Professional Documents

Culture Documents

Ps 10 30 e

Uploaded by

Walter Ruiz AstoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ps 10 30 e

Uploaded by

Walter Ruiz AstoCopyright:

Available Formats

Pump Division

CPX

ISO Chemical

Process Pumps

CPX

CPXS

CPXM

CPXP

CPXR

CPXV

Bulletin PS-10-30d (E)

Pump Division

Pump Supplier

To The World

Flowserve is the

driving force in the

global industrial

pump marketplace.

No other pump

company in the

world has the

depth or breadth of

expertise in

the successful

application of

pre-engineered,

engineered and

special purpose

pumps and

systems.

Pumping Solutions

Flowserve is providing pumping

solutions which permit customers to continuously improve

productivity, profitability and

pumping system reliability.

Market Focused

Customer Support

Product and industry specialists

develop effective proposals and

solutions directed toward market

and customer preferences.

They offer technical advice and

assistance throughout each

stage of the product life cycle,

beginning with the inquiry.

Dynamic Technologies

Flowserve is without peer in the

development and application of

pump technology, including:

Hydraulic engineering

Mechanical design

Materials science

Intelligent pumping

Manufacturing technology

Broad Product Lines

Flowserve offers a wide range

of complementary pump types,

from pre-engineered process

pumps, to highly engineered

and special purpose pumps

and systems. Pumps are built

to recognized global standards

and customer specifications.

Pump designs include:

Single stage process

Between bearing

single stage

Between bearing

multistage

Vertical

Submersible motor

Positive displacement

Nuclear

Specialty

Pump Division

CPX Family

of ISO Chemical

Process Pumps

Unmatched Versatility

and Flexibility

The CPX family of ISO chemical

process pumps offers a wide

range of configurations including

mechanically sealed, magnetically

driven, self-priming, close coupled

and vertical pumps. The CPX

family, therefore, offers

unmatched flexibility and breadth

of pumping solutions in

countless applications.

Spare Parts Interchangeability

Commonality among the

different pump configurations is

a key benefit of the CPX family.

All CPX pumps share the same

state-of-the-art hydraulics,

sealing options, and bearing

frame options. This interchangeability translates into inventory

and maintenance costs savings.

Industries

Chemical

Steel and primary metals

Marine

Wastewater treatment

Aquariums

Mining works

Semiconductor manufacturing

Pharmaceuticals

Petrochemical

Complementary Pump Designs

Mark 3 ASME (ANSI)

chemical process pump

PolyChem PFA lined series

of sealed or sealless ISO,

ASME (ANSI) or JIS pumps

PolyChem GRP ASME (ANSI)

non-metallic chemical

process pump

Table of Contents

CPX ISO Standard

Pump

CPX Standard..............4-5

Performance Curves.... 10

Interchangeability......... 11

PROS+ System............. 11

Features and

Enhancements

Seal Chambers............... 6

Mechanical Seals........... 7

Shaft Design................... 8

Bearings......................... 8

Parts and Materials........ 9

Baseplates...............22-23

CPXS

Magnetic Drive

Pump......................12-13

CPXSM................... 13, 15

CPXM

Close Coupled

Pump......................14-15

CPXP

Self-Priming

Pump......................16-17

CPXPM................... 15, 17

CPXPS.......................... 17

CPXPSM...................... 17

CPXR

Recessed Impeller

Pump......................18-19

CPXRV......................... 19

CPXRM.................. 15, 19

GRP

CPXV

Vertical Sump

Pump......................20-21

Complementary Pumps

and General Information

Non-Metallic

Pumps.......................... 24

Mark 3

ASME (ANSI) Pumps... 25

ASME (ANSI) In-Line

Pumps.......................... 25

Engineered Pumps....... 26

PolyChem S

Global Service and

Support........................ 27

Pump Division

CPX

ISO Standard

Overhung,

Single Stage

Chemical Process

Pump

The Standard for Chemical

Processing

The Flowserve CPX process

pump conforms to ISO 2858

dimensional and ISO 5199

design criteria. Offering

state-of-the-art hydraulics,

the CPX pump is designed for

applications where high

performance, high efficiency

and low NPSH are required.

The advanced design and

precision manufacture of the

rugged CPX provide significant

performance enhancing benefits

that help users to maximize

mean time between planned

maintenance (MTBPM) and to

reduce operating costs.

Applications

Acid transfer

Caustic and chlor-alkali

Man-made fibers

Polymers

Slurry processing

Solvents

Volatile organic compounds

Waste processing

Advanced 45 Conical Seal

Chamber with integral vortex flow

modifiers increases mechanical

seal life.

Heavy-Duty Casing with integral

foot and multi-ribbed discharge

flange provides superior resistance

to pipe loads and improves reliability.

Standard Non-Contacting

Labyrinth Seals keep lubricant in

and contaminants out.

External Three Bolt Rotor

Adjustment allows impeller clearances

to be reset in situ, thereby restoring

head and efficiency.

Heavy-Duty Pump End and

Drive End Bearings selected for

long life and reliability.

Operating Parameters

Flows to 1400 m3/h

(6160 US gpm)

Heads to 220 m

(720 ft)

Pressures to 25 bar

(365 psi)

Temperatures from

-80C (-110F) to

350C (660F)

Discharge sizes from

20 mm (3/4 in) to

200 mm (8 in)

Standards Compliance

The CPX is CE marked

and compliant with

applicable European

directives, such as ATEX.

One-Piece, Ductile Iron

Bearing Housing is

designed for safety,

maximum concentricity,

strength and alignment.

