Professional Documents

Culture Documents

WPS PQR A36.20

Uploaded by

gchaves504Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS PQR A36.20

Uploaded by

gchaves504Copyright:

Available Formats

1/5

A36.20

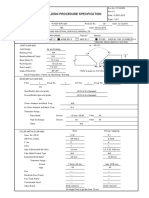

WELDING PROCEDURE SPECIFICATION (WPS) QW-482 According ASME, Section IX

(Ver QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)

Revision No. 2

Revision Date: 20/06/2012

Company

HL INGENIEROS S.A para CEMENTOS PANAM

Welding Procedure Specification

SMAW SAW- B161-PL-001

Revision No.

Welding Process(es)

By

Date

Date

01/04/2014

Omar Pinilla

PQR No.(s)

01/04/2014

SMAW / SAW

Type(s)

Manual / Semi-automatic

(Automatic, Manual, Machine, or Semi-Automatic)

JOINTS (QW-402)

Details

Joint Desing

Root Spacing

X SAW

Backing

Yes

Backing Material (Type)

Double Bevel

2mm +/- 1mm

X SMAW

No

Welding Metal

(Refer to both backing and retainers)

Metal

Non fusing Metal

Nonmetallic

Other

More details of the joint are specificated on PQR

BASE METAL (QW-403)

P-No.

Groupo No.

O

Specificacin and tipo/Grade or UNS Number

To specificacin and tipe/grade or UNS Number

To

Groupo No.

ASTM A36

ASTM A36

O

Chemical Analysis and mechaincal properties

**************

To Chemical Analysis and mechaincal properties

Thickness Range:

Base Metal:

Groove

**************

3/16" / 2"

Maximun pass Thickness 1/2 in. (13 mm)

(yes)

Fillet

(No)

all

X

Other

1

FILLER METAL (QW-404)

Espec. No. (SFA)

AWS No. (Class)

F-No

A-No.

Size of filler Metals

5.1

5.17

E-7018

4

E-7018

EM-12K

6

EM-12K

3/32" - 1/8" - 5/32"

1/8" (3mm)3/32" - 1/8" - 5/32"

Filler Metals Product form

Electrodo

Alambre

Supplemental Filler Metal

Weld Metal

Thickness Range:

NO

NO

***

ALL

NA

NA

NA

NA

NA

***

ALL

SFA 5.17

F7A2

NA

NA

NA

Electrode-Flux (Class)

Flux Tipe

Flux Trade Name

Consumable Insert

Other

Groove

Fillet

*Each Base Metal - filler metal combination should be recorded individually.

F-AAC-031-ME

A36.20

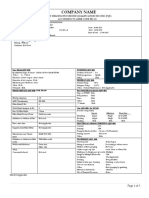

WELDING PROCEDURE SPECIFICATION (WPS) QW-482 According ASME, Section IX

(Ver QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)

Revision No. 2

Revision Date: 20/06/2012

2/5

QW-482 (Back)

WPS No.

SMAW SAW- B161-PL-001

POSITIONS (QW-405)

Rev.

POST WELD HEAT TREATMENT (QW-407)

Position(s) of groove

Welding Progression: Up

Positions(s) Of fillet

Other

SMAW: ALL

SMAW UP

SMAW: ALL

SAW: FLAT

Down

SAW: F, H

Temperature Range

Time Range

Other

****

NO

NA

NO

GAS (QW-408)

PREHEAT (QW-406)

Preheat Temperature, minimun

Interpass Temperature, maximun

Preheat Maintenance

Othe

100C (212F)

300C (572F)

as welder

Gas(es)

Shielding

Trailing

Backing

Other

NO

Percent Composition

(Mixture)

Flow Rate

NO

NO

NO

NO

NA

NA

NA

NA

NA

NA

NA

NA

CARACTERSTICAS ELCTRICAS (QW-409)

Filler Metal

Pass(es)

Process

Clasificacin

Dimetro

3/32"(2,4mm)1

/8" (3mm)

3/32"(2,4mm)

1/8" (3mm)

1-n

SMAW

E7018

n+1

SAW

EM-12K

Current

Type and

Polarity

Amps

(range)

DC+

100-145

DC+

350-700

Wire feed

Speed

(mm/min)

Other (p.e. Remarks,

Comments, Hot Wire,

Tchnique, etc.)

12-25 V

95-110

***

14-25 V

400- 530

***

Energy of

power

Volts

(range)

NA

2-6

123-181

Inch/min

2-6

(inch/min)

Travel

Speed

Amps and Volts or power or energy range, should be recorded for each electrode size, position or thickness.

