Professional Documents

Culture Documents

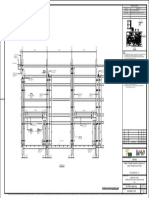

PCB Fab Wallchart

Uploaded by

smtdrkdOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PCB Fab Wallchart

Uploaded by

smtdrkdCopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10 11 12

DESIGN INFORMATION DESIGN AND FABRICATION TABLE

LAND SIZE

PRINTED CIRCUIT BOARD MANUFACTURING PROCESS MANUFACTURING DRAWINGS SHOULD INCLUDE A DESIGN AND

FABRICATION TABLE AS SHOWN BELOW. THE DRAWING SHALL

CONTAIN DIMENSIONS REFERENCING NPTH AND PTH HOLES

A TRACK TO PAD HOLE SIZE A

TO AN ORIGIN OR DATUM. FOR FULL DETAILS ON DIMENSIONING

AND TOLERANCING OF PRINTED BOARDS REFER IPC-D-300G.

CUSTOMER

MULTI- LAYER BOARDS ONLY Copies of this table are available from Morris Productions in a DXF file or Protel formats.

PAD

TRACK WIDTH

TO PREFERRED INPUTS NEEDED

STORE

ELECTRICAL TEST DESIGN INFORMATION

PAD NPTH - EG. BURIED VIAS

ACCOUNTS SUPPLIERS MATERIAL ISSUE

- GERBER FILES

TRACK TO TRACK BOARD TECHNOLOGY : BOARD SIZE :

- PROTEL PCB FILE

TRACK TO BOARD EDGE TRACK TO NPTH X (mm)

- 1:1 PHOTOPLOTS IMAGE ETCH STRIP DRY FILM PRESSING

MATERIAL LAY-UP (MIN. TRACKS/PADS/CLEARANCE IN 0.025mm (0.001") (REFER ALSO PROFILING INFORMATION)

ORDER MATERIALS - SPECIFIED MATERIAL INNER LAYER(S) INNER LAYER(S) INNER LAYER(S) PREPARATION

- MANUFACTURING DRAWINGS CUT

EXTERNAL SIGNAL LAYERS INTERNAL SIGNAL LAYERS ACCEPTANCE PURCHASING CUT TO REQUIRED

SHOWING ALL DIMENSIONS & FORMAT SIZE - LAMINATE DRY FILM - REMOVE UNWANTED - REMOVE PHOTO - BLACK OXIDE (IMPROVES - ALL LAYERS LAID - HIGH PRESSURE/ TEMPERATURE (MINIMUM ANNULAR RING 0.05mm (0.002")

FEATURE STANDARD SPECIAL FEATURE STANDARD SPECIAL SPECIFICATIONS (PHOTO SENSITIVE COPPER RESIST ADHESION AT BONDING TOGETHER, INTER- VACUUM CURING CYCLE

* PTH - LAND SIZE +0.50mm ON * PTH - LAND SIZE +0.50mm ON RESIST) STAGE) LEAVED WITH PREPREG, - CONTROLLED COOLING CYCLE CIRCUIT TYPE : SS DS PTH ML No. OFF _____

* NPTH - LAND SIZE APPLICATION - DIMENSIONED - INSPECT ( Q.C) - VISUAL INSPECTION MOULD RELEASE FILM

+0.70mm APPLICATION

OUTLINE DRAWING - PUNCH REGISTRATION - CONDITION ( REMOVE AND PRESS PLATES.

TRACK WIDTH 0.20mm 0.125mm TRACK WIDTH 0.20mm 0.125mm

ENGINEERING PRODUCTION FINGER CONNECTOR DIM PER : AS SHOWN

TRK/PAD TO PAD/TRK TRK/PAD TO PAD/TRK 0.20mm 0.125mm PCB DESIGN NORMALISE HOLES MOISTURE)

0.20mm 0.125mm PLANNING TOOLING

TRK TO EDGE (min) ** TRK TO EDGE (min) ** 0.50mm 0.50mm - NC DRILL AND

0.53mm 0.53mm No. OFF TOTAL ONE SIDE TWO SIDES

TRK TO NPTH (min) ** TRK TO NPTH (min) ** 0.50mm 0.50mm ROUT FILES - IMAGE (EXPOSE WITH

0.53mm 0.53mm 4 LAYER BOARD

NEGATIVE PHOTOTOOL)

* Land-to-hole relationship is established by the following equation: - TECHNICAL STANDARDS

- CHECK CUSTOMER - CHECK REGISTRATION - PROVIDES STRESS AS EXAMPLE 18um Foil VIAS : FEED THROUGH TENTED BURIED LAYER SEQ ____________

B (DESIGN RULES USED)

DOCUMENTATION, DATA, RELIEF AND AIDS

- DEVELOP

B

GERBER FILES / ARTWORK - ENSURE DRILL PATTERN DIMENSIONAL BLIND LAYER SEQ ____________

Refer to IPC-2221 Section 9.0 - Holes/Interconnections. This standard is also endorsed as Military Standard. NONE UNIQUE DRILL MIXED

SPECIFICATIONS ON TEST BOARD MATCHES STABILITY PREPREG (0.35mm)

FR4 SUBSTRATE

Land size, minimum = a + 2b +c

ARTWORK

(TYP. 0.71mm)

LAYER CONSTRUCTION PER : LAMINATION SEQUENCE AS SHOWN

- PERFORM DESIGN

where: PHOTO PHOTO REMOVE PREPREG (0.35mm)

RULE CHECKS - ADD VENTING, LOGOS BASE COPPER

a = Maximum diameter of the finished hole RESIST RESIST UNWANTED

CODING ETC. TYP. 18/35um

b = Minimum annular ring requirements ( see 9.1.2) COPPER

- STEP UP ARTWORK

TO DESIRED FORMAT SIZE - PREPARE FINAL NC 18um Foil ARTWORK : MANUAL CAD TYPE

** Min. distance between conductive area and the edge of a board is calculated by adding 0.4mm to the minimum electrical

TOOLING FILES FR4 SUBSTRATE

clearance as determined in IPC-2221, IPC-2222. Table 6-1.

- PRODUCE DRILL AND (TYP. 0.71mm)

For 0-100 Volts a spacing of 0.13mm is required for a PCB with external conductors. (Thus 0.4mm + 0.13mm = 0.53mm).