Back Pullout Design allows

removal of rotating element

without removing casing,

piping or motor.

Pump Division

Precision Cast, Semi-Open

Impeller delivers high efficiency

performance and low NPSHR.

Standard impeller material is

Duplex stainless steel, the

strength and hardness of which

significantly extend the life of

the impeller.

Benefits of CPX Semi-Open

Impellers Versus Closed

Impellers

Adjustability of rotor enables

head and efficiency to be

restored in situ

Improved solids handling

Suitable for a wider range

of applications

Improved seal chamber

environment in low NPSH

applications

Smooth entrance profile

minimizes snagging of

fibrous materials

Reliability and Performance

Enhancing Features

Precision cast, semi-open

impeller with backvanes and

shroud cutouts for axial

balance reduces maintenance

and downtime costs by

extending mechanical seal

and bearing life.

Precision machined, metal-tometal inter-connecting faces

at the casing, seal chamber

and bearing housing for

reliable sealing and optimum

concentricity.

Robust, solid shaft ensures

less than 0.05 mm (0.002 in)

deflection at the seal face and

low L3/D4 ratio, thereby

extending mechanical seal life.

Elimination of gaskets avoids

leakage and crevice corrosion.

Optional Jacketed Casing

An optional jacketed casing

is available for those

applications in which the

pumped fluid must be

heated or cooled to maintain optimal fluid viscosity.

Low Flow Sizes

The CPX is also available

in eight low flow, high

head designs. Engineered

specifically to cover flows

lower than ISO 2858,

these low flow pumps

eliminate the need for

throttling and the associated premature failure.

Additional benefits of low

flow CPX pumps:

Lower initial pump cost

Smaller motor sizing

Reduced energy costs

Greater reliability

Additional Features

Standard splash guard

3 mm (0.12 in)

minimum corrosion

allowance

Magnetic drain plug

Bulls-eye sight glass

Pump Division

CPX

45 Seal Chamber

Technology

Advanced Technology

Seal Chamber

The CPX 45 conically shaped

seal chamber with integral flow

modifiers is designed to redirect

solids and slurry away from the

seal, back into the flow path of

the process liquid.

Extends seal life

Self-venting

Self-flushing

Self-draining

Reduces maintenance and

repair costs

Provides a safer environment

for personnel

Permits use of less expensive

seal and flush plans

Improves pump reliability

45 Conical Seal Chamber

Provides Design Flexibility

Accommodates single, double

and tandem seal arrangements

Accepts single and double

cartridge seals to latest ISO

or DIN standards

Accepts Eccentric Pumping

Annulus (EPA) circulation

system, a wide range of flush

plans, and auxiliary systems

for maximum reliability

Provides optional jacketed

seal chamber for effective

heat transfer in the seal

chamber area or across the

entire surface area of the

process fluid

Flow Modifiers Extend

Mechanical Seal Life

Redirect flow from

circumferential to axial,

thereby reducing turbulence and abrasion

The mechanical seal

creates a centrifugal

action, pushing suspended solids away

from the seal faces and

into the return flow

created by the modifiers

Solids and slurry merge

into the returning flow

path and are flushed out

of the seal chamber

Balanced flow with low

pressure drop in the

chamber helps keep

solids in suspension,

minimizing erosive

characteristics

Optional Integrated

Solid Seal Cover

An integral solid seal cover

eliminates crevices where

corrosion could occur or

where potential contaminates could collect, while

reducing the parts count.

Pump Division

CPX

Mechanical Seals

The CPX 45 conical seal

chamber accommodates many

seal types including single,

double and tandem arrangements.

The double and tandem seals

are available for more severe

and environmentally sensitive

applications.

All seals can be backed up by

a range of flush plans and

auxiliary systems.

Conventional single and double

cartridge seals can be fitted in

accordance with the manufacturer's standard or with those

designed to meet the latest ISO

or DIN standards.

External seals and gland packing

are optional, as is the seal

housing jacket which controls

the seal environment.

Single seal with external

throttle bush and

controlled drain

Single seal with external

lip seal

Single internal seal with

internal PTFE neck bush

and PTFE throttle bush

Double back-to-back seal

with EPA circulation

Tandem seal with EPA

circulation

Double cartridge

tandem seal

Pump Division

CPX

Heavy-Duty

Shaft and

Bearings

CPX shafts and bearings are

designed to improve pump

reliability. The robust and stiff

solid shaft ensures less than

0.05 mm (0.002 in) shaft

deflection at the seal face and

low L3/D4 ratio to maximize

mechanical seal life.

Shaft Materials

To meet application requirements

shafts are available in a wide

range of corrosion-resistant

materials, including:

316 stainless steel

Duplex stainless steel

Alloy 20

Alloy C

Alloy B

Bearing Options

As standard the CPX is supplied

with a deep groove ball bearing

and double row angular contact

thrust bearing providing life in

excess of the minimum specified

by ISO 5199.

Oil Lubricated Bearing Housing

splash bath uses bulls-eye

sight glass with magnetic drain

plug as standard with constant

level oiler as an option.

As an optional upgrade, the

CPX can be supplied with a

deep groove ball bearing and

reinforced duplex, back-to-back

angular contact thrust bearing,

providing L10 bearing life in

excess of 50 000 hours.

Optional non-contacting

vapour block bearing

isolators

Grease Lubricated Bearing

Housing facilitates maintenance

by using grease nipples fitted at

the pump end and drive end.

Alternatively, sealed-for-life

bearings can be fitted.

