Professional Documents

Culture Documents

EVAPCO Fill Offerings 1

Uploaded by

Walter J Naspirán CastañedaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EVAPCO Fill Offerings 1

Uploaded by

Walter J Naspirán CastañedaCopyright:

Available Formats

Bulletin 685

EVAPCO has Fill Options for all

Cooling Tower Applications

Evap-Pak High Efficiency Fill installed in All Factory Assembled Cooling Towers

Titan-Pak Lightweight Stainless Steel Fill for Superior Corrosion Resistance

Wide-Pak, VertiCLEAN & Tech-Clean Wide Gap Counterflow Fills for Use

in Dirty Water Applications to Prevent Clogging

Cross-Pak Used for Crossflow Fill Kit Retrofits

Opti-Bar & Opti-Grid High Efficiency Splash Fills for Field Erected Cooling Towers

Mr. GoodTower

EVAPCOS

High Efficiency Fills

EVAPCOS

Wide Gap Fills

EVAPCOS

Splash Fills

EVAPCOs PVC Fill Technical Information

All of EVAPCOs Fill Products have been engineered for maximum performance in a variety of cooling tower applications. All bundled fill is fabricated from rigid thermoformed PVC sheets that are solvent welded for maximum strength.

The resulting structural integrity enables the fill to be used as a working platform and provides a safe working environment to perform preventative maintenance or service. The lightweight, easy to handle PVC bundles simplify installation thereby saving labor hours and cost.

EVAPCOs standard fill products are resistant to UV, rot, fungus, organic/inorganic solvents, acids, alkalis and chemicals

normally found in cooling tower waters. PVC material meets CTI standard 136.All PVC counterflow fill is suitable for

inlet water temperatures up to 130F/54.4C, and is available in HPVC material for inlet temperatures up to

150F/65.5C. Temperature fluctuations for counterflow fill of up to 15F/8.4C above the maximum continuous operating

temperature can be tolerated if kept to 2 hours or less. EVAPCOs Stainless Steel Fill is suitable for inlet water temperatures up to 150F/65.5C.

EVAPCOs Cross-Pak crossflow fill is suitable for inlet water temperatures up to 120F/49C, and is also available in

HPVC for inlet temperatures up to 130F/54.5C. Temperature fluctuations for the Cross-Pak fill of up to 5F/2.7C above

the maximum continuous operating temperature can be tolerated if kept to 1 hour or less.

Standard PVC sheet mil thickness is 10 mil after forming. Products are also available in 15 mil thickness after forming

for specialty applications where higher bundle strength is required. Additionally, all products are self-extinguishing with

a flame spread of 5 per ASTM E84-819.

Standard EVAP-PAK High Efficiency Counterflow Fill

The EVAP-PAK fill is standard in all factory assembled Evapco Cooling Towers and

is the highest efficiency fill on the market. EVAP-PAK Fill has 69 sq. ft. of surface

area per cubic foot. EVAP-PAK fill is also known as 1200 Fill.

EVAP-PAK Fill is ideal for towers where:

TSS<25 PPM (<10 PPM where bacteria activity is high)

Make up water is coming from uncontaminated sources

Biocidal water treatment program is in use

TDS < 1,000 PPM as Calcium Carbonate (CaCO3)

Minimal airborne contamination

No greases, oils, process contamination, or fibers

TITAN-PAK Stainless Steel High Efficiency Counterflow Fill

The TITAN-PAK stainless steel fill is used in factory assembled cooling towers, and

was designed for corrosive and high temperature applications. The TITAN-PAK fill

is completely constructed of stainless steel and is fire retardant. Stainless steel fill,

when properly maintained will last the life of the cooling tower. Its configuration is

very similar to the EVAP-PAK Fill, so performance de-rate is minimal.

TITAN-PAK Fill is ideal for towers where:

TSS<25 PPM (<10 PPM where bacteria activity is high)

Make up water is coming from uncontaminated sources

Biocidal water treatment program is in use

TDS < 1,000 PPM as Calcium Carbonate (CaCO3)

Minimal airborne contamination

No greases, oils, process contamination, or fibers

PPM Parts Per Million TDS Total Dissolved Solids TSS Total Suspended Solids

WIDE-PAK Cross Fluted Wide Gap Counterflow Fill

The WIDE-PAK Cross Fluted fill is often used in factory assembled cooling towers

for dirty water applications. The WIDE-PAK fill has 48 sq. ft. of surface area which

maximizes efficiency while maintaining a wide flute design. When designing around

WIDE-PAK, consideration for performance derates should be accounted for. WIDEPAK is also known as 1900 fill.