For 0-100 Volts a spacing of 0.10mm is required for a PCB with internal conductors. (Thus 0.4mm + 0.1mm= 0.5mm).

ROUT FILES - ENSURE ARTWORK MEETS REFER TO MORRIS' STANDARD MULTI-LAYER COMBINATIONS ARTWORK/PATTERN MASTER LIST

MANUFACTURING FOR DETAILS ON TYPICAL LAYUPS USING MATERIALS

Lands for surface mounting are covered extensively in this Standard and IPC - SM - 782A, as well as the various recommendations COMMONLY HELD IN STOCK.

- PRODUCE ELECTRICAL REQUIREMENTS TRACK PAD TRACK PAD TRACK PAD DESCRIPTION DRAWING No./CAD FILE REF. ISS ARTWORK/FILM REF GERBER FILE REF ISS

laid down by component manufacturers. TEST JIG FILES

- GENERATE PRODUCTION

INTERNAL POWER AND GROUND LAYERS

- PREPARE WORK AFTER PRESSING AND TRIMMING OF THE BOARD, THE MANUFACTURING

GND AND PWR LAND FEATURE STANDARD SPECIAL INSTRUCTIONS

PROCESS IS THE SAME AS FOR DOUBLE SIDED BOARDS.

CLEARANCE PAD SIZE LAND SIZE * D<=3.0mm +0.50mm ON

(Fin Hole D+) D>=3.0mm +0.55mm APPLICATION

CLEAR. PAD *D<=3.0mm +0.90mm "

(Fin Hole D+) D>=3.0mm +1.00mm "

WEB (CONDUCTOR) * 0.25mm "

AIR

GAP

AIR GAP

PWR/GND TO BRD EDGE **

0.25mm

1.27mm

"

"

DOUBLE SIDED AND MULTI-LAYER BOARDS MATERIAL :

C WEB PWR/GND TO NPTH ** 0.50mm 0.50mm

GLASS FIBRE EPOXY RESIN NEMA GRADE FR4 (IPC - 4101) C

FIN HOLE SIZE (D)

FIN HOLE * For further details on land size calculations refer IPC -2221 REFLOW SOLDER PROCESS OTHER

SIZE (D) IPC-2222. This standard is also endorsed as Military Standard.

Typically, web size is determined by dividing 60% of the minimum THICKNESS : 0.8mm 1.2mm 1.6mm 2.4mm 3.2mm

land size by the number of webs required. If a larger land size is

NI/GOLD PLATE TOLERANCE : IN A/W IPC - D - 300G CLASS OTHER + / -

used, the web size is reduced to allow adequate soldering dwell

NPTH AIR EDGE CONTACTS

GAP time. (Ensure that the web size is not thinner than the minimum

BOW AND TWIST : IN A/W IPC - D - 300G CLASS AS SHOWN

- LAB TEST

LAND ** Min. distance between conductive area and the edge of a board

SIZE

is calculated by adding 0.4mm to the minimum electrical STRIP SOLDER

COPPER (FINISHED) :

PWR AND GND TO NPTH clearance as determined in IPC-2221, IPC-2222. Table 6-1. EDGE CONTACTS OUTER : 18um 35um 70um

For 0-100 Volts a spacing of 0.1mm is required for a PCB

with internal conductors. (Thus 0.4mm + 0.1mm = 0.5mm). INNER SIG : 18um 35um 70um

PWR/GND TO However, for PWR/GND to board edge a clearance of 1.27mm

CLEAN REFLOW SOLDER INSPECT SOLDER MASK INNER PWR : 18um 35um 70um

BOARD EDGE is preferred.

It is not necessary to have a land around a pin which does not

make connection to anything on that plane. If a land is placed STRUCTURE : STANDARD 'MORRIS PRODUCTIONS' LAYUP

around a component lead, it increases the chance of a short

occuring if a small slither of copper bridges the land and a plane AS PER DRAWING AS SHOWN

DRILLING :

PAD TO RESIST

VIEWED FROM : COMPONENT SIDE WIRING SIDE

ELECTRICAL TEST

SOLDER RESIST ELECTROLESS NICKEL / IMMERSION GOLD PROCESS REFERENCE : AS SHOWN PATTERN MASTER LIST NC_DRILL FILES

D D

FEATURE STANDARD PTH MINIMUM COPPER THICKNESS : 20um OTHER

PAD TO RESIST:- NPTH : TENTED PADS REMOVED REMOVE PADS

(LIQUID PHOTOIMAGEABLE) 0.05mm (min)

(EPOXY SCREEN PRINT) 0.25mm FINAL 2nd DRILL BOTH AS SHOWN

0.15mm ELECTROLESS SCREEN PRINT

MASK TO MASK BLOCKOUT STRIP SOLDER INSPECT CLEAN SOLDER MASK PROFILING ACCEPTANCE DESPATCH

NICKEL / IMMERSION LEGEND

HOLE FIRST COPPER STRIP DRY TESTING

MASK TO MASK BLOCKOUT DRILLING

PREPARATION

IMAGE SECOND PLATE ETCH GOLD BOARD FINISH : ETCHING REFER PATTERN MASTER LIST

Vias which are to be tented &/or filled with resist must be PLATE FILM

- PHOTOIMAGEABLE

specified in your documentation. Note also, vias which are to be SOLDER REMOVED SOLDER MASK NICKEL / GOLD LEGEND / SCREEN PRINT : NONE COMP. SOLD.

- REMOVE - Q.C

tented (covered) with solder resist, must have a maximum

finished hole size no greater than 0.6mm. A unique hole size

- HIGH PRESSURE - CHEMICAL - LAMINATE DRY - 2ND COPPER PLATE - REMOVE UNWANTED COLOUR : WHITE YELLOW OTHER

WATER RINSE DEPOSITION OF FILM (PHOTO (BUILD UP COPPER PHOTO COPPER (TIN/LEAD - LAB TEST

should be used for these vias so that they can be identified

VIA (TENTED) COPPER TO ALL SENSITIVE TO FINAL RESIST PROTECTS COPPER

during manufacture.