Pulsing Corrurrent

Tungsten Electrode Size and Type

NA

Heat Input (max.)

NA

1275 J/mm

(Tungsteng puro, 2% de Thorzed, etc.)

Mode of Metal Transfer for GMAW (FCAW)

***

(Spray, Short Circuiting Arc, etc.)

Other

TECHNIQUE (QW-410)

String or Weave Bead

Orifice, Nozzle, or Gas Cup Size

Initial and Interpass Cleaning (Brushing, Grinding, etc.)

Method of Back Gouging

Oscillation

Contact Tube to Work Distance

Multiple or Single Pass (Per Side)

Multiple or Single Electrodes

Electrode Spacing

Peening

Other

NO

SMAW 1 y n+1 Ondeado / SAW 2-n+1 Recto

***

Arc Air

Arc Air

********

12mm - 25mm

Multiple en los dos lados

Multiple

NA

NO

NO

F-AAC-031-ME

A36.20

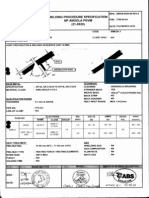

PROCEDURE QUALIFICATION RECORD (PQR) QW-483 According ASME, Seccin IX

(Ver QW-200.2, Seccin IX, ASME Boiler and Pressure Vessel Code)

3/5

Revision No. 2

Revision Date: 20/06/2012

Company

Procedure Qualification Record No.

WPS No.

SMAW-PL-003-B161

Welding Process(es)

Type(s) (Automatic, Manual, Machine, or Semi-Automatic)

HL INGENIEROS Para CEMENTOS PANAM

PQR 'SMAW-SAW-PL-001

Date

SMAW_SAW

MANUAL- SEMI-AUTOMATIC

05/07/2014

JUNTA (QW-402)

Joint Desing : DOBLE V

Backing:

BASE MATERIAL

ANGLE: 60 +/- 5

Root Spacing: 2 +/- 1 mm

Points: 3 Minimo

Others: See drawings details

(For combination qualifications, the deposited weld metal thickness shall be recorded for each filler metal and process used.)

BASE METALS (QW-403)

Material Specl

Type/Grade, or UNS Number

P-No.

1

Group No.

Thickness of Test Coupon

Diameter of Test Coupon

Maximum Pass Thickness

Other

A-36

1 a P-No.

1

Gruop. No.

1" (25,4mm)

N.A.

+++++

PWHT (QW-407)

N/A

N/A

****

Temperature

Time

Other

GAS (QW-408)

Percent Composition

FILLER METALS (QW-404)

SFA Specification

AWS Classification

Filler Metal F-No.

Weld Metal Analysis A-No.

Size of Filler Metal

Filler Metal Product Form

Supplemental Filler Metal

Electrode Flux Classification

Flux Type

Flux Trade Name

Weld Metal Thickness

Other

1

5.1 & 5.5

E7018

2

5.17

EM 12K

6

1

1/8" (3.8mm)

Wire

N/A

SFA 5.17

F7A2

ESAB OK 350

14mm

1

1/8" (3.8mm)

Electrode

N/A

N/A

N/A

N/A

8mm

POSITION (QW-405)

Position of Groove

SMAW: ALL

SAW FLAT

Weld Progression (Uphill, Downhill)

SMAW: Uphill, SAW: N/A

Other

***

PREHEAT (QW-406)

Preheat Temperature

Interpass Temperature

Other

100C

180C (350F)

***

Shielding

Trailing.

Backing

Other

Gas(es)

Mixture

Flow Rate

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

ELECTRICAL CHARACTERISTICS (QW-409)

Current

SMAW: DC(+), SAW: DC(+)

Polarity

POSITIVA

Amps.

100-145 AMP

Volts

12-25V

Tungsten Electrode Size

N/A

Mode of Metal Transfer for GMAW (FCAW)

N/A

Heat Input

1756,7 J/mm

Other

N/A

TECHNIQUE (QW-410)

Travel Speed

SMAW: ONDEADA SAW: RECTA

String or Weave Bead

SMAW: ONDEADA SAW: RECTA

Oscillation

NO

Multipass or Single Pass (Per Side)

MULTIPLE

Single or Multiple Electrodes

MULTIPLE

Other

F-AAC-198-ME

4/5

A36.20

QW-483 (REVERSE)

PQR No.

Spcimen

No.