WIDE-PAK Fill is ideal for towers where:

TSS <100 PPM (<25 PPM where bacterial activity is high)

Make up water is coming from surface waters

Biocidal water treatment program in use

TDS < 5,000 PPM as Calcium Carbonate (CaCO3)

Minimal airborne contamination

No greases, oils, process contamination, or fibers

VERTICLEAN Vertical Fluted Wide Gap Counterflow Fill

The VERTICLEAN Vertical Fluted fill is often used in factory assembled cooling

towers for dirty water applications. The VERTICLEAN fill maximizes efficiency

while maintaining a vertical flute design. This vertical flute design is ideal for dirty

water applications.

VERTICLEAN Vertical Fluted Fill is ideal for towers where:

TSS between 75 and 500 PPM

Make up water is coming from surface waters

Good biological control

TDS < 5,000 PPM as Calcium Carbonate (CaCO3)

Some process contamination is allowed

Oil or greases in system up to 5 PPM

No Fibers

Replacement Fill Options for Factory Assembled and Field Erected Units

The most important factor in a cooling towers performance is the design and condition of the fill media. Over time, the

fill in a cooling tower will experience scale build-up, become clogged with debris, and when subjected to poor water conditions, may even fall apart. Replacing a towers fill can greatly increase the thermal performance, reduce the towers operating cost, and solve many of your customers tower related problems. In addition to the counterflow fill options

discussed above, EVAPCO offers replacement fill for ALL manufactures evaporative cooling equipment, including BAC, Marley & Imeco.

CROSS-PAK High Efficiency Crossflow Fill

The CROSS-PAK Fill is designed to replace OEM hanging fill sheets in factory assembled crossflow cooling towers. The CROSS-PAK Fill is custom configured to suit

any crossflow cooling tower application, and includes bundles with integrated inlet

louvers and integrated drift eliminators when applicable. There is no capacity

reduction when replacing the OEM fill with EVAPCOs High Efficiency Crossflow Fill.

CROSS-PAK Fill is ideal for towers where:

TSS<100 PPM (<25 PPM where bacterial activity is high)

Make up water is coming from uncontaminated sources

Biocidal water treatment program is in use

TDS<5,000 PPM as Calcium Carbonate (CaCO3)

Minimal airborne contamination

No greases, oils, process contamination, or fibers

PPM Parts Per Million TDS Total Dissolved Solids TSS Total Suspended Solids

TECH-CLEAN Wide Gap Vertical Offset Fill

The TECH-CLEAN Fill is often used in field erected cooling towers. TECHCLEAN fill has offset flutes which keeps the water in suspension longer and promotes water mixing. This increases the effeciency while maintaining relatively open

flutes for dirty water applications.

TECH-CLEAN Fill is ideal for towers where:

TSS<50 PPM (<15 PPM where bacteria activity is high).

Make up water is coming from uncontaminated sources.

Biocidal water treatment program is in use.

TDS < 1,500 PPM as Calcium Carbonate (CaCO3).

Good scale control is in effect.

Minimal airborne contamination.

No greases, oils, process contamination, or fibers.

OPTI-BAR Splash Fill

OPTI-GRID Splash Fill

The OPTI-BAR High Efficiency Splash Fill is used in field erected cooling towers.

OPTI-BAR eliminates the streaming and channeling of water common with standard

bar fills, and the open areas between mesh strands allows water droplets to pass

through the bar and be cooled by the air passing under the bar. In a recent major research study by an independent consulting firm, OPTI-BAR was tested for performance and compared to all other splash fills available in the market today. The test

results showed that OPTI-BAR was at least 10% more efficient than the nearest

competitive splash fill design.

The OPTI-GRID Splash Fill has evolved over many years, and is the result of hours of

research and testing, searching for the optimum configuration of a counterflow splash

fill. Because of its strength and resistance to collecting fibers, OPTI-GRID is ideal for

waters with high amounts of fibers or pulp. Optimum performance in a splash fill is

the result of maximizing the number of water droplets in any unit volume of water,

and minimizing the size of those droplets in order to produce the highest surface

area of water available to the passing air. It was found through research that, rather

than bouncing droplets off flat surfaces, as found in typical wood and plastic lath fills,

more and smaller droplets were formed if the cascading water droplets were subject

to repeated shearing action. It was found that narrow horizontal strips, in uniformly

spaced tiers throughout the heat transfer area, provided the optimum efficiency.

