Professional Documents

Culture Documents

22 Content Compost Fertilizer Production From Sugar Press Mud

Uploaded by

rajupat123Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

22 Content Compost Fertilizer Production From Sugar Press Mud

Uploaded by

rajupat123Copyright:

Available Formats

Compost Fertilizer production from Sugar Press Mud (SPM)

Suneela Sardar, Suhaib Umer Ilyas+, Shahid Raza Malik and Kashif Javaid

Department of Chemical Engineering, NFC-Institute of Engineering & Fertilizer Research, Faisalabad

38090, Pakistan

Abstract: Compost produced from biological wastes does not contain any chemicals unfavorable to

living soil. This organic fertilizer is also one of them which contain phosphate, nitrogen solubilizing

bacteria and decomposing fungi, which is co-friendly and protect the plants from various soil borne

diseases. Results of trial based production of Compost at large scale is discussed. Different ratios of sugar

press mud (SPM), Molasses and Rock Phosphate was mixed, piled and transformed in to Compost

products in about 14-21 days. Single super phosphate (SSP) & Sulfur mud was also added and

investigated to increase the Phosphoric components of Compost to produce a good quality of biofertilizer.

In the end, granulation of this bio fertilizer was also investigated at different temperatures using Rotary

dryers to produce grains for the ease of farmers.

Keywords: Biological Waste, Nitrogen solubilizing bacteria, Sugar press mud (SPM), Soil borne disease,

Granulation

1. Introduction

Since 19th century, sugarcane is grown in

different countries for sugar production primarily.

Due to energy crises, scientists and researchers have

realized the value of sugarcane, its by products and

co-products. Sugarcane is processed to sugar and

biomass. This biomass contains many components

like lignin, fiber, pith and pentosans, which has

plenty of applications in biochemical & microbial

fields. [1] In this research paper, the main focus is to

use one of the by-product i.e. Sugar press mud

(SPM), which is converted in to compost fertilizer.

Production of composed fertilizer from lingocellulosic residues of by-products of sugar industries

is found to be worthy for maintaining health of plant

and soil properties and protects the plant from

various soil borne diseases. In this research paper, an

experimental large scale composting of SPM on trial

basis is discussed.

In many areas SPM is directly transported to

the fields from sugar mills as an organic

enhancement to fields. Due to this practice, cane

sugar yield has been increased causing decrease in

demand of inorganic fertilizers. [2] Being a flexible

crop, sugarcane is a rich source of:

(a) Fiber containing cellulose material

(b) Food containing sucrose, fructose, syrups

and jaggery

(c) Fodder made from green leaves and top of

cane, molasses, bagass, sugar press mud

(d) Fuel from residue/waste of sugar industry

(e) Chemicals like alcohol, bagasse & molasses

There are three main by-products of sugar industry,

which has great economic value:

(a) Sugar press mud (SPM)

(b) Bagasse

(c) Molasses

1.1 Availability in Pakistan:

In Pakistan there are almost 81 sugar mills

of crushing capacity of 6.1 Million tons. Sugarcane is

planted on approximately 1.1 M Hectors producing

5.5 Million tones sugar with an average yield of 51

tones per Hector. In which almost 82-84 % cane is

utilized in sugar industries. Sugar yield in Pakistan is

approximately 4 tones per hector. According to an

estimate Pakistan sugar industry is producing about

1.2-1.8 million tones of SPM every year.

2. Literature survey

For healthier crops and vegetables, organic

fertilizers that have negligible amounts of chemicals

are gaining more attention than chemical fertilizers.

They are preferable because they provide organic

nutrients to plant and enhance the yield. [3][4]

Compost fertilizer improves the microbial properties

of soil and raises the enzymes profile. [5] Sugar press

mud can be composted through degradation of

biological enzymes to improve plant growth and

crops productivity [6]. Organic wastes from sugar

industries like SPM are enriched with Nitrogen and

Phosphorous, which are the main part of nutrients of

Corresponding author. Tel.: +92-333-6556811; fax: +92-41-9220360

E-mail address: suhaibui@yahoo.com

crop [7]. To enhance the yield and growth of wheat,

application of N fixing bacteria, fungi, K solubilizing

bacteria and some microorganisms were reported by

Zadi & Khan [10]. SPM contains 50-70% moisture,

which is very favorable for earthworms as they

breathe through their skin [8]. Organic matter and

available K, Ca, Mg, P contents are also increased by

the addition of organic fertilizer. [9]. Application of

compost fertilizer consisting of many kinds of

microorganisms & Azotobacter were reported by

Gharib et al during his research on enhancing the

total amount of essential oil in sweet marjoram[11].