Additional Options

Sealed-for-life bearings

Additional condition

monitoring points

Tappings for instrumentation and monitoring

equipment

Bearing isolators

Standard or proprietary,

non-contact designs

Oil mist lubrication

technologies

Pump Division

CPX

Parts and

Materials

Flowserve Parts

Flowserve parts should be

specified for all pump

maintenance requirements.

In addition to improved

maintenance savings only

Flowserve offers:

Parts that are guaranteed to

fit, last and perform

24-hour emergency service

Application and materials

expertise

Complete analysis and

performance of your

maintenance needs with

recommended parts inventory

and management, if so required

CPX Materials

Construction

Casing &

Seal Housing

Ductile Iron

Ductile Iron

Carbon Steel

Carbon Steel

304 Stainless

Steel

304 Stainless

Steel

316 Stainless

Steel

316 Stainless

Steel

Impeller

Duplex

Stainless

Steel

Duplex Stainless Duplex Stainless

Steel

Steel

Solid Shaft

Sleeved Shaft Option

Shaft Sleeve

316 Stainless

Steel

316 Stainless

Steel

Carbon

Steel

Duplex Stainless

Steel

Duplex Stainless

Steel

Alloy 20

Alloy 20

Alloy 20

Alloy 20

Alloy C

Alloy C

Alloy C

Alloy C

Alloy B

Alloy B

Alloy B

Alloy B

Bearing

Housing

Ductile

Iron

Alloy 20

Stainless

Steel

Alloy C

Alloy B

Flowserve foundries are

widely regarded as among the

worlds best. They routinely

pour alloys from common

austenitic stainless steels to

light reactive alloys such as

titanium and zirconium.

Attesting to the world class

quality of its castings,

Flowserve was the first high

alloy foundry in the United

States of America to have

earned approval by Germanys

Technischer Uber-wachungs

Verein (TUV).

Pump Division

CPX

Performance

Curves and

Standards

Compliance

CPX Range Chart*

ft

2900 rpm

m

200

500

300 100

TDH - 50 Hz

200

50

100

20

50

40

1000

4000

500

2000

200

1000

100

500

50

200

20

100

10

50

40

20

gpm

10

10

m3/h

Flow Rate - 50 Hz

CPX Range Chart*

1450 rpm

ft

m

300 100

200

50

100

TDH - 50 Hz

50

20

10

20

10

500

2000

200

1000

500

100

50

200

20

100

40

10

50

4

20

5

2

10

1

m3/h

gpm

2000

4000

1000

5000

Flow Rate - 50 Hz

* Pumps can be used

on 50 Hz or 60 Hz

cycle supply

Standards Compliance

10

Compliant to the European

ATEX Directive

Compliant to the European CE

Directives

Pump Division

CASING and

IMPELLER

CONICAL OR

CYLINDRICAL

HOUSING

BEARING

HOUSING

40-25-125

POWER END

FRAME 2

CPX Standard Frame 2

CASING and

IMPELLER

CONICAL OR

CYLINDRICAL

HOUSING

BEARING

HOUSING

POWER END

FRAME 1

CPX Standard Frame 1

50-32-125

100-65-160

65-40-125

125-100-160

80-50-125

100-65-200

100-80-125

125-100-200

32-20-160

40-25-250

40-25-160

50-32-250

50-32-160

65-40-250

65-40-160

80-50-250

80-50-160

100-65-250

32-20-200

50-32-315

40-25-200

65-40-315

50-32-200

80-50-315

65-40-200

80-50-200

125-100-250

150-125-250

CASING and

IMPELLER

CONICAL OR

CYLINDRICAL

HOUSING

SEAL HOUSING

ADAPTER

POWER END

FRAME 4

BEARING

HOUSING

CPX Standard Frame 4

CASING and

IMPELLER

CONICAL OR

CYLINDRICAL

HOUSING

BEARING

HOUSING

CPX Standard Frame 3

POWER END

FRAME 3

CPX

Interchangeability

and FlowSelex

Interactive Pump

Selection

Application

200-150-400

200-150-250

100-65-315

250-200-400

125-80-315

150-125-315

200-150-500

100-65-400

125-80-400

150-125-400

FlowSelex

Interactive Pump

Selection Application

FlowSelex is a Web-based

interactive pump selection

program that allows users to

access an extensive database

of Flowserve pump sizing

information anytime,

anywhere.

This versatile tool delivers a

wide range of information,

from pump descriptions and

operating parameters to

custom application package

200-150-315

specifications with supporting

technical documentation,

including:

Performance curves

Hydraulic data sheets

General arrangement

drawings

Construction data sheets

FlowSelex can be accessed

at www.Flowserve.com/

FlowSelex.

11

Pump Division

CPXS

Magnetic Drive

Pump

Leak-Free Pumping

The CPXS magnetic drive

process pump provides leakfree pumping of hazardous,

toxic, flammable, explosive

or valuable liquids.

Conforming to ISO 2858

dimensional and ISO 5199

design criteria, the CPXS

magnetic drive pump is found

wherever reliability in severe

services is a requirement.

Operating Parameters

Flows to 420 m3/h

(1850 US gpm)

Heads to 160 m (525 ft)

Pressures to 25 bar (365 psi)

Temperatures from -40C

(-40F) to 250C (480F)

Precision Cast Semi-Open

Impeller delivers high efficiency

performance, low NPSHR, low

running cost and long life.

High Performance Rare Earth Magnets

possess superior permanent

strength and proven reliability.

