Professional Documents

Culture Documents

UoE Internal Audit Procedure

Uploaded by

danaka007Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UoE Internal Audit Procedure

Uploaded by

danaka007Copyright:

Available Formats

University of Eldoret

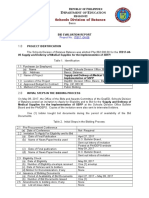

PROCEDURE FOR INTERNAL QUALITY AUDIT

UoE/QMS/MP/003

Authorization

Code:

UoE/QMS/MP/003

Title:

PROCEDURE FOR INTERNAL QUALITY AUDIT

Area:

CORPORATE

Version No.:

01

Revision No. :

00

Created by:

MANAGEMENT REPRESENTATIVE

Approved by:

VICE-CHANCELLOR

Date of version:

23RD MAY 2014

Signature:

Distribution list

Copy

Distributed to

No.

UoE/QMS/MP/003

Date

Signature

ver. [01] from [23/05/2014]

Returned

Date

Signature

Page 1 of 20

University of Eldoret

Change history

Date

Version

UoE/QMS/MP/003

Created by

Description of change

ver. [01] from [23/05/2014]

Page 2 of 20

University of Eldoret

UNIVERSITY OF ELDORET

PROCEDURE FOR INTERNAL QUALITY AUDIT

1.0. PURPOSE:

To describe all audit-related activities: writing the audit program, selecting an auditor,

conducting individual audits and reporting.

The Internal Audit determines if the QMS is effectively implemented and maintained.

2.0 SCOPE

This procedure is applied to all processes and/or areas at UoE within the QMS.

Users of this document are members of top management of UoE, as well as internal

auditors.

3.0

3.1

3.2

3.3

REFERENCES

ISO 9001:2008 Quality Management Systems Requirements

UoE Quality Manual

Procedure for Corrective and Preventive Action

4.0

4.1

ABBREVIATIONS/ DEFINITIONS

Audit -Systematic, independent and documented process for obtaining audit

evidence and evaluating it objectively to determine the extent to which the audit

criteria is fulfilled

4.2 Internal Quality Audit- Audits conducted by UoE using internal QMS auditors who

are University Staff

4.3 Audit Schedule Information that forms the basis for conducting the audits it gives

the dates for audit

4.4 Audit Plan Information directing the conduct of the individual audits within

the

schedule.

4.5 Audit Finding result of the audit

4.6 Nonconformity failure to fulfill a requirement

4.7 Observation result of a finding that does not necessarily constitute a nonconformity

4.8 Audit report Documentation that provides details of an individual audit exercise

4.9 CAR Corrective Action Request

4.10 Auditee a unit of the university that is to be audited

5.0

5.1

RESPONSIBILITIES

The MR shall be responsible for the effective implementation of this procedure by

appointing an audit team to audit processes and forward audit results for discussion

to the Management Review Committee.

UoE/QMS/MP/003

ver. [01] from [23/05/2014]

Page 3 of 20

University of Eldoret

5.2

A Lead Auditor appointed by the QMR shall be responsible for leading the audit team

and reporting of the findings of the audit to the appointing authority.

6.0 METHOD

6.1 Internal Audit Planning

6.1.1 The MR approves an Annual program for internal audits, considering the status

and importance of the process and/or area (part of the organization) that is

audited, as well as results of previous audits.

6.1.2 One internal audit shall be conducted in the course of one year, ensuring

cumulative coverage of the entire QMS scope. Internal audits shall conducted

before management review.

6.1.3 Additional internal audits may be conducted in the case of:

significant reclamation from client (decision about whether the reclamation

is significant and requires additional audit is made by VC/MR)

significant non-conformity in process or repetition of the same nonconformity (decision about whether the conformity is significant and

requires additional audit is made by VC/MR)

significant change in system (decision about whether the change in system is

significant and demands additional audit is made by VC/MR)

6.1.4 The MR shall prepare an audit Plan that shall be communicated to the relevant

process owners or auditees prior to the auditing exercise.

6.1.5 The audit plan shall indicate the area to be audited the week of the audit and the

names of the auditors. A trained Lead Auditor(s) shall be appointed by the MR to

carry out the audits. Qualification for the auditor(s) shall be by certification from

credible institutions.

6.1.6 The auditor(s) shall be independent of the area being audited, but may at times

be accompanied by a representative of the audited process area as part of the

audit team.

6.1.7 The MR shall send a notification to all auditors indicating the audit number. The

same shall be communicated to Head of department or Dean of school who shall

make the necessary arrangements and communicate appropriately.

6.1.8 The Lead Auditor shall prepare an audit program for the area(s) to be audited,

and this shall be augmented by audit check lists and other forms and working

papers. The auditor shall obtain a copy of auditees documents for the area to be

audited from the MR before the audit.

6.1.9 The Director QA is responsible for coordinating planning the internal audit,

reporting about results of internal audits and maintaining records on behalf of

MR.

6.2 Appointing internal auditors

6.2.1 The MR shall appoint internal auditors and a leader of the auditor team (if there

are more internal auditors). The leader of the audit team shall be a trained Lead

Auditor from a recognized institution.

UoE/QMS/MP/003

ver. [01] from [23/05/2014]

Page 4 of 20

University of Eldoret

6.2.2 An internal auditor shall be someone from the UoE or a person outside the

organization. Criteria for appointing internal auditors shall be:

knowledge of principles of auditing

possession of general knowledge for specific areas of audit

knowledge of standards ISO 19011 and ISO 9001

necessary competence achieved through education and/or experience

6.2.3 Internal auditors shall be selected in such a way as to ensure objectivity and

impartiality, i.e. to avoid conflict of interest, because auditors are not allowed to

audit their own work.

