Professional Documents

Culture Documents

Common Film Coating Defects and Their Causes

Uploaded by

Lea PesiganOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Common Film Coating Defects and Their Causes

Uploaded by

Lea PesiganCopyright:

Available Formats

NO. 40 PESIGAN, LEA ELLANA E.

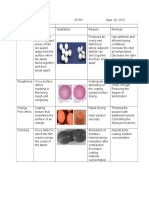

Name of Defect

1. Chipping

Description

Defect where the film becomes

chipped and dented, usually at the

edges of the tablet

SEPT. 30, 2015

Illustration

Reason

It may be due to sticking or

to damaged punches or

incorrectly

to

tablet

machine.

Remedy

- Increase hardness of the

film by increasing the

molecular weight grade of

polymer

2. Mottling

Unequal distribution of color on a

tablet, with light or dark spots

standing out in an otherwise

uniform surface

One reason for mottling is

drug whose colour differs

from the tablet excipients,

or a drug whose degradation

products are coloured.

-Use appropriate colorants

- Mix properly and reduce

size if it is of a larger size to

prevent segregation

3. Capping

Upper or lower segment of the

tablet separates horizontally, either

partially or completely from the

main body of a tablet and comes off

as a cap, during ejection from the

tablet press, or during subsequent

handling

Surface defect resulting in the film

being rough and nonglossy.

Appearance is similar to that of an

orange.

It is due to air entrapped in

the die which compressed as

punches move together to

apply pressure, and which

then expands when the

pressure is released.

- Use flat punches

- Reduce speed of turret

(Increase dwell time)

- Polish dies properly

- Dry the granules properly

Inadequate spreading of the

coating solution before

drying.

- Adjust the spray rate and

drying conditions.

Entrapment of gases in or

underneath the film due to

overheating either during

spraying or at the end of the

coating run.

Use of

condition.

4. Orange

Peel

(Roughn

ess)

5. Blisterin

g

6. Binding

7. Craterin

g

8. Laminati

on

It is local detachment of film from

the substrate forming blister.

The resistance of the tablet to

ejection from the die cavity, due to

adherence to the die wall.

Defect of film coating whereby

volcanic-like

craters

appears

exposing the tablet surface

It is the separation of a tablet into

two or more horizontal layers.

It is generally due

insufficient lubrication

to

The

coating

solution

penetrates the surface of the

tablet, often at the crown

where the surface is more

porous, causing localized

disintegra-tion of the core

and disruption of the coating

It is caused by the same

factors as capping but by

exaggerated conditions at

high speed. Its also due to

poorly cohesive or oily

granules.

9. Cracking

Small, fine cracks observed on the

upper and lower central surface of

tablets, or very rarely on the

sidewall are referred to as cracks

It is due to expansion to

expansion as distinguished

from

capping

and

laminating. It may be also

due to binding or sticking.

mild

drying

Can be solved in some cases

by modifying granules to

reduce granule size or by

increasing

punch

die

clearance.

- Use efficient and optimum

drying conditions

- Increase viscosity of

coating solution to decrease

spray application rate

Modifying mixing process.

Add adsorbent or absorbent.

Another one is to use a less

amount of lubricant or

change the type of lubricant.

Remedied by replacing or

refacing nicked or chipped

punches, resetting the tablet

machine, by increasing

binder or by wetting

granulation. It can also be

corrected

by

polishing

punch tips, removing some

or all lines and by reducing

the granule size.

10.Picking

Defect where isolated areas of film

are pulled away from the surface

when the tablet sticks together and

then part.

It is particular concern when

punch tips have engraving

or embossing letters, as well

as the granular material is

improperly dried.

- Use optimum and efficient

drying

conditions

or

increase the inlet air

temperature

- Decrease the rater of

application

of

coating

solution

by

increasing

viscosity

of

coating

solution.

