Professional Documents

Culture Documents

Butcher Shop Risk Assessment

Uploaded by

Srikanth BammhideOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Butcher Shop Risk Assessment

Uploaded by

Srikanth BammhideCopyright:

Available Formats

Health and Safety

Executive

Example risk assessment for a butchers shop

Setting the scene

The owner carried out the risk assessment in this

butchers shop, which is located on a busy high

street. The owner employs five people, two of

them part-time.The owner will soon be taking on a

17-year-old apprentice.

At the rear of the shop is a staff toilet and washing

facilities, an area where staff can make hot drinks

etc, a cold store and storage space for dry goods.

The shop trades from 7.00 am to 6.00 pm, six days a

week.

Important reminder

This risk assessment addresses the risks to the

owner and his staff from work activities in the shop.

It does not cover compliance with food safety and

hygiene legislation, information can be found at

www.foodstandards.gov.uk/foodindustry/meat/.

How was the risk assessment done?

The owner followed the guidance in Five steps to risk

assessment (www.hse.gov.uk/pubns/indg163.pdf).

Every business is different you need to think

through the hazards and controls required in your

business for yourself.

Example risk assessment: Butcher

2 The owner wrote down who could be harmed by the

hazards and how.

3 For each hazard, the owner wrote down what controls,

if any, were in place to manage these hazards. These

controls were then compared to the guidance on HSEs

website. Where existing controls were not considered

good enough, the owner wrote down what else needed

to be done.

1 To identify the hazards, the owner:

This example risk assessment shows the kind

of approach a small business might take. It can

be used as a guide to think through some of the

hazards in your business and the steps you need to

take to control the risks. Please note that it is not a

generic risk assessment that you can just put your

company name on and adopt wholesale without any

thought. This would not satisfy the law and would

not be effective in protecting people.

necessary, taking account of the apprentices lack of

both experience and awareness of risk.

looked at HSEs web pages for small businesses, to

learn where hazards can occur;

walked around the shop, the stockroom and all other

areas, noting what might pose a risk and taking

HSE guidance into consideration. The owner also

considered occasional activities, such as changing light

bulbs;

talked to staff to learn from their knowledge and

experience, and listen to their concerns and opinions

about health and safety issues in the shop;

looked at the accident book, to understand what

previous problems there have been;

decided that, on the apprentices first day at work,

they would go through the risk assessment with him

and decide what additional risk control measures were

4 The owner discussed the findings with staff, displayed

the risk assessment in the staffroom and made it part

of the induction process for new staff. The owner

decided when the actions that were needed would be

done, and who would do them, and decided to tick the

actions off as each was completed.

5 The owner decided to review and update the risk

assessment every year or straightaway if major

changes in the workplace happened.

1 of 4 pages

Health and Safety

Executive

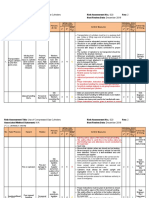

Company name: Smiths Butchers

Date of risk assessment: 1/7/07

What are the

hazards?

Who might be harmed What are you already doing?

and how?

Manual handling

Deliveries

Staff risk strains or

other injuries, to their

back or elsewhere, from

handling carcasses or

other stock.

All staff are trained how to lift properly.

High shelves are for light goods only.

Walkways kept clear.

Porters trolley available.

Carcasses quartered by supplier, prior to delivery.

Staff/customers risk

sprains, fractures or

bruising if they trip over

objects, such as stock,

or slip on spillages, eg

from fat build up.

Staff risk deep cuts

or amputations from

contact with blades or

other machinery parts.

Slips and trips

Machinery

Bandsaws, mincers,

cutters, slicers

Example risk assessment: Butcher

What further action is necessary?

Action by

who?

Action by

when?

Done

Remind staff that where possible, stock should

be moved using the trolley.

Owner

7/7/07

6/7/07

Remind staff of the need to lift properly and

safely, particularly when handling carcasses.

Owner

7/7/07

6/7/07

Staff try to stop meat debris/blood getting on the floor drip trays

used, leaks on machines are fixed and staff put meat debris straight

into bins.

Staff clean as they go.

Wet floor warning signs always used.

Tiled floor even, in good condition and has good drainage.