6.3 Conducting individual internal audits

6.3.1 The team leader and/or members of the auditor team shall define criteria, audit

scope and methods of audit.

6.3.2 The internal audit is conducted in two phases:

Document audit

Audit of compliance with documentation

6.3.3 Criteria of the audit can be compliance with ISO 9001 and/or alignment with

legal requirements and requirements of external parties that UoE agreed to.

6.3.4 Gathering of data is performed through reviewing existing documentation,

personal observation and interviews.

6.3.5 A checklist for internal audit shall be used for conducting the internal audit.

6.3.6 Opening and closing meetings shall be held between auditors and auditees to

guide the start of the auditing exercise and inform auditees about findings made

during the audit. This may be formal/informal.

6.4 Internal audit reporting

6.4.1 All non-conformances found during an audit shall be recorded and brought to

the attention of the auditee, who shall sign the corrective action reports (CARs)

and agree on when corrective actions shall be carried out

6.4.2 On the basis of the audit findings, the internal auditor (or internal audit team

leader if there are more internal auditors) shall make an internal audit report

that is delivered to Director, QA.

6.4.3 Lead auditors shall prepare 2 copies of the audit report in the format given and

submit the audit findings to the

Management Representative and

The head of department being audited

6.4.4 The internal audit report shall contain identified non-conformities (major and/or

minor) that require corrective actions, identified potential non-conformities that

require preventive action, good practice identified, any areas within the audit

scope not covered and recommendations for improvement of the QMS.

6.4.5 The internal audit report shall be delivered to top management within the

deadline defined by MR.

UoE/QMS/MP/003

ver. [01] from [23/05/2014]

Page 5 of 20

University of Eldoret

6.5 Follow-up activities

6.5.1 The owner of the process in which the non-conformities are identified shall

ensure that all necessary corrections and corrective actions for removing nonconformities and their cause are undertaken without unnecessary delays. They

shall detail the root cause of the problem before identifying the appropriate

action to prevent recurrence

6.5.2 Two weeks after date of audit, the auditors shall carry out follow-up audits to

assess auditees progress in implementing appropriate corrective actions and

record the findings.

6.5.3 Corrective and preventive actions are undertaken according to the Procedure for

Corrective and Preventive Actions.

6.5.4 After performing corrective actions, if necessary, audit follow up may be

conducted according to the Procedure for Corrective and Preventive Actions in

order to assess the effectiveness or verification of corrective actions.

6.5.5 The status of corrective actions resulting from the audit shall be reported to the

QMR for input at the next scheduled Management Review meeting if the

necessary action has not been taken within the agreed period of time.

6.5.6 The audit reports shall be summarized by the MR and a report on the entire

audit presented at the Management Review meeting.

6.5.7 Records of audit programs, audit plans, audit findings and corrective actions shall

be maintained in the departmental audit files at the Director QA office.

6.6

Managing Records kept on basis of this document

Storage

Record name

Code

Retention

time

Internal Audit Checklist

UoE/QMS/MP/003/1 2 years

Internal Audit Program

UoE/QMS/MP/003/2 2 years

Internal Audit Report

UoE/QMS/MP/003/3 2 years

Responsibility

Location

Office of

Director QA

Office of

Director QA

Office of

Director QA

MR

MR

MR

Only MR can grant other employees the right to access the Annual Internal Audit Program,

the Internal Audit Report and the Internal Audit Checklist.

7.0 APPENDICES

Internal Audit Checklist

Internal Audit Program

Internal Audit Report

UoE/QMS/MP/003

ver. [01] from [23/05/2014]

Page 6 of 20

University of Eldoret

Appendix 1 Internal Audit Checklist for ISO 9001

ISO 9001

Clause

4.1

4.2.1

4.2.2

4.2.3-01

4.2.3-02

4.2.3-03

4.2.4

5.1-01

5.1.-02

5.2

5.3

Requirement of the standard

Compliant

Yes/No

Evidence

Are the processes necessary for the QMS

determined, described, managed and applied

in the organization?

Did the organization document the Quality

Policy, quality objectives, Quality Manual, and

procedures and records required by ISO 9001

and all documents and records defined as

necessary by the organization?

Does the Quality Manual include the scope of

the QMS and justification for exclusions,

procedures or reference to procedures and

interaction between the QMS processes?

Does the organization have a documented

procedure that defines document approval,

review and update?

Did the organization ensure that changes,

current revision status and relevant versions

of applicable documents are legible and

readily identifiable and available at point of

use?

Did the organization apply suitable

identification of obsolete documents to

prevent their unintended use?

Did the organization establish records to

provide conformity to requirements of the

QMS and defined needs for identification,

storage protection, retrieval, retention and

disposition of records?

Did top management demonstrate its

commitment to development and

implementation of the QMS by emphasizing

the importance of meeting customer,

statutory and regulatory requirements?

Did top management established the Quality

Policy and quality objectives, conduct a

management review and ensure availability

of resources?

Is top management committed to meeting

customer requirements and enhancing

customer satisfaction?

Does top management ensure that the

Quality Policy is appropriate to the purpose of

the organization and demonstrates a

UoE/QMS/MP/003

ver. [01] from [23/05/2014]

Page 7 of 20

University of Eldoret

5.4.1

5.4.2-01

5.4.2-02

5.5.1

5.5.2

5.5.3

5.6.1

5.6.2

commitment to comply with the

requirements and continuous improvement

of the QMS, providing a framework for quality

objectives communicated within the

organization and reviewed?

