Professional Documents

Culture Documents

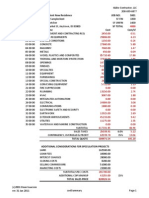

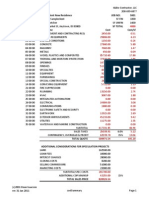

Sample Pages Build Cost

Uploaded by

ArunKumarVermaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sample Pages Build Cost

Uploaded by

ArunKumarVermaCopyright:

Available Formats

The Scientific Costing Guide

T

S

O

C

Build

Building Construction Cost Data

Item of Work Cost Database

2014

Unit Price Section - Table of Contents

Div. No.

01

01 45

01 45 23

02

02 32

02 32 19

02 41

02 41 13

03

03 05

03 05 13

03 11

03 11 13

03 15

GENERAL REQUIREMENTS

Quality Control

Title

1

3

Div. No.

Title

06

WOOD, PLASTICS, AND COMPOSITES

06 17

Shop-Fabricated Structural Wood

Testing and Inspecting Services

06 17 53

EXISTING CONDITIONS

Geotechnical Investigations

06 22

06 22 13

06 26

06 26 13

06 42

11

06 42 10

Exploratory Excavations

Demolition

Selective Site Demolition

CONCRETE

Common Work Results for Concrete

Basic Concrete Materials

Concrete Forming

Structural Cast-in-Place Concrete Forming

Page

13

06 43

13

06 43 13

13

06 48

13

06 48 16

15

07

03 15 05

Concrete Forming Accessories

16

07 11

03 15 13

Waterstops

16

07 11 17

03 21

03 21 10

03 22

03 22 05

03 31

03 31 05

03 35

03 35 29

03 41

Concrete Accessories

Reinforcing Bars

Uncoated Reinforcing Steel

Welded Wire Fabric Reinforcing

Uncoated Welded Wire Fabric

Structural Concrete

Normal Weight Structural Concrete

Concrete Finishing

Tooled Concrete Finishing

17

07 13

17

07 13 13

17

07 16

17

07 16 16

17

07 21

17

07 21 14

21

07 22

21

07 22 16

21

07 26

03 41 05

Precast Concrete Members

21

07 26 10

03 41 16

Precast Concrete Slabs

23

07 32

23

07 32 13

23

07 41

25

07 41 13

03 45

03 45 13

04

04 21

04 21 13

04 22

04 22 10

04 23

04 23 13

04 43

04 43 10

05

05 05

05 05 23

05 12

05 12 23

05 51

05 51 16

05 55

05 55 13

05 73

05 73 23

06

06 11

06 11 10

Precast Structural Concrete

Precast Architectural Concrete

Faced Architectural Precast Concrete

MASONRY

Clay Unit Masonry

27

07 41 34

27

08

Concrete Unit Masonry

31

08 09

Concrete Masonry Units

31

08 09 16

Brick Masonry

Glass Unit Masonry

Vertical Glass Unit Masonry

Stone Masonry

Stone Masonry

METALS

Common Work Results for Metals

Metal Fastenings

Structural Steel Framing

Structural Steel for Buildings

Metal Stairs

Metal Floor Plate Stairs

Metal Stair Treads and Nosings

Metal Stair Treads

Decorative Metal Railings

Ornamental Railings

WOOD, PLASTICS, AND COMPOSITES

Wood Framing

Wood Framing

32

08 09 21

32

08 12

33

08 12 21

33

08 14

39

08 14 50

41

08 33

41

08 33 23

41

08 33 33

41

08 44

41

08 44 13

41

08 71

42

08 71 20

42

09

42

09 21

42

09 21 13

43

09 22

45

09 22 26

45

Shop-Fabricated Wood Trusses

Millwork

Standard Pattern Wood Trim

Board Paneling

Profile Board Paneling

Wood Paneling

Wood Paneling

Wood Stairs and Railings

Wood Stairs

Wood Frames

