Professional Documents

Culture Documents

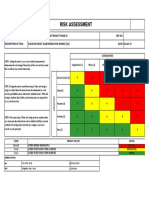

Contract Bricklayers Risk Assessment

Uploaded by

shamsukarim2009Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Contract Bricklayers Risk Assessment

Uploaded by

shamsukarim2009Copyright:

Available Formats

Health and Safety

Executive

Example risk assessment for contract bricklayers

Setting the scene

The manager of a successful bricklaying contractor,

with help from worker representatives, carried out

a general risk assessment that covered their typical

work. This assessment was used when tendering for

contracts to demonstrate the firms approach to health

and safety. In the tender documents the manager

was clear about what was needed from the principal

contractor to do the job safely and properly.

The firm won a bricklaying contract for a development

of three-storey flats. Work was due to start on 1 May

2006. The manager checked the construction phase

plan and met the principal contractors site manager on

the site. This extra information was used to amend the

general assessment so that it was specific to the work

and conditions.

How was the risk assessment done?

The manager followed the guidance in Five steps to risk

assessment (www.hse.gov.uk/pubns/indg163.pdf).

1 To identify the hazards, the manager:

read HSEs construction web pages and HSEs

publication HSG150 Health and safety in construction

(available from HSE Books, www.hsebooks.com);

checked the manufacturers instructions for tools/

machinery and the data sheet for mortar;

Example risk assessment: Contract bricklayers

thought about the work seen on sites; and

talked to employees to help identify the significant

hazards and particular work practices.

2 The manager then wrote down who could be harmed

by the hazards and how.

3 For each hazard identified, the manager recorded

what controls, if any, were in place to manage these

hazards. These controls were then compared to the

good practice guidance laid out in the manufacturers

instructions or the data sheets, Health and safety in

construction, Essentials of health and safety at work

publications and the HSE construction web pages.

Where existing controls did not meet good practice the

manager wrote down what further actions were needed

to manage the risk.

4 Putting the findings of the risk assessment into

practice, the manager decided and recorded who was

responsible for implementing the further actions and

when they should be done. When each action was

completed it was ticked off and the date was recorded.

5 The manager decided that for each new site it was

important to make sure the assessment was suitable

and amend it depending on the particular work and

conditions. A review and update of the general risk

assessment would be made each year and staff would

learn from the work on different sites.

How was the site-specific risk assessment

done?

1 To turn the general risk assessment into a site-specific

assessment the manager checked the following had

been identified:

the right hazards;

who might be harmed and how;

controls that would need to be taken on this particular

site; and

who would be responsible for putting the controls into

practice and when.

2 The manager did this by:

checking the construction phase plan for the site.

looking at the general layout of the site as well as what

materials were to be used (in particular what weight of

blocks and lintels), what equipment and plant would

be needed, and what general rules would need to be

followed;

visiting the site; and

discussing the work and the site conditions and general

rules with the principal contractors site manager.

3 The manager made the supervisor responsible for

briefing the bricklayers about the site rules on their first

day.

1 of 5 pages

Health and Safety

Executive

Company name: TVW Contract Bricklayers

Date of risk assessment: 6/3/2006

Important reminder

This example risk assessment shows the kind of approach a small business might take. Use it as a guide to think through

some of the hazards in your business and the steps you need to take to control the risks. Please note that it is not a generic

risk assessment that you can just put your company name on and adopt wholesale without any thought. This would not

satisfy the law and would not be effective in protecting people.

Every business is different you need to think through the hazards and controls required in your business for yourself.

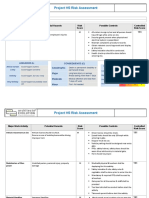

What are the hazards? Who might be harmed and

how?

Falling from height

Serious injury or even fatal

injury could occur if a worker

falls.

What are you already doing?

Collapse of scaffold

Falling objects

hitting head or body,

including feet

All operatives on scaffold

may incur crush injuries,

or worse, if the scaffold

collapses on top of them.

Serious head and other

injuries to workers, others

on site and members of the

public.

Example risk assessment: Contract bricklayers

What further action is necessary?

Action by

who?

Action by Done

when?