Width

Thickness

T11-197

T12-197

T21-197

T22-197

18,87mm

18,84mm

18,80mm

18,61mm

9,75mm

10.23mm

9,79mm

10mm

Tensile Test (QW-150)

Area

183.98mm2

192,73mm2

184,05mm2

186,61mm2

Ultimate

Total Load

(N)

95.357

98.225

96377

95473

PQR 'SMAW-SAW-PL-001

Type of

Failure and

Location

Welded Material

Base Material

Welded Material

Base Material

Ultimate

Unit Stress

(Mpa)

518

510

524

513

Guided-Bend Tests (QW-160)

Spcimen

No.

Bending Type

DL1-197

DL2-197

DL3-197

DL4-197

Side

Side

Side

Side

Length

164mm

164mm

164mm

164mm

Width

WELDING

THICKNESS IN

CUPON

Temp.

Resultado

9,94mm

9,96mm

9,68mm

9,69mm

25,05

25,05

25,05

25,05

19,4C

19,4C

19,4C

19,4C

Less at3 mm Open Discontinuity

Not Discontinuity

Less at3 mm Open Discontinuity

Not Discontinuity

Toughness Tests (QW-170)

Notch

Location

Spcimen

No.

Specimen

Size

Test

Temperature

Drop Weight Break (Y/N)

Impact Values

ft. - lbs. o J

% Shear

Mils (in.) o mm

Comments

Fillet-Weld Test (QW-180)

Result Satisfactory:

Macro Results

Yes

No

Penetration into Parent Metal:

Yes

No

Other Tests

Type of Test

Deposit Analysis

Other

Welders Name

Test guided by

Pedro Beltran, Luis Coy

Clock No.

Laboratory Test No.

WEST ARCO

N/A

Stamp. No

N/A

I-14197

We certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in accordance with the

requirements of Section IX of the ASME Boiler and Pressure Vessel Code.

Date

04/07/2014

Munufacturer

HL INGENIEROS

Certified by

OMAR PINILLA

(Detail of record of tests are illustrative only and may be modified to

conform to the type and number of tests required by the Code

F-AAC-198-ME

A36.20

5/5

You might also like

- WPS TITLEDocument2 pagesWPS TITLERichard Periyanayagam86% (14)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- WPSDocument6 pagesWPSNur Wijianto100% (1)

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- WPS For Structure Mild Steel Fillet WeldDocument2 pagesWPS For Structure Mild Steel Fillet WeldHarkesh Rajput76% (17)

- WPSDocument2 pagesWPSJuli Agus50% (2)

- WPS Sitelca S002Document2 pagesWPS Sitelca S002Jose Antonio GomezNo ratings yet

- WPS & PQRDocument46 pagesWPS & PQRJohn Candidate CIns88% (8)

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNo ratings yet

- WPSDocument3 pagesWPSKhurram Burjees100% (1)

- PQR FormatDocument2 pagesPQR Formatravi0009880% (5)

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- Procedure Qualification Record (PQR)Document3 pagesProcedure Qualification Record (PQR)Senthil KumaranNo ratings yet

- A 36 WPSDocument2 pagesA 36 WPSNaqqash Sajid100% (1)

- WPS-PQR (Er309l Mo)Document4 pagesWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 pagesWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniNo ratings yet

- 6GR WPS PQRDocument15 pages6GR WPS PQRKiukStaks100% (6)

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- WPS PQR-03Document12 pagesWPS PQR-03Ranjan KumarNo ratings yet

- WPS PQRDocument23 pagesWPS PQRHashim Khan88% (8)

- WPS GmawDocument2 pagesWPS Gmawasikur100% (6)

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- PT. MITRA KARYA SARANA Aluminum Welding ProcedureDocument1 pagePT. MITRA KARYA SARANA Aluminum Welding ProcedureAbu Zahid100% (1)

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (1)

- Piping WpsDocument37 pagesPiping WpsZulfokar FahdawiNo ratings yet

- GMAW welding parameters for SS400 pipeDocument2 pagesGMAW welding parameters for SS400 pipeAnonymous zfC1zo9C100% (1)

- WPS PQR WPQ PeiplDocument16 pagesWPS PQR WPQ PeiplKrishnamurthy Panchapakesan100% (4)

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- WPSDocument2 pagesWPSAlam MD Sazid100% (1)

- WPS, PQR, WPQ (Si007)Document5 pagesWPS, PQR, WPQ (Si007)Suresh RathodNo ratings yet

- Pwps Asme Gtaw & SmawDocument2 pagesPwps Asme Gtaw & SmawMuhammad Fitransyah Syamsuar Putra100% (1)

- WPS PQR-09Document11 pagesWPS PQR-09Ranjan KumarNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- Wps Gmaw SawDocument2 pagesWps Gmaw Sawupedro26No ratings yet