- VISUAL CHECK DRILLED HOLES RESIST) THICKNESS) PATTERN) SOLDER RESIST : LIQUID PHOTOIMAGEABLE SCREEN PRINT

VIA (MASKED) - VISUAL

Morris Productions uses solder resist that complies with

- DESMEAR/ - 1ST COPPER - IMAGE (EXPOSE WITH - TIN/LEAD PLATE INSPECTION COLOUR : GREEN BLUE YLW/GRN OTHER

MIL-I-46058 and meets the requirements of IPC-SM-840.

ETCHBACK PLATE POSITIVE PHOTOTOOL) SOLDER RESIST

Available in both liquid imageable and screen print, typical

- LAB TEST MATTE GLOSS

thickness is 15-20um and 20-25 um respectively.

- LAB TEST - DEVELOP

Photoimageable solder resists are preferred for surface mount HOT AIR LEVEL (SMOBC) PROCESS

applications. UL approved resists are also available. Typical TRACK FINISH : SELECTIVE SOLDER REFLOW TIN/LEAD

- INSPECT (Q.C)

colours available are green, green / yellow, and blue : other

ELECTROLESS Ni/Au - 0.1 / 0.2um GOLD OVER 3.0um NICKEL

DEPOSITION OF

NPTH (LANDLESS ELECTROLESS COPPER PHOTO RESIST AND REFER PATTERN MASTER LIST OTHER

THICKNESS LINES AND TEXT

OTHERWISE 2ND NOM. THK 2.0 um UNWANTED COPPER

LEGEND DRILLING) PHOTO RESIST REMOVED

SCREEN PRINT NI/GOLD PLATE

E LEGEND EDGE CONTACTS

EDGE BOARD 1.3um HARD GOLD OVER 5.0um NICKEL E

FEATURE MINIMUM

R1 TEXT HEIGHT - LAB TEST

CONTACTS : HARD FINISH GOLD PLATE OTHER

LINE THICKNESS 0.15mm

LEGEND

TEXT THICKNESS 0.15mm STRIP SOLDER

STRIP SOLDER INSPECT CLEAN SOLDER MASK HOT AIR LEVEL AS SHOWN REFER

TEXT HEIGHT 1.00mm EDGE CONTACTS

LEGEND TO PAD 0.25mm - SOLDER APPLIED COPPER

LEGEND TO EDGE 0.25mm

COMPONENT HOLE

- PHOTOIMAGEABLE TO BARE COPPER PROFILING : AS DIMENSIONED , MEASURED AND CUT FROM SPECIFIED DATUM.

LEGEND TO PAD DRY FILM TIN/LEAD OVER COPPER SOLDER MASK (PADS, VIAS ETC) TIN/LEAD

0R VIA TENTS(COVER) NPTH REFER PCB BLANK DWG No.

Typical colours available are white, yellow and black ; and ELECTROLESS NICKEL / GOLD

- Q.C USE PROFILE/ROUT TAPE SUPPLIED REFER PATTERN MASTER LIST

made

LEGEND TO BOARD EDGE

NOTES. 1: LAB TEST INCLUDES ALL TESTS THAT ARE REQUIRED TO PROVE PROCESS CAPABILITIES, SOLDER REMOVED - LAB TEST SELECTIVE SOLDER SOLDER RESIST SQUARE CUT N.C. ROUT V- GROOVE BLANK

BUT ALSO THOSE TESTS (SUCH AS MICROSECTIONS), AND DOCUMENTATION NEEDED TO

MEET CUSTOMER REQUIREMENTS INCLUDING IPC CERTIFICATION LEVELS AND MILITARY PHOTO RESIST ACCEPTABILITY : MATERIALS AND WORKMANSHIP FOR ALL PRINTED WIRING BOARDS

ARTWORK ALLOWANCES SPECIFICATIONS.

MUST MEET OR EXCEED THE REQUIREMENTS OF :

CONDUCTOR WIDTH : - To obtain minimum design conductor width refer tables such as those in IPC - 2221, IPC-2222 2 : THE PROCESSES SHOWN IN THIS DIAGRAM ARE TYPICAL OF MOST PCB MANUFACTURERS.

for the relevant current ratings. To allow for processing effects such as pits, nicks, undercut etc, PLEASE CHECK WITH YOUR MANUFACTURER WITH REGARD TO SPECIAL REQUIREMENTS.

IPC - 6011, IPC - 6012 CLASS 1 2 3

artwork track width should be drawn 0.05mm (0.002") wider for 35um (1oz) foil. SOLDER RESIST U.L CERTIFICATION

CONDUCTOR SPACING : - Refer electrical conductor spacing table as published in IPC -2221, IPC-2222 . To ensure minimum MIL -P- 55110D OTHER __________________

spacing allow 0.05mm (0.002") on artworks with 35um (1oz) copper.

ADDITIONAL REQUIREMENTS :

F RECOMMENDED MULTILAYER LAYUP COMBINATIONS ARTWORK REQUIREMENTS DRILLING, ROUTING & V-GROOVE QUALITY ASSURANCE DESIGN SERVICE MICROSECTION : NONE SAMPLE PLAN MIL - P - 55110D F

CERTIFICATION : NONE MIL - P - 55110D IPC CLASS 1 2 3

mm

Artwork Design Rules

Drill Design Rules Certifications QUALITY RELEASE REPORT OTHER __________________

Morris Productions offer our customers a PCB design service.

Morris Productions produce PCB'S to 24 layers . Unless there is a need to specify certain dielectric separations(eg.

- finished hole size should be specified rather than drill size ELEC. TEST : NONE REQUIRED PER ORDER REFER ______

Controlled To aid our Pre-production Engineers the designer should ensure that the following is adhered to : - Morris Productions has a committment to Quality. As a means of continuous improvement in our

- via hole size typically fall in the range of 0.3 to 0.7mm( via holes < 0.2mm should be avoided to ensure hole integrity) The service provides a number of facilities dependent on your requirements : -

Impedence), the thickness of core material or quantity of prepreg used between each successive conductive layer is

- if via hole size is < 0.2mm then land size should equal 0.5mm

manufacturing and technical capibilities Morris has gained the following certifications: ** Schematic Capture and laser plots MANUFACTURER'S LOGO : FOIL LEGEND OTHER __________

best left to the manufacturer. Most boards should have a minimum of 0.09mm separation between conductive layers. - separate file per artwork and layer sequence is specified..

