Professional Documents

Culture Documents

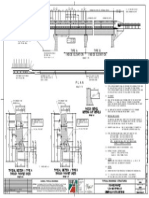

Steel Sheet Piling Specification

Uploaded by

Peter Jean-jacquesOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Sheet Piling Specification

Uploaded by

Peter Jean-jacquesCopyright:

Available Formats

Section 4 Steel Sheet Piling Work

SECTION 4

STEEL SHEET PILING WORK

MATERIALS

Steel sheet pile

sections

4.01

Steel sheet piles shall be weldable structural steel to BS EN 10025 Grade

S275.

Steelwork and accessories for use in the system of lateral support shall be as

Section 15 - Structural Steel Work.

Testing of steel sections and accessories shall be as Section 15 - Structural

Steel Work.

Fabricate special and non-standard sheet piles including corner piles and

junction piles from sheet pile sections approved for use in the Works.

Provide sheet piles in single continuous lengths unless otherwise specified.

INFORMATION TO BE PROVIDED

Tender

submission

4.02

Submit the following information when specified in the tender documents:

(i)

Type of sheet pile proposed including proprietary name, grade of

steel, sectional modulus and qualities.

(ii)

Proposed sequence for installation of sheet piles.

(iii)

Details of special or non-standard piles.

(iv)

Details of initial trenching and guide frames.

(v)

Details of pile driving equipment selected including proprietary

names.

(vi)

Proposed method of pitching and driving piles to the tolerances given

in Clause 4.10.

(vii)

Contingency proposals for the remedy of piles installed outside the

tolerances.

(viii) Detailed calculations of the proposed sheet piles and the system of

lateral support of sheet piles prepared by a Registered Structural

Engineer when specified.

(ix)

Proposed sequence of excavation and installation of system of lateral

support if applicable.

(x)

Proposed system to monitor the effect of excavation and dewatering

on adjacent buildings, pavements, public or private services and any

other structures or permanent features as Clause 4.06.

(xi)

Undertaking that the noise caused by the sheet piling works shall

satisfy the legislation currently in force.

4-1

Section 4 Steel Sheet Piling Work

Provision of

details

before

commencement

of works

4.03

When specified, submit detailed drawings with the method statements

showing:

(i)

The setting out arrangement for construction of the pile wall in

relation to the Site and to adjoining structures. Each pile shall be

annotated with a reference number and length.

(ii)

The sub-division of the pile wall into panels for the purposes of

driving.

(iii)

The location of corner and closure piles.

(iv)

Proposed work on standard piles, e.g. holes for lifting.

(v)

Design for the fabrication of corner, closure, taper and other

non-standard piles.

(vi)

The proposed sequence of driving by panel and by individual pile.

(vii)

Design of the guide frames required at all locations in the Works to

support piles for pitching and driving within required tolerances.

(viii) Design of lateral support if applicable, including details of

connections of walings, strutting, bracing, posts and splicing of

members and sequence of construction and sequence of subsequent

removal if applicable.

Do not change the method of installing sheet piles without approval.

WORKMANSHIP

Preliminary

ground

investigation

4.04

The Contractor shall carry out any additional preliminary ground

investigation he deems necessary to ascertain the nature of the ground and

sub-soil, including the oversite water table level and the nature of the

materials, (whether naturally occurring or otherwise), into which the sheet

piles shall be installed. Allow for liaising with the SO regarding access to

the Site and the execution of ground investigation works. Keep all nuisance

to a minimum and make good drill holes, trial pits etc., after completion in

accordance with the SO's requirements.

Existing

services

4.05

Comply with the following when it is necessary to carry out any work in the

vicinity of utility services:

Monitoring

system and

ground

settlement

4.06

(i)

Advise the relevant utility undertaking at least 7 days before

commencement of the Works.

(ii)

Excavate by hand to a depth sufficient to ascertain the position of

service pipes etc. to ensure that these services are not damaged .

Provide a system to monitor the effects of sheet piling work, subsequent

excavation and dewatering on adjacent buildings, pavements, public or

private services and any other structures or permanent features. The

monitoring system must be adequate to effectively monitor ground

movement.

Do not lower the ground water table level beyond the boundary of the Site

unless otherwise specified, and adopt the approved measures to control and

monitor ground water table levels.

4-2

Section 4 Steel Sheet Piling Work

Pre-load struts or braces and carry out grout injection if required by site

conditions to minimise ground settlement.