Does top management ensure that quality

objectives, including those needed to meet

product requirements established, are

measurable and aligned with the Quality

Policy?

Does top management plan the QMS in order

to comply with requirements from clause 4.1

and quality objectives?

Does top management ensure the integrity of

the QMS if planning and applying changes to

the QMS?

Are responsibilities and authorities defined by

top management communicated within the

organization?

Did top management appoint a management

representative who has the responsibility and

authority to ensure processes needed for

establishing, implementing and maintaining

the QMS, and who reports to top

management on QMS performance and need

for improvement and promotes awareness of

customer requirements throughout the

organization?

Did top management establish appropriate

communication processes within the

organization and communication regarding

the effectiveness of the QMS?

Does top management conduct a QMS review

that includes assessing opportunities for

improvement and need for changes to the

QMS including Quality Policy and Quality

objectives at planned intervals and maintain

records about the review in order to ensure

its continuous suitability, adequacy and

effectiveness?

Does the management review include

information on results of audits, customer

feedback, process performance and product

conformity, status of preventive and

corrective actions, follow-up action from

previous management reviews, changes that

UoE/QMS/MP/003

ver. [01] from [23/05/2014]

Page 8 of 20

University of Eldoret

5.6.3

6.1

6.2.1

6.2.2-01

6.2.2-02

6.3

6.4

7.1-01

7.1-02

7.1-03

could affect the QMS and recommendations

for improvement?

Do outputs from the management review

include decisions and actions related to

improvement of effectiveness of the QMS

and its processes, improvement of product

related to customer requirements and

resources needed?

Does the organization define and provide

resources needed for implementation and

maintenance of the QMS, continual

effectiveness improvement and enhance

customer satisfaction by meeting their

requirements?

Are personnel performing work affecting

conformity to product requirements

competent, on the basis of education,

training, skills and experience?

Did the organization determine necessary

competence of personnel and provide

training to achieve necessary competence

and review and record effectiveness of

actions taken?

Are personnel aware of relevance and

importance of their activities and how they

contribute to achievement of the QMS?

Did the organization determine, provide, and

maintain the infrastructure needed to achieve

conformity to product requirements including

buildings, workspace, associated utilities, and

equipment and supporting services?

Did the organization determine and manage

the work environment needed to achieve

conformity to product requirements?

Does the organization plan and develop

processes needed for product realization, and

is its planning compliant with the

requirements of the other processes of the

QMS?

While planning product realization, did the

organization determine, as appropriate,

quality objectives and product requirements

and the need to establish process documents

and provide resources specific to the

product?

While planning product realization, did the

UoE/QMS/MP/003

ver. [01] from [23/05/2014]

Page 9 of 20

University of Eldoret

7.1-04

7.2.1

7.2.2-01

7.2.2-02

7.2.2-03

7.2.3

7.3.1-01

7.3.1-02

organization determine, as appropriate,

required activities of verification, validation,

monitoring, measuring, controlling and

testing specific for product criteria for

product acceptance and records needed?

Are the planning outputs in a form suitable

for the organizations method of operations?

Did the organization determine requirements

specified by the customer, including

requirements for delivery and post-delivery

activities, requirements not stated by the

customer, statutory and regulatory

requirements regarding the product and any

additional requirements considered

necessary?

Did the organization review and approve

product requirements and its ability to meet

requirements regardless of whether the

requirements are documented prior to

commitment to supply product to the

customer, and maintain a record about the

review?

Did the organization ensure that contractual

requirements and other requirements

differing from those previously expressed are

resolved and defined?

Does the organization maintain records about

results and actions arising from this review,

update appropriate documents, and notify

relevant personnel in case of changed

requirements?

Did the organization determine and

implement effective arrangements for

communicating with customers related to

product information inquiries, contract or

other handling and customer feedback

including customer complaints?

Does the organization plan design and

development of product by determining

design and development stages, review,

verification and validation actions that are

appropriate to each design and development

stage and responsibilities and authorities for

design and development?

Does the organization manage the interfaces

between different groups involved in design

UoE/QMS/MP/003

ver. [01] from [23/05/2014]

Page 10 of 20

University of Eldoret

7.3.1-03

7.3.2-01

7.3.2-02

7.3.3-01

7.3.3-02

7.3.4-01

7.3.4-02

7.3.5

and development to ensure effective

communication and clear assignment of

responsibility?

Is planned output updated, as appropriate, as

design and development progresses?

Does the organization determine, maintain

records and review inputs adequacy related

to product, functional and performance

requirements, statutory and regulatory

requirements, information derived from

previous similar designs and other

requirements essential for design and

development and record maintenance?

Are outputs suitable for verification against

input product requirements, and do they

contain information for purchasing,

production and service provision, reference

to product acceptance criteria and specified

product characteristics essential for its safe

and proper use and approved prior to

release?

Are output elements of design and

development suitable for verification against

input elements and prior to release?

Do design and development outputs meet the

input requirements, provide appropriate

information for purchasing production and

service provision, contain or reference

product acceptance criteria and specify

characteristics of the product that are

essential for its safe and proper use?

Is a systematic review of design and

development conducted in appropriate

phases according to planned arrangements in

order to evaluate the ability of the results of

design and development to meet

requirements, and to identify any problems

and propose necessary actions?