Doormats at entrance in wet weather.

Good lighting in all areas.

Staff wear sensible, non-slip footwear.

Floor in all areas cleaned thoroughly according to a daily schedule.

Remind staff to check for ice debris in the cold

store and to clear this away.

Owner

20/7/07

19/7/07

Remind staff to clean shoes at end of day and

check soles have not worn smooth.

Owner

20/7/07

19/7/07

All machines guarded according to manufacturers instructions.

Staff trained in using machines safely, including pre-use checks and

safe systems of work for clearing blockages.

Blade carriers are always used when a blade is removed, and staff

are trained to use them safely.

Warning signs displayed at machines.

Sufficient space provided for operator around machines.

Push sticks provided as necessary.

Apprentice not to use or clean machinery where there is access to

moving parts.

Remind staff not to distract colleagues who are

using machinery.

Owner

20/7/07

19/7/07

Remind staff to do pre-use checks on

machinery guards and to follow the safe

system of work for clearing blockages, being

especially sure to turn off the machine before

doing so.

Owner

20/7/07

19/7/07

Plan a closely supervised programme for the

apprentice in how to use and clean machinery.

Owner

20/7/07

19/7/07

2 of 4 pages

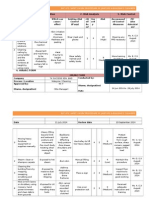

Health and Safety

Executive

What are the

hazards?

Who might be harmed What are you already doing?

and how?

Knives

Staff risk deep cuts

or amputations from

contact with blade.

What further action is necessary?

Action by

who?

Action by

when?

Done

Staff trained in the safe use, maintenance and storage of knives.

Staff use the right knives for the job.

Knives kept sharp.

PPE (chain mail gauntlet/apron) provided and staff know how to wear

it and for what jobs.

Sufficient space for staff to work safely.

Remind staff not to distract colleagues when

they are using knives.

Owner

20/7/07

17/7/07

Check that shop first-aiders are trained in first

aid for stab wounds.

Owner

20/7/07

17/7/07

Infection

Staff risk zoonotic

infection from

absorbing raw meat.

Good personal hygiene from all staff.

Good washing and welfare facilities.

Food waste stored in closed containers.

Staff trained in washing out puncture wounds and covering cuts with

food-grade plasters and dressings.

Remind staff to clean and disinfect waste

buckets every time they are emptied.

Manager

20/7/07

17/7/07

Work at height

Changing light bulbs

or displays

Falls from any height

can cause bruising/

fractures.

Suitable stepladder in good condition provided, and staff know how to

use it safely.

None.

Manager

20/7/07

17/7/07

Contact with

bleach and other

cleaning chemicals

Staff doing cleaning

risk skin irritation or

eye damage from direct

contact with cleaning

chemicals. Vapour

may cause breathing

problem.

Mops, brushes and strong rubber gloves are provided and used.

Staff shown how to use cleaning products safely, eg follow

instructions on the label, dilute properly and never transfer to an

unmarked container.

Replace irritant chemicals with milder

alternatives, where possible.

Manager

20/7/07

20/7/07

Staff reminded to check for dry, red or itchy

skin on their hands.

Manager

20/7/07

20/7/07

Staff reminded to wash gloves before taking

them off carefully and storing in a clean place.

Manager

20/7/07

20/7/07

Staff could get electrical

shocks or burns

from faulty electrics,

including portable

electrical equipment

heaters, fans etc.

Manager to do visual check of plugs, sockets,

cables and on/off switches every three months.

Manager

and all

staff

20/7/07

First

check

done on

18/7/07

Electrical

Faulty building

wiring, faulty

electrical appliances

Example risk assessment: Butcher

Staff trained to spot and report any defective plugs, discoloured

sockets, damaged cable and on/off switches and to take defective

equipment out of use.

Staff know where the fuse box is and how to turn electricity off in an

emergency.

Clear access to the fuse box.

Only qualified electricians work on electrical installation.

3 of 4 pages

Health and Safety

Executive

What are the

hazards?

Who might be harmed What are you already doing?

and how?

What further action is necessary?

Violence and

threatening

behaviour

Staff may suffer

assaults and abuse

from customers.

Staff trained not to resist a robbery.

