metres)

O (Overhang metres)

Counterweight

(kilogrammes)

Fulcrum

W = 3 (2.5 x G x O)

T

W = weight of counterweight

T = tail length in metres

G (Greatest lifted load)

G = greatest load to be lifted

O = overhang in metres

Hazard_12.doc

Fig 23 Counter Balance Loading

Page 6 of 6

You might also like

- Jazz ArrangementsDocument238 pagesJazz ArrangementsVignesh En100% (1)

- Crane, Rigging & LiftingDocument100 pagesCrane, Rigging & LiftingMarlon Arq100% (13)

- General Crane SafetyDocument4 pagesGeneral Crane SafetyEhab Mostafa AliNo ratings yet

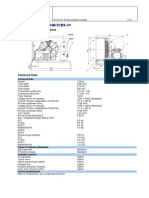

- Industrial Diesel Generator Set: Standby Power RatingDocument7 pagesIndustrial Diesel Generator Set: Standby Power RatingJavier SilvaNo ratings yet

- Bogged Vehicle Recovery PDFDocument2 pagesBogged Vehicle Recovery PDFcityofdarwingis100% (1)

- Instructions For The Safe Use Of: Wire Rope SlingsDocument2 pagesInstructions For The Safe Use Of: Wire Rope SlingsStuartWilliamGlennieNo ratings yet

- Pole Installation MethodologyDocument10 pagesPole Installation MethodologyHitesh Garg43% (14)

- Confident Powerboating: Mastering Skills and Avoiding Troubles AfloatFrom EverandConfident Powerboating: Mastering Skills and Avoiding Troubles AfloatNo ratings yet

- Flexbox cheatsheet guide with display, flex-direction, and flex-item propertiesDocument1 pageFlexbox cheatsheet guide with display, flex-direction, and flex-item propertiesCarlos PimentelNo ratings yet

- Lifting Tools SafetyDocument44 pagesLifting Tools Safetybalajirajasekaran100% (2)

- Septic Tank Analysis PDFDocument34 pagesSeptic Tank Analysis PDFChristian D. Orbe100% (3)

- Septic Tank Analysis PDFDocument34 pagesSeptic Tank Analysis PDFChristian D. Orbe100% (3)

- Solaris Hardening Guide v1Document56 pagesSolaris Hardening Guide v1GusGualdNo ratings yet

- Safe LiftingDocument22 pagesSafe LiftingMahmoud Abdallah67% (3)

- Offshore Crane Safety TrainingDocument29 pagesOffshore Crane Safety TrainingBergensur100% (3)

- Lifting Beams and SpreadersDocument2 pagesLifting Beams and SpreadersNadeem MalikNo ratings yet

- Hilman Roller Instruction Manual GuideDocument22 pagesHilman Roller Instruction Manual Guidevpizarro_23No ratings yet

- Beam Deflection FormulaeDocument2 pagesBeam Deflection Formulae7575757575100% (6)

- My Industrial Rigging and CranesDocument203 pagesMy Industrial Rigging and CranesJShearer67% (6)

- Basic-Rigging & SlingingDocument118 pagesBasic-Rigging & SlingingsidraNo ratings yet

- Fassi Crane: Use and MaintenanceDocument55 pagesFassi Crane: Use and MaintenanceJaime Sua100% (1)

- Data Sheet FOR Centrifugal Pump: Page 1 of 3Document3 pagesData Sheet FOR Centrifugal Pump: Page 1 of 3ThiênSứBanPhúcNo ratings yet

- Handbook Lifting Load SafelyDocument17 pagesHandbook Lifting Load SafelyAlok SinghNo ratings yet

- A Guide to the Use of Climbing Rope - A Collection of Historical Mountaineering Articles on Rope TechniqueFrom EverandA Guide to the Use of Climbing Rope - A Collection of Historical Mountaineering Articles on Rope TechniqueNo ratings yet

- Sec.2-61 Sky Climbers & Suspended Power PlatformsDocument6 pagesSec.2-61 Sky Climbers & Suspended Power Platformsbravo2uniform2736No ratings yet

- LTMC For Master Data Step by Step Process - SAP BlogsDocument24 pagesLTMC For Master Data Step by Step Process - SAP BlogsshamsNo ratings yet