Akbari et al reported the application of Azospirillum

sp., which is a bacterial specie producing auxin that

abruptly enhanced the wheat root system [12].

3. Compost Fertilizer:

3.1 Sugar press Mud:

Sugar press mud (SPM) is also termed as

press mud cake or filter cake. During the processing

of sugarcane, cane juice contains a large number of

impurities which are in the form of precipitates and

these impurities are separated using filtration process.

Both types of filtration processes i.e. batch type filter

presses or rotary vacuum filtration process or,

produces cake. SPM produced during extraction of

sugar as an impurity has multiplex uses like as a

fertilizer, animal feed and industrial use as a building

lime after calcinations process.

Composition of SPM varies with different industries

by the following factors:

(a) Classification methods

(b) Variety of cane

(c) Locality

(d) Mill efficiency

(e) Soil type

(f) Nutrients available

This SPM is produced at a rate of 7-9% of

total weight of sugar cane in Carbonation industries

and 3-5 % in sulfitation industries. The composition

of SPM used to produce biofertilizer is listed in Table

1.

Sr.

Nutrients

%

1

Moisture

50-65

2

Fiber

20-30

3

Crude wax

7-15

4

Sugar

5-12

5

Crude protein

5-10

6

Nitrogen

2-2.5

Silicon, Iron, Manganese, Calcium, MgO &

P2O5 is also detected in some appreciable amount in

SPM. Compost fertilizer is always evaluated by the

percentage of organic matters in the final product.

Organic matter contains all types of fiber, wax, crude

proteins sugar, and all other carbon containing

components available in the final product.

3.2 Molasses:

During production of sugar, the by-product is

Molasses. It is a viscous liquid which is separated

from masecuite. An average of 23 Liter of Molasses

is produced per ton of sugar cane. In Pakistan around

2.5 million metric tons (MMT) of molasses is

produced which has multiplex uses like production of

alco-chemical & ethanol, commercial purposes such

as alcohols and automobile fuel.

The composition of molasses has

considerable variation depending on the same factors

as discuses above in the SPM compositions. The

composition of molasses used to produce biofertilizer

is listed in Table 2.

Sr.

1

2

3

4

5

6

7

%

30-35

10-25

23-23.5

16-16.5

4.8-5

2-3

1-2

Table 2: Percentage of nutrients present in Molasses

3.3 Digestion process:

In case of aerobic digestion like composting,

the microorganisms present in the pile get free

oxygen from the air or its surrounding. Aerobic

process results in CO2 and water. If the biodegradable

starting material contains nitrogen, phosphorous and

sulfur then the end product of aerobic process may

also include their oxidized forms. Pile releases

energy due to the oxidization of CO2 and water in

aerobic digestion. Aerobic digestion contains those

microorganisms (fungi etc) which enhance the

composting process than anaerobic bacteria. Stable

products are formed by the aerobic digestion due to

reduction in mass and volume. Straws in the SPM

are also digested and converted into powder

form after 14-21 days piling process.

Table 1: Percentage of nutrients present in sugar press mud

Nutrients

Sucrose

Glucose & Fructose

Moisture

Ash

Calcium and Potassium

Non-sugar compounds

Other mineral contents

Corresponding author. Tel.: +92-333-6556811; fax: +92-41-9220360

E-mail address: suhaibui@yahoo.com

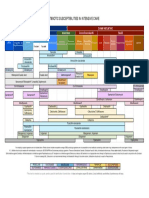

SPM

SSP + Sulfur Mud

Molasses

Piling + Mixing

Granulation Unit

Storage

Recycle

Screening Unit

Rock Phosphate

Packaging Unit

Distribution Unit

Figure 1: Block diagram of process description of Compost

fertilizer Production

4. Process Description:

Production of compost fertilizer is very

simple process as described in block diagram in

figure 1. These experiments and production are done

in Lyallpur Chemical and Fertilizer (Pvt) Ltd,

Jaranvala. Sugar press mud (SPM) and Molasses are

obtained directly from nearby sugar mills i.e.

Hussain Sugar Mill and Shaker Ganj Sugar Mill,

Jhang. SPM obtained from both industries have

different content of organic matter. It is the main raw

material and it contains 40-50% of organic matter.

4.1 Raw Materials Description:

For the production of bio-fertilizer raw

materials used are Sugar Press Mud (SPM), Local

Rock phosphate, Molasses, Single Super Phosphate

(SSP) & some amount of sulfur mud. The complete

specifications are given in Table 3.

