Professional Documents

Culture Documents

Wellplan Opticem Manual

Uploaded by

tibismtxOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wellplan Opticem Manual

Uploaded by

tibismtxCopyright:

Available Formats

Chapter 10

Cementing-OptiCem Analysis

Overview

Cementing can be used to optimize cementing operations and minimize

the possibility of costly cementing errors.

In this section of the course, you will become familiar with all aspects

of using the Cementing-OptiCem module, including:

Available analysis modes

Defining operating parameters

Defining cement fluids

Calculating centralizer placement

Defining the cement job

Defining analysis parameters

Analyzing results

Landmark

WELLPLAN

455

Chapter 10: Cementing-OptiCem Analysis

Workflow

Activate Cementing by clicking the

button.

Open the Case using the Well Explorer.

Define the wellbore. (Case > Hole Section Editor)

Define the workstring. Use the same dialog to define all

workstrings (drillstrings, casings, liners, etc.) (Case > String)

Enter wellpath data. (Case > Wellpath > Editor)

Define the fluids used. You can define as many fluids as you want.

(Case > Fluid Editor)

Define the pore pressure gradients. (Case > Pore Pressure)

Define the fracture gradients. (Case > Fracture Gradient)

Define the geothermal gradient. (Case > Geothermal Gradient)

Define the cement circulating system. (Case > Cement

Circulating System)

Specify centralizer information. (Parameter > Centralizer

Placement)

Specify cement job data including volumes, fluids used, back

pressure and whether or not this is a foam job. (Parameter > Job

Data)

If this is a foam job, specify the foam job data. (Parameter > Foam

Data)

Specify wellbore temperatures, depths of interest and whether or

not returns are taken at the sea floor. (Parameter > Additional

Data)

Specify additional pressure that may be required to seat the plug

and the eccentricity (standoff) to be used in the calculations.

(Parameter > Analysis Data)

Analyze the results.

456

WELLPLAN

Landmark

Chapter 10: Cementing-OptiCem Analysis

Introducing Cementing Analysis

What is Cementing?

The Cementing module can be used to predict what occurs in the well

during cementing operations. Cementing can be used to evaluate the

effects of various conditions on the simulated cementing operation. You

can use Cementing to calculate:

Safe pump rates

Surface pressure

Downhole pressures

Nitrogen concentration

Foam volume

Downhole rheology

Temperature thinning of fluids

Starting Cementing Analysis

There are two ways to start the Cementing Module.

Landmark

Select Cementing from the Modules menu.

Click the Cementing button.

WELLPLAN

457

Chapter 10: Cementing-OptiCem Analysis

Choose Cementing-OptiCem Analysis from Modules menu, or by

clicking the Cementing-OptiCem Module button.

Select desired Cementing-OptiCem Analysis mode

from submenu, or from Mode drop-down list.

458

WELLPLAN

Landmark

Chapter 10: Cementing-OptiCem Analysis

Defining the Case Data

Refer to Entering Case Data on page 162 for instructions on entering

data into the Case menu options. Case data specific to cementing will be

covered in this chapter.

Specify the Volume Excess %

The Case > Hole Section Editor is used to define the wellbore as the

current workstring sees it. You can also use the Case > Hole Section

Editor dialog to specify the extra percentage of annular cement volume

required for an enlarged wellbore. This volume will be based on the

Effective Hole Diameter field. For open hole sections, the Effective

Hole Diameter is used to represent the actual size of the hole. If you

specify the Effective Hole Diameter, the Volume Excess % is calculated

based on Effective Hole Diameter. Similarly, if you specify the Volume

Excess %, the Effective Hole Diameter will be calculated.

For example, if you are drilling an 8.5 inch hole that is 10% overgauge,

enter 8.5 for Hole Diameter and 10 for Volume Excess %. The extra

volume will be calculated. Do not use the Volume Excess % field to

raise the cement top. Use Parameter > Job Data to raise the cement

top.

Note: Specifying Volume Excess...

Be careful that you dont enlarge the wellbore in the Hole Diameter field and then

again using the Volume Excess % field.

Enter the Volume Excess % and the Effective Hole

Diameter is calculated.

Landmark

WELLPLAN

459

Chapter 10: Cementing-OptiCem Analysis

Defining the Cement Job

Defining the Cement Job Fluids

Defining Spacers

Use Case > Fluid Editor to define cement spacers by specifying the

basic characteristics of the fluid.