- aspect ratio should not exceed 1:8 ie. finished hole size divided by board thickness (Refer IPC - 2221, IPC - 2222) ** Bill of Materials

The layup should be kept balanced i.e. the distribution of layers, copper thickness, and layer separations shou ld be - Gerber files, aperture file & drill file formats eg.2,4 inch format or 3,3 metric Quality Management Systems - AS/NZS ISO9001: 1994 (Certified by LRQA) MANUFACTURER'S CERTIFICATION : AS/NZS ISO 9001 NONE

- preferred format for drill files is ASCII 2,4 inch leading zero's but will accept other formats (please specify) ** Board Layout (From Schematic or Netlist)

symmetrical to prevent warping, however some designs require large copper areas on the outside layers. Ensure these areas - Gerber 274X (Embedded Apertures) preferred Scope - "Design and Manufacture of single, double sided and multilayer printed circuit boards".

- separate drill fil es for Plated and Non-plated holes - Photoplots PACKAGING AND HANDLING : PER ORDER REFER ______

are cross- hatched to reduce the possibility of blistering or warping in the soldering process. Listed below are Morris' most - Gerber files are registered to one another ( has the same offset). Certification Number : 926131

- number of different drill sizes should be minimised, but there are no limits on the number of drill changes - Checkplots

common multilayer layups using materials generally kept in stock. Other layups are available on request. - files should be viewed from the "component side " (primary side).

- Photoplot Files

- use design standards (such as IPC-2221, IPC-2222) and adequate allowances for processing. Laboratory (N.A.T.A certified)

These layups are for 1.6mm nominal thickness. For thicker or thinner PCB's, please contact our Sales Engineer or PCB Designer. Tenting (NPTH) - Drill Files

- each corner should have corner delineation marks.

Foil lamination uses a 0.05mm maximum thickness resin backed foil. - NPTH less than 6.5mm dia should have pads removed to allow tenting of the hole during processing.

Registration Number : 365 - Shape Based Routing HOLE DATA

It is common for PCB's to have a mix of Plated(PTH) and Non-plated holes(NPTH). To aid in the positional tolerance ** Manufacturing Drawings

- ensure that legend markings are 0.25mm (0.010") from lands and/or holes. Underwriters Laboratories

of PTH to NPTH, drilling can be done in one operation. It is then necessary to tent (cover) the NPTH with photo- ** Arrangement of Production SYMBOL

- if you require gold edge connectors add a plating bar 5mm away from the fingers and extend the length UL approval to MP194V-0 and MP-2

4 LAYER BOARD 8 LAYER BOARD sensitive film during processing. There must be sufficient surface area around the NPTH for the tent to hold so it is ** Design advice

of the connector. The thickness of the bar and connections to the fingers to be 0.5mm (0.020"). SIZE (FIN)

important to have no land around the hole nor should there be any copper pattern within 2 x the diameter of the hole. ** Up to date information on current trends in manufacturing and specifications

Foil Lamination (Preferred) Conventional Build Foil Lamination (Preferred) Conventional Build - to aid in routing, at least two(2) diagonally opposite NPTH holes should be provided at the board

Maximum hole size for tenti ng NPTH is 4.5mm. If these design rules are not met, 2nd drilling will be necessary . ** Extract gerber files from Protel generated PCB files and amend

* SHEETS CORE Cu (um) * SHEETS CORE Cu (um)

* SHEETS CORE Cu (um) SHEETS CORE Cu (um) extremities, the diameter of which should be between 2.5 - 6.0mm. Preferred size is 3.175mm (1/8"). Conformance Testing TYPE

PREPREG THK(mm) PER SIDE PREPREG THK(mm) PER SIDE

PREPREG THK(mm) PER SIDE PREPREG THK(mm) PER SIDE

Rout Design Rules QUANTITY

Foil 18/00

Foil 18/00 .25 18/00 Morris can provide customers with a range of Quality Assurance Certifications dependent on need.

2xA .25 35/35

2xB 2xA - the smallest rout bit diameter should be equal to or greater than the board thickness Certificates of Conformance can be attained to customer's own specification, IPC-6011, IPC -6012 HOLE SIZE NPTH HOLES PTH HOLES

.18 35/35 Note - phototools and their condition are vital to PCB manufacture. For example, the maximum layer to

2xA - rout bit tolerance(+/-0.1mm) should be taken into consideration when determining finished board size or Military Standards such as MIL-P-55110D. Microsectioning is the means by which Quality TOLERANCE + / - 0.05

layer misregistration of pattern features should not exceed 0.003" (0.075mm) at full size. In this way Morris Assurance can be tested but requires the destruction of a good board. Rather than destroying a good 0 TO 0.8 + / - 0.03

.71 35/35 .50 35/35 especially panelised boards

G Pre-production engineers can perform a comprehensive design rule check, step and repeat artwork to a ON HOLE + / - 0.05 G

2xB 2xA

1xB

.18 35/35 2xA

.25 35/35

standard format size, add venting (to aid in the flow of prepreg for multilayer boards, and to give mechanical

- if panelised then breakout point positioning and number must taken into consideration to aid in the mechanical

strength of the PCB. Typically the distance between breakouts is 50 - 80 mm. Refer to drawing below.

board, Test Coupons (refer IPC-2221, IPC -2222 Section 12.4.3.1) positioned alongside and/or

between pairs ( or as a "popout" within the board outline) will exhibit all the basic qualities of the

SOLDER PASTE STENCILS SIZE

0.81 TO 1.6

1.61 TO 5.0

+ / - 0.05

+ / - 0.08 + / - 0.10

Foil 18/00 .25 18/00 strength and stability) and most importantly, ensure the accuracy and stability of the diazo's production board. Tests and Inspections that can be carried out are as follows:-

- preferred router bit size is 2.0mm

(phototools) used in manufacture.

1xB .25 35/35 VISUAL PHYSICAL ELECTRICAL MICROSECTION Head Office :

Morris stocks a full range of both drill and router bits. Quality, service and fast turn around have made us leaders in the Australian Market

.18 35/35 Stock drill bit sizes range from : 0.35 to 3.20mm in 0.05 increments and 3.30 to 6.5mm in 0.10 increments. General Appearance Plating adhesion Continuity Plating Thickness for Chemically milled Solder Paste and Glue Stencils. These are available with a shim

2xA

Cleanliness Conductor Peel Strength Current Carrying Capacity Plating Quality

2-12 Harp Street, P.O. Box 196, Campsie,

Stock rout bit sizes range from : 0.8, 1.0, 1.2, 1.5, 1.6, 1.8, 2.0, 2.4, 3.0 & 3.175mm.Other sizes available on request. thickness range of 0.010", .008" , .006", .005" and .004".