You might also like

- 10 Defects of TabletsDocument3 pages10 Defects of TabletsHolihuaChua100% (2)

- Tablet DefectsDocument5 pagesTablet Defectsaloutolentino50% (2)

- Tablet DefectsDocument2 pagesTablet Defectsophelion2112No ratings yet

- Problems Associated in Tablet ManufacturingDocument12 pagesProblems Associated in Tablet ManufacturingRajib Chowdhury100% (1)

- Common Tablet DefectsDocument2 pagesCommon Tablet DefectsMaiah Dinglasan0% (1)

- Tablet Coating PDFDocument6 pagesTablet Coating PDFAsif Hasan Niloy100% (1)

- Problems and Remedies For Tablet CoatingDocument7 pagesProblems and Remedies For Tablet CoatingAnowar HossainNo ratings yet

- Name of DefectDocument3 pagesName of DefectJana EncaboNo ratings yet

- Tablet Processing ProblemsDocument41 pagesTablet Processing ProblemsSơn Nguyễn Sỹ83% (6)

- 10 Tablet DefectsDocument2 pages10 Tablet DefectsJanisa100% (1)

- Pharmaceutical TabletDocument44 pagesPharmaceutical TabletMurtaza Choudhary100% (4)

- Tablet ProblemsDocument5 pagesTablet ProblemsAnup Bajracharya75% (8)

- Modified Release Drug ProductsDocument58 pagesModified Release Drug Productsmailtorubal2573100% (2)

- Quality Control Tests For Solid Dosage FormsDocument63 pagesQuality Control Tests For Solid Dosage FormsAlina Hira100% (1)

- 5packaging of Pharmaceutical Dosage FormsDocument19 pages5packaging of Pharmaceutical Dosage FormsTrii SakttiNo ratings yet

- Pilot Scale Up Techniques For Semi Dolid Dosage FormsDocument7 pagesPilot Scale Up Techniques For Semi Dolid Dosage FormsNidhiNo ratings yet

- INTERN 3 - Internship III (Manufacturing Pharmacy)Document6 pagesINTERN 3 - Internship III (Manufacturing Pharmacy)Princess Sittie Asiah Abdullah100% (2)

- Quality Control of Tablets Lecture 1Document15 pagesQuality Control of Tablets Lecture 1Muhammad AzeemNo ratings yet

- Tablet Evaluation Parameters: Size, Shape, Strength & DissolutionDocument27 pagesTablet Evaluation Parameters: Size, Shape, Strength & DissolutionAnkush DwivediNo ratings yet

- Tablet Coating With Its DefectsDocument56 pagesTablet Coating With Its Defectsjoshirohan100% (1)

- MQA204TDocument30 pagesMQA204TAshimaNo ratings yet

- Semi Solid Dosage FormDocument8 pagesSemi Solid Dosage FormSoham Das100% (1)

- Ipqc PDFDocument11 pagesIpqc PDFAshraf Farhoud100% (2)

- IPQC Test of TabletsDocument24 pagesIPQC Test of TabletsSk Anam100% (1)

- MFR Ciprofloxacin Tablets 500 MGDocument10 pagesMFR Ciprofloxacin Tablets 500 MGmaxtar biogenics100% (3)

- Scale Up and Post Approval Changes in ADocument29 pagesScale Up and Post Approval Changes in ADaruvuri Vaidehi Chowdary100% (2)

- Chapter 27 Suspensions and EmulsionsDocument49 pagesChapter 27 Suspensions and EmulsionsKate Montenegro67% (3)

- Particle Size Effects and Granulation Techniques for PowdersDocument4 pagesParticle Size Effects and Granulation Techniques for PowdersMXLTR100% (1)

- Powders For InjectionDocument11 pagesPowders For InjectionAbigail Mayled LausNo ratings yet

- USP Dissolution Apparatus 2Document8 pagesUSP Dissolution Apparatus 2Muhammad Masoom Akhtar100% (1)

- Tablet Technology EditedDocument42 pagesTablet Technology EditedPramod Kc100% (1)

- Selection & Evaluation of Pharmaceutical Packaging MaterialsDocument35 pagesSelection & Evaluation of Pharmaceutical Packaging MaterialsTushar Naik50% (2)

- Validate film-coated tablet processDocument12 pagesValidate film-coated tablet processFarhana Shermeen83% (6)

- Dosage - Chapter 14Document57 pagesDosage - Chapter 14Kim Manlangit100% (1)

- Tablet and Capsule ManufacturingDocument28 pagesTablet and Capsule ManufacturingShibaprasad DandapatNo ratings yet

- Pharmaceutical dosage forms guideDocument10 pagesPharmaceutical dosage forms guideprinceamitNo ratings yet

- Tablet: Types of TabletsDocument82 pagesTablet: Types of TabletsKema Akma100% (1)

- SOP Sampling Raw MaterialsDocument7 pagesSOP Sampling Raw Materialshafiz riasat100% (3)

- QC Tests For Oral Liquid Dosage FormsDocument13 pagesQC Tests For Oral Liquid Dosage FormsMitesh Jain100% (4)