You dont need to activate the

spacer. Spacer use is specified

using Parameter > Job Data.

460

WELLPLAN

To define a spacer, select Spacer

from the Type drop-down list.

Landmark

Chapter 10: Cementing-OptiCem Analysis

Defining Cement Slurries

Use Case > Fluid Editor to define cement slurries by specifying the

basic characteristics of the fluid.

You dont need to activate the

cement. Cement use is specified

using Parameter > Job Data.

To define a cement, check the

Cement box.

Specify the Standoff or Calculate the Centralizer Placement

Use the Parameter > Centralizer Placement dialog to calculate the

spacing between multiple centralizers and/or the variable standoff

between the casing and wellbore. Alternately, you can enter a manual

standoff value that applies to the entire well. Before using this dialog,

you should use the Centralizer catalog to specify all centralizers if you

plan on using centralizers not already in the catalog. Access the

Centralizer catalog using the Well Explorer. Refer to Working With

Catalogs on page 110 for more information.

Centralizer placement calculations are typically performed before

wellbore simulation. These calculations can also be performed

Landmark

WELLPLAN

461

Chapter 10: Cementing-OptiCem Analysis

independently using the Centralizer Placement mode. Refer to the

online help for more details concerning this dialog.

The Wellbore Fluid defaults from

the active fluid indicated on the

Case > Fluid Editor.

You can specify a

measured depth and

standoff above the top of

the centralized interval.

Enter the maximum and

minimum distance that can be

used when calculating centralizer

spacing.

Defining the Cement Job

Use the Parameter > Job Data dialog to define crucial job information

such as tracer fluid types, rate, volume, and placement for each fluid in

the cementing job. Refer to the online help for more information about

this dialog.

462

WELLPLAN

Landmark

Chapter 10: Cementing-OptiCem Analysis

Note: Mud

Erodibility

Mud Erodibility as used in cementing and WELLPLANs Cementing-OptiCem

refers to the ability of the wellbore fluid to be eroded away by a different fluid

passing by it in the annulus of the well. The Mud Erodibility option is available

only to Halliburton users. If you need this calculation performed, please contact

your local Halliburton Zonal Isolation Group.

Defining Temperatures, Depths of Interest and Offshore Returns

Information

The Parameter > Additional Data dialog is used to enter data for the

Wellbore Simulator mode in the Cementing module (OptiCem). This

dialog allows you to enter and manage offshore, zone depth, and

temperature information.

Landmark

WELLPLAN

463

Chapter 10: Cementing-OptiCem Analysis

Do not check this box because

we are not taking returns at

the sea floor.

Reservoir Zone and Fracture

Zone are the same in this

case.

Temperature can be defined in several ways.

If the Bottom Hole Circulating Temperature is

known, you can specify it.

You can calculate the API BHCT based on mud

outlet temperature and BHST.

You can specify a profile based on depth.

You can import a temperature profile from

WellCat.

Define the temperature

profile to be used or import

a temperature profile.

Specifying Additional Analysis Parameters

The Parameter > Analysis Data dialog provides supplemental control

of several values before performing the Wellbore Simulator

calculations.

If Eccentricity is turned off, then the wellbore simulator

performs its calculations assuming 100% standoff. If you want

the eccentricity calculations at a particular standoff, select the

Entered Standoff option on the Centralizer Placement Dialog.

Otherwise, it will run with an actual standoff profile.

To ensure proper plug

seating, additional pressure

may be applied to the

casing immediately after

the plug is landed.

Erodibility is only available to Halliburton personnel. If

you need this option, contact your local Zonal Isolation

Group.

Check Calculate Automatically for automatic

calculation of step size. Usually you will want to check

this box.

464

WELLPLAN

Landmark

Chapter 10: Cementing-OptiCem Analysis

Analyzing Results

Results for the Cementing analysis are presented in plots, tables and a

report. All results are available using the View menu.

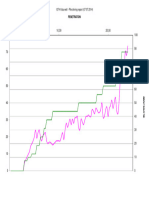

What is the Circulating Pressure Throughout the Cement Job?

Use the View > Plot > Circ Pres and Den - Frac Zone plot to

determine the circulating pressure fluid volume pumped at the fracture

zone specified on Parameter > Additional Data.

The circulating pressure during the displacement

stage exceeds the fracture pressure.

These lines indicate when the

various stages occur.