Large Inner Magnet Clearances of

1.5 mm (0.06 in) between shell and

inner magnet assembly ensure

effective cooling.

12

Reinforced PEEK Primary

Containment Shell eliminates eddy

current losses, enhancing efficiency.

Hastelloy Primary Containment

Shell may be specified.

Optimized Internal Flow Paths

lubricate bearings and cool

magnets.

Upgrading of mechanically sealed

to magnetically driven, sealless

pumps is made easy due to the

interchangeablity between pump

bearing frames.

Hastelloy is a registered trademark of

Haynes International, Inc.

Standards Compliance

The CPXS is CE marked

and compliant with

applicable European

directives, such as ATEX.

Pump Division

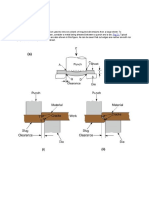

Standard Back Pullout for general maintenance and inspection.

Casing stays in-line and piping

connections remain intact.

Contained Back Pullout for

drive end maintenance. Process

fluid is fully contained; no

draining, purging or exposure

to harmful process fluids.

Pump Power Monitor

displays actual power to

the pump offering simultaneous protection from

underload and overload

operating conditions.

Optional Secondary

Containment Shell

A hydroformed Hastelloy

secondary containment

shell is available for

added security in critical

services.

CPXSM

Close coupled configuration also available.

Flow Circulation Path

Through analytical and practical

research, Flowserve has developed

a unique flow path analysis program to aid in the correct sizing

of magnetically driven pumps.

The program calculates flow,

temperature and axial thrust

within the drive unit, allowing

the pump liquid vapour point

to be determined.

Using this data, Flowserve is

able to appropriately select and

size pumps, preventing liquid

vapourization in the drive unit

and the associated damage.

13

Pump Division

CPXM

Close Coupled

Pump

Space Saving Configuration

With pump ends conforming to

ISO 2858 dimensional and technical standards and to ISO 5199

design criteria, the CPXM

provides a compact, space-saving

arrangement ideal for industrial

processes or installations when

space is at a premium.

CPXM pumps are fitted with

standard, readily available

electric motors so the user

can choose an enclosure to

suit the application.

Applications

Acid transfer

Caustic and chlor-alkali

Man-made fibers

Polymers

Slurry processing

Solvents

Volatile organic compounds

Waste processing

Radiating Surfaces dissipate

heat and extend bearing and

mechanical seal life.

Close Coupling eliminates influence

of the baseplate and foundation on

alignment.

External Impeller Adjustment

can be carried out without

taking measurements.

Optional Secondary Seal

controls leakage in the event of

primary seal failure, providing

increased safety and reduced

pump downtime.

Heavy-Duty Casing with integral

foot and multi-ribbed discharge

flange provides superior resistance

to pipe loads.

14

Operating Parameters

Flows to 570 m3/h

(2500 US gpm)

Heads to 125 m (400 ft)

Pressures to 25 bar (365 psi)

Temperatures from -20C

(-5F) to 160C (320F)

Available with most of the standard

and optional features of the CPX

ISO frame mounted pump.

Standards Compliance

The CPXM is CE marked

and compliant with

applicable European

directives, such as ATEX.

Pump Division

Other Configurations

Benefits of CPX Close

Coupling Design

Permits use of readily available

standard electric motors

Provides a thermal barrier

between pump and motor

Reduces installation cost by

eliminating pump to motor

alignment

Serves as an additional

deflector between mechanical

seal and motor

CPXRM

Close coupled, recessed impeller pump

CPXPM

Close coupled,

self-priming pump

CPXSM

Close coupled, magnetic

drive pump

CPXM

15

Pump Division

CPXP

Self-Priming

Pump

Surface Mounted Design

Costing less to buy, install and

maintain than submersible

pumps, the CPXP self-priming

pump is designed to draw from

liquid sources below ground

level or from sources with no

positive pressure to naturally

prime the pump. Its compact

design enables it to fit in tight

clearance locations. It can be

easily mounted on a trailer for

movement to various pumping

locations such as wastewater

lagoon service.

Operating Parameters

Flows to 250 m3/h

(1100 US gpm)

Heads to 130 m (425 ft)

Pressures to 25 bar (365 psi)

Temperatures from -80C

(-110F) to 350C (660F)

Applications

Sump service

Tanker unloading

Marine and river extraction

Wastewater and effluent

Dewatering

Vessel transfer

One-Piece Casing has large priming

chamber, air separator and volute in

one integral component, keeping

components to a minimum.

16

Semi-Open Impeller delivers high

efficiency performance, low NPSHR

and good solids handling.

Reflux Priming Principle eliminates

the need for internal valves and

external priming devices.

Suction Run Dry Capability allows

for minimum supervision.

Standards Compliance

The CPXP is CE marked

and compliant with

applicable European

directives, such as ATEX.

Pump Division

The Reflux Priming Principle

The CPXP self-priming pump

operates on the reflux principle,

using liquid recirculation to

prime the pump. The pressure

differential between the aerated

liquid at the impeller and the

non-aerated liquid in the priming

chamber creates a vacuum that

pulls liquid up the pipe.

This principle eliminates the

need for both internal valves and

external priming devices or

foot-valves. As a result, CPXP is

ideal for suction lift applications

or where a process involves

pumping a liquid with air or

gas phases.

Semi-Open Impeller

for high efficiency, low

NPSHR and good solids

handling.

Advanced Technology

45 Conical Seal

Chamber with integral

flow modifiers redirects

solids and slurry away

from seal and back into

the flow path of the

process liquid, extending

seal life and improving

pump reliability.