Among the participants of the design and

development review, are representatives of

functions concerned with design and

development stages present, and are records

maintained?

Do design and development output elements

meet the input requirements, and are

verification records maintained?

UoE/QMS/MP/003

ver. [01] from [23/05/2014]

Page 11 of 20

University of Eldoret

7.3.6-01

7.3.6-02

7.3.7-01

7.3.7-02

7.4.1

7.4.2

7.4.3-01

7.4.3-02

7.5.1-01

Does design and development result in the

product meeting specified requirement for

specified or intended use, or application,

where known?

Is validation done prior to delivery or

implementation of the product, and are

records about validation and any necessary

actions maintained?

Does the company identify changes in design

and maintain related records, review them,

verify, validate, and where applicable, accept

prior to implementation?

Does the design and development review

include evaluation of effects of changes to the

assembly parts and already delivered

products, and are related records

maintained?

Did the organization establish criteria for

selection, evaluation and reevaluation of

suppliers based on their ability to supply

product in accordance with the organizations

requirements, and maintain records about

results?

Is purchasing information adequate and

contain a description of the purchased

product, including, where appropriate,

approval of product, procedures, processes

and equipment, requirements for

qualification of personnel and QMS

requirements?

Did the organization establish and implement

the inspection or other activities necessary to

confirm that purchased product meets

specified purchase requirements?

Did the organization state the intended

verification arrangements and method of

product release in the purchasing information

when the organization or its customer intends

to perform verification at the suppliers

premises?

Does the organization plan and execute

production and service provision in managed

conditions that include, as applicable,

availability of information that describes the

product characteristics, work instructions,

and, as necessary, use of suitable equipment?

UoE/QMS/MP/003

ver. [01] from [23/05/2014]

Page 12 of 20

University of Eldoret

7.5.1-02

7.5.2-01

7.5.2-02

7.5.2-03

7.5.2-04

7.5.2-05

7.5.3-01

7.5.3-02

7.5.3-03

7.5.4-01

7.5.4-02

7.5.5

Does the organization provide conditions that

include availability and use of monitoring and

measuring equipment, implementation of

monitoring and measurement and

implementation of product release, delivery

and post-delivery activities?

Does the organization validate all production

processes and service provision where

resulting output cant be verified by

subsequent monitoring or measurement?

Does validation include all processes where

deficiencies become apparent only after the

product is in use or the service has been

delivered?

Does validation demonstrate the ability of

these processes to achieve planned results?

Does the organization establish arrangements

for this processes including, where

appropriate, defining criteria for the review

and approval of processes, equipment and

personnel qualification and use of specific

methods and procedures?

Did the organization establish requirements

for records and revalidation?

Does the organization, where appropriate,

identify product during its realization in a

suitable way?

Does the organization identify product status

considering requests for monitoring and

measuring?

Does the organization control and maintain

unique identification of the product?

Does the organization carefully handle

customer property while it is under the

organizations control or being used by the

organization?

Did the organization identify, verify, protect

and safeguard customer property provided

for use or incorporation into the product, and

does the organization report to the customer

and maintain records if customer property is

lost, damaged, or otherwise found unsuitable

for use?

Does the organization preserve the product

and constituent parts of a product during

internal processing and delivery to the

UoE/QMS/MP/003

ver. [01] from [23/05/2014]

Page 13 of 20

University of Eldoret

7.6-01

7.6-02

7.6-03

7.6-04

7.6-05

7.6-06

7.6-07

7.6-08

7.6-09

8.1-01

intended destination in order to maintain

conformity to requirements including

identification, handling, packaging, storage

and protection?

Does the organization determine monitoring

and measurement to be undertaken and the

monitoring and measuring equipment needed

to provide evidence of conformity of product

to determined requirements?

Does the organization establish processes to

ensure that monitoring and measurement can

be carried out and are carried out in a

manner that is consistent with the monitoring

and measurement requirements?

Is measuring equipment calibrated or

verified, or both, at specified intervals, or

prior to use, against measurement standards

traceable to international or national

measurement standards, and in cases when

such standards dont exist, are the bases used

for calibration and verification recorded?

Is measuring equipment adjusted or readjusted as necessary and identified in order

to determine its calibration status?

Is measuring equipment safeguarded from

adjustments that would invalidate the

measurement result?

Is measuring equipment protected from

damage and deterioration during handling,

maintenance and storage?

Does the organization assess and record the

validity of the previous measuring results

when the equipment is found not to conform

to requirements and take appropriate action

on the equipment and any product affected?

Does the organization maintain records of the

results of the calibration?

Does the organization confirm the ability of

computer software to satisfy the intended

application in cases when it is used for

monitoring and measurement of specified

requirements?

Does the organization plan and implement

the monitoring, measurement, analysis and

improvement processes to demonstrate

conformity to the product requirements and

UoE/QMS/MP/003

ver. [01] from [23/05/2014]

Page 14 of 20

University of Eldoret

8.1-02

8.2.1-01

8.2.1-02

8.2.2-01

8.2.2-02

8.2.2-03

8.2.2-04

8.2.2-05

8.2.2-06

8.2.2-07

8.2.2-08

the QMS, and continual improvement of the

effectiveness of the QMS?

Does this include determination of applicable

methods, including statistical techniques and

the extent of their use?

Does the organization monitor information

relating to customer perception as to

whether the organization has met customer

requirements?

Does the organization determine the

methods for obtaining and using this

information?

Does the organization conduct internal audits

at planned intervals to determine whether

the quality management system conforms to

the planned arrangements, to the

requirements of the ISO 9001:2008 standard,

and to the quality management system

requirements established by the

organization?