World Headquarters: EVAPCO, Inc. / P.O. Box 1300 / Westminster, MD 21158 / USA

Phone: 410-756-2600 / Fax: 410-756-6450 / E-mail: marketing@evapco.com

Visit EVAPCOs Website: www.evapco.com

3M/0910/YGS

2010EVAPC, Inc.

You might also like

- At - Cooling TowersDocument12 pagesAt - Cooling TowersDragos PopescuNo ratings yet

- Cross FluteDocument6 pagesCross FluteAvicena AlbiruniNo ratings yet

- Torres Enfr EvapcoDocument98 pagesTorres Enfr Evapcolaherrans100% (1)

- Mep Multi Effect Plate Evaporator DatasheetDocument4 pagesMep Multi Effect Plate Evaporator DatasheetKarim Sowley DelgadoNo ratings yet

- Refining Draps July 2013 WebDocument16 pagesRefining Draps July 2013 Webnaveenbaskaran1989No ratings yet

- AirPol Venturi Scrubber BrochureDocument8 pagesAirPol Venturi Scrubber Brochurejosedalceggio1955No ratings yet

- Technical Paper-WSD 2018Document6 pagesTechnical Paper-WSD 2018krbabu1969No ratings yet

- LSCB - LRC Catalog - 106-EDocument28 pagesLSCB - LRC Catalog - 106-ELhexter Bryan PasaguiNo ratings yet

- Cooling TowerDocument72 pagesCooling TowerRobert Nixon100% (1)

- Turbopower Web BrochureDocument5 pagesTurbopower Web BrochureBia AkramNo ratings yet

- Valve Solutions For Onshore Production BRDocument8 pagesValve Solutions For Onshore Production BRshamekhalmaamariNo ratings yet

- Evapco Cooling TowerDocument16 pagesEvapco Cooling TowermajortayNo ratings yet

- Panwater PET 300 & 400 FC Series Cooling Towers PDFDocument4 pagesPanwater PET 300 & 400 FC Series Cooling Towers PDFkingathur26681No ratings yet

- Tank Lining Brochure Corp 20140320Document7 pagesTank Lining Brochure Corp 20140320manuel25286262No ratings yet

- Cooling Tower PrinciplesDocument19 pagesCooling Tower Principlescalvin.bloodaxe4478100% (2)

- Bac TXV Stxvv00enDocument3 pagesBac TXV Stxvv00enjcrocafellaNo ratings yet

- Absorption Chillers 07Document52 pagesAbsorption Chillers 07Sujadi Cherbond100% (1)

- Alfa Laval Improving Sustainability With Welded Solutions Brochure enDocument30 pagesAlfa Laval Improving Sustainability With Welded Solutions Brochure enhamdy durraNo ratings yet

- Prime Surface Plate CoilDocument12 pagesPrime Surface Plate CoilGrimmo1979No ratings yet

- Alfa Laval Compabloc Welded Heat Exchangers Product BrochureDocument8 pagesAlfa Laval Compabloc Welded Heat Exchangers Product BrochureDoddy ChoiNo ratings yet

- Turflow Heat Exchanger High Efficiency Heat Transfer Solution-Sales BrochureDocument8 pagesTurflow Heat Exchanger High Efficiency Heat Transfer Solution-Sales BrochurePablo Angel ToiaNo ratings yet

- Refresh Refresh (Dynamic - Bypass - Reload) Click Here If You Are Not Automatically Redirected. For Assistance, Contact Your Network Support Team.Document4 pagesRefresh Refresh (Dynamic - Bypass - Reload) Click Here If You Are Not Automatically Redirected. For Assistance, Contact Your Network Support Team.Cheng Khie ChiehNo ratings yet

- Aro IrDocument52 pagesAro Irelpelos1959100% (3)

- Plate EvaporatorsDocument4 pagesPlate EvaporatorsRoger Andres OrdoñezNo ratings yet

- Steam Trap OverviewDocument15 pagesSteam Trap OverviewJodin Alido MahinayNo ratings yet

- Atlas Copco: Quality Air SolutionsDocument12 pagesAtlas Copco: Quality Air SolutionsCleiton CastilhosNo ratings yet

- Brochure HRFGDocument16 pagesBrochure HRFGjhobanybernalNo ratings yet

- A Steady Flow of Savings: The AQUA Freshwater GeneratorDocument6 pagesA Steady Flow of Savings: The AQUA Freshwater GeneratorBogi AndikaNo ratings yet