Raw Material

Sugar Press Mud

Local

Rock

Phosphate

Molasses

SSP

Sulfur Mud

Fraction

0.878

0.095

Percentage %

87.8

9.5

0.005

0.02

0.002

0.5

2.0

0.2

Table 3: Raw material specifications in terms of fractions

& percentages

Local Rock Phosphate of -200 mesh (80%)

is used in composting process. It is not taking part in

any reaction or during digestion process. Molasses is

used 0.5% of total raw material. If it is increased

from 0.5% then it will give the whitish color in the

product which shows its excess.

4.2 Testing of Raw Materials:

Following tests raw materials and products are

carried out before processing:

Maturity/stability of compost

Carbon test

Moisture test

PH test

Maturity/Stability of Compost: For stability of

compost, Solvita kit test was carried out on

laboratory scale to estimate the CO2 and NH3

contents by a colorimetric gel enclosed in a plastic

container which is fixed with paddle. Container was

marked at the filing point of material which is to be

tested for approximately 4-5 hours at room

temperature. The color of the gel was changed. This

color change was then compared with the chart

available and recorded. Seed germination tests were

also done, in which the compost fertilizer was tested

on seeds of many crops and their effect was

compared with other types of chemical fertilizers.

Carbon Test/Organic matter: Organic matter in

SPM contains carbonaceous material which is tested

Corresponding author. Tel.: +92-333-6556811; fax: +92-41-9220360

E-mail address: suhaibui@yahoo.com

through Carbon Test. Sample of SPM is heated in

the furnace up to 450oC for 30 min. Organic matter

starts burning when the temperature reaches to 250C

and completely burned at 450C. And then by

subtracting the initial weight from the final weight,

amount of organic matter is obtained as shown in

Figure 1.

Figure 2: Turner mixing the compost and watering during

piling of compost.[2]

Figure 1: Effect of temperature on orgnaic matter

Moisture Test: The sample is placed in an oven and

heated at 100-1030C for about 160 mins. Then the

moisture contents are calculated by subtracting the

final weight of sample from initial weight.

PH test:

PH test of molasses was carried out and found it 5.1

Density test:

Density test of molasses was also carried out and

found to be 11.7lb/gal.

4.3 Processing:

Composting/Digestion:

This experiment was done in open air

atmospheric conditions at a temperature of 30-35 0C.

First the SPM, local rock phosphate, SSP and sulfur

mud with the specifications given in Table 1, were

mixed thoroughly and piled of approximately 100110 ft in length above ground level, 3-4 ft in width

and 2-2.5 ft high in semicircle shape. These piles

were given time to be composited and to complete

digestion process for about 14-21 days. During

piling, the mixture was mixed, turned and watered

after every three days to maintain moisture content of

50-60 %. A turner was used for turning process to

maintain uniformity and thoroughly mixing as shown

in Figure 2.

Granulation Unit:

The compost mixture from the digestion unit

is then sent to granulation unit. Here molasses (0.5 %

of total raw material) and water are sprayed before

entering the dryer for the formation of granules. A

horizontal Rotary dryer is used to form granules at a

temperature of 240-250 0C.

+

Screening Unit:

After granulation of compost, it is sent to

screening unit. Average size of the bio-fertilizer

should be of 5mm diameter for the ease of farmer and

good quality granule. Oversize and undersize

granules are recycled again to dryer unit. This

screening unit is same as the screening process used

for SSP screening. Product of required size is sent to

Packaging unit where it is packed in the bags through

auto-filling. And then finally product is sent to

distribution unit.

Testing of final product:

After the production of bio-fertilizer it is tested; 25%

of organic matter is present in the final product and

amount of molasses present is 0.5%.

5. Results:

Bio-fertilizer as a final product is shown in fig 3.

Figure 3: Final product of compost fertilizer

Final product contains 25% organic matter.

Corresponding author. Tel.: +92-333-6556811; fax: +92-41-9220360

E-mail address: suhaibui@yahoo.com

Bio-fertilizer produced is high in phosphorous

contents due to the addition of SSP and local rock

phosphate as both contain 18.5% and 30-32% P2O5

respectively.

Granules of bio-fertilizer produced are of good

quality and spherical in shape due to the addition of

Rock phosphate. If it is not added or added in lesser

amount, granules will not stay in spherical shape and

will easily be de-shaped due to less stiffness.

If it is added in excess quantity then the granule

become so stiff; cannot be easily soluble in water.

During Piling, a significant change in moisture

contents was seen during digestion process. In order

to keep 50-60% moisture in the pile watering was

carried out.

It enhances the fertility of land and increase the yield

of crops by improving the nutrient conditions of soil.