Does the organization conduct internal audits

at planned intervals to determine whether

the quality management system is effectively

implemented and maintained?

Does the organization plan the auditing

program, considering status and importance

of the processes and areas to be audited, as

well as results of previous audits?

Does the organization define the audit

criteria, scope, frequency and methods?

Does the organization select auditors and

conduct audits to ensure objectivity and

impartiality of the audit process and prevent

auditors from auditing their own work?

Does the organization establish documented

procedures to define the responsibilities and

requirements for planning and conducting

audits, establishing and maintaining records

and reporting results?

Does the management responsible for the

area being audited ensure that any necessary

corrections and corrective actions are taken

without undue delay to eliminate detected

non-conformities and their causes?

Do the follow-up activities include the

verification of actions taken and reporting of

UoE/QMS/MP/003

ver. [01] from [23/05/2014]

Page 15 of 20

University of Eldoret

8.2.3-01

8.2.3-02

8.2.4-01

8.2.4-02

8.2.4-03

8.2.4-04

8.3-01

8.3-02

8.3-03

8.3-04

8.3-05

8.3-06

verification results?

Does the organization apply suitable methods

for monitoring and, where applicable,

measurement of the quality management

system processes?

Do methods of monitoring and measurement

demonstrate the ability of the processes to

achieve planned results?

Does the organization monitor and measure

the characteristics of the product to verify

that product requirements have been met?

Does the organization maintain evidence of

conformity with the acceptance criteria?

Do records indicate the person(s) authorizing

release of product for delivery to the

customer?

Is the release of product and service to the

customer prevented until the planned

arrangements have been satisfactorily

completed unless otherwise approved by a

relevant authority and, where applicable, by

the customer?

Does the organization ensure that product

that does not conform to product

requirements is identified and controlled to

prevent its unintended use or delivery?

Does the organization establish a

documented procedure to define the controls

and related responsibilities and authorities

for dealing with non-conforming product?

Does the organization, where applicable, deal

with non-conforming product by taking action

to eliminate the detected nonconformity?

Does the organization, where applicable, deal

with non-conforming product by authorizing

its use, release or acceptance under

concession by a relevant authority and, where

applicable, by the customer?

Does the organization, where applicable, deal

with non-conforming product by taking action

to preclude its original intended use or

application?

Does the organization, where applicable,

deal with non-conforming product by taking

action appropriate to the effects, or potential

effects, of the nonconformity when non-

UoE/QMS/MP/003

ver. [01] from [23/05/2014]

Page 16 of 20

University of Eldoret

8.3-07

8.3-08

8.4-01

8.4-02

8.5.1

8.5.2-01

8.5.2-02

8.5.2-03

8.5.2-04

8.5.2-05

8.5.2-06

8.5.2-07

conforming product is detected after delivery

or use has started?

Does the organization subject corrected

product to re-verification to demonstrate

conformity to the requirements?

Does the organization maintain the records of

the nature of nonconformities and any

subsequent actions taken, including

concessions obtained?

Does the organization determine, collect and

analyze appropriate data to demonstrate the

suitability and effectiveness of the QMS and

to evaluate where continual improvement of

the effectiveness of the QMS can be made?

Does the analysis of data provide information

relating to: customer satisfaction, conformity

to product requirements, characteristics and

trends of processes and products, including

opportunities for preventive action and

suppliers?

Does the organization continually improve

the effectiveness of the QMS through the use

of the Quality Policy, Quality objectives, audit

results, analysis of data, corrective and

preventive actions and management review?

Does the organization take action to

eliminate the causes of nonconformities in

order to prevent recurrence?

Are corrective actions appropriate to the

effects of the nonconformities encountered?

Does the organization establish a

documented procedure to define

requirements for reviewing nonconformities

(including customer complaints)?

Does the organization establish documented

procedures to define requirements for

determining the causes of nonconformities?

Does the organization establish documented

procedure to define requirements for

evaluating the need for action to ensure that

nonconformities do not recur?

Does the organization establish documented

procedures to define requirements for

determining and implementing action

needed?

Does the organization establish documented

UoE/QMS/MP/003

ver. [01] from [23/05/2014]

Page 17 of 20

University of Eldoret

8.5.2-08

8.5.3-01

8.5.3-02

8.5.3-03

8.5.3-04

8.5.3-05

8.5.3-06

8.5.3-07

procedures to define requirements for

records of the results of action taken?

Does the organization establish documented

procedures to define requirements for

reviewing the effectiveness of the corrective

action taken?

Does the organization determine action to

eliminate the causes of potential

nonconformities in order to prevent their

occurrence?

Does the organization ensure that preventive

actions are appropriate to the effects of the

potential problems?

Does the organization ensure that a

documented procedure has been established

to define requirements for determining

potential nonconformities and their causes?

Does the organization ensure that a

documented procedure has been established

to define requirements for evaluating the

need for action to prevent occurrence of

nonconformities?

Does the organization ensure that a

documented procedure has been established

to define requirements for determining and

implementing action needed?

Does the organization ensure that a

documented procedure has been established

to define requirements for records of results

of action taken?

Does the organization ensure that a

documented procedure has been established

to define requirements for reviewing the

effectiveness of the preventive action taken?

UoE/QMS/MP/003

ver. [01] from [23/05/2014]

Page 18 of 20

UoE

Appendix 2 Annual Internal Audit Program

This annual program is written for the period from July to June.