2xA

Foil 18/00

.25 35/35

BARE BOARD TESTING Holes greater than 6.50mm are either stitched drilled, hand machined or routed, and preferably nonplated.

Plating Appearance

Etched line widths

Solderability

Thermal Stress (solder

Co-Planer and layer to

layer insulation. Dielectric

Interconnection

hole/inner layer

.

It is strongly recommended that you contact your printed circuit board assembler to

N.S.W., Australia 2194

Telephone: (02) 97896200

and Spacings. float test) withstanding voltage test Hole Quality determine the desired aperture size opening, fiducial marks, mounting position and the

6 LAYER BOARD 10 LAYER BOARD Morris Productions employs advanced, flexible and fully integrated Bare Board testing systems.

Typical routing breakout methods 5.0 +/- 0.2mm to IPC -6011, IPC-6012 Annular Ring (internal) thickness of the stencil. Morris prefers to work from Gerber Files and aperture table. Facsimile: (02) 97872529

class 3 (1 KV DC for 30 Layer Registration The ap erture size should be the same as for the lands used on your track artwork. There

Foil Lamination (Preferred) Conventional Build Foil Lamination (Preferred) Conventional Build Modem: (02) 97188671

Viking Digital Bed of Nails Testing Probot - Flying Probe Testing 2.4mm +/- 0.1mm TYP ROUTER DIA 2.4mm +/- 0.1mm Copper thickness (inner) is no need to reduce the size of the lands on the solder paste artwork, as Morris must

* SHEETS

PREPREG

CORE

THK(mm)

Cu (um)

PER SIDE

* SHEETS CORE Cu (um) * SHEETS

PREPREG

CORE

THK(mm)

Cu (um)

PER SIDE

SHEETS

PREPREG

CORE

THK(mm)

Cu (um)

PER SIDE

2.5 +/- 0.2mm TYP ROUTER DIA Pre-production Integrity Checks Dielectric Separations reduce your artwork to allow for etch factors. If the assembler requires a smaller Email : Sales@morris.com.au

PREPREG THK(mm) PER SIDE

Board Integrity following

Capabilities Capabilities aperture opening than the land size used, then Morris will allow for this as well. For Web Site: www.morris.com.au

0.5 +/- 0.1mm

Foil 18/00 Foil 18/00

.15 18/00 We recommend customers approve production tooling generated from their own information. Gerber files,

2xA 2xA .15 35/35 - testing to known good board or netlist - netlist testing

2xA

- analyse and create netlist for PCB's upto 24 layers - analyse and create netlist for PCB's upto 24 layers This may reveal errors in design, manufacturability or potential design improvements. For large it is preferred if you create your pads as flashes ( rather than as shape fills).

.15 35/35 2xA - high complexity designs - high complexity designs production runs, we also recommend that pre-production samples be obtained. Both Morris and our

.38 35/35 .25 35/35 This publication is copyright and all rights are reserved. Other than as permitted under the Copyright Act, no part may be reproduced by any

- Fine Pitch SMD to 0.5mm pitch and below - Fine Pitch SMD to 0.25mm pitch and below customers are then assured of the boards suitability for manufacture, and can see at first hand the Morris can provide you with the stencil only, the stencil mounted in your frame, or, the

1xB .15 35/35 4 NPTH HOLES process without the written permission of Morris Productions Pty Limited. The information contained in this publication is based upon IPC

1xB 4xA - high volume work - low volume work

2.0 +/- 0.2mm 0.8 +/- 0.1mm quality expected. If either option is not requested the customer must accept responsibility for errors stencil mounted in a frame by us. The frame will be custom designed to your

.15 35/35 0.6 to 0.8 DIA standards. The information is advisory only and its use or adaption is entirely voluntary. Morris Productions Pty Limited and its servants or

2xA - Fault Finding capability for Netlist Testing - high speed discharge test due to incorrect data supplied.

EQUALLY SPACED agents shall not be responsible for continued currency of the information or fo r any errors, omissions or inaccuracies in this publication

.38 35/35 .25

35/35 - Simultaneous Double sided Testing - Ball Grid Array Handling & Storage of PCB's

1xB STANDARD BRIDGE METHOD INTERNAL BREAKOUT METHOD arising from negligence or otherwise howsoever or for any consequense arising therefrom.

2xA .15 35/35 - Fault Finding capability for Netlist Testing

2xA

0

Foil 18/00 .15 18/00 .15 35/35 Aging and storage of your PCB's impacts upon solderability and flatness therefore the following

2xA V - Groove Detail MORRIS CIRCUITS &

ORDER DRAWN EXAM APPD DATE

* Overall thickness of the board can be altered by varying the quantity & type of prepreg.

Test Parameters Test Parameters Board V -Groove general guidelines should be applied:

MORRIS GRAPHICS

CHKD AMENDMENTS ISS MORRIS PRODUCTIONS

1xB - clean, tidy environment,

H Morris standard prepreg types are as follows: .15 35/35 Thickness Width

CERTIFIED BY : - PL PL JF GE 25.5.92 1 H

Test Method - 12 volt digital Test Method - Analogue - avoid allowing the board to come into contact with silicones (hand creams, etc), MORRIS CIRCUITS

0.8mm = 0.4 +/-0.1

1.6mm = 0.5 +/-0.1

2.4mm = 0.6 +/-0.1

A = 1 piece of 1080 prepreg with an approximate finished thickness of 0.07mm .15 35/35 Board Dimensions 0.8mm = 0.16mm 0.5 mm Min

2xA sulphur -containing material which may degrade solderability.

B = 1 piece of 7628 prepreg with an approximate finished thickness of 0.175mm.