- Oral FormulationsDocument10 pagesOral FormulationsSiddhartha MuppallaNo ratings yet

- Unit IV. Solid Modified Release Dosage FormsDocument24 pagesUnit IV. Solid Modified Release Dosage FormsMary-Ann Valencia SapnuNo ratings yet

- Process ValidationDocument41 pagesProcess ValidationDANIBATA100% (3)

- DiluentsDocument18 pagesDiluentsApurba Sarker Apu100% (7)

- Capsules Explained: Types, Materials, Manufacturing & ApplicationsDocument35 pagesCapsules Explained: Types, Materials, Manufacturing & Applicationsde_rigorry67% (3)

- Tablet Coating Problems & SolutionDocument3 pagesTablet Coating Problems & Solutionsiddpandit89100% (2)

- BPUT Preformulation Studies Chapter 1 SummaryDocument18 pagesBPUT Preformulation Studies Chapter 1 Summarykartik sharmaNo ratings yet

- Quality AssuranceDocument43 pagesQuality Assurancepure_5abiz100% (1)

- Impact of Packaging Materials On Product Stability - FinalDocument54 pagesImpact of Packaging Materials On Product Stability - Finalhenrykayode4100% (1)

- Friability Tester Operation GuideDocument4 pagesFriability Tester Operation GuideNavdeep ChaudharyNo ratings yet

- Supacfinal 110724233556 Phpapp01Document32 pagesSupacfinal 110724233556 Phpapp01varun rajNo ratings yet

- Ophthalmic Dosage Forms Types and Characteristics 1) Liquid ...Document6 pagesOphthalmic Dosage Forms Types and Characteristics 1) Liquid ...Kiran VemaNo ratings yet

- D7 Quality Control Tests For Suspension & Emulsions Finalized OkDocument36 pagesD7 Quality Control Tests For Suspension & Emulsions Finalized OkAlishba Mushtaq100% (3)

- Quality Control Tests for Parenteral PreparationsDocument23 pagesQuality Control Tests for Parenteral PreparationsChemistry UstadNo ratings yet

- Common tablet defects and remedies under 40 charactersDocument3 pagesCommon tablet defects and remedies under 40 charactersLea PesiganNo ratings yet

- Pharmaceutical Dosage (Lec) HWDocument3 pagesPharmaceutical Dosage (Lec) HWKimberly Mae MesinaNo ratings yet

- Problem Illustration Remidies 1. CappingDocument4 pagesProblem Illustration Remidies 1. CappingMikee MeladNo ratings yet

- Tablet Coating - Final 2Document20 pagesTablet Coating - Final 2kayes_abuNo ratings yet

- Pante, Jaselle A. 2F-PH: Name Illustration Reason RemedyDocument2 pagesPante, Jaselle A. 2F-PH: Name Illustration Reason RemedyJasellePanteNo ratings yet

- Tablet DefectsDocument3 pagesTablet Defectsjeniccax17No ratings yet

- Processing Problems, Pharmaceutical Dosage FormsDocument3 pagesProcessing Problems, Pharmaceutical Dosage FormsFleur Jeizl Perez100% (1)

- HYP 0000000000000065 Full PDFDocument481 pagesHYP 0000000000000065 Full PDFSergio ChangNo ratings yet

- Medicamenta, Inc.: Pesigan, Lea Ellana E. 4A-ClphDocument1 pageMedicamenta, Inc.: Pesigan, Lea Ellana E. 4A-ClphLea PesiganNo ratings yet

- Typhoid 4-7Document2 pagesTyphoid 4-7Lea PesiganNo ratings yet

- Sexual Health UpdateDocument8 pagesSexual Health UpdateLea PesiganNo ratings yet

- Human Being in Plato & AristotleDocument14 pagesHuman Being in Plato & AristotleLea PesiganNo ratings yet

- Chapter 5 Laws of BadmintonDocument6 pagesChapter 5 Laws of BadmintonLea PesiganNo ratings yet

- EXCIPIENTSDocument12 pagesEXCIPIENTSLea PesiganNo ratings yet

- Pcog Assignment 1Document5 pagesPcog Assignment 1Lea PesiganNo ratings yet

- New MethodsDocument1 pageNew MethodsLea PesiganNo ratings yet

- Pharmacokinetics PDFDocument14 pagesPharmacokinetics PDFLea PesiganNo ratings yet