Fracture

pressure

The formation breakdown pressure at this depth is indicated by one of

the curves on this plot. If the Automatic Rate Adjustment option was

selected (on Parameter > Job Data), then a second curve indicates the

safety factor. If the circulating pressure exceeds the fracture zone

pressure, the fluid can fracture the formation and result in lost

circulation from the wellbore.

If the circulating pressure exceeds the fracture zone pressure, reduce the

pump rates or turn on the Automatic Rate Adjustment option. If

reducing the pump rates does not completely solve the problem,

decrease the density of one or more fluids (with foamed fluids, or by

Landmark

WELLPLAN

465

Chapter 10: Cementing-OptiCem Analysis

increasing the nitrogen concentration), or decrease the volume of the

heaviest stages.

If you prefer, you can view this information as ECD versus volume

pumped.

Click the right mouse button anywhere on the plot to

open the plot selection box. Highlight the plot you

want displayed and click the left mouse button.

Observe the circulating

density as a function of

volume pumped.

466

WELLPLAN

Landmark

Chapter 10: Cementing-OptiCem Analysis

Is There Free Fall?

The View > Plot > Comparison of Rates In and Out plot displays the

total annular return rate and corresponding pump rate versus the fluid

pumped into the well. This data may be correlated with information in

the Volume and Rates Calculations table in the Cementing Report.

(View > Report)

Differences between the two rate curves indicates free fall without

nitrogen injection. If free fall occurs and the well goes on vacuum, the

rate out will initially exceed, and then fall below, the planned pumped

rate.

Notice that cement

free fall does occur

because rate out

initially exceeds the

rate in, but then

falls below the

pump rate in.

Notice the rate out initially

exceeds the rate in.

After initial high, rate out then

falls below rate in.

What is the Surface Pressure?

Use the View > Plot > Calculated Wellhead/Surface Pressure plot to

view the pressure changes as varying density fluids are pumped at

varying rates through the well. If the Surface Iron option was selected

(on the Case > Cement Circulating System dialog) this graph is titled

Calculated Surface Pressure. This data may be correlated with

information in the Volume and Rates Calculations table on the

cementing report.

The calculated wellhead pressure is lower than pump pressure because

of the hydrostatic head and friction in the lines between the pump and

cementing head.

Landmark

WELLPLAN

467

Chapter 10: Cementing-OptiCem Analysis

A horizontal graph line along the x-axis indicates free fall. Often, as the

majority of the cement moves from the casing to the annulus, the slope

of this curve beings to increase. Usually, it continues to increase as the

heavier cementing fluids are forced up the annular gap.

Free Fall indicated when pressure is constant.

Automatically Adjusting the Flowrate

Because the circulating pressure exceeds the fracture pressure using the

rates specified on the Parameter > Job Data dialog, you can allow the

468

WELLPLAN

Landmark

Chapter 10: Cementing-OptiCem Analysis

software to automatically adjust the pump rates. Click the Automatic

Rate Adjustment box on the Parameter > Job Data dialog.

Click Automatic Rate Adjustment to have the rate

adjusted to avoid exceeding the fracture pressure.

If you allow automatic rate adjustment, you must specify a

Safety Factor.

These rates will be adjusted.

Landmark

WELLPLAN

469

Chapter 10: Cementing-OptiCem Analysis

Using automatic rate

adjustment, the

maximum circulating

pressure is less than

the fracture pressure.

Notice the safe

pressure (based on

safety factor) is

indicated on the plot.

What Are the Adjusted Rates?

The View > Plot > Comparison of Rates In and Out plot displays the

total annular return rate and corresponding pump rate versus the fluid

pumped into the well. This data may be correlated with information in

470

WELLPLAN

Landmark

Chapter 10: Cementing-OptiCem Analysis

the Volume and Rates Calculations table in the Cementing Report.

(View > Report)

You can view the adjusted rates

using this plot. Rates have been

decreased to reduce the circulating

pressure as a result of checking the

Automatic Rate Adjustment box on

the Parameter > Job Data dialog.

Refer to the Job Data dialog to view

the rates specified prior to the rate

adjustment.

Using Foamed Cement

Using foamed cement is another means to reduce the circulating

pressures.

The Parameter > Foam Data dialog is available only if you check the

Use Foam Schedule box on the Parameter > Job Data dialog while

using the Wellbore Simulator analysis mode. This dialog lets you

Landmark

WELLPLAN

471

Chapter 10: Cementing-OptiCem Analysis

describe calculation methods and stages when simulating foam in a

cement job.