Agree scaffolding requirements at contract stage, including

appropriate load rating and provision of loading bays.

Bricklayers supervisor to check with the site manager that the

correct scaffold is provided and inspected.

Workers instructed not to interfere with or misuse scaffold

supervisor to keep an eye out for problems.

Ladders in good condition, adequately secured (lashed) and

placed on firm surface.

Band stands with handrails to be used for work on internal walls.

Workers trained to put up bandstands.

Scaffold requirements agreed, including

loading bays and appropriate load rating.

TB

20/3/06

Supervisor to speak regularly to site

manager to arrange scaffold alterations and

ensure that weekly inspections have been

carried out.

LG

From

1/5/06

Agree scaffolding requirements at contract stage, including

appropriate load rating and provision of loading bays.

Bricklayers supervisor to check with the site manager that the

correct scaffold is provided and inspected.

Supervisor to keep a check to make

sure that scaffold is not overloaded with

materials.

LG

From

1/5/06

Brick guards kept in position on scaffold lifts.

Waste materials removed from scaffolding and placed in skip.

Safety helmets and protective footwear (with steel toecaps and

mid-soles) supplied and worn at all times.

Supervisor to monitor use of safety hats and

protective footwear.

LG

From

1/5/06

20/3/06

2 of 5 pages

Health and Safety

Executive

What are the hazards? Who might be harmed and

how?

Manual handling

All workers could suffer from

back injury and long-term

pain if regularly lifting/

carrying heavy or awkward

objects.

What are you already doing?

Workers struck or

crushed by moving

vehicles on site

Slips and trips

Workers could suffer serious

or even fatal injuries from

vehicles and machines on

site particularly when

reversing.

All workers may suffer

sprains or fractures if they

trip over waste including

brick bands and pallet debris.

Slips at height could result in

a serious fall.

Example risk assessment: Contract bricklayers

What further action is necessary?

Action by

who?

Action by Done

when?

Bricks, mortar etc to be transported and lifted to scaffold using

telehandler provided by principal contractor.

Provision of lifting bay agreed with principal contractor.

Bricks/blocks to be covered with tarpaulin when stored on site to

prevent taking up water.

Spot boards to be raised with blocks to easy working height.

Trolley to be used for moving loads of bricks around the scaffold

lift.

Check at tender stage for any blocks or lintels over 20 kg and

make arrangements.

Heaviest blocks are 15 kg, no special

arrangements necessary.

VP

From

1/5/06

Concrete lintels are well over 20 kg, to

be positioned using telehandler (all are

accessible).

VP

From

1/5/06

All workers to be instructed not to carry

materials up by hand.

LG

From

1/5/06

Manager to agree safe route to work area with principal

contractor based upon the construction phase health and safety

plan.

Induction to each site to be carried out for all workers on first

day.

Safe route agreed with principal contractor

TB

20/3/06

Supervisor to liaise with site manager to

ensure safe route stays clear.

LG

From

1/5/06

Instruct staff that they must never drive

vehicles and plant on this site.

LG

From

1/5/06

High-visibility vests to be provided.

LG

From

1/5/06

Supervisor to check vests are worn on all

sites where the principal contractor requires

them.

LG

From

1/5/06

Temporary storage locations to be agreed

with site manager.

TB

20/2/06

Supervisor to ensure that workers wear

safety footwear whenever on site.

LG

From

1/5/06

Good housekeeping maintained at all times.

Waste including brick bands and pallet debris disposed of in

skip.

Safety footwear provided to all workers.

Safe route to workplace agreed with principal contractor based

on construction phase health and safety plan.

20/3/06

20/3/06

3 of 5 pages

Health and Safety

Executive

What are the hazards? Who might be harmed and

how?

Stepping on nails and

sharp objects

All workers could suffer foot

injuries.

What are you already doing?

Safety boots with steel toecaps and mid-soles provided to all

workers.

Waste disposed of in skips.

What further action is necessary?

Action by

who?

Action by Done

when?

Explain the need to wear safety boots and

dispose of waste in skips repeat annually.

LG

1/5/06

Supervisor to check that safety boots are

always worn and waste disposed of properly.

LG

From

1/5/06

Hazard to eyes,

cutting bricks

Bricklayers could suffer eye

injury through flying brick

fragments.