Lateral support

4.07

Design by a Registered Structural Engineer when specified, the system of

lateral support to the sheet piles to resist horizontal soil and water pressure

arising from sub-soil conditions.

Construct the system of lateral support as Section 15 - Structural Steel Work

when detailed design is provided.

Install members of the system of lateral support as excavation proceeds in

stages in accordance with the approved construction sequence in the method

statement as Clause 4.03 (viii) or the designed sequence provided,

whichever is applicable.

Marking

4.08

Identify sheet piles on Site by marking with the relevant number in

accordance with the approved drawings of the sheet pile arrangement.

Mark the length on each pile and calibrate the pile at 1 m intervals along the

length to permit checking by the SO.

Welding and

splicing

4.09

Welding shall be in accordance with Section 15 - Structural Steel Work.

Sheet piles not exceeding l2 m long shall be in single lengths. Piles in

excess of l2 m may be spliced with approval. Splice sheet piles by full

strength butt welding and maintain the true vertical alignment.

Form special and non-standard sheet piles by full strength butt welding.

Tolerance

4.10

Install sheet piles within the following tolerances:

(i)

Deviation from the correct line at ground level: Not exceeding 15

mm.

(ii)

Deviation from verticality of individual piles in any direction:

(a)

Generally: Less than 1 : 400.

(b)

For end piles in panels and for guide piles: Less than 1 : 500.

Notwithstanding these specified tolerances, piles shall always be driven to

ensure that the stated dimensions of any permanent structural elements are

not reduced.

Pitching

4.11

Provide rigid guide frames at upper and lower levels on both sides of the

sheet piles. Accurately set out and interlock piles within the guide frames.

Guide frames shall be designed to maintain piles in their true positions

within tolerance during driving.

Driving

4.12

Keep noise and vibration to a minimum when driving sheet piles. Comply

with the legislation currently in force in connection with noise control.

Drive piles to the specified penetration with high frequency vibration pile

drivers. For hard driving only, other methods could be adopted if approved.

Extract and re-drive sheet piles installed outside tolerance. Replace any

extracted piles that the SO considers as unfit for re-driving. Alternatively,

the SO may approve the insertion of taper or other non-standard piles or

other methods of correcting the plumb of piles.

4-3

Section 4 Steel Sheet Piling Work

Drive sheet piles in any length or panel progressively, with the top of no

individual pile exceeding 600 mm below the top of the adjacent piles.

Obstructions

4.13

Advise the SO immediately when obstructions are encountered that prevent

the installation of any sheet piles to the specified penetration.

Adopt an approved method for overcoming the obstruction which,

depending on actual circumstances, may include:

(i)

Withdrawing the sheet piles, excavating for and removing the

obstruction, backfilling and subsequently re-driving the sheet piles.

(ii)

Leaving the sheet piles at the depth of penetration achieved,

excavating for and removing the obstruction, backfilling and

subsequently completing the installation of the sheet piles.

(iii)

Driving the sheet piles on either side of the piles obstructed to the full

penetration specified, removing the obstruction during general

excavation work and subsequently completing the driving of the

piles obstructed. This method of removing obstructions may only be

adopted with the express permission of the SO.

(iv)

Driving through the obstruction under controlled conditions.

Replace any sheet piles damaged through the adoption of this

method.

(v)

Withdrawing and temporarily removing sheet piles, boring through

the obstruction from ground level with approved drilling equipment

and subsequently replacing and re-driving the piles.

Provide temporary propping/bracing to obstructed sheet piles when a

significant length of pile remains above the general top level of adjacent

piles.

Extraction

4.14

Do not extract sheet piles unless otherwise specified.

Burning off

4.15

Burn off the tops of sheet piles driven to full penetration to the level required

when specified.

Burn off the tops of sheet piles damaged by hard driving when so directed.

Sheet pile

record

4.16

Provide the SO with a record, in duplicate, for sheet piles driven the previous

day giving for each pile its identity number and the reference of the rig used.

The following data shall also be included:

(i)

Date sheet pile pitched.

(ii)

Length of completed sheet pile and whether spliced.

(iii)

Type of pile drivers used at all stages to achieve specified

penetration.

(iv)

Depth of penetration below an agreed datum level.

(v)

Details of any driving damage.

(vi)

Alignment of completed sheet pile.