Select Constant or Staged Gas Flow to keep the

nitrogen constant for a segment.The foam

density will follow the pressure gradient, and

thus decreases from the bottom to the top of the

segment. The longer the segment, the greater

the density variance.

Type concentrations for

Surfactant, Stabilizer.

Select this option if the

nitrogen ratio will be adjusted

to offset pressure changes

and thus hold density more

constant. Use this option

only with automated nitrogen

pumping equipment.

Click the stage you

want to define using

the bottom portion of

this dialog.

This information is read-only.

It is defaulted from the Job

Data dialog.

The Gas Rate Stage

Number is used to tell

how many different gas

rates are to be used

under the Stage Gas

option and where each

of the rates are used.

In order to foam a segment,

you must check the Foam

box.

Enter Foam Density and Quality (the volume

percentage of gas in the foam) is calculated.

or

Enter Quality (the volume percentage of gas

in the foam) and Foam Density is calculated.

Using the Foam Schedule

Use View > Foam Schedule dialog to calculate and view the Foam

Pumping Schedule. This dialog lists liquid volume and gas rates of the

fluids left in the annulus at the end of the simulation. The calculated

hydrostatic pressure for the frac zone and reservoir zones are displayed

at the bottom of the table. The frac zone and reservoir zones are

specified using the Parameter > Additional Data dialog.

472

WELLPLAN

Landmark

Chapter 10: Cementing-OptiCem Analysis

Notice that some of these fluids may not be foamed. Some fluids may

not appear in this report if they were pumped completely out of the

annulus.

If an error occurs during the calculation process, an error dialog appears

displaying a description of the error. When you finish reading it, click

OK. The Error dialog and the Calculate dialog close so you can begin

working on solving the source of the error.

These are design depths (as specified on the Job Data dialog) and may not be the actual

depths. Review the View > Final Density and Hydrostatic plot for accurate cement

locations.

Click Calculate to ensure

you are looking at accurate

results.

Adjusted Liquid Volume and Adjusted Gas Rate

sliders adjust the cement tops or placement.

These are the calculated hydrostatic pressure

gradients for the depths of interest specified on

the Additional Data dialog.

Final Gas Rate and Adjusted

Final Gas Rate do not apply

when you are using constant or

stage gas flow.

To check results of the foam schedule calculation:

1) Check the Fluid Animations Schematic to see whether the

desired top of cement was achieved, check the Final Positions of

Stages table in the reports, or downhole density plot.

2) Check the circulation Pressure and Density-Fracture Zone graph

and the Circulation Pressure and Density-Reservoir Zone graphs

to see if the density is acceptable.

3) Adjust, rerun, and recheck the job as follows:

Landmark

WELLPLAN

473

Chapter 10: Cementing-OptiCem Analysis

Checking Results

If TOC is....

and ECD is....

then do this:

Low

Light

1. Increase density or decrease

quality.

2. Rerun the Foam Schedule.

3. Use the slider bar (top of

Foam Data dialog) to increase

the Adjusted Liquid Volume.

4. Click the Calculate button.

5. Check the Fluid Animation

Schematic and the Circ Pres

and Den plots.

Low

Acceptable

1. Use the slider bar (top of

Foam Data dialog) to increase

the Adjusted Liquid Volume.

2. Repeat steps 4 and 5 above.

Low

Heavy

1. Use the slider bar (top of

Foam Data dialog) to increase

the Adjusted Gas Rate.

2. Repeat steps 4 and 5 above.

Low

Light

1. Increase the density or

decrease quality.

2. Rerun the Foam Schedule.

3. Repeat steps 4 and 5 above.

Acceptable

Acceptable

Do nothing.

Acceptable

Heavy

1. Decrease density or increase

quality.

2. Rerun the Foam Schedule.

3. Repeat steps 4 and 5 above.

Acceptable

Heavy

1. Decrease density or increase

quality.

2. Rerun the Foam Simulator.

3. Repeat steps 4 and 5 above.

474

WELLPLAN

Landmark

Chapter 10: Cementing-OptiCem Analysis

Checking Results (Continued)

High**

Light

1. Manually decrease N2 in the

Adjusted Start Gas Rate

column.

2. If calculation method is

constant density, also

manually decrease N2 in the

Adj. Final Gas Rate column.

3. Repeat steps 4 and 5 above.

High**

Acceptable

1. Manually decrease liquid

volume in the Adj. Liq. Vol.

column.*

2. Repeat steps 4 and 5 above.

High**

Heavy

1. Decrease density or increase

quality.