- Alfa Laval Packinox+ Product Leaflet enDocument5 pagesAlfa Laval Packinox+ Product Leaflet enJavadAminpourNo ratings yet

- Trane Classic Absorption Single-Stage Hot Water or Steam-Fired Absorption Chillers 112 To 465 TonsDocument2 pagesTrane Classic Absorption Single-Stage Hot Water or Steam-Fired Absorption Chillers 112 To 465 TonsAhmed AzadNo ratings yet

- Alfa Laval Packinox: Combined Feed/effluent Heat ExchangersDocument3 pagesAlfa Laval Packinox: Combined Feed/effluent Heat ExchangersAgnes JoseNo ratings yet

- AMS Catalogue Air DifuserDocument12 pagesAMS Catalogue Air DifuserShinigami01001No ratings yet

- Optimize performance and save space with AlfaVap and AlfaCond plate evaporators and condensersDocument13 pagesOptimize performance and save space with AlfaVap and AlfaCond plate evaporators and condensersMiaoluan ChanNo ratings yet

- Water cooled condensers: Shell and tube condensers for fresh and sea water applicationsDocument24 pagesWater cooled condensers: Shell and tube condensers for fresh and sea water applicationsyeshig2000No ratings yet

- DepVAPOR290409 PDFDocument8 pagesDepVAPOR290409 PDFltrevino100No ratings yet

- Completions Company. Baker Oil ToolsDocument32 pagesCompletions Company. Baker Oil ToolsHamid Reza BabaeiNo ratings yet

- Elbi Expamsion VesselDocument20 pagesElbi Expamsion VesselAhamed KyanaNo ratings yet

- Heat Exchangers Deaerator Feedwater TankDocument2 pagesHeat Exchangers Deaerator Feedwater TankNury RinjaniNo ratings yet

- Document Lamella Ecoflow Brochure 482Document4 pagesDocument Lamella Ecoflow Brochure 482Zerihun AlemayehuNo ratings yet

- Chiller - CarrierDocument27 pagesChiller - CarrierJose Francisco Varela CruzNo ratings yet

- New De-Oiling Hydrocyclone OutperformsDocument17 pagesNew De-Oiling Hydrocyclone OutperformsUci SianiparNo ratings yet

- Air Sentry - Energy Statement App 3 Dessicant and Filters PDFDocument20 pagesAir Sentry - Energy Statement App 3 Dessicant and Filters PDFEsteban Fernando Meza IbacetaNo ratings yet

- Epv Bro Pres 02Document20 pagesEpv Bro Pres 02Miguel CastilloNo ratings yet

- KFBE Fluidized Bed Structured PackingDocument8 pagesKFBE Fluidized Bed Structured PackingMeli ChiambaNo ratings yet

- Overview of Cooling Tower Components, Operation and MaintenanceDocument79 pagesOverview of Cooling Tower Components, Operation and MaintenanceHamid Ariz100% (2)

- Doosan Steam TurbinesDocument24 pagesDoosan Steam TurbinesUhrin Imre0% (1)

- Superfrac Koch PDFDocument16 pagesSuperfrac Koch PDFMPilarAlfonsoGonzálezNo ratings yet

- RAMVAC Dental ProductsDocument16 pagesRAMVAC Dental Productswhagen1974No ratings yet

- Foam ChamberFCADocument6 pagesFoam ChamberFCAarachman297988No ratings yet

- Condensate Recovery-Sales Brochure PDFDocument20 pagesCondensate Recovery-Sales Brochure PDFSasitharan MNo ratings yet

- 55 Emerson Catalog PDFDocument82 pages55 Emerson Catalog PDF050678No ratings yet

- Company ProfileDocument8 pagesCompany ProfileSourabh ManujaNo ratings yet

- Ehandbook Strategize Your Steam SystemDocument18 pagesEhandbook Strategize Your Steam SystemMPham100% (1)

- Ehandbook Strategize Your Steam SystemDocument18 pagesEhandbook Strategize Your Steam Systemoritas100% (1)

- High SO2 catalystsDocument8 pagesHigh SO2 catalystsHero19No ratings yet

- Packaged STPDocument25 pagesPackaged STPFarooqNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisFrom EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisRating: 5 out of 5 stars5/5 (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Managing Toxic Chemical Processes / Process Gases in ManufacturingDocument39 pagesManaging Toxic Chemical Processes / Process Gases in ManufacturingWalter J Naspirán CastañedaNo ratings yet