Bio-fertilizer gives significant results when it is

mixed with inorganic fertilizer according to the

requirements of different crops.

References:

[1] R.L.YADAV and S.SOLOMON(2006). Potential of

Developing Sugarcane By-product Based Industries in

India.Indian Institute of Sugarcane Research, P.O. Dilkusha,

Rae Bareli Road, Lucknow-226 002, India Pp. 104-111.

Potential of developing Sugarcane by-products based industry in

India, R.L.Yadev and S.Solomon, Sugar Tech 8(2&3) (2006):

104-111

[2] Sugar Tech (2010) 12(1) : 15-20, Windrow composting of

sugarcane and coffee byproducts, C. Rolz R. de Len R.

Cifuentes C. Porres.

During digestion process even cane straws present in

SPM were converted in to particles after completion

of digestion process.

[3]Shu YY, Soil Sci. Plant Nutr., 51, 443-449 (2005).

Whitish color appeared in the final product due to

addition of excess amount of molasses as shown in

Figure 4.

[5]Bulluk LR, Brosius M, Evanylo GK, and Rastaino JB, Apll. Soil

Ecol.,19, 147-160 (2002).

[4]Zhu P, Ren J, Wang L, Zhang X, Yang X, and Tavish DM, J.

Plant Nutr., Soil Sci., 170, 219-233 (2007).

[6]Shivani Chaturvedi & Balraj Singh & Lata Nain, Ann

Microbiol (2010) 60:685691

[7]Narval et al. 1990; Raman et al. 1999

[8] Domnguez J and Edwards CA, Effects of stocking rate and

moisture content on the growth and maturation of Eisenia Andrei

(Oligochaeta) in pigmanure. Soil Biol Biochem 29:743746 (1997).

[9] Edmeades DC, Nutr. Cycle Agroecosyst., 66, 165-180 (2003).

[10] Zaidi A and Khan MDS, J. Plant Nutr., 28, 2079-2092 (2005).

[11] Gharib FA, Moussa LA, and Massoud ON, Int. J. Agric. Biol.,

10, 381-387 (2008).

[12] Akbari GA, Arab SM, Alikhani HA, Allandadi I, and Azanesh

MH, World J. Agric. Sci., 3, 523-529 (2007).

Figure 4: Whitish color appears in the final product due to

addition of excess amount of Molasses

Key advantages of aerobic digestion/composting as

compared to anaerobic digestion are:

Enhanced fungi activity

Low capital equipment cost and

Simple operational control

Conclusions:

Bio-fertilizer reduces the hardness of soil and makes

it more porous due to the presence of organic matter,

phosphate, sulfur and other minerals.

+

Corresponding author. Tel.: +92-333-6556811; fax: +92-41-9220360

E-mail address: suhaibui@yahoo.com

You might also like

- Compost Fertilizer Production From Sugar Press Mud (SPM)Document5 pagesCompost Fertilizer Production From Sugar Press Mud (SPM)rammeshbankarNo ratings yet

- Final PPT CADocument90 pagesFinal PPT CAFatma M. BarakatNo ratings yet

- Enzyme ProductionDocument15 pagesEnzyme ProductionAlejandra Lopez100% (1)

- Lipase Applications in Food IndustryDocument19 pagesLipase Applications in Food IndustryKomagatae Xylinus100% (1)

- Full Project Final PDFDocument84 pagesFull Project Final PDFR K SagarNo ratings yet

- Media For Industrial Fermentation (English)Document49 pagesMedia For Industrial Fermentation (English)Faiz Muttaqin100% (1)

- Biosurfactants in Food IndustryDocument8 pagesBiosurfactants in Food Industry2begeniusNo ratings yet

- Carbohydrate Metabolism in Dairy CowsDocument4 pagesCarbohydrate Metabolism in Dairy CowsEduardo Bonilha100% (2)

- Bioethanol Production From Banana Peels: June 2016Document8 pagesBioethanol Production From Banana Peels: June 2016Charlie Micah AquinoNo ratings yet

- Design and Construction of an Improved Motorized Groundnut ShellerDocument38 pagesDesign and Construction of an Improved Motorized Groundnut Shellermuhammad m butuNo ratings yet

- Peanut Processing PlantDocument19 pagesPeanut Processing PlantfaizkauNo ratings yet

- Aquatic Plant Extracts-2004!02!14Document18 pagesAquatic Plant Extracts-2004!02!14pedro41No ratings yet

- Optimization of Baker's Yeast Drying in Industrial Continuous Fluidized Bed DryerDocument6 pagesOptimization of Baker's Yeast Drying in Industrial Continuous Fluidized Bed DryerMohamadMostafaviNo ratings yet