Internal audits according to ISO 9001 standards will be conducted in the following way:

No.

Month

Organization unit/process

Jul

Aug

Sep

Oct

Nov

Dec

Jan

Feb

Mar

Apr

May

Jun

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Legend:

- Planned Audit

- Realized Audit

- Postponed Audit

_________________________

[signature]

[name]

[job title]

UoE/QMS/MP/003

ver. [01] from [23/05/2014]

Page 19 of 20

UoE

Appendix 3 Internal Audit Report

Audit scope:

Criteria:

Objectives:

Audit team:

1.) [name of auditor], team leader

2.) [name of auditor], team member

Date of audit:

Audit Summary:

General observations:

Non-conformities:

Good practices identified:

Processes/areas from Audit scope that havent been audited:

Document is distributed to:

1. [job title]

2. [job title]

_________________________

[signature]

[name]

[job title]

UoE/QMS/MP/003

ver. [01] from [23/05/2014]

Page 20 of 20

You might also like

- Audit Planning Conducting and ReportingDocument49 pagesAudit Planning Conducting and ReportingjackhanNo ratings yet

- ISO 9001 Internal Audit ProcedureDocument3 pagesISO 9001 Internal Audit ProcedureAcholonu Emeka Jp100% (2)

- Internal Audit SOPDocument4 pagesInternal Audit SOPIftikhar Khan100% (1)

- Internal Audit ReportsDocument1 pageInternal Audit ReportsCQMS 5S DivisionNo ratings yet

- INTERNAL AUDIT PROCEDURESDocument7 pagesINTERNAL AUDIT PROCEDURESAmer Rahmah100% (1)

- Sample - 2 Procedure For Management ReviewDocument6 pagesSample - 2 Procedure For Management ReviewKauser Kazmi100% (1)

- Audit Report-2 SignedDocument12 pagesAudit Report-2 Signedmanil_5100% (2)

- Audit Report 2 - ClientDocument10 pagesAudit Report 2 - Clientmanil_5No ratings yet

- Annual Quality Objectives Action Plan SummaryDocument1 pageAnnual Quality Objectives Action Plan Summarymullanji0% (1)

- ISO Internal Audit ChecklistDocument9 pagesISO Internal Audit ChecklistMarian Mihai100% (1)

- 1.1. Management Review InputDocument3 pages1.1. Management Review InputCok Mayun WidyatmikaNo ratings yet

- Audit Plan: Order No. Customer NoDocument2 pagesAudit Plan: Order No. Customer NofaradayNo ratings yet

- Internal Auditing As ISO 1900:2000Document74 pagesInternal Auditing As ISO 1900:2000mwlwaji100% (2)

- Procedure for Purchase SOPDocument6 pagesProcedure for Purchase SOPShakti ShuklaNo ratings yet

- F4E-QA-102 Supplier Audit Implementation 296E7T v2 3Document18 pagesF4E-QA-102 Supplier Audit Implementation 296E7T v2 3Jai BhandariNo ratings yet

- Internal Audit Procedure ExampleDocument4 pagesInternal Audit Procedure Examplestephenb4uNo ratings yet

- Optimizing MSPO Internal Audit ProceduresDocument8 pagesOptimizing MSPO Internal Audit ProceduresAhmad RufiNo ratings yet

- 9001 Planning Checklist - Production ProcessDocument14 pages9001 Planning Checklist - Production ProcessMowheadAdelNo ratings yet

- Internal Quality Audit ReportDocument3 pagesInternal Quality Audit ReportCacptCoaching100% (4)

- Audit Check ListDocument7 pagesAudit Check Listtuan mai vanNo ratings yet

- 1.2 Quality ObjectivesDocument1 page1.2 Quality ObjectivesIsHq Vishq60% (5)

- 01 Quality Objectives SummaryDocument1 page01 Quality Objectives SummaryDenny Dagger100% (1)

- MRM AgendaDocument2 pagesMRM AgendaBAlaNo ratings yet

- ISO QMS PresentationDocument29 pagesISO QMS PresentationFarid B. Mahali100% (1)

- Internal Quality Audit ChecklistDocument56 pagesInternal Quality Audit Checklistronnie santiago100% (4)

- Internal Audit ProcedureDocument6 pagesInternal Audit ProcedureUsaid KhanNo ratings yet

- Royersford Spring 2007 Audit PlanDocument4 pagesRoyersford Spring 2007 Audit PlanTravisNo ratings yet

- Quality ObjectivesDocument1 pageQuality ObjectivesDiogo KramelNo ratings yet

- ISO 9001 Audit Report Puskmas Utan KayuDocument15 pagesISO 9001 Audit Report Puskmas Utan Kayuhanisukastoberi100% (1)

- Quality Objective PRSDocument1 pageQuality Objective PRSKurt ClaveriaNo ratings yet

- 17vendor Pre-Qualification FormDocument10 pages17vendor Pre-Qualification FormHervian LanangNo ratings yet

- Medford Fabrication Management Review Procedure SP-010Document2 pagesMedford Fabrication Management Review Procedure SP-010Bisma MasoodNo ratings yet

- Supplier Audit Check SheetDocument33 pagesSupplier Audit Check SheetMotive PostNo ratings yet

- Internal - Audit ChecklistDocument19 pagesInternal - Audit ChecklistHasan100% (2)

- Management Review Meeting Presentation For QMS (Example)Document49 pagesManagement Review Meeting Presentation For QMS (Example)Kevin LaganaoNo ratings yet