Staff provide good, polite service.

Fire, eg smoking,

faulty electrics,

arson

If trapped, staff could

suffer from smoke

inhalation/burns.

Fire risk assessment done, see www.communities.gov.uk/fire and

necessary action taken.

Action by

who?

Action by

when?

Done

Contact local police for advice on what else

can be done (eg safe procedures for opening/

closing).

Manager

20/7/07

20/7/07

Remind staff to keep backyard gate locked out

of hours to stop intruders getting in.

Manager

20/7/07

20/7/07

Assessment review date: 1/7/08

Example risk assessment: Butcher

Published by the Health and Safety Executive

4 of 4 pages

10/08

You might also like

- HairdressersDocument4 pagesHairdresserssjmpak0% (1)

- Office Cleaning Risk AssessmentDocument3 pagesOffice Cleaning Risk Assessmentisak23No ratings yet

- Example Risk Assessment For A Motor Vehicle ShowroomDocument4 pagesExample Risk Assessment For A Motor Vehicle Showroomdogankku100% (1)

- F&B Risk Assessment SampleDocument5 pagesF&B Risk Assessment Samplephilip100% (2)

- Example Risk Assessment For A Poultry Farm: Setting The Scene How Was The Risk Assessment Done?Document4 pagesExample Risk Assessment For A Poultry Farm: Setting The Scene How Was The Risk Assessment Done?Olivera NovkovicNo ratings yet

- Example Risk Assessment For A Pub: Setting The Scene How Was The Risk Assessment Done?Document6 pagesExample Risk Assessment For A Pub: Setting The Scene How Was The Risk Assessment Done?Blas de LezoNo ratings yet

- Kitchen Risk AssessmentDocument4 pagesKitchen Risk Assessmentamnaakram996100% (1)

- How To Use This Kitchen Inspection Checklist: Safetyunit@gre - Ac.uk October 2010 Page 1 of 8Document8 pagesHow To Use This Kitchen Inspection Checklist: Safetyunit@gre - Ac.uk October 2010 Page 1 of 8tzryadNo ratings yet

- Hazard Identification ChecklistDocument4 pagesHazard Identification Checklistmanishpandey1972No ratings yet

- Risk Assessment - KitchenDocument3 pagesRisk Assessment - KitchenOlivia BrookesNo ratings yet

- Kitchen Risk Assessment Template TitleDocument3 pagesKitchen Risk Assessment Template TitleShah Jahan75% (4)

- Risk Assessment for Compressed Gas Cylinder UseDocument7 pagesRisk Assessment for Compressed Gas Cylinder UsejeffreyNo ratings yet

- JSA-012 Low-Flow Groundwater SamplingDocument3 pagesJSA-012 Low-Flow Groundwater SamplingfrancisseeNo ratings yet

- First Aid Record Form TemplateDocument1 pageFirst Aid Record Form Templatepuput utomoNo ratings yet

- Personal Protective Equipment Hazard Assessment: Location: Conducted By: Date: Tasks Performed at This LocationDocument4 pagesPersonal Protective Equipment Hazard Assessment: Location: Conducted By: Date: Tasks Performed at This LocationAnge JuanNo ratings yet

- FoodSHAP Food Safety Inspection Checklist-Checklist-Home KitchenDocument3 pagesFoodSHAP Food Safety Inspection Checklist-Checklist-Home Kitchenmarian2277100% (1)

- Hazard IdentificationDocument4 pagesHazard IdentificationsuhailpmNo ratings yet

- Kitchen Jad Jsa RevisedDocument2 pagesKitchen Jad Jsa Revisedsinghajitb100% (3)

- Heat Stress Assessment Checklist: Section IDocument3 pagesHeat Stress Assessment Checklist: Section IninisaisNo ratings yet

- Objectives of The House Keeping Departmen1Document20 pagesObjectives of The House Keeping Departmen1Rakeshwar WaliaNo ratings yet

- S01 PresentationDocument258 pagesS01 PresentationJoshua Romero100% (1)

- Workers 8 Hours Mandatory Training - Module 1Document89 pagesWorkers 8 Hours Mandatory Training - Module 1Robert Ecleo100% (4)