Additional

Configurations

CPXPM

Close coupled, selfpriming pump

CPXPS

Magnetically driven,

self-priming pump

CPXPSM

Close coupled,

magnetically driven,

self-priming pump

CPXP

17

Pump Division

CPXR

Recessed

Impeller Pump

Low-Shear Pumping

The CPXR recessed impeller

pump provides low-shear

pumping of friable solids and

trouble-free pumping of stringy

or fibrous slurries. It combines

the state-of-the-art hydraulics

of the CPX with the vortex

action of a recessed impeller.

The CPXR has a wide clearance

at the front of the semi-open

impeller allowing passage of

larger particles. Solids are

drawn into the vortex of swirling liquid and discharged by

centrifugal force through the

open area in front of the

impeller with little contact,

minimizing particle degradation.

Furthermore, the air and gas

handling capability of the pump

is improved.

Operating Parameters

Flows to 750 m3/h

(3300 US gpm)

Head to 100 m (330 ft)

Pressures to 25 bar

(365 psi)

Temperatures from -80C

(-110F) to 350C (660F)

Applications

Light slurries

Corrosive/erosive services

Large diameter solids

Waste streams

Shear-sensitive fluids

Friable solids

Fibrous materials

Standards Compliance

The CPXR is CE marked

and compliant with

applicable European

directives, such as ATEX.

Advanced 45 Conical Seal

Chamber with integral vortex flow

modifiers increases mechanical

seal life.

Standard Non-Contacting

Labyrinth Seals keep lubricant in

and contaminants out.

18

Heavy-Duty Pump End and Drive

End Bearings selected for long

life and reliability.

Vortex Action causes only a

fraction of the media to contact

the impeller, minimizing abrasive

wear and maintaining solids

integrity.

Pump Division

Benefits of the CPXR

Improved solids handling

Improved air and gas handling

Improved ability to pass

fibrous or stringy materials

Reduced wear

Other Features

Back pullout design

Non-contacting labyrinth seals

Bosses for inlet and outlet

pressure gauges

Precision Cast, Semi-Open

Impeller delivers high

efficiency performance,

low NPSHR and long life.

Backvanes and shroud

cutouts for axial balance

extend seal life and

bearing reliability

Impeller is screwed to

the shaft for high

strength and improved

shaft end corrosion

resistance

Additional Configurations

CPXRV

Recessed impeller,

vertical pump

CPXRM

Recessed impeller,

close coupled pump

CPXRM

19

Pump Division

CPXV

ISO & API

Vertical Sump

Pump

Vertical Sump Pump

The Flowserve CPXV is a

vertical sump pump incor

porating state-of-the-art

hydraulic design for efficient

and reliable service.

The CPXV can be customized

to meet a wide range of needs.

Compliant with ISO 5199,

the CPXV is available in 40

hydraulic wet-ends and a wide

variety of materials of construction. It is also available

with multiple mechanical seal

options and sump depths.

The CPXV is also available

in an ISO 13709/API 610

compliant version.

Operating Parameters

Flows to 1400 m3/h

(6160 US gpm)

Heads to 250 m (820 ft)

Temperatures from

-40C (-40F) to

350C (660F)

Pressures to 25 bar

(365 psi)

Speeds to 4700 rpm

Modular Construction ensures

installation flexibility with a

standard column length of 0.5 m

(1.6 ft), which equates to a

minimum sump depth of

0.7 m (2.3 ft).

Additional Column Lengths are

provided up to a maximum of

10 m (32 ft).

Heavy-Duty Thrust Bearings

with axial adjustment made at

soleplate level.

Recessed Impeller version is

available for enhanced solids

handling capability.

Suction Strainer optional.

Fully Jacketed version is available

for molten sulfur applications.

20

API 610 Configuration

The Flowserve CPXV

vertical sump pump

is also available in an

optional ISO 13709/API

610 compliant model,

specifically engineered

for the hydrocarbon

and petrochemical

processing industries.

Rectangular or circular

soleplates are standard.

A full ANSI 150/300 lb

RF soleplate is optional.

Standards Compliance

The CPXV is CE marked

and compliant with

applicable European

directives, such as ATEX.

Pump Division

Bearing Options

Mechanical Seal Options

A variety of mechanical

seal options are available,

from simple vapour sealing to tandem cartridge.

Thrust Bearings are heavy-duty

grease lubricated or sealed-forlife. Either allows axial adjustment

at the soleplate.

Unbalanced

Mechanical Seal

Radial Bearings can be flushed

by product or from an external

source and are available in a

variety of materials, including

silicon carbide.

Couplings

Flexible disc coupling

available

Spacer coupling available

Balanced Mechanical Seal

Additional Options

Recessed impeller

Vapour/mechanical

seal option

Fully jacketed version

Various motor

enclosures

Rectangular or circular

soleplates

Full ASME (ANSI)

Class 150/300 RF

soleplate

Non-spacer coupling

Oil lubrication to thrust

bearing

Optional Spacer Coupling

21

Pump Division

Flowserve

Pre-Engineered

Baseplate Designs

Extend MTBPM and Reduce

Maintenance Costs

The Flowserve family of preengineered baseplate designs

further extends MTBPM by

reducing internal pump stress

and vibrations. That is why

Flowserve recommends

reinforced rigid baseplates.

Flowserve offers a broad range

of metallic and non-metallic,

grout and stilt mounted

designs with standard options.

This provides flexibility in

choosing the baseplate that

best meets application needs

and operating budget.