Interior Wood Door Frames

THERMAL AND MOISTURE PROTECTION

Dampproofing

Damp-Proof Course

Sheet Waterproofing

Bituminous Sheet Waterproofing

Cementitious And Reactive Waterproofing

Crystalline Waterproofing

Page

43

45

45

45

45

46

46

46

46

47

47

47

47

49

51

51

51

51

52

52

Thermal Insulation

55

Building Insulation

56

Roof and Deck Insulation

Roof Board Insulation

56

57

Vapor Retarders

57

Vapor Retarders

57

Roof Tiles

Clay Roof Tiles

Roof Panels

57

57

58

Metal Roof Panels

58

Asbestos Roof Panels

60

OPENINGS

Metal Doors, Windows And Frames

61

Aluminum Doors, Windows and Frames

63

Steel Doors, Windows and Frames

63

63

Metal Frames

64

Steel Frames

64

Wood Doors

Wood Shutters

Coiling Doors and Grilles

65

65

69

Overhead Coiling Doors

69

Side Coiling Doors

69

Curtain Wall and Glazed Assemblies

Glazed Aluminum Curtain Walls

Door Hardware

Hardware

FINISHES

Plaster and Gypsum Board Assemblies

Plaster Assemblies

Supports for Plaster & Gypsum Board

Suspension Systems

69

69

71

71

77

79

79

79

79

Unit Price Section - Table of Contents

Div. No.

Title

09

FINISHES

09 23

Gypsum Plastering

09 23 20

09 24

Gypsum Plaster

Portland Cement Plastering

Page

80

Div. No.

Title

22

PLUMBING

22 12

Facility Potable-Water Storage Tanks

22 12 23

Facility Indoor Potable-Water Storage Tanks

80

22 13

77

80

Facility Sanitary Sewerage

Page

115

126

126

127

09 24 20

Portland Cement Plaster

80

22 13 16

Sanitary Waste and Vent Piping

127

09 24 26

Pointing On Walls And Floors

82

22 13 23

Sanitary Waste Interceptors

136

83

22 33

83

84

22 33 30

22 41

09 28

09 28 13

09 30

Backing Boards and Underlayments

Cementitious Backing Boards

TILING

Electric Domestic Water Heaters

Residential, Electric Domestic Water Heaters

Residential Plumbing Fixtures

136

136

136

09 30 10

Precast Pre-polished Tiling

84

22 41 13

Residential Water Closets, Urinals, & Bidets

136

09 30 13

Ceramic Tiling

84

22 41 16

Residential Lavatories and Sinks

139

09 30 23

Glass Mosaic Tiling

85

22 41 19

Residential Bathtubs

141

09 30 35

Terrazo Tiling

86

22 41 39

Residential Faucets, Supplies, and Trim

141

86

22 42

09 51

09 51 23

09 63

Acoustical Ceilings

Acoustical Tile Ceilings

Masonry Flooring

86

87

22 42 13

23

09 63 13

Brick Flooring

87

23 07

09 63 30

Marble Flooring

87

23 07 13

09 63 35

Granite Flooring

93

23 09

09 63 40

Stone Flooring

09 64

09 64 16

09 65

09 65 16

09 66

09 66 13

09 91

09 91 13

09 91 23

10

10 14

10 14 53

10 28

10 28 16

10 44

Wood Flooring

Wood Block Flooring

Resilient Flooring

Resilient Sheet Flooring

Terrazzo Flooring

Portland Cement Terrazzo Flooring

Painting

Exterior Painting

Interior Painting

SPECIALTIES

Signage

Traffic Signage

Toilet, Bath, and Laundry Accessories

Bath Accessories

94

97

Commercial Plumbing Fixtures

Commercial Water Closets, Urinals, & Bidets

HEATING, VENTILATING, AND AIR

CONDITIONING (HVAC)