- Customer Feedback and Complaint ManagementDocument6 pagesCustomer Feedback and Complaint ManagementdenemeNo ratings yet

- Aarti Drugs Audit Report Finds Issues with Change Management and EDC MonitoringDocument12 pagesAarti Drugs Audit Report Finds Issues with Change Management and EDC MonitoringVijay KotwalNo ratings yet

- Management Review ReportDocument11 pagesManagement Review ReportBrian Rasco100% (1)

- Change Management and ISO 9001Document7 pagesChange Management and ISO 9001Siddique Mansoor100% (3)

- COMP-OPP-02 Procedure For Control and Validation of Service ProvisionDocument6 pagesCOMP-OPP-02 Procedure For Control and Validation of Service ProvisionISODCC DSPINo ratings yet

- Audit ReportDocument11 pagesAudit ReportbasukirachmatNo ratings yet

- Master List of Quality Procedures IndexDocument71 pagesMaster List of Quality Procedures IndexLILIANAMAR100% (2)

- Guidance On INTERNAL AUDITSDocument7 pagesGuidance On INTERNAL AUDITSdhir.ankurNo ratings yet

- 10 IMS - DocumentationDocument4 pages10 IMS - DocumentationantivariNo ratings yet

- 5 AuditsandAssessmentsDocument44 pages5 AuditsandAssessmentsChinh Lê Đình100% (1)

- Corrective Action Plan (CAP) TemplateDocument3 pagesCorrective Action Plan (CAP) TemplateAna Cronym100% (1)

- Context of The OrganizationDocument23 pagesContext of The OrganizationIbrahim SirpiNo ratings yet

- QSP 02 - Record Control ProcedureDocument5 pagesQSP 02 - Record Control ProcedureVivek V100% (1)

- IMS Management Review 10 Minutes Conducted On 10.11.16Document7 pagesIMS Management Review 10 Minutes Conducted On 10.11.16kisipopiNo ratings yet

- ISO 9001 Audit Checklist in Human EnglishDocument9 pagesISO 9001 Audit Checklist in Human EnglishBryant Castillo Gonzalez50% (2)

- ISO 9001 QMS Internal Audit ChecklistDocument14 pagesISO 9001 QMS Internal Audit ChecklistEhab SaadNo ratings yet

- MRF Management ReviewDocument4 pagesMRF Management ReviewhastinkakaNo ratings yet

- CLAUSE 8.5 Production and Service ProvisionDocument10 pagesCLAUSE 8.5 Production and Service ProvisionNavnath TamhaneNo ratings yet

- 014 IITS Internal AuditDocument5 pages014 IITS Internal AuditSirajul IslamNo ratings yet

- ABC ABC Company: Internal Audit PlanDocument1 pageABC ABC Company: Internal Audit PlanCQMS 5S DivisionNo ratings yet

- Release of Products and ServicesDocument1 pageRelease of Products and ServiceschrisgamellaNo ratings yet

- P 008 Corrective Preventive Action Process 110414Document8 pagesP 008 Corrective Preventive Action Process 110414adam_3000No ratings yet

- ProEngineer Wildfire TutorialsDocument141 pagesProEngineer Wildfire Tutorialsdanaka007No ratings yet

- SPC PresentationDocument45 pagesSPC Presentationdanaka007No ratings yet

- Quality ManualDocument45 pagesQuality Manualhmp90100% (1)

- Control of NC ComponentDocument3 pagesControl of NC Componentdanaka007No ratings yet

- Audit SkillsDocument36 pagesAudit SkillsSudhagarNo ratings yet

- QAS P008 Control of Non-Conforming Processes, Services or Products ProcedureDocument2 pagesQAS P008 Control of Non-Conforming Processes, Services or Products Proceduredanaka007No ratings yet

- Quality Manual TrostelDocument51 pagesQuality Manual Trosteldanaka007No ratings yet

- Executive OverviewDocument66 pagesExecutive Overviewdanaka007No ratings yet

- Iso TS 16949 2009Document30 pagesIso TS 16949 2009AndroidFlaghipNo ratings yet

- PR018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2Document9 pagesPR018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2uks444100% (1)

- Audit SkillsDocument36 pagesAudit SkillsSudhagarNo ratings yet

- 85-04, The BW Preventive Action Register.: Purpose and ScopeDocument2 pages85-04, The BW Preventive Action Register.: Purpose and Scopedanaka007No ratings yet

- Quality Improvement and Statistical Process ControlDocument64 pagesQuality Improvement and Statistical Process ControlSakthi Tharan SNo ratings yet

- SPC IntroDocument38 pagesSPC Introdanaka007No ratings yet

- GD&T Fundamentals in 40 CharactersDocument76 pagesGD&T Fundamentals in 40 CharactersAnish PaiNo ratings yet

- Limit, Fits and ToleranceDocument13 pagesLimit, Fits and ToleranceAnkit NautiyalNo ratings yet

- Fundamentals of GDandTDocument75 pagesFundamentals of GDandTanjaiah_19945100% (4)

- Basic Components & Elements of Surface TopographyDocument30 pagesBasic Components & Elements of Surface TopographyXin YuNo ratings yet

- Unified Thread StandardDocument8 pagesUnified Thread Standarddanaka007No ratings yet

- Strut Vs ColumnDocument1 pageStrut Vs Columndanaka007No ratings yet

- Acceptence Criteria IMTEDocument12 pagesAcceptence Criteria IMTEdanaka007100% (1)