- Performance Study of Pesticide Sprayer Using Solar EnergyDocument39 pagesPerformance Study of Pesticide Sprayer Using Solar EnergyPRAVIN KUMAR NNo ratings yet

- Soil and Water Testing Labortary of KVK, Kapurthala, (P.A.U, Ludhiana)Document12 pagesSoil and Water Testing Labortary of KVK, Kapurthala, (P.A.U, Ludhiana)Rajan Bhatt, Ph.D (Soil Science)No ratings yet

- Developing BioIsoprene as a Renewable Alternative to Natural RubberDocument3 pagesDeveloping BioIsoprene as a Renewable Alternative to Natural RubbervjguercioNo ratings yet

- Soybean Protein Fiber PDFDocument6 pagesSoybean Protein Fiber PDFYaronBabaNo ratings yet

- Importance of MushroomDocument2 pagesImportance of MushroomSalai Lh100% (1)

- COMPARISON BETWEEN TRADITIONAL AND MODERN AGRICULTUREDocument4 pagesCOMPARISON BETWEEN TRADITIONAL AND MODERN AGRICULTURENoraishah IsaNo ratings yet

- Bioresource Technology: Raveendran Sindhu, Parameswaran Binod, Ashok PandeyDocument7 pagesBioresource Technology: Raveendran Sindhu, Parameswaran Binod, Ashok PandeyMuhammad Fakhrizal Fahmi100% (1)

- Cross-Linking Starch at Various Moisture Contents by PhosphateDocument4 pagesCross-Linking Starch at Various Moisture Contents by PhosphateMateo Torres TorresNo ratings yet

- Notes On BiofertilizerDocument31 pagesNotes On BiofertilizerH Janardan PrabhuNo ratings yet

- Theses of Mr. Sulieman AlDocument214 pagesTheses of Mr. Sulieman Alsambinu1No ratings yet

- Extraction, Purification and Industrial Applications of Pectinase: A ReviewDocument6 pagesExtraction, Purification and Industrial Applications of Pectinase: A ReviewYago L100% (1)

- Comparative Studies On The Production of Glucose and High Fructose Syrup From Tuber StarchesDocument8 pagesComparative Studies On The Production of Glucose and High Fructose Syrup From Tuber StarchesDebora Pasaribu100% (1)

- Changes in Key Aroma Compounds of Criollo Cocoa Beans During Roasting 1Document8 pagesChanges in Key Aroma Compounds of Criollo Cocoa Beans During Roasting 1Moyo AntNo ratings yet

- (PDF) Bioethanol Production From Banana PeelsDocument1 page(PDF) Bioethanol Production From Banana PeelsMidyaa TariqNo ratings yet

- Biological Pretreatment of Oil Palm Empty Fruit BunchesDocument1 pageBiological Pretreatment of Oil Palm Empty Fruit BunchesIsroi.comNo ratings yet

- Corn Steep Liquor in Microbiology PDFDocument15 pagesCorn Steep Liquor in Microbiology PDFNasser KemmouNo ratings yet

- Liquid Biofertilizer Manufacturing PlantsDocument2 pagesLiquid Biofertilizer Manufacturing PlantssuryasanNo ratings yet

- Chapter 2 Material and Energy BalancesDocument15 pagesChapter 2 Material and Energy Balancesaa0809No ratings yet

- Biofuel Production-Recent Developments and ProspectsDocument606 pagesBiofuel Production-Recent Developments and ProspectsRuifei WangNo ratings yet

- Effect of Different Agro-Wastes, Casing Materials and Supplements On The Growth, Yield and Nutrition of Milky MushroomDocument11 pagesEffect of Different Agro-Wastes, Casing Materials and Supplements On The Growth, Yield and Nutrition of Milky MushroomHà BrunyNo ratings yet

- High Fructose Syrup ProductionDocument4 pagesHigh Fructose Syrup ProductionPriyank LashkariNo ratings yet

- Environmental BiotechnologyDocument10 pagesEnvironmental BiotechnologyRochelle Ann SevillaNo ratings yet

- Role of Microbes in Dairy IndustaryDocument34 pagesRole of Microbes in Dairy IndustaryShubham Dwivedi0% (1)

- Physicochemical Properties of Banana Peel Flour As Influenced by Variety and Stage of Ripeness Multivariate Statistical AnalysisDocument14 pagesPhysicochemical Properties of Banana Peel Flour As Influenced by Variety and Stage of Ripeness Multivariate Statistical AnalysisnalmondsNo ratings yet