Standard steel

baseplate

Cast iron baseplate

PolyBase baseplate

foundation or

stilt mounted

Reinforced

baseplate

spring stilt

mounted

Baseplate Materials

Cast iron

Steel

Rolled steel

Stainless steel

Polymer concrete

Solid polymer

22

Baseplate Options

Stilt mounting

Spring mounting

Drain rims, pans, and

connections

Polycrete mounts

Motor feet adjusters

Earthing points

Baseplates to ISO 3661

and ISO 13709/API 610

standards

Inertia baseplates

Polybase Solid

Polymer Concrete

Baseplate

Low installed cost

Superior vibration

dampening

Corrosion resistant

Superior resistance to

twisting or diaphragming

Designed to be flat

Available with or

without catch basin

and grout holes

Inserts can be located

to mount alternate

equipment configuration

requirements

Pump Division

Flowserve

Polyshield

Polymer

Baseplate and

Foundation

System

The Flowserve Polyshield

baseplate and foundation

system is the superior solution

for cost effective, high

performance pump installation.

In one complete unit, it

combines the traditional

baseplate and formed concrete

foundation for pump-drive sets.

Benefits of Selecting the

Polyshield Baseplate and

Foundation System

Time savings

Quick installation time

Reduces time span from

receipt at jobsite to

commissioning

Cost savings

Reduces total installed cost

Dramatically minimizes

field rework necessary to

meet specifications

Better performance and

reliability

Improved MTBPM

Reduced vibration

Improved corrosion

resistance

Single structure convenience

One-piece construction

Flat mounting surfaces

One-piece motor

mounting block

The Polyshield baseplate

and foundation system

can be combined with

numerous pump

designs, including:

ISO and ASME

(ANSI) metallic and

non-metallic

Foot- and framemounted general

industrial

Foot-mounted

between bearing

ISO 13709/API 610

Please see Bulletin

PS-90-2 for more

complete product

information.

Product literature

available at

www.flowserve.com

23

Pump Division

Flowserve

PolyChem

and GRP

Non-Metallic

Process Pumps

PolyChem Non-Metallic

Process Pumps

The Flowserve PolyChem

non-metallic pump is available

in ISO, ASME (ANSI), and JIS

configurations to meet global

demands. Its PFA lined wet end

offers outstanding corrosion

resistance and temperature

resistance to 150C (300F).

PolyChem S-Series

PolyChem S-Series Sealed

Pump Operating Parameters

Capacities

60 Hz: to 320 m3/h

(1400 US gpm)

50 Hz: to 260 m3/h

(1150 US gpm)

Heads

60 Hz: to 230 m (760 ft)

50 Hz: to 160 m (530 ft)

PolyChem M-Series

Magnetic Drive Pump

Operating Parameters

Capacities

60 Hz: to 170 m3/h

(750 US gpm)

50 Hz: to 140 m3/h

(625 US gpm)

Heads

60 Hz: to 135 m (450 ft)

50 Hz: to 95 m (310 ft)

PolyChem M-Series

GRP Non-Metallic Pump

The Flowserve GRP non-metallic

pump is designed to ASME (ANSI)

B73.5 M standards. Having

corrosion resistance superior to

more expensive, high alloy

metals, the GRP costs only

slightly more than ductile iron.

The GRP pump has proven to be

the low-cost, long-term solution

in corrosive applications.

GRP

24

Operating Parameters

Flows to 2500 m3/h

(11 000 US gpm)

Heads to 150 m

(500 ft)

Pressures to 17 bar

(250 psi)

Temperatures to

120C (250F)

Product literature available

at www.flowserve.com

Pump Division

Durco

Mark 3 ASME

Standard and

In-Line Pumps

Mark 3 ASME (ANSI) Standard

With its reverse vane impeller,

SealSentry family of seal

chambers, and the optional

ANSI 3A power end, the

Mark 3 Standard pump is

recognized worldwide as the

premier name in ASME (ANSI)

chemical process pumps.

Thirty Sizes

Seven Group 1

Sixteen Group 2

Seven Group 3

Capacities

60 Hz: to 1680 m3/h

(7400 US gpm)

50 Hz: to 1390 m3/h

(6120 US gpm)

Heads

60 Hz: to 300 m (985 ft)

50 Hz: to 200 m (655 ft)

Please see Bulletin P-10-500

for more complete product

information.

Mark 3 In-Line

The Mark 3 In-Line ASME

(ANSI) pump, with its own

independent bearing housing

and rigid style motor adapter,

remains one of the most

reliable process pump

designs available.

Nine sizes available.

Capacities

60 Hz: to 370 m3/h

(1630 US gpm)

50 Hz: to 290 m3/h

(1280 US gpm)

Heads

60 Hz: to 140 m (460 ft)

50 Hz: to 95 m (315 ft)

Please see Bulletin PS-10-15

for more complete product

information.

Product literature available at

www.flowserve.com

25

Pump Division

Engineered

Pumps

ERPN Centerline Mounted

Process Pump

The ERPN is the pump of

choice for severe chemical,

petrochemical, refining and

heavy duty industrial service

applications where full

compliance with ISO 13709/

API 610 is not required.

Operating Parameters

Flows to 1100 m3/h

(4800 US gpm)

Heads to 230 m (755 ft)

Working pressures to 60 bar

(870 psi)

Temperatures to 350C

(660F)

Please see Bulletin PS-10-20

for more complete product

information.