- WPS MigDocument3 pagesWPS MigAJOJOY00960% (5)

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- SS WPSDocument1 pageSS WPSMOHAMEDABBASNo ratings yet

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- PQRDocument2 pagesPQRalokbdasNo ratings yet

- WPQR Welding Procedure QualificationDocument3 pagesWPQR Welding Procedure QualificationThanasis KyrgiazoglouNo ratings yet

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez MartinezNo ratings yet

- List of Qualified WeldersDocument3 pagesList of Qualified WeldersdavNo ratings yet

- Welder Qualification Test Certificate for Mohan ReddyDocument2 pagesWelder Qualification Test Certificate for Mohan Reddyvijay100% (1)

- WPS for 316L Pipe WeldingDocument3 pagesWPS for 316L Pipe WeldingRichard Periyanayagam100% (3)

- QIR-104-Welding Parameters Record SheetDocument1 pageQIR-104-Welding Parameters Record SheetSamer Bayati100% (1)

- WPS (AsmeDocument8 pagesWPS (AsmeMohammad Elhedaby100% (6)

- PWPS For Piping-API 1104Document6 pagesPWPS For Piping-API 1104Nguyen Tien Luong100% (1)

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- Des QC 8505 Ab 08Document3 pagesDes QC 8505 Ab 08Touseef RafiqueNo ratings yet

- Plates ASTM-A240 Gr 304LDocument6 pagesPlates ASTM-A240 Gr 304Labhishek198327No ratings yet

- Welding Procedure Specification-1Document8 pagesWelding Procedure Specification-1Suresh Rathod100% (1)

- WPS GTAW pipe welding procedureDocument2 pagesWPS GTAW pipe welding procedureRichard PeriyanayagamNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- BK5TQ4 248 094 - WPS For Ducting & Support Structure Stainless Steel V Groove WeldDocument2 pagesBK5TQ4 248 094 - WPS For Ducting & Support Structure Stainless Steel V Groove WeldHarkesh RajputNo ratings yet

- WELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELDocument4 pagesWELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELAldeline SungahidNo ratings yet

- Fab-Wps-002sfasf Asfh Fhjsafgjha Sfsa FSDocument2 pagesFab-Wps-002sfasf Asfh Fhjsafgjha Sfsa FSabidaliabid1100% (1)

- WELDING PROCEDURE AND QUALIFICATION RECORDSDocument4 pagesWELDING PROCEDURE AND QUALIFICATION RECORDSETSNo ratings yet

- Sand Dam Manual FINALDocument44 pagesSand Dam Manual FINALAndrew MutuaNo ratings yet

- 1 3814 GY SE 901003 IS03 Technical EspecificationDocument43 pages1 3814 GY SE 901003 IS03 Technical Especificationgchaves504No ratings yet

- Alineacion CoronaDocument16 pagesAlineacion Coronagchaves504No ratings yet

- 240 Ton GMK5240Document16 pages240 Ton GMK5240Javier PáezNo ratings yet

- 24 3814 YZ LD 000002 IS01 List of Codes and StandrsDocument11 pages24 3814 YZ LD 000002 IS01 List of Codes and Standrsgchaves504No ratings yet

- 7 3814 AX SG 000002 IS05 Structural Steel SpecificationDocument34 pages7 3814 AX SG 000002 IS05 Structural Steel Specificationgchaves504No ratings yet

- 3814-AI-SG-000001-Is04 General Specification For Steel WorksDocument19 pages3814-AI-SG-000001-Is04 General Specification For Steel Worksgchaves504100% (1)

- 3814 GY VD AC - 901 - 2101 IS01 Structural Calculation NotesDocument272 pages3814 GY VD AC - 901 - 2101 IS01 Structural Calculation Notesgchaves504No ratings yet

- 3814 VW SG 000001 IS03 Coating SpecificationsDocument28 pages3814 VW SG 000001 IS03 Coating Specificationsgchaves504No ratings yet

- KleinTools Grips CatalogDocument28 pagesKleinTools Grips Cataloggchaves504No ratings yet

- MetalSamples General Catalog XIIIDocument40 pagesMetalSamples General Catalog XIIIDavid Cruz ZamoraNo ratings yet

- Circumferential Welders LiteratureDocument6 pagesCircumferential Welders LiteratureMohammed Elmodathir AliNo ratings yet

- Weldwell Catalogue 2015Document8 pagesWeldwell Catalogue 2015jaganelrNo ratings yet