- EVT471Document3 pagesEVT471Nurul AqielaNo ratings yet

- Confine Space Entry (Excavation)Document32 pagesConfine Space Entry (Excavation)Delta akathehuskyNo ratings yet

- Example Risk Assessment For A Warehouse PDFDocument8 pagesExample Risk Assessment For A Warehouse PDFrediet dinoNo ratings yet

- Risk assessment identifies hazards of installing cables and excavationDocument6 pagesRisk assessment identifies hazards of installing cables and excavationMohammed Shiful0% (1)

- Emergency Response ProcedureDocument8 pagesEmergency Response ProcedureAhmad KharisNo ratings yet

- Injury Prevention for Bathroom CleaningDocument1 pageInjury Prevention for Bathroom CleaningSajid HussainNo ratings yet

- Risk Assessment Forms - Appendix 5 (22102016)Document2 pagesRisk Assessment Forms - Appendix 5 (22102016)Sơn Nguyễn-Lê100% (1)

- Scaffolding-Fixed and Mobile: Safety Operating ProceduresDocument1 pageScaffolding-Fixed and Mobile: Safety Operating Proceduresmohammed muzammilNo ratings yet

- Risk AssessmntDocument5 pagesRisk Assessmntapi-456358200No ratings yet

- Hotel Safety Program PDFDocument29 pagesHotel Safety Program PDFJean Marie Vallee100% (2)

- A. 3 HirarcDocument29 pagesA. 3 HirarcJeny MulyaNo ratings yet

- Job Hazard AssessmentDocument26 pagesJob Hazard AssessmentGeherson AbustanNo ratings yet

- Activity Hazard AnalysisDocument4 pagesActivity Hazard AnalysisGerrard Singh100% (1)

- Sample Safety ProgramDocument35 pagesSample Safety ProgramNeal LesterNo ratings yet

- Metal Chop Saw SopDocument2 pagesMetal Chop Saw SopkylealamangoNo ratings yet

- HIRA NewDocument107 pagesHIRA NewPrabhakaran Gurunathan100% (1)

- Job HazardDocument2 pagesJob HazardBre WirabumiNo ratings yet

- Pha ExcavationDocument13 pagesPha ExcavationirshadNo ratings yet

- JHA For Plumbing and Piping TradesDocument84 pagesJHA For Plumbing and Piping TradesKhurram Iqbal100% (2)

- Chisels Risk AssessmentDocument1 pageChisels Risk AssessmentTawfik Mohamed Abu Zaid100% (1)

- Forklift Operations - Risk Assessment & Hazard IdentificationDocument5 pagesForklift Operations - Risk Assessment & Hazard IdentificationSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- 2017 Food Safety For PantriesDocument55 pages2017 Food Safety For Pantriessoniaditia_chemistNo ratings yet

- Job Hazard AnalysisDocument3 pagesJob Hazard AnalysisChristine YasaNo ratings yet

- Pregnancy Risk AssessmentDocument6 pagesPregnancy Risk AssessmentSTEVEN DELAHUNTYNo ratings yet

- Job Description Safety & HealthDocument1 pageJob Description Safety & HealthNiz IsmailNo ratings yet

- Manual Handling WorksheetDocument4 pagesManual Handling WorksheetRudi Fajardo100% (1)

- Food Safety Training ManualDocument15 pagesFood Safety Training Manualmohd sharique100% (2)

- 2.4 Attachments - Risk Assessment and Method StatementDocument10 pages2.4 Attachments - Risk Assessment and Method StatementFahad MaqsoodNo ratings yet

- HSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0Document15 pagesHSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0عمروNo ratings yet

- Dole Safety ProcedureDocument13 pagesDole Safety ProcedureROLAN RULLODA100% (1)

- 01 Safety and HygieneDocument16 pages01 Safety and Hygienerode1234100% (1)

- Monthly HSE Statistics SeptemberDocument2 pagesMonthly HSE Statistics SeptemberRaza Muhammad SoomroNo ratings yet

- Monthly Fire Extinguisher ChecklistDocument4 pagesMonthly Fire Extinguisher Checklistberkah meidraNo ratings yet

- Health and Safety in HRDocument49 pagesHealth and Safety in HRArthur AguilarNo ratings yet