- Antinutritional Factors in Legumes: M.Narayanan 2019508202 GPB - 512Document10 pagesAntinutritional Factors in Legumes: M.Narayanan 2019508202 GPB - 512narayananNo ratings yet

- Agricultural engineering variables affecting hydroponic grass production 1647-1666Document1 pageAgricultural engineering variables affecting hydroponic grass production 1647-1666pipestressNo ratings yet

- Msds Hydroxypropyl Starch Ether HpsDocument8 pagesMsds Hydroxypropyl Starch Ether HpsWANGYUSHENG Kima Chemical Co LtdNo ratings yet

- 40351-Article Text-142880-1-10-20190301Document12 pages40351-Article Text-142880-1-10-20190301Stella Marie Padilla AlvaradoNo ratings yet

- Bypass Fat in Dairy Ration-A ReviewDocument17 pagesBypass Fat in Dairy Ration-A ReviewKadiwala Dairy FarmNo ratings yet

- Plant Gum ReviewDocument10 pagesPlant Gum ReviewHaroon RahimNo ratings yet

- Nigerian Journal of Soil Science Vol 25 2015 PDFDocument198 pagesNigerian Journal of Soil Science Vol 25 2015 PDFMayowa Adelekun0% (1)

- Nutrient Use Efficiency Different Type of Nutrient Use Efficiency and Factor Affecting Nutrient Use EfficiencyDocument8 pagesNutrient Use Efficiency Different Type of Nutrient Use Efficiency and Factor Affecting Nutrient Use EfficiencyNARENDRA JAMRA100% (1)

- Effect of Vermicompost and Biofertilizers On Yield and Soil PDFDocument3 pagesEffect of Vermicompost and Biofertilizers On Yield and Soil PDFAgricultureASDNo ratings yet

- NMRG Soil Nutrients, Sources and Uptake PDFDocument9 pagesNMRG Soil Nutrients, Sources and Uptake PDFYosephNo ratings yet

- Bioplastic ProductionDocument2 pagesBioplastic ProductionLukmanKuntajiNo ratings yet

- Chapter 1 3 Water Hyacinth FinalDocument63 pagesChapter 1 3 Water Hyacinth FinalRyan Lorenzo Garcia PerezNo ratings yet

- Food TechnologyDocument41 pagesFood Technologydynav100% (2)

- Silk Sericin As A Biomaterial For Tissue Engineering: A ReviewDocument17 pagesSilk Sericin As A Biomaterial For Tissue Engineering: A ReviewHozefa DhilaNo ratings yet

- Handbook of Processing of JaggeryDocument34 pagesHandbook of Processing of JaggerySachinNo ratings yet

- New Syllabus ICAR JRFDocument22 pagesNew Syllabus ICAR JRFMechanical EngineeringNo ratings yet

- Latest Technology in Cereals ProductionDocument5 pagesLatest Technology in Cereals ProductionNadherah MohamadNo ratings yet

- Octenylsuccinylated Starches-Structure and FunctionDocument187 pagesOctenylsuccinylated Starches-Structure and FunctionPhạm Thanh VấnNo ratings yet

- Gluconic AcidDocument11 pagesGluconic AcidpalkybdNo ratings yet

- Urease Activity in Soybean MealDocument4 pagesUrease Activity in Soybean MealAJ QuintoNo ratings yet

- Protein Contribution of Feedstuffs for Ruminants: Application to Feed FormulationFrom EverandProtein Contribution of Feedstuffs for Ruminants: Application to Feed FormulationNo ratings yet

- Book List-2Document3 pagesBook List-2rajupat123No ratings yet

- ClimateDocument5 pagesClimaterajupat123No ratings yet

- Envi News-2018-19Document13 pagesEnvi News-2018-19rajupat123No ratings yet

- Britain Allows TweakingDocument1 pageBritain Allows Tweakingrajupat123No ratings yet

- 3 Potentially Habitable' Planets Discovered - NATIONAL - The HinduDocument1 page3 Potentially Habitable' Planets Discovered - NATIONAL - The Hindurajupat123No ratings yet

- Form 30 (See Rule 55 (2) and (3) ) Application For Intimation and Transfer of Ownership of A Motor VehicleDocument2 pagesForm 30 (See Rule 55 (2) and (3) ) Application For Intimation and Transfer of Ownership of A Motor Vehiclenarasimha raoNo ratings yet

- Drought PoliticsDocument3 pagesDrought Politicsrajupat123No ratings yet

- Cement Factories, Air Pollution and ConsequencesDocument65 pagesCement Factories, Air Pollution and Consequencesrajupat1230% (1)