- Lifting Equipments and Procedure: Compiled by Safety Trainees PeclDocument83 pagesLifting Equipments and Procedure: Compiled by Safety Trainees PeclvarunstuffNo ratings yet

- Mechanical Material HandlingDocument64 pagesMechanical Material HandlingsivaguruaksNo ratings yet

- Industrial Safety of Lifting ProcedureDocument83 pagesIndustrial Safety of Lifting Proceduresaravanan_c1No ratings yet

- HCH Series Hand Chain Hoist ManualDocument14 pagesHCH Series Hand Chain Hoist ManualRoni AdiNo ratings yet

- ENV 1991-2-1-1996 - Withdrawn PDFDocument37 pagesENV 1991-2-1-1996 - Withdrawn PDFcatalina_tudosaNo ratings yet

- GT Manual HoistDocument16 pagesGT Manual HoistAntohi CatalinNo ratings yet

- Lifting OperationDocument6 pagesLifting OperationOchulor IsaacNo ratings yet

- Gear Pump and API 676Document42 pagesGear Pump and API 676ThiênSứBanPhúc50% (2)

- Hazard Sheet 12: Lifting OperationsDocument6 pagesHazard Sheet 12: Lifting OperationsThiênSứBanPhúcNo ratings yet

- Terms Used in Ultrasonic Testing BSEN 1330-4 PDFDocument95 pagesTerms Used in Ultrasonic Testing BSEN 1330-4 PDFThe Normal HeartNo ratings yet

- SYS600 - IEC 61850 System DesignDocument74 pagesSYS600 - IEC 61850 System Designelo_elo_elo_eloNo ratings yet

- Nokia ReportsDocument2 pagesNokia Reportsnarendraiit2003100% (3)

- Owner's Manual for 12V DC Electric Winch with Safety PrecautionsDocument8 pagesOwner's Manual for 12V DC Electric Winch with Safety Precautionshugggy_bearNo ratings yet

- F390se.24 GC PDFDocument44 pagesF390se.24 GC PDFDennis XenosNo ratings yet

- Coffing LSB Manual MICASDocument16 pagesCoffing LSB Manual MICASGuatemalan1979No ratings yet

- The Single Most Important Precaution in Rigging and Hoisting Is To Determine Load Weight Before Attempting Any LiftDocument19 pagesThe Single Most Important Precaution in Rigging and Hoisting Is To Determine Load Weight Before Attempting Any LiftBinoy GopinathanNo ratings yet

- C Hook+Operator+Safety+ManualDocument7 pagesC Hook+Operator+Safety+ManualAshokNo ratings yet

- Handling Standard Specification - MCE EG011 CDocument9 pagesHandling Standard Specification - MCE EG011 CSenol LimanNo ratings yet

- MSD - Nov 23Document7 pagesMSD - Nov 23chinmayeducationtrustNo ratings yet

- Material Handling SafetyDocument8 pagesMaterial Handling SafetyAnonymous LFgO4WbIDNo ratings yet

- UntitledDocument24 pagesUntitledRoshan MaindanNo ratings yet

- Rules To Follow When Lifting and Moving Loads by CraneDocument13 pagesRules To Follow When Lifting and Moving Loads by Cranehk331984No ratings yet

- Usage of Cranes: General IntroductionDocument13 pagesUsage of Cranes: General Introductionசரவணகுமார் மாரியப்பன்No ratings yet

- Safelift Overhead Crane Operation, Maintenance & Safety InstructionsDocument6 pagesSafelift Overhead Crane Operation, Maintenance & Safety Instructionsmuthuswamy77No ratings yet

- Final Drywall Lift Manual PDFDocument48 pagesFinal Drywall Lift Manual PDFtopbedrtNo ratings yet

- Ramsey Dc200 Dcy2000Document30 pagesRamsey Dc200 Dcy2000imagex5No ratings yet

- Roundslings: ManualDocument2 pagesRoundslings: ManualPernando SagaNo ratings yet

- Handling Steel Plate For Fabrication: National Safety Council Data Sheet 565 Rev. March 2007Document8 pagesHandling Steel Plate For Fabrication: National Safety Council Data Sheet 565 Rev. March 2007Shivpriya SarafNo ratings yet