2. Rerun the Foam Simulator.

3. Repeat steps 4 and 5 above.

* To estimate the percentage by which to change the volume, use the

percentage by which the simulated foamed length differs from the

desired length. (If the foamed length 1,500 feet and the desired length is

2,000 feet, increase by 33%.)

** This scenario is unlikely because the Fluid Placement calculations

should prevent excessive top of cement.

Repeat these steps until you are satisfied with the results. Round the

slurry and gas rate quantities before running the Wellbore Simulator.

Landmark

WELLPLAN

475

You might also like

- Drilling AnalysisDocument36 pagesDrilling Analysisgplese0No ratings yet

- HE Hydra Jar Manual 6-80Document31 pagesHE Hydra Jar Manual 6-80Yuri KostNo ratings yet

- Cem CadeDocument2 pagesCem CadeAndres AmayaNo ratings yet

- Wiper Trip Opertion ProcedureDocument3 pagesWiper Trip Opertion ProcedureAlexander KlmNo ratings yet

- MWD Troubleshooting GuideDocument13 pagesMWD Troubleshooting GuidefedericoNo ratings yet

- Effects of Thickening Time On The Application of Cement Slurry For High PressureDocument10 pagesEffects of Thickening Time On The Application of Cement Slurry For High PressureAlexander DeckerNo ratings yet

- Formulas y Calculos de PerforacionDocument22 pagesFormulas y Calculos de Perforacionjairaso2950No ratings yet

- CTD Liner Running & CementingDocument6 pagesCTD Liner Running & CementingAdel Ahmed AlkhaligyNo ratings yet

- User Manual: CSD - Completion String DesignDocument220 pagesUser Manual: CSD - Completion String DesignIdress AhmedNo ratings yet

- SPE-105068-MS-How Good Is The Torque-Drag ModelDocument9 pagesSPE-105068-MS-How Good Is The Torque-Drag ModelHassaanAhmedNo ratings yet

- Pressure Rating For SSII Float EquipmentDocument2 pagesPressure Rating For SSII Float EquipmentMahmoud Ahmed Ali AbdelrazikNo ratings yet

- A New Cutting Transport Equation for Low Density Drilling FluidDocument14 pagesA New Cutting Transport Equation for Low Density Drilling FluidSteven Chandra100% (1)

- ENM210 Cementing Operations Lecture 2 - Stage Cementing - 1 StageDocument8 pagesENM210 Cementing Operations Lecture 2 - Stage Cementing - 1 StageHamid Reza BabaeiNo ratings yet

- Expandable Liner Hangers reduce pressure drop in Ecuador wellsDocument22 pagesExpandable Liner Hangers reduce pressure drop in Ecuador wellsHosam Ali100% (1)

- SPE-143623-MS-Torque and Drag Software Model Comparison Impact On Application and Calibration of Field DataDocument11 pagesSPE-143623-MS-Torque and Drag Software Model Comparison Impact On Application and Calibration of Field DataHassaanAhmedNo ratings yet

- CSG Design by AmrDocument19 pagesCSG Design by AmrSudish BhatNo ratings yet

- Guía para Tapones de CementoDocument15 pagesGuía para Tapones de CementoJunnior López PintadoNo ratings yet

- Directional Drilling MathDocument18 pagesDirectional Drilling MathSazzadul HossainNo ratings yet

- Multilateral Well Technology OverviewDocument18 pagesMultilateral Well Technology OverviewKaouachi Ahmed LouayNo ratings yet

- Openwells® Performance Reviews Version 5000.1.12.0: Release Notes and User GuideDocument19 pagesOpenwells® Performance Reviews Version 5000.1.12.0: Release Notes and User GuideWALDO DAVID SILVA SANCHEZNo ratings yet

- Well Plan PDFDocument280 pagesWell Plan PDFTanaNo ratings yet

- Drill Bit Selection Criteria in DrillingDocument7 pagesDrill Bit Selection Criteria in DrillingEyanya MtilaNo ratings yet

- Leak Off TestDocument2 pagesLeak Off TestLuisBlandónNo ratings yet

- Bit Hydraulics Optimization for Maximum Drilling PerformanceDocument23 pagesBit Hydraulics Optimization for Maximum Drilling PerformanceShakerMahmood100% (1)

- Superior Packer Setting ProceduereDocument10 pagesSuperior Packer Setting ProcedueretarangtusharNo ratings yet