Voltage Test - 12 volt Voltage Test - 0.5 to 500 VDC (programmable) * Min Size = 80 x 80mm 1.6mm = 0.50mm GR PL REDRAWN JF GE 6.3.95 2

2xA Resistance Test - breakpoint 70 kOhms Resistance Tests - 1Ohm to 500MOhms 2.4mm = 0.80mm 45 +/- 5 - avoid abrasive materials,moisture and handling edge contacts. PRINTED CIRCUIT BOARD

DO NOT SCALE Note - approximate finished thickness can vary with the amount of copper area. .15 35/35 Max Size = 400 x 400mm Track PL REDRAWN

Foil 18/00 - boards should be left in sealed and dessicated bags GR JF GE 10.7.98 3

DIMENSIONS IN (programmable) * - not applicable to panelised boards

MILLIMETRES The fibreglass core thickness does not include the foil (copper thickness). The required Card Size (Maximum)

or Pad

- should be stoved flat for a min. 6 hrs at 115 - 120 deg C in an air circulating oven immediately DESIGNERS GUIDE

board thickness should be stated as the finished size (after plating and addition of solder Single Sided Test Card Size (Maximum) prior to assembly to remove moisture wicking (ingress of moisture absorbed by epoxy glass at

Tolerances

resist), however, in critical areas, such as edge connectors, the thickness tolerance may be - 488 mm x 406mm board edge). Failure to perform this function and applying rapid heating (eg. hand soldering) can

V-Groove depth = +/- 0.1mm BLOCK DIAGRAM

more stringent . Overall board thickness tolerances in general, (including double and single Double Sided Simultaneous Test - 863 x 609mm result in localised separation of the inner layer surfaces(delamination)..

V-Groove to V-Groove = +/- 0.2mm

boards) should be in as per IPC - D - 300G, and typically + / - 0.2mm. - 325mm x 244mm (Top) 3.5 mm Min 0.1 max deviation SHEET 1

V-Groove to Board Edge = +/- 0.2mm

Specific inspection, acceptability, packaging and handling methods are detailed in IPC-2221, AS/NZS ISO 9001 : 1994 MD1001 OF 1

1 2 3 4 5 6 7 8 9 10 11 12

PCBPRO7A C Copyright Morris Productions Pty. Limited 1998 A1

You might also like

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- BGA InspectionDocument115 pagesBGA InspectionezonelineNo ratings yet

- PCB Book v5.0.4 e Demo WDocument56 pagesPCB Book v5.0.4 e Demo Whlgc63100% (1)

- Repair Manual Rev 0 6Document28 pagesRepair Manual Rev 0 6Bob WettermannNo ratings yet

- Nevada Reply BriefDocument36 pagesNevada Reply BriefBasseemNo ratings yet

- PCB Layout TipsDocument34 pagesPCB Layout TipsMallappa Patil100% (2)

- Stencil Aperture and Area Ratio Table For Optimum PrintingDocument4 pagesStencil Aperture and Area Ratio Table For Optimum PrintingsmtdrkdNo ratings yet

- Stencil Aperture and Area Ratio Table For Optimum PrintingDocument4 pagesStencil Aperture and Area Ratio Table For Optimum PrintingsmtdrkdNo ratings yet

- What You Always Wanted To Know About Wave Soldering But Were Afraid To AskDocument43 pagesWhat You Always Wanted To Know About Wave Soldering But Were Afraid To Asksmtdrkd100% (4)

- What You Always Wanted To Know About Wave Soldering But Were Afraid To AskDocument43 pagesWhat You Always Wanted To Know About Wave Soldering But Were Afraid To Asksmtdrkd100% (4)

- PCB DFM DFT GuidelinesDocument42 pagesPCB DFM DFT Guidelinesduzhenhuan50% (2)

- Printed Circuit Board (PCB) Design ChecklistDocument4 pagesPrinted Circuit Board (PCB) Design ChecklistQuickteck100% (1)

- IPC Industry MappingDocument47 pagesIPC Industry MappingleandrokamargoNo ratings yet

- Area Ratio For Different SMT PartsDocument1 pageArea Ratio For Different SMT PartssmtdrkdNo ratings yet

- PCB Designing Fundamentals GuideDocument42 pagesPCB Designing Fundamentals GuideChintaan PatelNo ratings yet

- Accounts - User Guide: Release R15.000Document207 pagesAccounts - User Guide: Release R15.000lolitaferozNo ratings yet

- SMT and Through Hole DFM GuidelinesDocument30 pagesSMT and Through Hole DFM Guidelinessmtdrkd100% (5)

- Introduction To Surface Mount Technology 24 April 2002 Helen HolderDocument38 pagesIntroduction To Surface Mount Technology 24 April 2002 Helen HolderbercincNo ratings yet

- Real Estate Developer Resume SampleDocument1 pageReal Estate Developer Resume Sampleresume7.com100% (2)

- Surface Mount Technology, SMTDocument38 pagesSurface Mount Technology, SMTwattafillingNo ratings yet

- NFPA 99 Risk AssessmentDocument5 pagesNFPA 99 Risk Assessmenttom ohnemusNo ratings yet

- PSISA Free Practice Exams TestsDocument2 pagesPSISA Free Practice Exams TestsGoodmanBeguel50% (2)

- Pcbdesignguide 1Document67 pagesPcbdesignguide 1Beta-Ömega CircuitsNo ratings yet

- Simple Project Management Template On ExcelDocument2 pagesSimple Project Management Template On Excelsmtdrkd100% (1)

- Description of PULSE EDM CircuitDocument1 pageDescription of PULSE EDM CircuitMahmut Aydin0% (1)

- Carnatic Music Composition DatabaseDocument142 pagesCarnatic Music Composition Databasesmtdrkd86% (14)

- Carnatic Music Composition DatabaseDocument142 pagesCarnatic Music Composition Databasesmtdrkd86% (14)

- Paste Troubleshoot PDFDocument52 pagesPaste Troubleshoot PDFbehzad0% (1)

- Wonderful PCB (HK) Limited - UpdateDocument28 pagesWonderful PCB (HK) Limited - UpdateFercho QuezadaNo ratings yet

- Lead Free Reliability Study by BoeingDocument23 pagesLead Free Reliability Study by Boeingsmtdrkd100% (1)

- PCB Surface Finishes Presentation by MultekDocument54 pagesPCB Surface Finishes Presentation by Multeksmtdrkd100% (1)