4-4

Section 4 Steel Sheet Piling Work

(vii)

Re-use steel

sheet pile from

other site

4.17

Details of any obstructions encountered and measures adopted for

overcoming the same if applicable.

Re-use of steel sheet piles from other site is permissible if they are used as

temporary works and their physical conditions are considered satisfactory by

the SO.

4-5

You might also like

- Pavment Design GuideDocument54 pagesPavment Design GuideNahomNo ratings yet

- Pipe Jacking & Microtunnelling GuideDocument48 pagesPipe Jacking & Microtunnelling GuideHizbar ArsjadNo ratings yet

- End BlockDocument16 pagesEnd Blockdon2hmrNo ratings yet

- Dokumen - Tips Arahan Teknik Jalan 6 85 Guidelines For Presentation of Engineering DrawingDocument29 pagesDokumen - Tips Arahan Teknik Jalan 6 85 Guidelines For Presentation of Engineering Drawingiris engineeringNo ratings yet

- Joints in Concrete Pavement Technical PaperDocument22 pagesJoints in Concrete Pavement Technical Paperphyo_thar_1100% (1)

- Installation of Steel Sheet PilesDocument2 pagesInstallation of Steel Sheet PilesAdam Lim100% (1)

- Welded Wire Reinforcement WWM WWR Common SizesDocument2 pagesWelded Wire Reinforcement WWM WWR Common Sizesgullipalli100% (1)

- Austroads Guide Geotextiles AP 3 90 1990Document77 pagesAustroads Guide Geotextiles AP 3 90 1990aaaaaNo ratings yet

- Sika Crack Injection Method Statement v4 2021Document19 pagesSika Crack Injection Method Statement v4 2021Jamsheed Ap KadangodNo ratings yet

- Ruukki Splicing of Steel Piles by WeldingDocument8 pagesRuukki Splicing of Steel Piles by Weldingyanickdouce1206100% (1)

- Method Statement For Pad FoundationDocument13 pagesMethod Statement For Pad FoundationAbdul Rahman Hilmi0% (1)

- Body Corporate Guidelines PDFDocument17 pagesBody Corporate Guidelines PDFmaNo ratings yet

- Review of Permeable Pavement Systems in Malaysia ConditionsDocument10 pagesReview of Permeable Pavement Systems in Malaysia ConditionsEkki GustiNo ratings yet

- Rock FillDocument8 pagesRock FillMahmoud Mansour100% (1)

- Supply and Installation of Driven PilesDocument7 pagesSupply and Installation of Driven PilesTAHER AMMARNo ratings yet

- Design and Construction of Microtunneling ProjectsDocument3 pagesDesign and Construction of Microtunneling ProjectsMahmood AliNo ratings yet

- Subgrade and Pavement MaterialsDocument30 pagesSubgrade and Pavement MaterialshimathkumarNo ratings yet

- Registered Eng. Consulting Firms Tanzania 2015Document9 pagesRegistered Eng. Consulting Firms Tanzania 2015Adam Maranja100% (1)

- v2 TD S P 1002 1 F Shape Parapet 1 22m High Type A B General Layout and SectionsDocument1 pagev2 TD S P 1002 1 F Shape Parapet 1 22m High Type A B General Layout and SectionsSudathipTangwongchaiNo ratings yet

- Waterproofing Structures Installed Below Ground Level PDFDocument50 pagesWaterproofing Structures Installed Below Ground Level PDFDirk BummNo ratings yet

- Basics of post-installed rebar connectionsDocument33 pagesBasics of post-installed rebar connectionsHaitham KayyaliNo ratings yet

- 6-Impact of Adhesive Thickness On The Capacity of The Surface Mounting Steel Plates Strengthening TechniqueDocument9 pages6-Impact of Adhesive Thickness On The Capacity of The Surface Mounting Steel Plates Strengthening TechniqueMr A. M. OlajumokeNo ratings yet

- Method Statement For Providing Pipe Sleeve Opening On R.C. BeamDocument1 pageMethod Statement For Providing Pipe Sleeve Opening On R.C. Beamhiyumiwks100% (1)

- Retaining WallDocument22 pagesRetaining WallDr-Moamen Abd El Raouf100% (1)

- Bollards Catalogue en A4 Metric v.2.0 WebDocument20 pagesBollards Catalogue en A4 Metric v.2.0 WebspasmNo ratings yet