- World Class Ammonia RefrigerationDocument33 pagesWorld Class Ammonia RefrigerationWalter J Naspirán CastañedaNo ratings yet

- Ammonia Fueled Sports Car - Marangoni Toyota GT86 Eco Explorer - NH3 FuelDocument5 pagesAmmonia Fueled Sports Car - Marangoni Toyota GT86 Eco Explorer - NH3 FuelWalter J Naspirán CastañedaNo ratings yet

- 39nx 2pdDocument808 pages39nx 2pdWalter J Naspirán Castañeda100% (1)

- Algunas Referencia Casos - de Exito Cond. Evap SnowkeyDocument42 pagesAlgunas Referencia Casos - de Exito Cond. Evap SnowkeynascasNo ratings yet

- Official Distributor Certificate for Snowman Group Products in ColombiaDocument1 pageOfficial Distributor Certificate for Snowman Group Products in ColombianascasNo ratings yet

- Manual MantenimientocondensadorDocument12 pagesManual MantenimientocondensadorWalter J Naspirán CastañedaNo ratings yet

- What Is Aluzinc, What It Is Used For and What Is The Difference With Galvanized Steel?Document2 pagesWhat Is Aluzinc, What It Is Used For and What Is The Difference With Galvanized Steel?Walter J Naspirán CastañedaNo ratings yet

- Snowkey Application HandbookDocument160 pagesSnowkey Application HandbookWalter J Naspirán CastañedaNo ratings yet

- 39nx 2pdDocument219 pages39nx 2pdWalter J Naspirán CastañedaNo ratings yet

- 39nx 2pdDocument219 pages39nx 2pdWalter J Naspirán CastañedaNo ratings yet

- Elgenerering Opcon Energy SystemDocument25 pagesElgenerering Opcon Energy SystemWalter J Naspirán CastañedaNo ratings yet

- Icm IcadDocument81 pagesIcm IcadWalter J Naspirán CastañedaNo ratings yet

- AfSialexRing User Manual, EnglishDocument24 pagesAfSialexRing User Manual, EnglishWalter J Naspirán CastañedaNo ratings yet

- Pipe Fitting and Piping Handbook GuideDocument231 pagesPipe Fitting and Piping Handbook Guidejuanroman88% (42)

- Advanced DX Ammonia Case Study Joliet Cold Storage Joliet IlDocument2 pagesAdvanced DX Ammonia Case Study Joliet Cold Storage Joliet IlWalter J Naspirán CastañedaNo ratings yet

- Hvac CoilsDocument28 pagesHvac CoilsWalter J Naspirán CastañedaNo ratings yet

- Rating 971TC Actual 1Document1 pageRating 971TC Actual 1Walter J Naspirán CastañedaNo ratings yet

- SRM26 Service Manual enDocument50 pagesSRM26 Service Manual enWalter J Naspirán CastañedaNo ratings yet

- Platecoil Album 2009Document28 pagesPlatecoil Album 2009Walter J Naspirán CastañedaNo ratings yet

- Chapter-Cooling TowersDocument17 pagesChapter-Cooling TowersSAGIS ETIENNENo ratings yet

- Applied Thermal Energy 2012 1Document30 pagesApplied Thermal Energy 2012 1Walter J Naspirán CastañedaNo ratings yet

- Paper DeshumidifiersDocument31 pagesPaper DeshumidifiersWalter J Naspirán CastañedaNo ratings yet

- Article Hydrocarbon Engineering Feb 2011Document0 pagesArticle Hydrocarbon Engineering Feb 2011Sook Thiam LeeNo ratings yet

- Water Cooling CoilsDocument20 pagesWater Cooling CoilsWalter J Naspirán CastañedaNo ratings yet

- Rating 971TC Propuesto 1Document1 pageRating 971TC Propuesto 1Walter J Naspirán CastañedaNo ratings yet

- Air Conditioning Design - Psychrometrics & Coil Load CalculationDocument13 pagesAir Conditioning Design - Psychrometrics & Coil Load Calculationvsajv83% (6)

- Energy Impacts of Chiller Water Piping ArrangementDocument8 pagesEnergy Impacts of Chiller Water Piping ArrangementSharon LambertNo ratings yet

- AirflowDocument6 pagesAirflowamechmar5935No ratings yet

- FM (MEE84) Module-1 PresentationDocument29 pagesFM (MEE84) Module-1 Presentationsonic somannaNo ratings yet

- Exceptional Electronic Configuration Atomic StructureDocument1 pageExceptional Electronic Configuration Atomic StructurenischayNo ratings yet