- HSM01 A133900066MS Installation and AdjustmentDocument51 pagesHSM01 A133900066MS Installation and AdjustmentjokoNo ratings yet

- Final Drywall Lift ManualDocument48 pagesFinal Drywall Lift ManualLenning Peña100% (1)

- 6-Safety in DrillingDocument31 pages6-Safety in DrillingrahulNo ratings yet

- TBT - 037 Scissor LiftsDocument4 pagesTBT - 037 Scissor LiftsRich PellettNo ratings yet

- Pa RTS, Operation and Maintenance Manual For Ultra-Lo'" Rigid Trolley ModelsDocument36 pagesPa RTS, Operation and Maintenance Manual For Ultra-Lo'" Rigid Trolley Modelspaulbw100% (1)

- 2xy33 Polipasto Hoist DaytonDocument12 pages2xy33 Polipasto Hoist DaytonNeto CorleoneNo ratings yet

- Synthetic Web Sling GuideDocument5 pagesSynthetic Web Sling Guidesapi_buntekNo ratings yet

- Operation Manual &: Motorized TrolleyDocument44 pagesOperation Manual &: Motorized TrolleymigueljesusmNo ratings yet

- 59 Acop For Mobile GantriesDocument2 pages59 Acop For Mobile Gantriesdsn_sarmaNo ratings yet

- Forklift Course Pre-Reading Information March 2011Document9 pagesForklift Course Pre-Reading Information March 2011ThanhNo ratings yet

- Manual de Rio Tirfor T 532DDocument2 pagesManual de Rio Tirfor T 532DraulguardaNo ratings yet

- COMEUP Winch Users GuideDocument49 pagesCOMEUP Winch Users GuidecarsoffeuropeNo ratings yet

- Vehicle Recovery Electric Winch 13000LB-16800LB: InstructionsDocument14 pagesVehicle Recovery Electric Winch 13000LB-16800LB: InstructionstalibanindonesiaNo ratings yet

- AccountantDocument3 pagesAccountantThiênSứBanPhúcNo ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract PagesThiênSứBanPhúcNo ratings yet

- Giao DucDocument9 pagesGiao DucThiênSứBanPhúcNo ratings yet

- XSXSXSXSXDocument40 pagesXSXSXSXSXAfiq JuwaidiNo ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract PagesThiênSứBanPhúcNo ratings yet

- Rao PresentationDocument36 pagesRao PresentationThiênSứBanPhúcNo ratings yet

- Aço Sa 537 cl1Document23 pagesAço Sa 537 cl1pcorreia68100% (1)

- Rao PresentationDocument36 pagesRao PresentationThiênSứBanPhúcNo ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract PagesThiênSứBanPhúcNo ratings yet

- Department of Agriculture and Food: MARCH 2006Document29 pagesDepartment of Agriculture and Food: MARCH 2006ThiênSứBanPhúcNo ratings yet

- Department of Agriculture and Food: MARCH 2006Document29 pagesDepartment of Agriculture and Food: MARCH 2006ThiênSứBanPhúcNo ratings yet

- XSXSXSXSXDocument40 pagesXSXSXSXSXAfiq JuwaidiNo ratings yet

- BUTTING Vessels Tanks ColumnsDocument16 pagesBUTTING Vessels Tanks ColumnsThiênSứBanPhúcNo ratings yet

- PHU LUC 3 - Co KhiDocument18 pagesPHU LUC 3 - Co KhiThiênSứBanPhúcNo ratings yet

- A01 PEDFinal ReportDocument33 pagesA01 PEDFinal ReportThiênSứBanPhúcNo ratings yet

- Usda Guidelines For The Sanitary Design and Fabrication of Dairy Processing EquipmentDocument54 pagesUsda Guidelines For The Sanitary Design and Fabrication of Dairy Processing EquipmentThiênSứBanPhúcNo ratings yet

- Difference Between Hot - & Cold-Rolled Steel - EHowDocument4 pagesDifference Between Hot - & Cold-Rolled Steel - EHowThiênSứBanPhúcNo ratings yet