- Hy-Rib: Permanent Formwork For Concrete Product BrochureDocument4 pagesHy-Rib: Permanent Formwork For Concrete Product Brochuremeetvisu118No ratings yet

- KDS 41 17 00 건축물 내진설계기준Document131 pagesKDS 41 17 00 건축물 내진설계기준colt0No ratings yet

- KDOT Bridge Design Manual Section on Expansion Joints and BearingsDocument54 pagesKDOT Bridge Design Manual Section on Expansion Joints and BearingsbrelightsNo ratings yet

- QCS 2010 Section 21 Part 30 Duct Bank and Manholes PDFDocument7 pagesQCS 2010 Section 21 Part 30 Duct Bank and Manholes PDFbryanpastor106100% (1)

- Earthwork SpecificationDocument5 pagesEarthwork Specificationmzrosfaizal100% (1)

- CIP 6 Joints in Concrete Slaabs On Grade PDFDocument2 pagesCIP 6 Joints in Concrete Slaabs On Grade PDFAli ParvezNo ratings yet

- Method Statement Geo Technical Investigation: 1. PurposeDocument7 pagesMethod Statement Geo Technical Investigation: 1. PurposeJ. Kumar Infraprojects LtdNo ratings yet

- P 1-11 Storm Drainage PDFDocument11 pagesP 1-11 Storm Drainage PDFMahmoud GwailyNo ratings yet

- U Drain SpecDocument4 pagesU Drain Speckenji_sanNo ratings yet

- Method Statement For Installation of Road Culverts in Water CoursesDocument5 pagesMethod Statement For Installation of Road Culverts in Water Coursesabsalom mkhatshwaNo ratings yet

- Boiling or Heaving in CofferdamsDocument2 pagesBoiling or Heaving in Cofferdamsslawek780303No ratings yet

- Sample Method Statement For Pile DrivingDocument2 pagesSample Method Statement For Pile Drivingaimkcl90No ratings yet

- Professional PracticeDocument3 pagesProfessional Practiceforbeska100% (1)

- RCBC SizesDocument5 pagesRCBC Sizesenggmohan100% (1)

- Aashto Rigid Pavement DesignDocument5 pagesAashto Rigid Pavement DesignJorge Luis MezaNo ratings yet

- Qatar Industrial Area Boundary Works Method StatementsDocument32 pagesQatar Industrial Area Boundary Works Method StatementsSyed Umair HashmiNo ratings yet

- Specification For Pile EmbankmentDocument5 pagesSpecification For Pile EmbankmentamirriyyahNo ratings yet

- Cut and Cover Bridge Construction with Rolling RCC BoxDocument5 pagesCut and Cover Bridge Construction with Rolling RCC BoxradhakrishnangNo ratings yet

- SW Juntas CwsDocument5 pagesSW Juntas CwsflylilaNo ratings yet

- Method Statement for Substructure ExcavationDocument14 pagesMethod Statement for Substructure ExcavationĐărsĥąna RanasingheNo ratings yet

- K017-T12-0003 - 0 Method Statement For Extension Work of Temporary JettyDocument16 pagesK017-T12-0003 - 0 Method Statement For Extension Work of Temporary JettyBayu PutraNo ratings yet

- OKA G45 RC - Square PilesDocument4 pagesOKA G45 RC - Square PilesTee Bun PinNo ratings yet

- Fhwa RD 91 062 PDFDocument122 pagesFhwa RD 91 062 PDFSharath AndeNo ratings yet

- Pile Instalation Methods 2Document9 pagesPile Instalation Methods 2Bright MuzaNo ratings yet

- Do's and Dont's in Civil EngineeringDocument20 pagesDo's and Dont's in Civil EngineeringRam1028100% (1)

- Flexible Vs RigidDocument1 pageFlexible Vs Rigidsilvereyes18No ratings yet

- RTA Spec. - Soil InvenstigationDocument2 pagesRTA Spec. - Soil InvenstigationSheril Chandrabose100% (1)

- Water Storage Tank Construction MethodologiesDocument14 pagesWater Storage Tank Construction Methodologiesadnan-651358No ratings yet

- Lecture 4 - Elevated Circular TankDocument22 pagesLecture 4 - Elevated Circular TankUsama AhmedNo ratings yet

- Road Construction MethodsDocument150 pagesRoad Construction Methodsblaze14911100% (1)

- Microtunneling enDocument7 pagesMicrotunneling enTauha Aziz ShahNo ratings yet

- Hyrib User Guide PDFDocument35 pagesHyrib User Guide PDFYoong Lai YeeNo ratings yet