Safety goggles (EN 166 B standard) worn when breaking bricks.

Use of goggles to be monitored by

supervisor.

LG

From

1/5/06

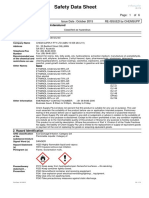

Hazardous

substances, mortar

Direct skin contact with the

mortar could also cause

bricklayer contact dermatitis

and burns.

Risk of dermatitis or cement burns and precautions explained to

all workers.

Use cement or cement containing products within the use-by

date.

Direct skin contact to be avoided, CE marked PVC gloves used

when handling mortar.

Good washing facilities on site, with hot and cold water, soap

and basins large enough to wash forearms.

Principal contractors first aid includes emergency eyewash.

Training on how to treat exposure to be given

to all operatives.

TB

17/4/06

Supervisor to be aware of anyone with early

signs of dermatitis.

LG

From

1/5/06

Supervisor to check mixer daily for obvious

damage.

LG

From

1/5/06

Dust from cutting

bricks

Operating cement

mixer

Dust exposure could cause

silicosis.

Workers could be crushed

or cut if the mixer topples or

they get caught in moving

parts. Damage to electrics

could result in a shock.

Example risk assessment: Contract bricklayers

Angle grinders replaced with block splitter, removing the risk of

significant dust exposure.

The use of a grinder for chasing etc is not needed on this job.

Cement mixer located on firm, level ground.

Mixer is fully guarded and guards in place during operation.

Mixer is 110 volt and PAT tested every three months.

1/5/06

26/4/06

4 of 5 pages

Health and Safety

Executive

What are the hazards? Who might be harmed and

how?

What are you already doing?

Noise from use of

equipment, eg angle

grinder

Workers using grinders or

working near people who

may suffer hearing loss.

Vibration from use of

equipment such as

angle grinder

Exposure to vibration can

lead to the development of

vibration white finger (VWF).

Angle grinders replaced with block splitter. No significant

vibration left.

Fire/explosion

All operatives in the vicinity

could suffer from smoke

inhalation or burns.

Welfare/first aid

Good facilities help prevent

dermatitis etc.

Angle grinders replaced with block splitter, removing high noise

levels from our work.

Construction phase plan show other trades using grinders etc

should not be working close enough to cause problems.

What further action is necessary?

Action by

who?

Action by Done

when?

Supervisor to monitor and talk to site

manager if noisy work does start close by.

LG

From

1/5/06

Suitable fire extinguisher kept in site office and welfare block.

Good housekeeping monitored by supervisor.

Supervisor to brief all workers on first day

on emergency arrangements agreed with

principal contractor.

LG

1/5/06

1/5/06

Principal contractor will have facilities on site by the time

bricklaying starts, including:

-- flushing toilet;

-- hot and cold running water, soap, towels and full-size

washbasins;

-- heated canteen with kettle etc;

-- first-aid equipment;

-- principal contractor will arrange clearing and ensure the

necessary electrical and heating safety checks are made;

and

-- site agent is appointed person for first aid.

Supervisor to brief workers on facilities and

keeping them clean.

LG

1/5/06

1/5/06

Assessment review date: 25/8/06

Example risk assessment: Contract bricklayers

Published by the Health and Safety Executive

5 of 5 pages

11/08

You might also like

- Safe Work Method StatementDocument7 pagesSafe Work Method StatementianllagasNo ratings yet

- Example Risk Assessment For A Bricklaying Company Updated 20-11-12Document9 pagesExample Risk Assessment For A Bricklaying Company Updated 20-11-12Ali Mohamed100% (1)

- Safe Work Method Statement TemplateDocument6 pagesSafe Work Method Statement Templatechassas100% (1)

- Risk Assesment 16 - Pre - Assembly and Erection ofDocument7 pagesRisk Assesment 16 - Pre - Assembly and Erection ofRochdi BahiriNo ratings yet

- Brick Masonry - EHS Risk AssessmentDocument2 pagesBrick Masonry - EHS Risk Assessmentnagarjuna100% (3)

- Brick/Block Work Hazards AssessmentDocument40 pagesBrick/Block Work Hazards AssessmentGyanendra Srivastava0% (1)