- Universal WPS Packages For MIG/MAG and MMA Welding: Get The Jump On EN 1090 With KemppiDocument7 pagesUniversal WPS Packages For MIG/MAG and MMA Welding: Get The Jump On EN 1090 With KemppiKamil Reichert0% (1)

- AWS-CWI PROGRAM MODEL EXAM REVIEWDocument46 pagesAWS-CWI PROGRAM MODEL EXAM REVIEWLala Bhai0% (1)

- CSWIP-WI-6-92 13th Edition July 2015 PDFDocument17 pagesCSWIP-WI-6-92 13th Edition July 2015 PDFjaisonaeroNo ratings yet

- Bs 15610Document13 pagesBs 15610Jamil SalmanNo ratings yet

- PRODUCTIONTECHNOLOGYDocument4 pagesPRODUCTIONTECHNOLOGYSamiullah MohammedNo ratings yet

- Lecture 3.4: Welding Processes: 1. Introduction - Heat Sources and Methods of ShieldingDocument10 pagesLecture 3.4: Welding Processes: 1. Introduction - Heat Sources and Methods of ShieldingMihajloDjurdjevicNo ratings yet

- Educational Resources PamphletDocument9 pagesEducational Resources PamphletBala SingamNo ratings yet

- 5.4 ESW and EGW Processes: AWS D1.1/D1.1M:2015 Clause 5. FabricationDocument1 page5.4 ESW and EGW Processes: AWS D1.1/D1.1M:2015 Clause 5. FabricationRohit KambleNo ratings yet

- Day-1 LECTURE 2-Welding TechnologyDocument64 pagesDay-1 LECTURE 2-Welding TechnologySamNo ratings yet

- 44) API 653 DAY 7 BOOK (1 To 52)Document53 pages44) API 653 DAY 7 BOOK (1 To 52)SHAHIDALI100% (2)

- 00 - AVANTech Capabilities & Experience - NUCLEAR (No Attachments) 11-2018Document12 pages00 - AVANTech Capabilities & Experience - NUCLEAR (No Attachments) 11-2018Laura StoutNo ratings yet

- ED442 Bobcat 260 EnglishDocument8 pagesED442 Bobcat 260 EnglishVictor PATIÑO100% (1)

- Standard Description View ImageDocument32 pagesStandard Description View ImageRakesh ParaNo ratings yet

- Welding HistoryDocument87 pagesWelding HistoryKarlaColina100% (2)

- API 570 Flash CardsDocument13 pagesAPI 570 Flash CardsSarathiraja Sekar100% (5)

- Bhel-2 Block ReportDocument45 pagesBhel-2 Block ReportdeepakneedsloveNo ratings yet

- ACCORDING TO EN ISO 9606-1:2013: ISO 9606-1 Ss NB 141 T BW Fm4 S s3.6 D60 PHDocument1 pageACCORDING TO EN ISO 9606-1:2013: ISO 9606-1 Ss NB 141 T BW Fm4 S s3.6 D60 PHAnup SharmaNo ratings yet

- Effect of Current On Metal Transfer in SAW Part 2: AC: Welding Journal August 2017Document9 pagesEffect of Current On Metal Transfer in SAW Part 2: AC: Welding Journal August 2017Andrés Mauricio UribeNo ratings yet

- Experimental Study and Analysis of Weld Parameters by GRA On MIG WeldingDocument9 pagesExperimental Study and Analysis of Weld Parameters by GRA On MIG WeldingM R MANJU COMPUTERSNo ratings yet

- SMAW Electrode For P91Document18 pagesSMAW Electrode For P91mohd as shahiddin jafriNo ratings yet

- WELDINGDocument51 pagesWELDINGStewart StevenNo ratings yet

- NES 769 Approval System For Welding Consumables For Structural Steels Category 2Document74 pagesNES 769 Approval System For Welding Consumables For Structural Steels Category 2JEORJENo ratings yet

- EN - Basics of Robotic WeldingDocument657 pagesEN - Basics of Robotic WeldingMihail AvramovNo ratings yet

- AWS D1.1:2020 - Changes To Structural Welding Code - SteelDocument1 pageAWS D1.1:2020 - Changes To Structural Welding Code - SteelVuong Tran VanNo ratings yet

- Dissimilar WeldingDocument42 pagesDissimilar WeldingMan MNo ratings yet

- SRM University Project ReportDocument56 pagesSRM University Project ReportTony Joanne67% (3)

- PW - RENTALS - Catalog A5 EN - US 2021 7 1Document72 pagesPW - RENTALS - Catalog A5 EN - US 2021 7 1Shih-Bou WangNo ratings yet