MSP Vertical In-Line Medium

Speed Pump

Closely following API 610, 8th

edition design criteria, the MSP

vertical in-line medium speed

pump is specifically designed

for low flow, high head

applications. Available in one

and two stage designs.

Operating Parameters

Flows to 25 m3/h

(110 US gpm)

Heads to 600 m

(1970 ft)

Pressures to 100 bar

(1450 psi)

Temperatures to

200C (390F)

Please see Bulletin PS-10-1

for more complete product

information.

26

HPX API 610 Hydrocarbon

Processing Pump

Fully compliant with ISO 13709/

API 610, latest edition design

criteria, the HPX pump is the

workhorse of the hydrocarbon

processing industry due to its

unequaled versatility, reliability

and hydraulic coverage. The

most stringent emissions containment is achieved as the ISO

21049/API 682 seal chamber

accommodates all combinations

of seal models and styles,

including advanced barrier

seal technology.

Operating Parameters

Flows to 2000 m3/h

(9000 US gpm)

Heads to 350 m (1100 ft)

Pressures to 80 bar (1160 psi)

Temperatures to 450C

(850F)

Please see Bulletin PS-10-5

for more complete product

information.

Product literature available

at www.flowserve.com

Pump Division

Global

Engineered Services

and Support

Total Cost Reduction

Asset Management

Product Life Cycle

Performance Re-rates

Site Diagnostics

Repair Services

Energy Management

Spare Parts

Maintenance Contracts

Materials Upgrades

Turnkey Services

Field Repairs

Installation

Service Dedication

Flowserve Engineered Services is

focused on providing customers

with uncompromising service and

support, where and when needed.

Engineered Services is dedicated

to delivering the highest quality

support by integrating its

extensive pump and materials

engineering knowledge with

creative service solutions.

Engineered Services prides itself

in understanding the business

challenges facing customers and

is prepared to manage solutions

to succeed as a team.

A worldwide network of service

and repair centers staffed by

highly skilled engineers and

technicians is available around

the clock, seven days a week to

respond to customer queries,

to evaluate and troubleshoot

problems and to provide

reliable solutions.

Strength of Experience,

Commitment to Excellence

Flowserve has long served

industries requiring superior

equipment performance and

service life.

Oil and gas production

Hydrocarbon processing

Chemical processing

Water resources

Power generation

Nuclear

Mining and mineral processing

Pulp and paper

General industry

Engineered Services is dedicated

to maximizing equipment

performance and providing

reliability-centered maintenance

programs for pumps and related

equipment, regardless of manufacturer. Using the FlowStar

asset management software,

Engineered Services tracks

performance and supports

improvement programs using a

service life cycle cost business

approach. The results are

improved reliability and

increased profitability.

Your Business Partner

Flowserve partners with

customers to respond to

the dynamic business

conditions that affect

them. Flowserve will work

with customers to drive

efficiency, maximize

throughput and control

process quality. Whether

your needs involve onsite technical assistance

or broader project

planning with full turnkey

responsibility, you can

rely on the strength of

Flowserve Engineered

Services to deliver professional, reliable results.

Project Supervision

Commissioning

Equipment Upgrades

Condition Monitoring

Systems Analysis

Field Machining

27

Flowserve... Supporting Our Customers

With The Worlds Leading

Pump Brands

USA and Canada

Flowserve Corporation

5215 North OConnor Blvd.

Suite 2300

Irving, Texas 75039-5421 USA

Telephone: +1 937 890 5839

Europe, Middle East, Africa

Flowserve Corporation

Parallelweg 13

4878 AH Etten-Leur

The Netherlands

Telephone: +31 76 502 8100

Pump Division

Your local Flowserve representative:

To find your local Flowserve representative,

please use the Sales Support Locator System

found at www.flowserve.com

or call: +1 937 890 5839.

Latin America

Flowserve Corporation

Martn Rodriguez 4460

B1644CGN-Victoria-San Fernando

Buenos Aires, Argentina

Telephone: +54 11 4006 8700

Telefax: +54 11 4714 1610

Asia Pacific

Flowserve Pte. Ltd.

10 Tuas Loop

Singapore 637345

Telephone: +65 6771 0600

Telefax: +65 6862 2329

Printed in U.S.A.

September 2011

Flowserve Corporation

You might also like

- NFPA 255: Standard Method of Test of Surface Burning Characteristics of Building Materials 2006 EditionDocument37 pagesNFPA 255: Standard Method of Test of Surface Burning Characteristics of Building Materials 2006 EditionGualaNo ratings yet

- A Study of Chlorobenzene PyrolysisDocument9 pagesA Study of Chlorobenzene PyrolysisWalter Ruiz AstoNo ratings yet

- A Study of Chlorobenzene PyrolysisDocument9 pagesA Study of Chlorobenzene PyrolysisWalter Ruiz AstoNo ratings yet

- OGP 434-3 Storage Incident FrequenciesDocument23 pagesOGP 434-3 Storage Incident FrequenciesJose QuinteroNo ratings yet

- Matlab Practica 4Document6 pagesMatlab Practica 4Walter Ruiz AstoNo ratings yet

- Pump Protection For Minimum Flow - 1555947008Document3 pagesPump Protection For Minimum Flow - 1555947008anon_262582629No ratings yet

- Optimization PDFDocument6 pagesOptimization PDFWalter Ruiz AstoNo ratings yet

- The Design ColummDocument8 pagesThe Design ColummWalter Ruiz AstoNo ratings yet

- Partial Stroke Test Yokogawa A.F.M. Prins PDFDocument42 pagesPartial Stroke Test Yokogawa A.F.M. Prins PDFWalter Ruiz AstoNo ratings yet