- PCB Surface Finishes Presentation by MultekDocument54 pagesPCB Surface Finishes Presentation by Multeksmtdrkd100% (1)

- Pick-And-Place Machine: SMT (Surface Mount Technology) Component Placement SystemsDocument5 pagesPick-And-Place Machine: SMT (Surface Mount Technology) Component Placement SystemsMadhusudanan AshokNo ratings yet

- BGA Construction and ReworkDocument24 pagesBGA Construction and ReworkyogeshleostarNo ratings yet

- Surface Mount TechnologyDocument138 pagesSurface Mount Technologynksharma44100% (2)

- Altium Rigid Flex GuidebookDocument40 pagesAltium Rigid Flex GuidebookGustavo Dallaqua100% (3)

- Estrogen Dominance-The Silent Epidemic by DR Michael LamDocument39 pagesEstrogen Dominance-The Silent Epidemic by DR Michael Lamsmtdrkd75% (4)

- Best Practices FactoryDocument207 pagesBest Practices FactorysmtdrkdNo ratings yet

- Design For Manufacturing Course - by DFRDocument257 pagesDesign For Manufacturing Course - by DFRhlgc63100% (2)

- Manufacturable Lead Free SMT ProcessDocument4 pagesManufacturable Lead Free SMT Processsmtdrkd100% (1)

- SMT Troubleshooting GuideDocument20 pagesSMT Troubleshooting Guidedbuschel100% (2)

- Nasa - Workmanship Standard For Surface Mount Technology - Nasa Technical Standard - Nasa-Std-8739.2 - ManualDocument84 pagesNasa - Workmanship Standard For Surface Mount Technology - Nasa Technical Standard - Nasa-Std-8739.2 - Manualhbpr9999100% (1)

- Jedec Industry Standard Classifications and Peak Solder TemperatureDocument8 pagesJedec Industry Standard Classifications and Peak Solder TemperatureGuillermo VillarNo ratings yet

- PCB Concepts GuideDocument296 pagesPCB Concepts GuideAli Ahmad100% (1)

- OrCAD Capture and Layout Tutorial ExcellentDocument55 pagesOrCAD Capture and Layout Tutorial Excellentbalajiiece100% (1)

- 4412A Amendment 1 (3 07)Document7 pages4412A Amendment 1 (3 07)Aani MazharNo ratings yet

- PCB Design Presentation: Jakia AfruzDocument33 pagesPCB Design Presentation: Jakia AfruzParth MangukiyaNo ratings yet

- Ipc Oem Stds A4 English 1111 OnlineDocument4 pagesIpc Oem Stds A4 English 1111 OnlineAnonymous nMavFhZNo ratings yet

- Generic Project Plan Template On ExcelDocument3 pagesGeneric Project Plan Template On Excelsmtdrkd100% (36)

- PCB Designing and Manufacturing ProcessDocument26 pagesPCB Designing and Manufacturing ProcessBaikunth PandeyNo ratings yet

- PCB GuideDocument35 pagesPCB Guidesmtdrkd100% (12)

- Design Rules Selective SolderingDocument20 pagesDesign Rules Selective SolderingemirNo ratings yet

- E-Book Proof of Design DFM and Concurrent EngineeringDocument425 pagesE-Book Proof of Design DFM and Concurrent Engineeringsmtdrkd100% (7)

- E-Book Proof of Design DFM and Concurrent EngineeringDocument425 pagesE-Book Proof of Design DFM and Concurrent Engineeringsmtdrkd100% (7)

- Lecture 1 Basics of PCBDocument32 pagesLecture 1 Basics of PCBjaltitiNo ratings yet

- SMT Manufacturability Design GuidelinesDocument25 pagesSMT Manufacturability Design GuidelinespcbppcNo ratings yet

- PCB ProcessDocument10 pagesPCB ProcessChetan AwasthiNo ratings yet

- PCB LabDocument26 pagesPCB LabsunilsmNo ratings yet

- Printed Circuit Board: CharacteristicsDocument23 pagesPrinted Circuit Board: CharacteristicsSai Gautam100% (1)

- SMT Stencil DesignDocument34 pagesSMT Stencil DesignVinceDeSilva100% (2)

- PCB Assembly Guidelines From Southbay CircuitsDocument43 pagesPCB Assembly Guidelines From Southbay Circuitssmtdrkd100% (3)

- Intro To SMTDocument38 pagesIntro To SMTShelly NandalNo ratings yet

- SMT Process EngineeringDocument4 pagesSMT Process Engineeringshaktiss24_147930359No ratings yet

- Wave Soldering: Wave Soldering Is A Bulk Soldering Process Used in TheDocument5 pagesWave Soldering: Wave Soldering Is A Bulk Soldering Process Used in TheMadhusudanan Ashok0% (1)

- Siplace S: Best-In-Class For Flexible High SpeedDocument4 pagesSiplace S: Best-In-Class For Flexible High Speedamrina23No ratings yet

- DLA-X3-xx - XC380-xx - X7-xx - XC780-xx - X9-xx - XC980-xx (SCH)Document36 pagesDLA-X3-xx - XC380-xx - X7-xx - XC780-xx - X9-xx - XC980-xx (SCH)ixigen2115No ratings yet

- Assembly of Flexible Circuits With Lead - Free Solder AlloyDocument16 pagesAssembly of Flexible Circuits With Lead - Free Solder AlloyBorad AlpeshNo ratings yet

- 4660d1090015632-pcb Fab Wall ChartDocument3 pages4660d1090015632-pcb Fab Wall ChartMcael Timanta GintingNo ratings yet

- 1 Level 01 Floor Plan Sector 2: Bus Infrastructure Study, Design and Construction Supervision ServicesDocument1 page1 Level 01 Floor Plan Sector 2: Bus Infrastructure Study, Design and Construction Supervision ServicesAbid AyubNo ratings yet

- Top View Section X-X: Design DataDocument1 pageTop View Section X-X: Design DatakishoreNo ratings yet

- 0-8936-2 Golden Triangle Polymers Company LLCDocument1 page0-8936-2 Golden Triangle Polymers Company LLCLester MuscaNo ratings yet

- 1 Level 00 Floor Plan Sector 8: Bus Infrastructure Study, Design and Construction Supervision ServicesDocument1 page1 Level 00 Floor Plan Sector 8: Bus Infrastructure Study, Design and Construction Supervision ServicesAbid AyubNo ratings yet