- Casting ConcreteDocument9 pagesCasting ConcreteNontobeko MkhizeNo ratings yet

- Risk Assessment MasonryDocument1 pageRisk Assessment Masonrymohamed ghalyNo ratings yet

- Risk AssessmentDocument3 pagesRisk AssessmentAkinbami Olorunnifemi100% (1)

- Thohoyandou - NZG Renovation Project Baseline Risk Assessment G306 2018 PDFDocument17 pagesThohoyandou - NZG Renovation Project Baseline Risk Assessment G306 2018 PDFbubele pamlaNo ratings yet

- SMS - SF 4.4.6.6.1 Method Statement Glass Partition InstallationDocument7 pagesSMS - SF 4.4.6.6.1 Method Statement Glass Partition InstallationAli SahibzadaNo ratings yet

- Ohs-Pr-09-10-F05 (A) Explosive Power Tool & Cartridge Issuing RegisterDocument2 pagesOhs-Pr-09-10-F05 (A) Explosive Power Tool & Cartridge Issuing RegisterSiddiqui100% (1)

- Risk Assessment For Stone Works: Project NameDocument7 pagesRisk Assessment For Stone Works: Project NameharikrishnaNo ratings yet

- HIRADC Asphalt RoadDocument1 pageHIRADC Asphalt RoadAshadi Amir100% (1)

- Ra 02 - Anti-Termite TreatmentDocument4 pagesRa 02 - Anti-Termite TreatmentHafiz M WaqasNo ratings yet

- Risk-Assessment Ducts & AccessoriesDocument13 pagesRisk-Assessment Ducts & AccessoriesMohammed Amer PashaNo ratings yet

- Method Statements 02 - Work at HeightDocument10 pagesMethod Statements 02 - Work at HeightMathewNo ratings yet

- Risk Assessment Construction of Lighting Pole at Site OfficeDocument9 pagesRisk Assessment Construction of Lighting Pole at Site OfficeSinaNo ratings yet

- 7-Block Work Risk Assessment ReportDocument7 pages7-Block Work Risk Assessment ReportSyed Ali Hassan100% (4)

- Method Statement For Installation of Temporary Plumbing, Drainage System and Electrical SupplyDocument48 pagesMethod Statement For Installation of Temporary Plumbing, Drainage System and Electrical SupplyAnandu AshokanNo ratings yet

- Risk Assessment Template For Combo Roof Waterproofing Work.Document14 pagesRisk Assessment Template For Combo Roof Waterproofing Work.Majaga MabhenaNo ratings yet

- Risk AssessmentDocument3 pagesRisk AssessmentSam HodgsonNo ratings yet

- Risk Assessment - FinalDocument7 pagesRisk Assessment - FinalHaymanAHMEDNo ratings yet

- Formwork Safety Manual Section 3Document1 pageFormwork Safety Manual Section 3Rickesh Nunkoo100% (1)

- Construction Job Hazards Analysis: This Is A TEMPLATEDocument1 pageConstruction Job Hazards Analysis: This Is A TEMPLATEPrakash PavuralaNo ratings yet

- HAZARD IDENTIFICATION & RISK ASSESSMENT FOR EXCAVATION OF ROAD WITH TLBDocument7 pagesHAZARD IDENTIFICATION & RISK ASSESSMENT FOR EXCAVATION OF ROAD WITH TLBCharles LambNo ratings yet

- Hazard Risk Assessment of Jack HammerDocument14 pagesHazard Risk Assessment of Jack HammerAkhtar BahramNo ratings yet

- Risk Assessment Excavation For Trenches, Duct Bank, Pole Foundations and Back-FillingDocument3 pagesRisk Assessment Excavation For Trenches, Duct Bank, Pole Foundations and Back-FillingSafety Professional0% (1)

- OSHA Training and Reference Materials Library - PPE AssessmentDocument10 pagesOSHA Training and Reference Materials Library - PPE AssessmentOluwafemi Samuel AdesanmiNo ratings yet

- Job Safety Analysis For Concrete Casting (R-01)Document13 pagesJob Safety Analysis For Concrete Casting (R-01)Suju RajanNo ratings yet