- OKW 61 (De Comp.) TimelineDocument6 pagesOKW 61 (De Comp.) TimelineVibhu GuptaNo ratings yet

- Evaluasi Kinerja Pemboran Aerated pada Sumur GeothermalDocument10 pagesEvaluasi Kinerja Pemboran Aerated pada Sumur GeothermalDen YogaNo ratings yet

- Stuck Pipe Differential StickingDocument13 pagesStuck Pipe Differential StickingDaniyarNo ratings yet

- 04 - 4 - Spacer Design ConsiderationsDocument23 pages04 - 4 - Spacer Design Considerationsolmetaj1011No ratings yet

- WBPDocument426 pagesWBPahmed_497959294No ratings yet

- Cementing: Habiburrohman, B.Eng, M.EngDocument52 pagesCementing: Habiburrohman, B.Eng, M.EngNamwangala Rashid NatinduNo ratings yet

- Drilling Jar Manual PDFDocument33 pagesDrilling Jar Manual PDFsmithyry2014No ratings yet

- RSS Drilling PDFDocument4 pagesRSS Drilling PDFSakthivel MurthyNo ratings yet

- 3 USIT InterpretationDocument18 pages3 USIT InterpretationAnkit Sharma100% (1)

- Section 01 - IntroductionDocument12 pagesSection 01 - IntroductionRafael GarateNo ratings yet

- WellPlan Exercie Book PDFDocument115 pagesWellPlan Exercie Book PDFMJ arab100% (1)

- Lost CirculationDocument24 pagesLost CirculationAboZaidNo ratings yet

- Drilling Application: Name of Company: Well Name & Number: DateDocument1 pageDrilling Application: Name of Company: Well Name & Number: DatescrbdgharaviNo ratings yet

- 03 - Differential StickingDocument0 pages03 - Differential StickingSam AbdulNo ratings yet

- Special ProblemsDocument42 pagesSpecial Problemsdriller22No ratings yet

- RTTS Circulating ValveDocument2 pagesRTTS Circulating ValveHamid Reza BabaeiNo ratings yet

- RT Bit Specific Energy SPE#00092194Document10 pagesRT Bit Specific Energy SPE#00092194Asahel NuñezNo ratings yet

- Introduction to Underbalanced Drilling Technologies (M2Document57 pagesIntroduction to Underbalanced Drilling Technologies (M2bon1ngNo ratings yet

- Bit Dull GradeDocument99 pagesBit Dull GradeGNo ratings yet

- Hollow Sphere Dual Gradient Drilling SystemDocument72 pagesHollow Sphere Dual Gradient Drilling SystemJosue FishNo ratings yet

- MWD BosDocument15 pagesMWD Bosarifin ubaidNo ratings yet

- Measuring Density of Mud SamplesDocument11 pagesMeasuring Density of Mud SamplesCistus AbenNo ratings yet

- Drilling 1 AutoRecoveredDocument52 pagesDrilling 1 AutoRecoveredKhaled AdelNo ratings yet

- Evolution of Directional Drilling Since 1900Document7 pagesEvolution of Directional Drilling Since 1900Rafique ArisarNo ratings yet

- Dynamic Model For Stiff String Torque and DragDocument16 pagesDynamic Model For Stiff String Torque and DragMOHAMED ALi IBRAHIM HASSANNo ratings yet

- Squeeze Remedial CementingDocument4 pagesSqueeze Remedial CementingMahesh MahajanNo ratings yet

- Rhino PDFDocument16 pagesRhino PDFAbraham RojasNo ratings yet

- Cementing: IntroductionDocument4 pagesCementing: IntroductionanuNo ratings yet

- Well Engineering Guidlines For Hole CleaningDocument13 pagesWell Engineering Guidlines For Hole CleaningWilliam100% (1)

- IRP 22 - Underbalanced Drilling & Managed Pressure Drilling Operations Using Jointed Pipe - Oct 17 - 2018 PDFDocument158 pagesIRP 22 - Underbalanced Drilling & Managed Pressure Drilling Operations Using Jointed Pipe - Oct 17 - 2018 PDFJohnny BreuerNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- 20019A Bulletin CRTiPinchPointDocument2 pages20019A Bulletin CRTiPinchPointtibismtxNo ratings yet

- 1374 Vata Well - Pile Driving Chart (07 07 2014)Document1 page1374 Vata Well - Pile Driving Chart (07 07 2014)tibismtxNo ratings yet