- Why Coal-Fired Power Stations Need To Shut On Health GroundsDocument3 pagesWhy Coal-Fired Power Stations Need To Shut On Health Groundsrajupat123No ratings yet

- Controversial Weed-Killer Gets 18-Month Extension From European CommissionDocument2 pagesControversial Weed-Killer Gets 18-Month Extension From European Commissionrajupat123No ratings yet

- Brick Kiln PollutionDocument5 pagesBrick Kiln Pollutionrajupat123No ratings yet

- A Welcome Relief - in SCHOOL - The HinduDocument1 pageA Welcome Relief - in SCHOOL - The Hindurajupat123No ratings yet

- Bull Fight, An Inextricable Feature of Tamil Culture - TAMIL NADU - The HinduDocument1 pageBull Fight, An Inextricable Feature of Tamil Culture - TAMIL NADU - The Hindurajupat123No ratings yet

- A Sea of Humanity at Tiruvanaikaval Car Festival - TAMIL NADUDocument2 pagesA Sea of Humanity at Tiruvanaikaval Car Festival - TAMIL NADUrajupat123No ratings yet

- A Plant-Derived Drug For Dengue Soon - NATIONAL - The HinduDocument1 pageA Plant-Derived Drug For Dengue Soon - NATIONAL - The Hindurajupat123No ratings yet

- Back in The Skies Again - in SCHOOL - The HinduDocument1 pageBack in The Skies Again - in SCHOOL - The Hindurajupat123No ratings yet

- An App To Root Out Farming Troubles - in SCHOOL - The HinduDocument2 pagesAn App To Root Out Farming Troubles - in SCHOOL - The Hindurajupat123No ratings yet

- It Is People Who Make Smart Cities' - ANDHRA PRADESH - The HinduDocument2 pagesIt Is People Who Make Smart Cities' - ANDHRA PRADESH - The Hindurajupat123No ratings yet

- New Opportunities Unveiled in Shipping SectorDocument10 pagesNew Opportunities Unveiled in Shipping Sectorrajupat123No ratings yet

- There Is Possibility of Earth-Like Planets' - TELANGANA - The HinduDocument2 pagesThere Is Possibility of Earth-Like Planets' - TELANGANA - The Hindurajupat123No ratings yet

- Animal Groups Demand Swift Action On Court Orders - TELANGANA - The HinduDocument1 pageAnimal Groups Demand Swift Action On Court Orders - TELANGANA - The Hindurajupat123No ratings yet

- SC Should Decide On The Issue of Jurisdiction in Delhi' - NEW DELHI - The HinduDocument2 pagesSC Should Decide On The Issue of Jurisdiction in Delhi' - NEW DELHI - The Hindurajupat123No ratings yet

- Govt Drops Idea of Defining Online Marketplace - Print View - LivemintDocument3 pagesGovt Drops Idea of Defining Online Marketplace - Print View - Livemintrajupat123No ratings yet

- A Big Boost For Solar Rooftops in IndiaDocument2 pagesA Big Boost For Solar Rooftops in Indiarajupat123No ratings yet

- Devangshu Datta - Where Democracy Wins - Business Standard ColumnDocument3 pagesDevangshu Datta - Where Democracy Wins - Business Standard Columnrajupat123No ratings yet

- Back in The Skies Again - in SCHOOL - The HinduDocument1 pageBack in The Skies Again - in SCHOOL - The Hindurajupat123No ratings yet

- The Challenge For India at WTO - Print View - LivemintDocument3 pagesThe Challenge For India at WTO - Print View - Livemintrajupat123No ratings yet

- Rakesh Mohan Committee Submits Its ReportDocument1 pageRakesh Mohan Committee Submits Its Reportrajupat123No ratings yet

- Sehat' Unique Initiative For Health Care LaunchedDocument2 pagesSehat' Unique Initiative For Health Care Launchedrajupat123No ratings yet

- Rakesh Mohan Committee Report On Transport Development PolicyDocument13 pagesRakesh Mohan Committee Report On Transport Development Policyrajupat1230% (1)

- A Case of Eclectic Family TherapyDocument88 pagesA Case of Eclectic Family Therapygun gorNo ratings yet

- 8 Week Shred 1470077297538Document2 pages8 Week Shred 1470077297538Jesus Castro Machuca0% (1)

- A. Define Infertility: Objectives: Intended Learning Outcomes That TheDocument2 pagesA. Define Infertility: Objectives: Intended Learning Outcomes That TheJc Mae CuadrilleroNo ratings yet