HVAC Insulation

Duct Insulation

Instrumentation and Control for HVAC

23 09 33

Electric and Electronic Control System for HVAC

23 09 53

Pneumatic and Electric Control System for HVAC

151

Hydronic Pumps

152

98

23 21 24

Hydronic Piping

98

23 31

100

23 31 13

100

23 33

101

23 33 11

105

23 34

107

23 34 11

107

23 41

107

23 41 13

107

23 52

HVAC Ducts and Casings

Metal Ducts

Air Duct Accessories

Air Duct Accessories

HVAC Fans

Fans

Particulate Air Filtration

23 64

111

22 05 23

22 05 76

22 11

General-Duty Valves for Plumbing Piping

Facility Drainage Piping Cleanouts

Facility Water Distribution

161

164

165

109

PLUMBING

Common Work Results for Plumbing

161

161

164

Fire Extinguishers

22 05

161

161

165

10 44 16

22

159

161

Panel Air Filters

Cast-Iron Boilers

Wet-Pipe Sprinkler Systems

151

Heating Boilers

Electric Boilers

Fire-Suppression Sprinkler Systems

151

23 21 23

23 52 23

21 13 13

148

98

23 52 13

21 13

148

Hydronic HVAC Piping Specialties

Hydronic Piping and Pumps

109

Fire-Suppression Hoses and Nozzles

147

23 21

109

21 12 13

147

23 21 20

Fire Extinguisher Cabinets

FIRE SUPPRESSION

Fire-Suppression Standpipes

145

98

Fire Protection Specialties

21 12

143

97

10 44 13

21

143

165

Packaged Water Chillers

166

23 64 10

Packaged Water Chillers

166

113

23 64 13

Absorption Water Chillers

113

23 65

113

23 65 11

114

23 73

115

23 73 13

117

23 74

117

23 74 33

119

23 76

120

23 76 13

22 11 13

Facility Water Distribution Piping

120

23 81

22 11 19

Domestic Water Piping Specialties

126

23 81 19

Cooling Towers

Cooling Towers

Indoor Central-Station Air-Handling Units

Modular Indoor Central-Station Air-Handling Unit

168

170

170

171

171

Packaged Outdoor HVAC Equipment

172

Packaged, Outdoor, Heating and Cooling

Makeup Air-Conditioners

172

Evaporative Air-Cooling Equipment

172

Direct Evaporative Air Coolers

Decentralized Unitary HVAC Equipment

Self-Contained Air-Conditioners

172

173

173

Unit Price Section - Table of Contents

Div. No.

Title

23

HEATING, VENTILATING, AND AIR

23 81

23 81 26

23 82

CONDITIONING (HVAC)

Decentralized Unitary HVAC Equipment

Split-System Air-Conditioners

Convection Heating and Cooling Units

Page

145

Div. No.