- 1368 Vata Well - Pile Driving Chart (06 07 2014)Document1 page1368 Vata Well - Pile Driving Chart (06 07 2014)tibismtxNo ratings yet

- OWS - 5.5in 17ppf Torque V PinDocument1 pageOWS - 5.5in 17ppf Torque V PintibismtxNo ratings yet

- 9-5/8" 36# BTC Torque Ring SpecsDocument1 page9-5/8" 36# BTC Torque Ring SpecstibismtxNo ratings yet

- SCT1020HDocument17 pagesSCT1020HAndrez Zarate MerinoNo ratings yet

- WI13-VolantCRTiRunning Procedure - Pipe HandlerDocument4 pagesWI13-VolantCRTiRunning Procedure - Pipe HandlertibismtxNo ratings yet

- 17556A TechnicalFeedback FormDocument1 page17556A TechnicalFeedback FormtibismtxNo ratings yet

- Hoist and Torque CapacitiesDocument1 pageHoist and Torque CapacitiestibismtxNo ratings yet

- 20007P-CRTi2-8.63 Specification SummaryDocument5 pages20007P-CRTi2-8.63 Specification Summarytibismtx100% (1)

- 36# BTC J55 Torque V PinDocument1 page36# BTC J55 Torque V PintibismtxNo ratings yet

- 47ppf Torques V Pin Nose - Premiere Torque Rings (2020 - 05 - 20 01 - 58 - 29 UTC)Document4 pages47ppf Torques V Pin Nose - Premiere Torque Rings (2020 - 05 - 20 01 - 58 - 29 UTC)tibismtxNo ratings yet

- Pred-O-Tor 7 000 Casing X 8 300 OD Single Valve L80 29ppf Tenaris BlueDocument1 pagePred-O-Tor 7 000 Casing X 8 300 OD Single Valve L80 29ppf Tenaris BluetibismtxNo ratings yet

- Helix 13625-15500-0.870-SPDocument1 pageHelix 13625-15500-0.870-SPtibismtxNo ratings yet

- Premiere patented torque ring technical specificationsDocument1 pagePremiere patented torque ring technical specificationstibismtxNo ratings yet

- Journal of Petroleum Technology - August 2012Document107 pagesJournal of Petroleum Technology - August 2012tibismtxNo ratings yet

- Helix 09625-10587-0.433-SP30Document1 pageHelix 09625-10587-0.433-SP30tibismtxNo ratings yet

- CRTi Saver Sub ProposalDocument1 pageCRTi Saver Sub ProposaltibismtxNo ratings yet

- Drill Pipe JapanDocument28 pagesDrill Pipe JapaniancathNo ratings yet

- Reaper 7 000 Casing X 8 300 Od l80 38ppf Tenaris BlueDocument1 pageReaper 7 000 Casing X 8 300 Od l80 38ppf Tenaris BluetibismtxNo ratings yet

- Articulation Compensator Tool (ACT)Document1 pageArticulation Compensator Tool (ACT)tibismtxNo ratings yet

- CATALOG Weatherford CentralizerDocument20 pagesCATALOG Weatherford CentralizertibismtxNo ratings yet

- Erland - Petter - Indbjo Centralizer OptiCEM DrillingDocument84 pagesErland - Petter - Indbjo Centralizer OptiCEM DrillingManuel ChNo ratings yet

- Hydraulics Report for Romania WellDocument1 pageHydraulics Report for Romania WelltibismtxNo ratings yet

- Logan Fishing Jar (Z Type) ManualDocument38 pagesLogan Fishing Jar (Z Type) ManualtibismtxNo ratings yet

- Bit HydraulicsDocument11 pagesBit HydraulicstibismtxNo ratings yet

- OWS - A18 A2 - WBCU Swab Surge Tripping ScheduleDocument10 pagesOWS - A18 A2 - WBCU Swab Surge Tripping ScheduletibismtxNo ratings yet

- Roller Cone Catalog 2012Document32 pagesRoller Cone Catalog 2012tibismtxNo ratings yet

- Drilling With Casing PDFDocument69 pagesDrilling With Casing PDFtibismtxNo ratings yet

- NetworkingDocument1 pageNetworkingSherly YuvitaNo ratings yet

- Understanding The Self Metacognitive Reading Report 1Document2 pagesUnderstanding The Self Metacognitive Reading Report 1Ako Lang toNo ratings yet