- Mat SelecDocument7 pagesMat SelecmeskeydegamaNo ratings yet

- TOYO-VIETNAM Corp. LTD.: Project: Dap-No Client: Vinachem Fabricator: Lisemco 2 - Hai Phong LILAMA 69.3 - Hai DuongDocument41 pagesTOYO-VIETNAM Corp. LTD.: Project: Dap-No Client: Vinachem Fabricator: Lisemco 2 - Hai Phong LILAMA 69.3 - Hai DuongThiênSứBanPhúcNo ratings yet

- ABC Siemens IECMotorsDocument168 pagesABC Siemens IECMotorsFernando MuneraNo ratings yet

- 03 Energy Efficient Electric Motor Selection Handbook PDFDocument65 pages03 Energy Efficient Electric Motor Selection Handbook PDFnicu_psiNo ratings yet

- Ijmet: ©iaemeDocument7 pagesIjmet: ©iaemeIAEME PublicationNo ratings yet

- IP Packet Switching: COS 461: Computer Networks Spring 2006 (MW 1:30-2:50 in Friend 109)Document35 pagesIP Packet Switching: COS 461: Computer Networks Spring 2006 (MW 1:30-2:50 in Friend 109)ajazahmednet3946No ratings yet

- Smartline: Str700 Smartline Remote Diaphragm Seals Specification 34-St-03-124, November 2018Document32 pagesSmartline: Str700 Smartline Remote Diaphragm Seals Specification 34-St-03-124, November 2018Angel AvilaNo ratings yet

- Definition of Physical Educated PeopleDocument5 pagesDefinition of Physical Educated PeopleJzarriane JaramillaNo ratings yet

- 4.0 - P34x - EN - IN - I76 PDFDocument96 pages4.0 - P34x - EN - IN - I76 PDFDiana Vanessa VelCruzNo ratings yet

- Tailings storage facility audit guideDocument21 pagesTailings storage facility audit guideBOOBOONo ratings yet

- DCFDocument47 pagesDCFJordan Yun-Chiang KungNo ratings yet

- ITD 21203 - Creating tables and lists in HTML/CSSDocument6 pagesITD 21203 - Creating tables and lists in HTML/CSSkhairitkrNo ratings yet

- National Heavy Vehicle General Dimension RequirementsDocument5 pagesNational Heavy Vehicle General Dimension RequirementsMilan SjausNo ratings yet

- Microsoft Visual C++ 2008 Express Edition EnuDocument5 pagesMicrosoft Visual C++ 2008 Express Edition EnuMeghan WoodsNo ratings yet

- Manual Implem Note 1982417 CONTRATOS SEPEDocument24 pagesManual Implem Note 1982417 CONTRATOS SEPEfrubenvegaNo ratings yet

- Unix 1Document50 pagesUnix 1Kunchi PraveenaNo ratings yet

- DP-DMX20L: User Manual User ManualDocument8 pagesDP-DMX20L: User Manual User ManualPavlo RiverosNo ratings yet

- Water Distribution System Specifications: St. Charles County Public Water Supply District NO. 2Document45 pagesWater Distribution System Specifications: St. Charles County Public Water Supply District NO. 2muhammad iqbalNo ratings yet

- 1722-2.2000 - Wire Mesh FencesDocument33 pages1722-2.2000 - Wire Mesh FencesBARUWA tomiNo ratings yet

- Writing ToR For An Evaluation (2004)Document4 pagesWriting ToR For An Evaluation (2004)Tukang UsilNo ratings yet

- Atlas Copco: GeneratorsDocument4 pagesAtlas Copco: GeneratorsBane RadovicNo ratings yet

- Proceq Operating Instructions Dyna EDocument35 pagesProceq Operating Instructions Dyna Ecristina_romanescuNo ratings yet

- Silay Patag PDF Page 1 - 9 PDFDocument10 pagesSilay Patag PDF Page 1 - 9 PDFRalph Emmanuel MercadoNo ratings yet

- 434 HW 2 SolDocument5 pages434 HW 2 SolAnhTuan NguyenHuuNo ratings yet

- NRB SyllabusDocument3 pagesNRB SyllabusRoshan GhimireNo ratings yet

- Atmel 42071 DALI Slave Reference Design Application Note AT01244Document19 pagesAtmel 42071 DALI Slave Reference Design Application Note AT01244flo72afNo ratings yet

- Iso 5211 2017 en PDFDocument11 pagesIso 5211 2017 en PDFshaggy0078No ratings yet