- Government AgenciesDocument2 pagesGovernment AgenciesGrd MarcelsNo ratings yet

- Activity 2Document1 pageActivity 2Lea PesiganNo ratings yet

- DFL E-25Document13 pagesDFL E-25Lea PesiganNo ratings yet

- Sexual Health FactfileDocument79 pagesSexual Health FactfileLea PesiganNo ratings yet

- Logic - 2BDocument21 pagesLogic - 2BLea PesiganNo ratings yet

- Examples Fallacy 1Document1 pageExamples Fallacy 1Lea PesiganNo ratings yet

- Opposition ExerciseDocument10 pagesOpposition ExerciseLea PesiganNo ratings yet

- Therapeutic and Medicinal Uses of Aloe VeraDocument12 pagesTherapeutic and Medicinal Uses of Aloe VeraazaliaswNo ratings yet

- Chapt18 UrinaryDocument19 pagesChapt18 UrinaryLea PesiganNo ratings yet

- CDP FinalDocument6 pagesCDP FinalLea PesiganNo ratings yet

- UNIK Guide and Evaluation FormDocument1 pageUNIK Guide and Evaluation FormMelissa SueltoNo ratings yet

- IDocument10 pagesILea PesiganNo ratings yet

- Rubrics For Footwork and StrokeDocument2 pagesRubrics For Footwork and StrokeLea PesiganNo ratings yet

- John Q ImpedimentsDocument1 pageJohn Q ImpedimentsLea PesiganNo ratings yet

- Principles in Making Moral DecisionsDocument29 pagesPrinciples in Making Moral DecisionsLea PesiganNo ratings yet

- PH Demand For HCDocument24 pagesPH Demand For HCLea PesiganNo ratings yet

- ConscienceDocument34 pagesConscienceLea PesiganNo ratings yet

- Reactions of Alkyl Halides-GDocument37 pagesReactions of Alkyl Halides-GLea PesiganNo ratings yet

- CDP Format 2015Document4 pagesCDP Format 2015Lea PesiganNo ratings yet

- PH Cost of Getting SickDocument9 pagesPH Cost of Getting SickLea PesiganNo ratings yet

- Pharmaceutical Dosage Froms and Drug Delivery SystemsDocument14 pagesPharmaceutical Dosage Froms and Drug Delivery SystemsChantelle MeaNo ratings yet

- The Stability of Folic Acid Suspension: Gobi Hariyanayagam Gunasekaran, Nurul Hidayah Bt. Jusoh, Nurhazirah Bt. SaridinDocument9 pagesThe Stability of Folic Acid Suspension: Gobi Hariyanayagam Gunasekaran, Nurul Hidayah Bt. Jusoh, Nurhazirah Bt. SaridinMeili Hasian BatubaraNo ratings yet

- Hera Rauf 7 Semester (A) Ipqc Assignment Pharmaceutical Quality Control and Management Submitted To: Dr. Khurram RehmanDocument11 pagesHera Rauf 7 Semester (A) Ipqc Assignment Pharmaceutical Quality Control and Management Submitted To: Dr. Khurram RehmanAlina HiraNo ratings yet

- Cellulose Microcrystalline SEMDocument5 pagesCellulose Microcrystalline SEMMarsha Fendria PrastikaNo ratings yet

- Relationship Between Slugging Pressure and Brittle Fracture Tendency - A Case Study For Aspirin TabletsDocument5 pagesRelationship Between Slugging Pressure and Brittle Fracture Tendency - A Case Study For Aspirin TabletsNailal MudliatunnurNo ratings yet

- DrugDocument90 pagesDrugamalia noviyantiNo ratings yet

- Azimac antibiotic overviewDocument9 pagesAzimac antibiotic overviewSara ANo ratings yet

- CZT001 Test ReportDocument1 pageCZT001 Test ReportShagorShagorNo ratings yet

- MEDICATION LISTDocument16 pagesMEDICATION LISTUber FoundationNo ratings yet

- Administering Oral Medication (Print)Document5 pagesAdministering Oral Medication (Print)Binoy Serino100% (1)

- A Comprehensive Review On Process and Engineering Aspects of Pharmaceutical Wet GranulationDocument31 pagesA Comprehensive Review On Process and Engineering Aspects of Pharmaceutical Wet GranulationManuel AlemanNo ratings yet

- Piab Vacuum Conveyors and AccessoriesDocument2 pagesPiab Vacuum Conveyors and AccessoriesSuhas KODRENo ratings yet