- Clean Tank WaterDocument1 pageClean Tank Waterblahblah100% (1)

- HSE Risk Assessment WarehouseDocument6 pagesHSE Risk Assessment WarehouseSean Clark100% (1)

- Health and Safety Risk AssessmentDocument4 pagesHealth and Safety Risk Assessmenthello3232No ratings yet

- Office Cleaning RiskDocument3 pagesOffice Cleaning RiskR Chandra Jaya Listiandoko100% (3)

- BhagavatamDocument558 pagesBhagavatamSarmaBvr100% (1)

- Vitamin BDocument1 pageVitamin BSrikanth BammhideNo ratings yet

- Lyrics English Songs FavDocument20 pagesLyrics English Songs FavSrikanth BammhideNo ratings yet

- Offshore Safety Training ManualDocument5 pagesOffshore Safety Training ManualSrikanth Bammhide67% (3)

- Get MoneyDocument1 pageGet MoneySrikanth BammhideNo ratings yet

- Lva1 App6892Document15 pagesLva1 App6892Srikanth BammhideNo ratings yet

- AlmansooriDocument1 pageAlmansooriSrikanth BammhideNo ratings yet

- Drilling HseDocument2 pagesDrilling HseSrikanth BammhideNo ratings yet

- Hiring of Service For Drilling Rig PackageDocument2 pagesHiring of Service For Drilling Rig PackageSrikanth BammhideNo ratings yet

- Ten CommandmentDocument44 pagesTen CommandmentSrikanth BammhideNo ratings yet

- KG Basin Project Civil Works ConsultancyDocument12 pagesKG Basin Project Civil Works ConsultancySrikanth BammhideNo ratings yet

- Eoi Oilkgbeoi18 27072012Document12 pagesEoi Oilkgbeoi18 27072012Srikanth BammhideNo ratings yet

- GC-2 Element 5-8Document15 pagesGC-2 Element 5-8Srikanth BammhideNo ratings yet

- 101 Tactical TipsDocument34 pages101 Tactical TipsBallu BaluNo ratings yet

- Fresh Rs. 250 Duplicate Rs. 100 Renewal Rs. 150 Online ApplicationDocument3 pagesFresh Rs. 250 Duplicate Rs. 100 Renewal Rs. 150 Online Applicationiqbal2525No ratings yet

- Markandeya PuranamuDocument356 pagesMarkandeya PuranamuVenu Srikanth DarlaNo ratings yet

- Code of Safe Drilling Practices: California Department of TransportationDocument9 pagesCode of Safe Drilling Practices: California Department of TransportationSrikanth BammhideNo ratings yet

- GC-2 Element 1-4Document21 pagesGC-2 Element 1-4Srikanth BammhideNo ratings yet

- 12 Drilling PreventersDocument82 pages12 Drilling PreventersDavid Kusuma100% (1)

- Accumulator or Koomey UnitDocument3 pagesAccumulator or Koomey Unitmmohsinaliawan100% (3)

- Slimane ResumeDocument5 pagesSlimane ResumeSrikanth BammhideNo ratings yet

- API 6A Hydraulic Actuator Operation InstructionDocument7 pagesAPI 6A Hydraulic Actuator Operation InstructionSrikanth Bammhide100% (1)

- Accumulator Function TestDocument1 pageAccumulator Function TestamirakhavansafarNo ratings yet

- Job Safety AnalysisDocument4 pagesJob Safety AnalysisDedi Apriadi71% (7)

- Surface Test TreeDocument4 pagesSurface Test TreeSrikanth BammhideNo ratings yet

- Dropped Objects ObservationsDocument4 pagesDropped Objects ObservationsSrikanth BammhideNo ratings yet

- AccumulatorDocument15 pagesAccumulatorSrikanth Bammhide100% (2)

- QHSE Policy and Procedures GuideDocument105 pagesQHSE Policy and Procedures GuideSrikanth Bammhide100% (1)

- DrillingDocument87 pagesDrillingSrikanth BammhideNo ratings yet

- Drilling Rig Operations & A To Z Rotary Drilling Rig ComponentsDocument130 pagesDrilling Rig Operations & A To Z Rotary Drilling Rig ComponentsAhmad93% (28)