- De-Shuttering PermitDocument1 pageDe-Shuttering PermitHariharan Muthukrishanan100% (1)

- Risk Assessment For Elevator Shaft Slab Demolition (C01, S10)Document1 pageRisk Assessment For Elevator Shaft Slab Demolition (C01, S10)rayNo ratings yet

- HSE RISK ASSESSMENT FOR MANHOLE CONNECTIONDocument9 pagesHSE RISK ASSESSMENT FOR MANHOLE CONNECTIONsandeep reshmaNo ratings yet

- RA-for Glass Installation 30-04-2022Document6 pagesRA-for Glass Installation 30-04-2022Muideen Oyedele100% (2)

- Project HS Risk Assessment for Sandvik Pvt Ltd Ceiling WorkDocument8 pagesProject HS Risk Assessment for Sandvik Pvt Ltd Ceiling WorkParasNo ratings yet

- Risk Assessment Steel FixingDocument1 pageRisk Assessment Steel Fixingmohamed ghalyNo ratings yet

- Project Baseline Risk Assessment REF DIA61362019RFPDocument26 pagesProject Baseline Risk Assessment REF DIA61362019RFPThandabantu Magengelele100% (1)

- Safe Formwork Erection ProcedureDocument1 pageSafe Formwork Erection ProcedureSiti Norsyazana Abd Majid100% (1)

- Risk Assessment - Wall Reinforcement and FormworkDocument4 pagesRisk Assessment - Wall Reinforcement and FormworkSarfraz Randhawa100% (1)

- Risk Assessment for Canal Construction WorksDocument9 pagesRisk Assessment for Canal Construction WorksAshoka Indunil WickramapalaNo ratings yet

- Risks of Working at Height AssessmentsDocument30 pagesRisks of Working at Height AssessmentsSamboy DionisioNo ratings yet

- Method Statement For Interfacing With The Tarping & De-Tarping Station of 021-c13 Ver.00Document6 pagesMethod Statement For Interfacing With The Tarping & De-Tarping Station of 021-c13 Ver.00bryanNo ratings yet

- Risk Assessment - Concrete CastingDocument3 pagesRisk Assessment - Concrete Castingdnmule50% (2)

- Risk Assessment of WaterproofingDocument7 pagesRisk Assessment of WaterproofingAbdul MujeebNo ratings yet

- Rebar Job Hazard AnalysisDocument1 pageRebar Job Hazard Analysisjoker batmanNo ratings yet

- Environmental, Health and Safety Risk AssessmentDocument2 pagesEnvironmental, Health and Safety Risk AssessmentAdnan100% (2)

- JSA - Civil Compaction WorkDocument4 pagesJSA - Civil Compaction WorkRajuNo ratings yet

- Heavy Lifting Safety ChecklistDocument1 pageHeavy Lifting Safety ChecklistMock ProjectNo ratings yet

- Safe Work Method Statement TemplateDocument3 pagesSafe Work Method Statement TemplateJonasNo ratings yet

- RMDJV-PJ74-HIRADC-SUBE 03 (Installation of Outdoor Equipment)Document2 pagesRMDJV-PJ74-HIRADC-SUBE 03 (Installation of Outdoor Equipment)myn maliQueNo ratings yet

- ZFP Sor 2021-6-9Document5 pagesZFP Sor 2021-6-9Muhammad JamshidNo ratings yet

- JHA For Pipe Work-01.09Document3 pagesJHA For Pipe Work-01.09Anonymous Xb3zHio100% (1)

- Work Method Statement For Sub Structure Works: (Pile Cap)Document9 pagesWork Method Statement For Sub Structure Works: (Pile Cap)AlbawaviNo ratings yet

- AsbestosDocument4 pagesAsbestoskoketsoNo ratings yet

- Risk Assesment For CompactionDocument12 pagesRisk Assesment For CompactionAzhar MushtaqNo ratings yet

- SWMS - PlumberDocument7 pagesSWMS - PlumberSiddiqueShaikhNo ratings yet

- RA - For Precast ChambersDocument5 pagesRA - For Precast ChambersKallem RajashekarNo ratings yet