- EC Firmware Update SOP For Windows enDocument6 pagesEC Firmware Update SOP For Windows enStereo PodNo ratings yet

- 6 (1) 0 Sample CV Data SheetDocument1 page6 (1) 0 Sample CV Data SheetWalter Ruiz AstoNo ratings yet

- ENGINEERING DESIGN GUIDELINE - Flare Rev1.1Document19 pagesENGINEERING DESIGN GUIDELINE - Flare Rev1.1ashutosh_mishra_9No ratings yet

- Matlab Practica 4Document6 pagesMatlab Practica 4Walter Ruiz AstoNo ratings yet

- Matlab Practica 4Document6 pagesMatlab Practica 4Walter Ruiz AstoNo ratings yet

- 1004 ACCC Petrol Report Macro July 2015 FADocument33 pages1004 ACCC Petrol Report Macro July 2015 FAWalter Ruiz AstoNo ratings yet

- Manual and Parts List: SubmersibleDocument12 pagesManual and Parts List: SubmersibleWalter Ruiz AstoNo ratings yet

- 3196 I FRAME BulletinDocument19 pages3196 I FRAME BulletinWalter Ruiz Asto100% (1)

- Manual and Parts List: SubmersibleDocument12 pagesManual and Parts List: SubmersibleWalter Ruiz AstoNo ratings yet

- 2012 PTQ q4Document148 pages2012 PTQ q4George GeorgiadisNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 26.strengthening of Structural Elements by Ordinary Reinforcement (New One)Document49 pages26.strengthening of Structural Elements by Ordinary Reinforcement (New One)deepesh3191No ratings yet

- Borates in Gypsum BoardDocument2 pagesBorates in Gypsum BoardChetan PatelNo ratings yet

- Saramet PDFDocument2 pagesSaramet PDFGiovanna Tigre0% (1)

- Profile Company MG IndonesiaDocument21 pagesProfile Company MG Indonesiaapi-245029688No ratings yet

- The Global Environment and Operations StrategyDocument73 pagesThe Global Environment and Operations StrategyJoy LuNo ratings yet

- TACO Faurecia Design Center Private Limited (TFDC)Document55 pagesTACO Faurecia Design Center Private Limited (TFDC)Subash SathyanathanNo ratings yet

- Disc Coupling Selection GuideDocument28 pagesDisc Coupling Selection GuideamericolatinoNo ratings yet

- M M Gears (P) LTD - Gishnu GearsDocument2 pagesM M Gears (P) LTD - Gishnu GearsNavaneeth MylsamyNo ratings yet

- Factory Layout PDFDocument17 pagesFactory Layout PDFSyed MahirNo ratings yet

- 69B09 190 Vol1Document630 pages69B09 190 Vol1alberto1954No ratings yet

- Disc Type Pipe Cleaning Tool Easy Clean Flyer ROSENDocument4 pagesDisc Type Pipe Cleaning Tool Easy Clean Flyer ROSENadvisoraffairsNo ratings yet

- ANEXO 5 - Catalogo Sumideros JR Smith PDFDocument22 pagesANEXO 5 - Catalogo Sumideros JR Smith PDFCamilo VelásquezNo ratings yet

- Comprehensive Study of Textile From Fiber To FashionDocument10 pagesComprehensive Study of Textile From Fiber To Fashiondeepakshi.inNo ratings yet

- Frontier School Division Job Safety Analysis for Milling Machine OperationsDocument5 pagesFrontier School Division Job Safety Analysis for Milling Machine OperationsAshok SureshNo ratings yet

- Thermal CrackingDocument24 pagesThermal Crackingmihir kumar100% (1)

- Extreme Weather Concreting and Chemical Admixtures in ConcreteDocument8 pagesExtreme Weather Concreting and Chemical Admixtures in ConcretetyashraniNo ratings yet

- Grindability TestsDocument6 pagesGrindability TestskidcatNo ratings yet

- ISO 11607 Compliance RequirementsDocument22 pagesISO 11607 Compliance Requirementsdrmohamed120No ratings yet

- Offshore Natural Gas Liquefaction Process and Development IssuesDocument7 pagesOffshore Natural Gas Liquefaction Process and Development Issuesthlim19078656No ratings yet

- SHEARINGDocument6 pagesSHEARINGanmol6237No ratings yet

- Cost of Goods Manufactured Formula Excel TemplateDocument5 pagesCost of Goods Manufactured Formula Excel TemplatePrecious UmingaNo ratings yet

- Modern Steelmaking IITSDocument207 pagesModern Steelmaking IITSSanjeev SahuNo ratings yet

- En Standard SpecificationDocument33 pagesEn Standard SpecificationSimbu ArasanNo ratings yet

- Norma de Aluminio B686Document8 pagesNorma de Aluminio B686Jefferson CalderónNo ratings yet

- Waste To Energy: Municipal Solid Waste (MSW) Refuse Derived Fuel (RDF)Document3 pagesWaste To Energy: Municipal Solid Waste (MSW) Refuse Derived Fuel (RDF)vijaykumarbitlaNo ratings yet

- TSTI Project Reference List.Document9 pagesTSTI Project Reference List.saleemNo ratings yet

- Is 2770Document12 pagesIs 2770Ankur SinghNo ratings yet

- 71 PutilovaDocument8 pages71 Putilova1xlaleNo ratings yet

- PepsiCo SupplychainDocument24 pagesPepsiCo SupplychainSagarSuryavanshiNo ratings yet