Title

32

EXTERIOR IMPROVEMENTS

32 11

173

32 11 23

Aggregate Base Courses

251

174

32 11 26

Asphaltic Base Courses

251

23 82 16

Air Coils

174

32 12

Fan Coil Units

175

32 12 16

177

32 13

26 05

ELECTRICAL

Common Work Results for Electrical

179

32 13 13

26 05 13

Medium -Voltage Cables

179

32 14

26 05 19

Low-Voltage Electrical Power Conductors and

Cables

185

32 14 13

26 05 26

Grounding & Bonding for Electrical Systems

26 05 29

Hangers & Supports for Electrical Systems

194

32 16 13

26 05 33

Raceway and Boxes for Electrical Systems

194

32 31

26 05 36

Cable Trays for Electrical Systems

196

32 31 13

26 05 90

Residential Wiring

199

33

219

33 11

219

33 11 13

220

33 36

26 24

26 24 13

26 27

26 27 26

26 28

26 28 16

26 41

26 41 13

26 51

26 51 13

27

27 15

27 15 10

28

28 31

28 31 23

31

31 11

31 11 10

31 14

31 14 13

31 22

31 22 16

31 23

Switchboards and Panelboards

Switchboards

Low-Voltage Distribution Equipment

Wiring Devices

Low-Voltage Circuit Protective Devices

Enclosed Switches and Circuit Breakers

Facility Lightning Protection

Lightning Protection for Structures

Interior Lighting

Interior Lighting Fixtures, Lamps, & Ballasts

COMMUNICATIONS

Communications Horizontal Cabling

Special Communications Cabling

ELECTRONIC SAFETY AND SECURITY

Fire Detection and Alarm

Fire Detection and Alarm Annunciation Panels

and Fire Stations

193

33 36 13

223

33 41

223

33 41 13

230

33 44

230

33 44 13

230

230

233

235

235

237

239

239

241

Clearing and Grubbing

243

Soil Stripping and Stockpiling

Grading

Fine Grading

Excavation and Fill

243

243

243

243

243

243

31 23 16

Excavation

243

31 23 19

Dewatering

245

31 23 23

Fill

245

31 31

31 31 16

31 50

31 50 13

31 62

31 62 13

31 63

31 63 23

Soil Treatment

246

Termite Control

246

EXCAVATION SUPPORT and

PROTECTION

Excavation Support And Protection

Driven Piles

Concrete Piles

Bored Piles

Bored Concrete Piles

32 16

220

EARTHWORK

Clearing and Grubbing

Earth Stripping and Stockpiling

249

173

23 82 19

26

Page

246

246

247

247

247

247

Base Courses

Flexible Paving

Asphalt Paving

Rigid Paving

Concrete Paving

Unit Paving

Precast Concrete Unit Paving

Curbs, Gutters, Sidewalks, And Driveways

Curbs And Gutters

Fences and Gates

Chain Link Fences and Gates

UTILITIES

Water Utility Distribution Piping

Public Water Utility Distribution Piping

Utility Septic Tanks

Utility Septic Tank and Effluent Wet Wells

Storm Utility Drainage Piping

Public Storm Utility Drainage Piping

Storm Utility Water Drains

Utility Area Drains

251

252

252

253

253

253

253

254

254

254

254

257

259

259

268

268

269

269

271

271

BuildCOST

01 45

01 45 23

GENERAL REQUIREMENTS

Quality Control

Testing And Inspecting Services

BARE COST

UNIT

Material

21

Equipment

TOTAL

TOTAL INCL

OHP

Pile Test

10005

Vertical load testing ( INITIAL ) of piles in

accordance with IS 2911 (Part IV) including

installation of loading platform / or reaction piles

and preparation of pile head or construction of

test cap and dismantling of test cap after test

etc. to 150% of designed load, complete, of pile

capacities :

upto 50 ton

/test

36,000.00

36,000.00

41,400.00

/test

73,125.00

73,125.00

84,093.75

add for every additional 50 ton or part thereof

/test/50 t

36,000.00

36,000.00

41,400.00

Vertical load testing ( ROUTINE ) of piles in

accordance with IS 2911 (Part IV) including

installation of loading platform / or reaction piles

and preparation of pile head or construction of

test cap and dismantling of test cap after test

etc. to 150% of designed load, complete, of pile

capacities :

Upto 50 ton

/test

36,000.00

36,000.00

41,400.00

/test

73,125.00

73,125.00

84,093.75

10010

above 50 ton and upto 100 ton

10015

10020

10025

above 50 ton and upto 100 ton

10030

add for every additional 50 ton or part thereof

/test/50 t

29,812.50

29,812.50

34,284.38

10035

Cyclic vertical load testing of pile in accordance

with IS:2911 (part IV) including preparation of pile

head etc., to 150% of designed load, complete,

of pile capacities :

upto 50 ton

/test

36,000.00

36,000.00

41,400.00

/test

73,125.00

73,125.00

84,093.75

10040

above 50 t and upto 100 ton

10045

add for every additional 50 ton or part thereof

/test/50 t

36,000.00

36,000.00

41,400.00

10050

Lateral load testing of single pile in accordance

with IS:2911 (Part IV) to 150% of designed load,

complete, of pile capacities :

upto 50 ton

/test

36,000.00

36,000.00

41,400.00

/test

63,562.50

63,562.50

73,096.88

36,000.00

36,000.00

41,400.00

36,000.00

36,000.00

41,400.00

73,125.00

84,093.75

10055

10060

10065

50

Labour

Above 50 ton and upto 100 ton

Add for every additional 50 ton or part /test/50 t

thereof.