- Soil Compaction Earthworks - Notes PDFDocument47 pagesSoil Compaction Earthworks - Notes PDFGnabBangNo ratings yet

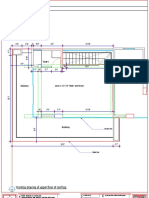

- Architectural DetailsDocument1 pageArchitectural DetailsPeter Jean-jacquesNo ratings yet

- Key To Test DataDocument1 pageKey To Test DataRheymar Dela Rosa DiwaNo ratings yet

- Environmental and Social Management FrameworkDocument107 pagesEnvironmental and Social Management FrameworkPeter Jean-jacquesNo ratings yet

- Acronyms and GlossaryDocument6 pagesAcronyms and GlossaryPeter Jean-jacquesNo ratings yet

- Argos Usa - Cements For MasonryDocument39 pagesArgos Usa - Cements For MasonryPeter Jean-jacques0% (1)

- Equipment: Method of Assessment:: Block Extraction and ExaminationDocument2 pagesEquipment: Method of Assessment:: Block Extraction and ExaminationPeter Jean-jacquesNo ratings yet

- Soil PenetrometerDocument4 pagesSoil PenetrometerPeter Jean-jacquesNo ratings yet

- How To Design A Junction With Civil 3DDocument30 pagesHow To Design A Junction With Civil 3DPeter Jean-jacquesNo ratings yet

- Consistent slope through sidelines prevents muddy football bench areasDocument3 pagesConsistent slope through sidelines prevents muddy football bench areasPeter Jean-jacquesNo ratings yet

- Geotechnical Ckeck and GuidelinesDocument42 pagesGeotechnical Ckeck and GuidelinesPeter Jean-jacquesNo ratings yet

- Keyboard shortcuts for Tekla StructuresDocument2 pagesKeyboard shortcuts for Tekla StructuresUmt KcNo ratings yet

- Design of Custom ElementsDocument5 pagesDesign of Custom ElementsPeter Jean-jacquesNo ratings yet

- Member Assessment Guidance ICEDocument17 pagesMember Assessment Guidance ICEkushar_geoNo ratings yet

- Typical Rebar Detail WeigthDocument3 pagesTypical Rebar Detail WeigthPeter Jean-jacquesNo ratings yet

- Stabilization Work FlowDocument10 pagesStabilization Work FlowPeter Jean-jacquesNo ratings yet

- RICS Standard Form For Consultants AppointmentDocument39 pagesRICS Standard Form For Consultants AppointmentPeter Jean-jacquesNo ratings yet

- Fiona Aish, Collins Get Ready For Ielts Writing (Collins English For Exams)Document135 pagesFiona Aish, Collins Get Ready For Ielts Writing (Collins English For Exams)Inderdeep Singh80% (5)

- Gang Nail Trussed Rafter Manual-WoodDocument49 pagesGang Nail Trussed Rafter Manual-Woodfacagaua100% (1)

- Allowable Bearing PressureDocument2 pagesAllowable Bearing PressureyuegengmingNo ratings yet

- The Wastes of Production in Construction A TFV Based TaxonomyDocument12 pagesThe Wastes of Production in Construction A TFV Based TaxonomyPeter Jean-jacquesNo ratings yet

- Implementing Lean Construction Understanding and ActionDocument9 pagesImplementing Lean Construction Understanding and ActionPeter Jean-jacquesNo ratings yet

- Exploring The Value of Project Management - Linking Project Management Performance and Project SuccessDocument16 pagesExploring The Value of Project Management - Linking Project Management Performance and Project SuccessPeter Jean-jacques100% (1)

- Deadman AnchorDocument1 pageDeadman AnchorPeter Jean-jacquesNo ratings yet

- Soil Classification & PropertiesDocument16 pagesSoil Classification & PropertiesmovorusNo ratings yet

- Sample 842377Document65 pagesSample 842377Peter Jean-jacques100% (2)

- Beg Course AgendaDocument5 pagesBeg Course AgendaPeter Jean-jacquesNo ratings yet

- Effect of Shear Wall Location in Buildings Subjected To Seismic LoadsDocument11 pagesEffect of Shear Wall Location in Buildings Subjected To Seismic LoadsSujtth MathewNo ratings yet