- Risk Assessment For Demolition WorksDocument5 pagesRisk Assessment For Demolition Worksappu pocom3100% (1)

- Risk assessment for plastering companyDocument3 pagesRisk assessment for plastering companyhello3232No ratings yet

- Accelerometer Sensor Data Analysis of Bridge Structural Health Monitoring SystemDocument7 pagesAccelerometer Sensor Data Analysis of Bridge Structural Health Monitoring Systemshamsukarim2009No ratings yet

- Letter of Appreciation Paper 90 Sharaf AhmadDocument1 pageLetter of Appreciation Paper 90 Sharaf Ahmadshamsukarim2009No ratings yet

- Ces512 Jan 2017Document5 pagesCes512 Jan 2017shamsukarim2009No ratings yet

- Ces512 Jan 2017Document5 pagesCes512 Jan 2017shamsukarim2009No ratings yet

- Understanding What Is Meant by Holistic AssessmentDocument4 pagesUnderstanding What Is Meant by Holistic Assessmentshamsukarim2009No ratings yet

- MATLAB OPTIMIZATION (LINEAR PROGRAMMINGDocument13 pagesMATLAB OPTIMIZATION (LINEAR PROGRAMMINGshamsukarim2009100% (1)

- Jurnal Kemerosotan Aliran SainsDocument9 pagesJurnal Kemerosotan Aliran SainsnamujaNo ratings yet

- CES512 Set 2Document7 pagesCES512 Set 2shamsukarim2009No ratings yet

- CES512 Set 2Document7 pagesCES512 Set 2shamsukarim2009No ratings yet

- Corrosion-Damaged Beam Manuscript ImprovementsDocument3 pagesCorrosion-Damaged Beam Manuscript Improvementsshamsukarim2009No ratings yet

- Holistic Youth Development: A Short Guide ToDocument28 pagesHolistic Youth Development: A Short Guide Toshamsukarim2009No ratings yet

- CIPP BookDocument2 pagesCIPP Bookshamsukarim2009No ratings yet

- Supplementary Lab Sheet No 7. Name of Student: Group: DateDocument3 pagesSupplementary Lab Sheet No 7. Name of Student: Group: Dateshamsukarim2009No ratings yet

- ArticleDocument7 pagesArticleshamsukarim2009No ratings yet

- CES 512: Finite Element Method Introduction, Theory, Applications & ImplementationDocument32 pagesCES 512: Finite Element Method Introduction, Theory, Applications & Implementationshamsukarim2009No ratings yet

- 07 Matrix FrameDocument72 pages07 Matrix FrameAminatul Fadillah MarpaungNo ratings yet

- Understanding What Is Meant by Holistic AssessmentDocument4 pagesUnderstanding What Is Meant by Holistic Assessmentshamsukarim2009No ratings yet

- 2014-04 Motorcycle Parking at StationsDocument14 pages2014-04 Motorcycle Parking at Stationsshamsukarim2009No ratings yet

- Developing Research GapDocument2 pagesDeveloping Research Gapshamsukarim2009No ratings yet

- Program Bengkel CES512Document5 pagesProgram Bengkel CES512shamsukarim2009No ratings yet

- CES 512/513 computational analysis formative assessmentDocument1 pageCES 512/513 computational analysis formative assessmentshamsukarim2009No ratings yet

- Fyp1 184573Document31 pagesFyp1 184573shamsukarim2009No ratings yet

- Service Quotation PretechDocument2 pagesService Quotation Pretechshamsukarim2009No ratings yet

- FEA KeyDocument1 pageFEA Keyshamsukarim2009No ratings yet

- Open 3rd Party Transfer: SuccessfulDocument1 pageOpen 3rd Party Transfer: Successfulshamsukarim2009No ratings yet

- Fyp2 184573Document107 pagesFyp2 184573shamsukarim2009No ratings yet

- Receipt Iem Renewal 2017Document1 pageReceipt Iem Renewal 2017shamsukarim2009No ratings yet

- The Development of Skewness Correction Factor of Bridge SystemDocument3 pagesThe Development of Skewness Correction Factor of Bridge Systemshamsukarim2009No ratings yet