- Articole FarmaciaDocument12 pagesArticole Farmaciagiamatti2005No ratings yet

- 1-Classification of MedicinesDocument21 pages1-Classification of MedicinesErica BecariNo ratings yet

- PE 009-12 GMP Guide (XAnnexes)Document18 pagesPE 009-12 GMP Guide (XAnnexes)fajarrachmadi69_8540No ratings yet

- Calculation of Oral and Parenteral DosesDocument10 pagesCalculation of Oral and Parenteral DosesHilary LaneNo ratings yet

- BP505T PJ Unit - IiDocument27 pagesBP505T PJ Unit - IiVijiNo ratings yet

- Floating FilmDocument13 pagesFloating Filmchittam suvarnaNo ratings yet

- RP-HPLC Method For The Quantitative Determination of Fexofenidine HCL in Coated Tablets and HumanDocument13 pagesRP-HPLC Method For The Quantitative Determination of Fexofenidine HCL in Coated Tablets and HumanchiralicNo ratings yet

- Soal LabelDocument7 pagesSoal LabelGabriela SiadariNo ratings yet

- Auspar Gliclazide 160719Document35 pagesAuspar Gliclazide 160719santiNo ratings yet

- Ed.1.Pharmaceutics 1Document57 pagesEd.1.Pharmaceutics 1Shubham Sabale PatilNo ratings yet

- A REVIEW Selection of Dissolution MediaDocument21 pagesA REVIEW Selection of Dissolution MediavunnamnareshNo ratings yet

- 5 RatioOptimizationofGLIDANTLUBRICANTANTIADHERANTinSolidOralsbyD-OptimalConstrainedMixtureDesign PDFDocument11 pages5 RatioOptimizationofGLIDANTLUBRICANTANTIADHERANTinSolidOralsbyD-OptimalConstrainedMixtureDesign PDFMartin CelestinoNo ratings yet

- Pharmaceutical Aid HoneyDocument11 pagesPharmaceutical Aid HoneySamsonNo ratings yet

- API II Vol 2Document434 pagesAPI II Vol 2TerryNo ratings yet

- Single Punch MachineDocument3 pagesSingle Punch MachineMuttu DambalNo ratings yet

- ACTIVITY-14 Tablet HardnessDocument6 pagesACTIVITY-14 Tablet HardnessdavenNo ratings yet

- Design and Characterization of Bilayer Tablet of Rifampicin and Isoniazid For Tuberculosis TherapyDocument5 pagesDesign and Characterization of Bilayer Tablet of Rifampicin and Isoniazid For Tuberculosis TherapyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Final Reduction of Process Batch TimeDocument3 pagesFinal Reduction of Process Batch Timesamik senNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Incidents That Define Process SafetyFrom EverandIncidents That Define Process SafetyNo ratings yet

- Inherently Safer Chemical Processes: A Life Cycle ApproachFrom EverandInherently Safer Chemical Processes: A Life Cycle ApproachRating: 5 out of 5 stars5/5 (1)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Safety Fundamentals and Best Practices in Construction IndustryFrom EverandSafety Fundamentals and Best Practices in Construction IndustryNo ratings yet

- Radium Girls: Women and Industrial Health Reform, 1910-1935From EverandRadium Girls: Women and Industrial Health Reform, 1910-1935Rating: 4.5 out of 5 stars4.5/5 (4)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)

- 3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionFrom Everand3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionArnaud PerrotNo ratings yet

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeFrom EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo ratings yet

- Exercise, Sport, and Bioanalytical Chemistry: Principles and PracticeFrom EverandExercise, Sport, and Bioanalytical Chemistry: Principles and PracticeNo ratings yet

- Fire Fighting Pumping Systems at Industrial FacilitiesFrom EverandFire Fighting Pumping Systems at Industrial FacilitiesRating: 4.5 out of 5 stars4.5/5 (3)

- Safety and Intelligent Transport Systems Development in the People’s Republic of ChinaFrom EverandSafety and Intelligent Transport Systems Development in the People’s Republic of ChinaNo ratings yet

- Safety Critical Systems Handbook: A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849From EverandSafety Critical Systems Handbook: A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849Rating: 4 out of 5 stars4/5 (5)

- Fire Protection Engineering in Building DesignFrom EverandFire Protection Engineering in Building DesignRating: 4.5 out of 5 stars4.5/5 (5)