- Steel Design - SAP 2000Document5 pagesSteel Design - SAP 2000Nayolle CoelhoNo ratings yet

- Steel Build Engineering Catalogue PDFDocument6 pagesSteel Build Engineering Catalogue PDFArshalNo ratings yet

- Simple Bridges NicholsonDocument94 pagesSimple Bridges Nicholsonfarhaad shaikNo ratings yet

- The Design of Water PDFDocument7 pagesThe Design of Water PDFSahan Chanchana Perumpuli Arachchi100% (1)

- 3 2.5m Thick Cement Concrete 1:1/1.5:3 Damp Proof Course (DPC)Document7 pages3 2.5m Thick Cement Concrete 1:1/1.5:3 Damp Proof Course (DPC)NATIONAL XEROXNo ratings yet

- Methodology For RCC Rectangular DrainDocument4 pagesMethodology For RCC Rectangular DrainAkash Yadav100% (2)

- VSL News 1997 1Document16 pagesVSL News 1997 1DrPadipat ChaemmangkangNo ratings yet

- Night School 16 Session 8Document62 pagesNight School 16 Session 8LCSNo ratings yet

- Protection Pile Summary and Calculation Sheets PDFDocument35 pagesProtection Pile Summary and Calculation Sheets PDFPrakash Singh RawalNo ratings yet

- Spacelab KunsthausGrazDocument10 pagesSpacelab KunsthausGrazGsha AjkNo ratings yet

- Foundation and Structural DetailsDocument1 pageFoundation and Structural DetailsSi Thu AungNo ratings yet

- Comparative Study of Diagrid Structures Over Braced Tube StructuresDocument9 pagesComparative Study of Diagrid Structures Over Braced Tube StructuresNguyễn Trúc LâmNo ratings yet

- IN Mishra CVDocument9 pagesIN Mishra CVIndra MishraNo ratings yet

- Transformer Plinth For 2.1MWDocument1 pageTransformer Plinth For 2.1MWSarin100% (2)

- Slab layout of penthouse roofDocument2 pagesSlab layout of penthouse roofAbrarNo ratings yet

- The Cyclic Behaviour of Steel Elements and ConnectionsDocument41 pagesThe Cyclic Behaviour of Steel Elements and ConnectionsconeyquNo ratings yet

- Introduction To Fe Modeling of Composite Beam To CFST Column Connection - Phase - 1Document60 pagesIntroduction To Fe Modeling of Composite Beam To CFST Column Connection - Phase - 1Harshil DevaniNo ratings yet

- Aslan TBM Soft Eye Asia Pacific EDocument12 pagesAslan TBM Soft Eye Asia Pacific EpraupdNo ratings yet

- BILL OF MATERIALS FOR PROPOSED MEZZANINEDocument4 pagesBILL OF MATERIALS FOR PROPOSED MEZZANINEPankaj BansalNo ratings yet

- Bill of Materials CalculatorDocument8 pagesBill of Materials Calculatorgreen stringNo ratings yet

- AS 5100.2 Supplement 1-2007: Bridge Design-Design Loads - Commentary (Supplement To AS 5100.2-2004)Document81 pagesAS 5100.2 Supplement 1-2007: Bridge Design-Design Loads - Commentary (Supplement To AS 5100.2-2004)AndyNo ratings yet

- Design and check of reinforced concrete according to EurocodesDocument4 pagesDesign and check of reinforced concrete according to EurocodesMuscadin MakensonNo ratings yet

- Hilti CatalougeDocument7 pagesHilti CatalougeumashankarsinghNo ratings yet

- Fatigue Provision in IRS Girder Vs InternationalDocument27 pagesFatigue Provision in IRS Girder Vs Internationalpant_tcNo ratings yet

- TN-326 Average Pre CompressionDocument3 pagesTN-326 Average Pre CompressionPartha Pratim RoyNo ratings yet

- Towards Improvement in Facilities Operation and Maintenance Through Feedback To The Design TeamDocument16 pagesTowards Improvement in Facilities Operation and Maintenance Through Feedback To The Design TeamGebremeskel TigabuNo ratings yet

- Refsheet-My-Thuan-II-Bridge-ENDocument1 pageRefsheet-My-Thuan-II-Bridge-ENIndra Nath MishraNo ratings yet

- Bid Addendum Report: 105 Road Division BiratnagarDocument8 pagesBid Addendum Report: 105 Road Division Biratnagarnitish JhaNo ratings yet