- IS STD - IS 16714 - 2018 - GGBSDocument11 pagesIS STD - IS 16714 - 2018 - GGBSSoumyakanti S. Samanta (Pgdm 09-11, Batch II)0% (1)

- Fatigue PDFDocument67 pagesFatigue PDFsabaris ksNo ratings yet

- WPS D1.3-2012 BlankDocument1 pageWPS D1.3-2012 BlankpjbedelNo ratings yet

- Phd. ProposalDocument2 pagesPhd. ProposalDr-naser MahmoudNo ratings yet

- Food Science Lab Report 2Document6 pagesFood Science Lab Report 2Hazim Hs100% (1)

- 5 Dental AmalgamDocument64 pages5 Dental AmalgamSmiley Josh100% (1)

- Seminar Kimia SPM Mmu 2017 CG Adura Jawapan Kertas 2 PDFDocument48 pagesSeminar Kimia SPM Mmu 2017 CG Adura Jawapan Kertas 2 PDFNoorleha Mohd YusoffNo ratings yet

- Methane to Chloromethanes Process DescriptionDocument15 pagesMethane to Chloromethanes Process DescriptionAlsello Diveni ManuputtyNo ratings yet

- Rheology of Melts and Solutions Part 1: Viscosity and Its MeasurementDocument6 pagesRheology of Melts and Solutions Part 1: Viscosity and Its Measurementzeqs9No ratings yet

- Production of Cyclohexane From BenzeneDocument151 pagesProduction of Cyclohexane From BenzeneGerald Lim60% (5)

- Ocr 33983 PP 09 Jan L Gce 2815 01Document12 pagesOcr 33983 PP 09 Jan L Gce 2815 01Philip_830No ratings yet

- CH 2 - Properties of MixturesDocument47 pagesCH 2 - Properties of MixturesQuezza Phola S PatulinNo ratings yet

- CMET 106: Introduction to Process Heat TransferDocument10 pagesCMET 106: Introduction to Process Heat TransferBilal AhmedNo ratings yet

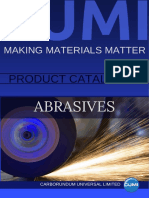

- Making Materials Matter: Product CatalogueDocument7 pagesMaking Materials Matter: Product Cataloguemustafasenbagci3693No ratings yet

- A574m PDFDocument7 pagesA574m PDFLeonardo GomideNo ratings yet

- Volume-I Part II SpecificationDocument118 pagesVolume-I Part II SpecificationHiren DesaiNo ratings yet

- Stain Removal GuideDocument1 pageStain Removal Guidekhamid arifNo ratings yet

- 27 3138 01 Supracare 780 AdditiveDocument6 pages27 3138 01 Supracare 780 AdditiveRicardo BohorquezNo ratings yet

- Experiment No. 6: Determination of The Solubility Product Constant of Calcium HydroxideDocument2 pagesExperiment No. 6: Determination of The Solubility Product Constant of Calcium HydroxideAliaArellano100% (1)

- Thermoplastic Elastomeric (TPE) Gasket Materials For Drain, Waste, and Vent (DWV), Sewer, Sanitary and Storm Plumbing SystemsDocument2 pagesThermoplastic Elastomeric (TPE) Gasket Materials For Drain, Waste, and Vent (DWV), Sewer, Sanitary and Storm Plumbing SystemsĐường Nguyễn ThừaNo ratings yet

- Tight BiteDocument1 pageTight BiteAlex DaniciNo ratings yet

- 10 - Equipment Damage Curves Motors PDFDocument5 pages10 - Equipment Damage Curves Motors PDFMoulay m'hammed LOUKILINo ratings yet

- MECH466 Lecture 4 PDFDocument28 pagesMECH466 Lecture 4 PDFSaran ArunNo ratings yet

- Wax Glue2Document6 pagesWax Glue2Gamal FouadNo ratings yet

- MSS SP-55 (Quality Standard For Steel Casting Valve, Flange, Fitting, Etc.Document23 pagesMSS SP-55 (Quality Standard For Steel Casting Valve, Flange, Fitting, Etc.Muhammad RizkiNo ratings yet

- Bjorn Tore Lovfall TriallectureDocument45 pagesBjorn Tore Lovfall Triallecturegreenhen15No ratings yet

- Production of Sulfure-FreeDocument90 pagesProduction of Sulfure-Freeزهراء عادل عبد الزهرة إسماعيلNo ratings yet