- AssumptionDocument1 pageAssumptiondanaka007No ratings yet

- Sample Calibration ProceduresDocument37 pagesSample Calibration ProceduresGabriel Dediu100% (1)

- Pelton Wheel TurbineDocument7 pagesPelton Wheel Turbinedanaka007No ratings yet

- SOP-QAD-001 - Inhouse CalibrationDocument4 pagesSOP-QAD-001 - Inhouse Calibrationdanaka00750% (2)

- Creating Product and Process Control SystemsDocument35 pagesCreating Product and Process Control Systemsdanaka007No ratings yet

- Cmo 54-1991Document8 pagesCmo 54-1991mick_15No ratings yet

- 511.1 Internal Control Questionnaire OKDocument11 pages511.1 Internal Control Questionnaire OKBerthold SilalahiNo ratings yet

- 2022 - Risk-Management-Guideline For The B.C. Public SectorDocument25 pages2022 - Risk-Management-Guideline For The B.C. Public SectorGuy YgalNo ratings yet

- 2013 Paper F3 QandA Sample Download v1Document31 pages2013 Paper F3 QandA Sample Download v1acca_kaplan100% (1)

- Risk & Opportunity Turtle DiagramDocument1 pageRisk & Opportunity Turtle Diagrambrian.dibbleNo ratings yet

- L2 - P4 - Corporate Governance - 1.0Document84 pagesL2 - P4 - Corporate Governance - 1.0javedaslam38No ratings yet

- Cooperative: A Lecture For Narvacan National High School MPC August9, 2013Document70 pagesCooperative: A Lecture For Narvacan National High School MPC August9, 2013gregbaccayNo ratings yet

- Importance of internal controls and COSO frameworkDocument4 pagesImportance of internal controls and COSO frameworklorie anne valleNo ratings yet

- CreditManagerEurope 2014-Issue 5Document40 pagesCreditManagerEurope 2014-Issue 5Anonymous bDCiOqNo ratings yet

- Project Finance - Test - QuestionDocument18 pagesProject Finance - Test - QuestionDeepika67% (3)

- Abs 2019 20Document66 pagesAbs 2019 20Jawad Khan GNo ratings yet

- QianHu AR FS07Document129 pagesQianHu AR FS07costie86No ratings yet

- Technical Report On Asset Declarations Greece enDocument99 pagesTechnical Report On Asset Declarations Greece enjacobo_dopicoNo ratings yet

- Coperative Society FinalDocument41 pagesCoperative Society Finalvenkynaidu100% (1)

- A. Hand Book of Agriculture PDFDocument42 pagesA. Hand Book of Agriculture PDFMuqtar Khan100% (2)

- Gland Pharma LimitedDocument316 pagesGland Pharma LimitedPranav WarneNo ratings yet

- Suzuki Annual Report 2012Document103 pagesSuzuki Annual Report 2012Ahmed SiddiquiNo ratings yet

- Bsa Midterm Non Graded Exercises Journalizing Periodic and Perpetual Method FFFDocument6 pagesBsa Midterm Non Graded Exercises Journalizing Periodic and Perpetual Method FFFGarp BarrocaNo ratings yet

- WSU Faculty of Business Sciences Prospectus 2022Document272 pagesWSU Faculty of Business Sciences Prospectus 2022Asiphe BiyoNo ratings yet

- SoundCloud: Directors' Report, Consolidated Financial Statements, Y/e 31 December 2015Document23 pagesSoundCloud: Directors' Report, Consolidated Financial Statements, Y/e 31 December 2015Digital Music NewsNo ratings yet

- Auditing Derivatives - Think of What Can Go Wrong: Trading FloorDocument3 pagesAuditing Derivatives - Think of What Can Go Wrong: Trading FloorJasvinder JosenNo ratings yet

- 600 Essential Words For TOEIC PDFDocument187 pages600 Essential Words For TOEIC PDFSoledad Lillo LeivaNo ratings yet

- Please LastDocument13 pagesPlease LastGamers HubNo ratings yet

- SBD ACA Palma, JDADocument3 pagesSBD ACA Palma, JDAJames Daniel PalmaNo ratings yet

- Schools Division of Batanes: Bid Evaluation ReportDocument2 pagesSchools Division of Batanes: Bid Evaluation Reportaracelipuno100% (3)

- Chap 21-2Document8 pagesChap 21-2JackNo ratings yet

- Accounting ScandalDocument12 pagesAccounting ScandalHannah Pamela LegaspiNo ratings yet

- Anup Deka: Areas of ExpertiseDocument6 pagesAnup Deka: Areas of ExpertiseYash JalanNo ratings yet

- Annual Report and Unaudited Financial Statements 2020Document67 pagesAnnual Report and Unaudited Financial Statements 2020Kwadwo AsareNo ratings yet

- CA firms servicesDocument13 pagesCA firms servicesmail2dhootNo ratings yet

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoFrom EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoRating: 5 out of 5 stars5/5 (1)

- Arizona, Utah & New Mexico: A Guide to the State & National ParksFrom EverandArizona, Utah & New Mexico: A Guide to the State & National ParksRating: 4 out of 5 stars4/5 (1)

- The Bahamas a Taste of the Islands ExcerptFrom EverandThe Bahamas a Taste of the Islands ExcerptRating: 4 out of 5 stars4/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensFrom EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNo ratings yet

- New York & New Jersey: A Guide to the State & National ParksFrom EverandNew York & New Jersey: A Guide to the State & National ParksNo ratings yet

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptFrom EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptRating: 5 out of 5 stars5/5 (1)