- Evolution of Insulation Piercing Connector TechnologyDocument7 pagesEvolution of Insulation Piercing Connector TechnologyJRNo ratings yet

- Operating Instructions for R 32 Radial Drill PressDocument23 pagesOperating Instructions for R 32 Radial Drill PressOsama EidNo ratings yet

- TMC Mp2cp Ug PendantDocument65 pagesTMC Mp2cp Ug PendantMichael DresnerNo ratings yet

- Manual de Serviço Sharp MX2410Document529 pagesManual de Serviço Sharp MX2410Sidnei Oliveira100% (4)

- 1993 Ford Thunderbird - 3.8L V6-VIN (4) & 3.8L SC V6 - VIN (R)Document46 pages1993 Ford Thunderbird - 3.8L V6-VIN (4) & 3.8L SC V6 - VIN (R)g_garcia_c_996374095100% (2)

- Especificaciones Polipastos PDFDocument28 pagesEspecificaciones Polipastos PDFMichaeluiMichaelui100% (1)

- Model 3150 Downflow: Service ManualDocument36 pagesModel 3150 Downflow: Service ManualАлександр РодионовNo ratings yet

- 005 Risk Assessment T&C Fire Suppression SystemDocument10 pages005 Risk Assessment T&C Fire Suppression SystemJohn RazaNo ratings yet

- Festo Szelepsziget TYP10-G - ENDocument64 pagesFesto Szelepsziget TYP10-G - ENEde HeimNo ratings yet

- DLT2 Manual (1.32)Document5 pagesDLT2 Manual (1.32)shortbus_scribdNo ratings yet

- Samsung LN40D630M3FXZA Fast Track Guide (SM)Document4 pagesSamsung LN40D630M3FXZA Fast Track Guide (SM)Carlos OdilonNo ratings yet

- SHE - NGTS 2.1 - SubstationsDocument27 pagesSHE - NGTS 2.1 - SubstationsandcrisdanmatNo ratings yet

- Motherboard Manual Gigabyte Ga-Ma780g Ud3h eDocument104 pagesMotherboard Manual Gigabyte Ga-Ma780g Ud3h enikok66100% (1)

- Regulations For The Installation of Electrical WiringDocument129 pagesRegulations For The Installation of Electrical Wiringmdoc24No ratings yet

- Fan RegulatorDocument4 pagesFan RegulatorBinesh KanayiNo ratings yet

- AmezcuaDocument3 pagesAmezcuapsNo ratings yet

- Solenoid ValveDocument76 pagesSolenoid ValveazlanNo ratings yet

- (Barnes J.R.) Designing Electronic Systems For ESDDocument8 pages(Barnes J.R.) Designing Electronic Systems For ESDJHYNo ratings yet

- DVC6200Document4 pagesDVC6200Jesus BolivarNo ratings yet

- School Linamon Central Grade Level Teacher Learning Area Time & Dates I. ObjectivesDocument4 pagesSchool Linamon Central Grade Level Teacher Learning Area Time & Dates I. ObjectivesROSAFLOR BESASNo ratings yet

- L 0606279Document179 pagesL 0606279Jeff ImmerNo ratings yet

- S2000 Hard Top Installation & Adjustment InstructionsDocument8 pagesS2000 Hard Top Installation & Adjustment InstructionsNick ArNo ratings yet

- Dual Row Right Angle SMT Pin Header 2037 SeriesDocument1 pageDual Row Right Angle SMT Pin Header 2037 SeriesEstefaniaNo ratings yet

- Sample of PASS M0 SBB - Installation Manual - 2GJA700101 (E)Document34 pagesSample of PASS M0 SBB - Installation Manual - 2GJA700101 (E)dwas1314No ratings yet

- VMFT Radar InstallationDocument54 pagesVMFT Radar InstallationHoovers RamirezNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document20 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Angga supriyantoNo ratings yet

- Digital Bending Machine User Manual - BD SeriesDocument7 pagesDigital Bending Machine User Manual - BD SeriesTatiane Silva BarbosaNo ratings yet

- Hidrolavadora Eléctrica 2000 PSIDocument24 pagesHidrolavadora Eléctrica 2000 PSINelson GarzónNo ratings yet