Vertical load

testing ( INITIAL ) of piles

in

accordance with IS 2911 (Part IV) including

installation of loading plateform / or reaction piles

and preparation of pile head or construction of

test cap and dismantling of test cap after test

etc. to 250% of designed load complete, of pile

capacities :

upto 50 ton

/test

10070

above 50 ton and upto 100 ton

/test

73,125.00

10075

add for every additional 50 ton or part thereof

/test/50 t

36,000.00

36,000.00

41,400.00

10080

Vertical load

testing ( ROUTINE ) of piles

in

accordance with IS 2911 (Part IV) including

installation of loading plateform / or reaction piles

and preparation of pile head or construction of

test cap and dismantling of test cap after test

etc. to 250% of designed load, complete, of pile

capacities :

upto 50 ton

/test

36,000.00

36,000.00

41,400.00

/test

59,062.50

59,062.50

67,921.88

/test/50 t

36,000.00

36,000.00

41,400.00

10085

above 50 ton and upto 100 ton

10090

add for every additional 50 ton or part thereof

Testing

Conducting

laboratory

tests

at

approved

laboratory, including preparation and taking of

samples to laboratory, testing of samples and

getting and submitting test results :

BuildCOST

01 45

01 45 23

GENERAL REQUIREMENTS

Quality Control

Testing And Inspecting Services

BARE COST

UNIT

Material

Labour

Equipment

TOTAL

TOTAL INCL

OHP

10005

Compressive strength test on rock samples

/test

3,150.00

3,150.00

3,622.50

10010

Chemical analysis of soil samples

/test

2,812.50

2,812.50

3,234.38

10015

Chemical analysis of water samples

/test

2,812.50

2,812.50

3,234.38

BuildCOST

02 32

02 32 19

EXISTING CONDITIONS

Geotechnical Investigations

Exploratory Excavations

BARE COST

UNIT

Material

17

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Test Pit

10005

10010

10015

10020

10025

10030

10035

10040

02 41

02 41 13

Drilling 150 mm diameter bore holes in all type of

soils by manual auguring, conducting standard

penetration

tests,

collecting

disturbed

and

undisturbed soil samples, conducting necessary

laboratory tests, recommending suitable type of

foundation and allowable bearing pressure and

submission of report in three copies :

Ground

level

to

6.0 m

or

refusal,

whichever is earlier

Over 6.0 m and upto 10.0 m or refusal,

whichever is earlier

Over 10.0 m and upto 12.0 m or refusal,

whichever is earlier

Drilling 150 mm diameter bore holes in all type of

soils by Calyx drilling, conducting standard

penetration

tests,

collecting

disturbed

and

undisturbed soil samples, conducting necessary

laboratory tests, recommending suitable type of

foundation and allowable bearing pressure and

submission of report in three copies :

Ground level to 6.0 m or refusal, which is

earlier

Over 6.0 m and upto 10.0 m or refusal,

which is earlier

Over 10.0 m and upto 12.0 m or refusal,

which is earlier

Drilling 100 mm dia bore hole in rock using

double

core

barrel

Diamond/TC

including

recovery

of

cores,

wherever

possible

and

keeping a log of the same :

Weathered / disintegrated rock

Hard rock

393.75

393.75

452.81

427.50

427.50

491.63

506.25

506.25

582.19

900.00

900.00

1,035.00

956.25

956.25

1,099.69

1,012.50

1,012.50

1,164.38

2,025.00

2,025.00

2,328.75

4,725.00

4,725.00

5,433.75

Demolition

Selective Site Demolition

BARE COST

UNIT

Material

21

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Concrete / Rcc / Masonry Demolition

10005

10010

10015

10020

Demolishing

lime

concrete

/

cement

concrete in all mixes, in foundations, super

structure and basement, at all heights /

depths, including disposal of unserviceable

materials upto a 50 m lead.