- Detailed Advertisement of Various GR B & C 2023 - 0 PDFDocument47 pagesDetailed Advertisement of Various GR B & C 2023 - 0 PDFMukul KostaNo ratings yet

- RPNDocument21 pagesRPNAruna Teja Chennareddy43% (7)

- BG Gluc2Document3 pagesBG Gluc2Nghi NguyenNo ratings yet

- Strupp ArticleDocument10 pagesStrupp ArticleDental SpaNo ratings yet

- 'No Evidence That CT Scans, X-Rays Cause Cancer' - Medical News TodayDocument3 pages'No Evidence That CT Scans, X-Rays Cause Cancer' - Medical News TodayDr-Aditya ChauhanNo ratings yet

- Labcorp: Patient ReportDocument4 pagesLabcorp: Patient ReportAsad PrinceNo ratings yet

- Pediatric Malignant Bone TumoursDocument28 pagesPediatric Malignant Bone TumourscorneliusNo ratings yet

- Swollen Feet During PregnancyDocument2 pagesSwollen Feet During PregnancyDede YasminNo ratings yet

- Community and Public Health DefinitionsDocument3 pagesCommunity and Public Health DefinitionsSheralyn PelayoNo ratings yet

- Updates On Upper Eyelid Blepharoplasty.4Document8 pagesUpdates On Upper Eyelid Blepharoplasty.4Dimitris RodriguezNo ratings yet

- ICU antibiotic susceptibilities guideDocument1 pageICU antibiotic susceptibilities guideFaisal Reza AdiebNo ratings yet

- Curriculum Map Grade 9 Health: T (N .) M U T C C S P S C S A A R I C V Quarter 1Document5 pagesCurriculum Map Grade 9 Health: T (N .) M U T C C S P S C S A A R I C V Quarter 1joan niniNo ratings yet

- LabTec Product SpecificationsDocument292 pagesLabTec Product SpecificationsDiego TobrNo ratings yet

- Week 6 - LP Modeling ExamplesDocument36 pagesWeek 6 - LP Modeling ExamplesCharles Daniel CatulongNo ratings yet

- SGLGB Form 1 Barangay ProfileDocument3 pagesSGLGB Form 1 Barangay ProfileMark Lenon Par Mapaye100% (1)

- Reviewer in Community Health NursingDocument8 pagesReviewer in Community Health NursingFahtma Irene Faye AnayatinNo ratings yet

- Dmaema SDSDocument6 pagesDmaema SDSToffLinNo ratings yet

- GIGITAN ULAR BERBISA: GEJALA, PENANGANAN DAN JENIS ULAR PALING BERBISADocument19 pagesGIGITAN ULAR BERBISA: GEJALA, PENANGANAN DAN JENIS ULAR PALING BERBISAYudhistira ArifNo ratings yet

- Life Threatening Rhythm: Presenter: Muhammad Najmuddin Bin Hussain 2. Wan Muhammad Nasirudin Bin Wan YusoffDocument17 pagesLife Threatening Rhythm: Presenter: Muhammad Najmuddin Bin Hussain 2. Wan Muhammad Nasirudin Bin Wan YusoffWan NasirudinNo ratings yet

- Intro To MycologyDocument8 pagesIntro To Mycologycamille chuaNo ratings yet

- 11 - Chapter 7 PDFDocument41 pages11 - Chapter 7 PDFRakesh RakiNo ratings yet

- Delivery Guide Flood PreparednessDocument23 pagesDelivery Guide Flood Preparednesshsehamad173No ratings yet

- Thalassemia: Submitted By: Jovan Pierre C. Ouano Submitted To: Mark Gil T. DacutanDocument8 pagesThalassemia: Submitted By: Jovan Pierre C. Ouano Submitted To: Mark Gil T. DacutanJvnpierre AberricanNo ratings yet

- Resume - K MaclinDocument3 pagesResume - K Maclinapi-378209869No ratings yet

- Above Knee Amputation Exc PDFDocument5 pagesAbove Knee Amputation Exc PDFSenthilkumar ThiyagarajanNo ratings yet

- Prevalence of Pneumonia and Factors Associated Among Children 259 Months Old in Wondo Genet District Sidama Zone SNNPR Ethiopia - PDDocument7 pagesPrevalence of Pneumonia and Factors Associated Among Children 259 Months Old in Wondo Genet District Sidama Zone SNNPR Ethiopia - PDMusainah FeisalNo ratings yet

- Management of Class I Type 3 Malocclusion Using Simple Removable AppliancesDocument5 pagesManagement of Class I Type 3 Malocclusion Using Simple Removable AppliancesMuthia DewiNo ratings yet