- 001 - CC - Tierra N - SDP - 200629 - Final - 1593395965 PDFDocument1 page001 - CC - Tierra N - SDP - 200629 - Final - 1593395965 PDFPatrick manuelNo ratings yet

- 5802002614_WIRING_GENSET_WITHOUT_BOX_TIER_4B_B_13_NO_20_Document1 page5802002614_WIRING_GENSET_WITHOUT_BOX_TIER_4B_B_13_NO_20_cesar saavedra saavedraNo ratings yet

- The Story of Spanish MossDocument10 pagesThe Story of Spanish MosssmtdrkdNo ratings yet

- The Story of Spanish MossDocument10 pagesThe Story of Spanish MosssmtdrkdNo ratings yet

- Stencil Design - 10 % Reduction RuleDocument1 pageStencil Design - 10 % Reduction RulesmtdrkdNo ratings yet

- Ph.d. Thesis On Modeling Imc Growth and SolderingDocument180 pagesPh.d. Thesis On Modeling Imc Growth and Solderingsmtdrkd100% (6)

- Failure Analysis Tools, Techniques and Process FlowDocument1 pageFailure Analysis Tools, Techniques and Process Flowsmtdrkd100% (1)

- Why Creation of Universe Is Not An AccidentDocument48 pagesWhy Creation of Universe Is Not An AccidentsmtdrkdNo ratings yet

- Fantastic TripDocument68 pagesFantastic Tripabiramikdevi100% (17)

- Greeting Card Calendar 2009Document1 pageGreeting Card Calendar 2009smtdrkdNo ratings yet

- SMCWP 001Document37 pagesSMCWP 001Wandyy GonçalvesNo ratings yet

- Land Pattern Parameters For Different Bga GeometriesDocument4 pagesLand Pattern Parameters For Different Bga Geometriessmtdrkd100% (1)

- Myths and Beliefs in Modern Electronic Assembly and Soldering TechniquesDocument8 pagesMyths and Beliefs in Modern Electronic Assembly and Soldering TechniquessmtdrkdNo ratings yet

- PB Free Soldering Paper From MassechusettsDocument52 pagesPB Free Soldering Paper From Massechusettssmtdrkd100% (1)

- 24 Amazing Pictures of MoneyDocument15 pages24 Amazing Pictures of Moneysmtdrkd100% (1)

- Impact of PB Free On Test and Inspection by TeradyneDocument3 pagesImpact of PB Free On Test and Inspection by TeradynesmtdrkdNo ratings yet

- Andhragaaru RecipesDocument38 pagesAndhragaaru Recipessmtdrkd100% (5)

- Engineering Ethics in Practice ShorterDocument79 pagesEngineering Ethics in Practice ShorterPrashanta NaikNo ratings yet

- FINAL Session 3 Specific GuidelinesDocument54 pagesFINAL Session 3 Specific GuidelinesBovelyn Autida-masingNo ratings yet

- تقرير سبيس فريم PDFDocument11 pagesتقرير سبيس فريم PDFAli AkeelNo ratings yet

- Memo in Motion For ContemptDocument118 pagesMemo in Motion For ContemptMark SternNo ratings yet

- TSM V5.3 Technical GuideDocument456 pagesTSM V5.3 Technical GuideparifsNo ratings yet

- Shenzhen Gooky Technology Co.,Ltd.: Laptop Price ListDocument1 pageShenzhen Gooky Technology Co.,Ltd.: Laptop Price ListOusman KabaNo ratings yet

- Recent Advances in Mobile Robotics - TopalovDocument464 pagesRecent Advances in Mobile Robotics - TopalovBruno MacedoNo ratings yet

- CSCE 3110 Data Structures and Algorithms NotesDocument19 pagesCSCE 3110 Data Structures and Algorithms NotesAbdul SattarNo ratings yet

- Practice Questions & Answers: Made With by SawzeeyyDocument141 pagesPractice Questions & Answers: Made With by SawzeeyyPhake CodedNo ratings yet

- Product Models Comparison: Fortigate 1100E Fortigate 1800FDocument1 pageProduct Models Comparison: Fortigate 1100E Fortigate 1800FAbdullah AmerNo ratings yet

- COA (Odoo Egypt)Document8 pagesCOA (Odoo Egypt)menams2010No ratings yet

- SQL DBA Mod 1 IntroDocument27 pagesSQL DBA Mod 1 IntroDivyaNo ratings yet

- Tutorial 2 EOPDocument3 pagesTutorial 2 EOPammarNo ratings yet

- Nº SSR-1 NS-R-3 Draf R1 Site Evaluation For Nuclear Installations FRDocument33 pagesNº SSR-1 NS-R-3 Draf R1 Site Evaluation For Nuclear Installations FRdaniel addeNo ratings yet

- GeM Bidding 2568310Document9 pagesGeM Bidding 2568310SICURO INDIANo ratings yet

- Basic Concept of Process Validation in Solid Dosage Form (Tablet) : A ReviewDocument10 pagesBasic Concept of Process Validation in Solid Dosage Form (Tablet) : A Reviewqc jawaNo ratings yet

- CP Exit Srategy Plan TemplateDocument4 pagesCP Exit Srategy Plan TemplateKristia Stephanie BejeranoNo ratings yet

- CIGB B164 Erosion InterneDocument163 pagesCIGB B164 Erosion InterneJonathan ColeNo ratings yet

- 60 Years of Cannes Lions Infographics: The 50sDocument9 pages60 Years of Cannes Lions Infographics: The 50sSapientNitroNo ratings yet

- ENY1-03-0203-M UserDocument101 pagesENY1-03-0203-M UserAnil KumarNo ratings yet

- Csit 101 Assignment1Document3 pagesCsit 101 Assignment1api-266677293No ratings yet

- This Study Resource Was: ExercisesDocument1 pageThis Study Resource Was: Exercisesىوسوكي صانتوسNo ratings yet

- Ge Dir ReportsDocument1 pageGe Dir Reportsselvam chidambaramNo ratings yet

- Ts 391 IltDocument5 pagesTs 391 IltFunnypoumNo ratings yet

- TVS Sport User Manual BS6Document69 pagesTVS Sport User Manual BS6tonemetoneNo ratings yet