- Book 2 - Test 1Document2 pagesBook 2 - Test 1Đức LongNo ratings yet

- CH 22 Solutions ManualDocument22 pagesCH 22 Solutions Manuallmbrn0415No ratings yet

- PExam 2020Document126 pagesPExam 2020Omama MaazNo ratings yet

- VANSINA, Jan. Art History in AfricaDocument250 pagesVANSINA, Jan. Art History in AfricaRaphaelTim100% (1)

- Case Study On Maruti 800Document4 pagesCase Study On Maruti 800Nizar MesaniNo ratings yet

- Absolute Value - WikipediaDocument10 pagesAbsolute Value - WikipediaVenu GopalNo ratings yet

- Pembahasan Soal UN Bahasa Inggris SMP 2012 (Paket Soal C29) PDFDocument15 pagesPembahasan Soal UN Bahasa Inggris SMP 2012 (Paket Soal C29) PDFArdi Ansyah YusufNo ratings yet

- 360 PathwaysDocument4 pages360 PathwaysAlberto StrusbergNo ratings yet

- ECE 4400 Performance Analysis Local Computer Networks HomeworkDocument2 pagesECE 4400 Performance Analysis Local Computer Networks HomeworkNguyen Phi HungNo ratings yet

- BS EN 1677-5-2001 - Inc.Document3 pagesBS EN 1677-5-2001 - Inc.Ameer Sadimin SGNo ratings yet

- Calibration GuideDocument8 pagesCalibration Guideallwin.c4512iNo ratings yet

- Footprints 080311 For All Basic IcsDocument18 pagesFootprints 080311 For All Basic IcsAmit PujarNo ratings yet

- Tipolo WH Gantt ChartDocument15 pagesTipolo WH Gantt ChartMayeterisk RNo ratings yet

- Digital Burner Controller: Tbc2800 SeriesDocument4 pagesDigital Burner Controller: Tbc2800 SeriesSUDIP MONDALNo ratings yet

- About Topsøe - and What We DoDocument20 pagesAbout Topsøe - and What We DoAbhishek ChaudharyNo ratings yet

- Interview Question SalesforceDocument10 pagesInterview Question SalesforcesomNo ratings yet

- SpringDocument4 pagesSpringarun123123No ratings yet

- TR-Pharmacy Services NC IIIDocument135 pagesTR-Pharmacy Services NC IIIAljon Fortaleza Balanag100% (2)

- Penilaian Risiko Kerja Menggunakan Metode Hirarc Di Pt. Sinar Laut Indah Natar Lampung SelatanDocument7 pagesPenilaian Risiko Kerja Menggunakan Metode Hirarc Di Pt. Sinar Laut Indah Natar Lampung SelatanIndun InsiyahNo ratings yet

- Roxas Avenue, Isabela City, Basilan Province AY: 2018-2019: Claret College of IsabelaDocument2 pagesRoxas Avenue, Isabela City, Basilan Province AY: 2018-2019: Claret College of IsabelaJennilyn omnosNo ratings yet

- Fancy YarnsDocument7 pagesFancy Yarnsiriarn100% (1)

- Unit 01 Family Life Lesson 1 Getting Started - 2Document39 pagesUnit 01 Family Life Lesson 1 Getting Started - 2Minh Đức NghiêmNo ratings yet

- Agitators: Robert L. Bates, President Chemineer, IncDocument24 pagesAgitators: Robert L. Bates, President Chemineer, InctenshinomiyukiNo ratings yet

- 4900 DatasheetDocument2 pages4900 DatasheetMakam Raghu100% (1)

- Escalado / PLC - 1 (CPU 1214C AC/DC/Rly) / Program BlocksDocument2 pagesEscalado / PLC - 1 (CPU 1214C AC/DC/Rly) / Program BlocksSegundo Angel Vasquez HuamanNo ratings yet

- Predictive Analytics: QM901.1x Prof U Dinesh Kumar, IIMBDocument36 pagesPredictive Analytics: QM901.1x Prof U Dinesh Kumar, IIMBVenkata Nelluri PmpNo ratings yet

- What Are Your Observations or Generalizations On How Text/ and or Images Are Presented?Document2 pagesWhat Are Your Observations or Generalizations On How Text/ and or Images Are Presented?Darlene PanisaNo ratings yet

- ES1 Work Panel DatasheetDocument3 pagesES1 Work Panel DatasheetGerardo Alberto Navarro LopezNo ratings yet