- IEM Renewal 2017Document1 pageIEM Renewal 2017shamsukarim2009No ratings yet

- Transtech Surge Handout Rev2Document44 pagesTranstech Surge Handout Rev2Anonymous 0iYfWI6fNo ratings yet

- Thermal Insulation MonoPanDocument1 pageThermal Insulation MonoPanNihad MohammedNo ratings yet

- 18 - Tds - Emaco r202 NBDocument3 pages18 - Tds - Emaco r202 NBaahtagoNo ratings yet

- Jotun Penguard Express CF TDSDocument5 pagesJotun Penguard Express CF TDSnihad_mNo ratings yet

- General Rules and Guidelines For IMDS Material DatasheetsDocument22 pagesGeneral Rules and Guidelines For IMDS Material DatasheetsVanessa Alves MoreiraNo ratings yet

- Touchwood 2 PK PU Top CoatDocument2 pagesTouchwood 2 PK PU Top CoatmuthukumarNo ratings yet

- Amplify Io 3701Document2 pagesAmplify Io 3701Julio GarcíaNo ratings yet

- TDS 26140 Jotashield Colourlast Silk Euk GBDocument4 pagesTDS 26140 Jotashield Colourlast Silk Euk GBMido AbdoNo ratings yet

- Jotun - Technical Data Sheet - Tankguard Storage - 09.2019Document5 pagesJotun - Technical Data Sheet - Tankguard Storage - 09.2019Victor PomboNo ratings yet

- Jotafloor Sealer: Technical Data SheetDocument1 pageJotafloor Sealer: Technical Data SheetTamerTamerNo ratings yet

- ZR22 Cree SmartCast Technology Spec SheetDocument3 pagesZR22 Cree SmartCast Technology Spec SheetPrimeraEspada, StarkNo ratings yet

- Durable, high-gloss acrylic coating for aggressive exposureDocument5 pagesDurable, high-gloss acrylic coating for aggressive exposureGurdeep Sungh AroraNo ratings yet

- EU HazMat PDF PDFDocument96 pagesEU HazMat PDF PDFMikaela SantosNo ratings yet

- Green Supplier GuideDocument13 pagesGreen Supplier GuideBen GeorgeNo ratings yet

- TDA6107Document20 pagesTDA6107pacoman74No ratings yet

- ANNEXURE 1 - Binding Proposal of CZD2x12XW-CBK030 - de Heus Can Tho 1 - 3834064Document12 pagesANNEXURE 1 - Binding Proposal of CZD2x12XW-CBK030 - de Heus Can Tho 1 - 3834064Thien Nguyenngoc100% (1)

- 80010668Document2 pages80010668Marco MendesNo ratings yet

- Ethylene Glycol Msds PDFDocument2 pagesEthylene Glycol Msds PDFKevinNo ratings yet

- Magelis SCU EngDocument200 pagesMagelis SCU Engrullycosta85No ratings yet

- Phosphoric AcidDocument3 pagesPhosphoric AcidhussainNo ratings yet

- Sensor H2S 0-100ppm Part. No. 2112B2025Document3 pagesSensor H2S 0-100ppm Part. No. 2112B2025Pedro PérezNo ratings yet

- Ethanol SdsDocument6 pagesEthanol SdsRoad BlasterNo ratings yet

- Manual Valves ENI - 15801E05Document516 pagesManual Valves ENI - 15801E05bureqq100% (7)

- P 51Document2 pagesP 51Parashuram ChauhanNo ratings yet

- General Catalogue: State of The ArtDocument82 pagesGeneral Catalogue: State of The Artfroy richmond silverioNo ratings yet

- Aplied Biosystems Step One Plus TR PCR Manual UtilizareDocument320 pagesAplied Biosystems Step One Plus TR PCR Manual UtilizareFlorea RodicaNo ratings yet

- Amine Mixing Tank DatasheetDocument3 pagesAmine Mixing Tank DatasheetGhi TtaNo ratings yet

- Mapi FluidDocument7 pagesMapi FluidkifleNo ratings yet

- DS-050-1-EN - Exertherm - EM Cable Sensor DatasheetDocument1 pageDS-050-1-EN - Exertherm - EM Cable Sensor DatasheetJose Javier Costa LarragaNo ratings yet