Demolishing RCC work in foundations, super

structure and basement, at all heights /

depths,

including

cutting,

straightening

scrapping,

cleaning

and

stacking

of

reinforcement

bars

and

disposal

of

unserviceable materials upto a 50 m lead.

Demolishing RB work in foundations, super

structure and basement, at all heights /

depths,

including

cutting,

straightening

scrapping,

cleaning

and

stacking

of

reinforcement

bars

and

disposal

of

unserviceable materials upto a 50 m lead.

Dismantling / Demolishing brick work in

cement / lime mortar in foundations, super

structure and basement, at all heights /

depths,

including

removing

of

mortar ,

cleaning bricks and stacking of serviceable

materials and disposed of unserviceable

materials upto 50 m lead

cum

203.25

203.25

233.74

cum

833.33

833.33

958.32

cum

757.58

757.58

871.21

cum

925.93

925.93

1,064.81

BuildCOST

02 41

02 41 13

EXISTING CONDITIONS

Demolition

Selective Site Demolition

BARE COST

UNIT

Material

10025

22

Equipment

TOTAL

TOTAL INCL

OHP

cum

581.40

581.40

668.61

sqm

38.53

38.53

44.31

sqm

57.80

57.80

66.47

sqm

77.21

77.21

88.79

sqm

38.53

38.53

44.31

sqm

19.14

19.14

22.01

sqm

29.29

29.29

33.68

sqm

35.98

35.98

41.37

sqm

62.98

62.98

72.42

Ceiling Demolition

10005

10010

Dismantling false ceiling, partitions, wall lining,

etc supported / fixed to wooden / aluminium /

metal frame including dismantling of frame,

stacking of serviceable material and disposal of

unserviceable material upto a 50 m lead, with :

Plaster of Paris /Gypsum / Plywood / Block

board / Particle board / MDF sheets / tiles

Wooden planks

10015

Glass / Mirror / Fabric / Extruded metal

10020

Asbestos

board

24

cement,

celotax

or

other

hard

Flooring Demolition

10005

10010

10015

10020

Dismantling tile work in

cement mortar/lime mortar

serviceable

material

unserviceable material upto

thickness :

10 mm to 25 mm

floors and roofs

including stacking

and

disposal

a lead of 50 m,

in

of

of

of

over 25 mm and upto 40 mm

Dismantling dry brick pitching in floors,

drains etc, including stacking of serviceable

materials and disposal of unserviceable

materials within a 50 m lead.

Dismantling stone slab flooring in cement

mortar / lime mortar, including stacking of

serviceable

materials

and

disposal

of

unserviceable materials within a 50 m lead.

Demolition of flooring including stacking of

serviceable

materials

and

disposal

of

unserviceable materials upto a 50m lead, with :

Parquet flooring

sqm

22.00

22.00

25.30

10030

PVC flooring

sqm

5.00

5.00

5.75

10035

Carpet flooring

sqm

5.00

5.00

5.75

10025

25

Framing Demolition

10005

Dismantling woodwork in frames, trusses, purlins

and rafters upto a 10 metres span and 5 metres

height including stacking the material within a 50

m lead, of sectional areas :

upto 4000 sqmm

10010

over 4000 sqmm

10015

Dismantling steel work in built up sections at

all heights and depths, in angles, tees, flats,

channels and tubes including all gusset

plates, bolts, nuts, cutting

rivets, welding

etc. including dismembering and stacking

within 50 m lead.

Dismantling steel work in single sections at

all

heig h t s

and

depths

including

dismembering and stacking within a 50 m

lead.

10020

26

Dismantling

/

demolishing

stone

rubble

masonry in cement / lime mortar in

foundations, super structure and basement

at all heights / depths including stacking of

serviceable

materials

and

disposal

of

unserviceable materials upto a 50 m lead.

Labour

4.80

4.80

5.52

cum

1,200.00

1,200.00

1,380.00

Quintal

145.00

145.00

166.75

Quintal

87.00

87.00

100.05

Lining Dismantling

Dismantling and removing wooden boardings in

lining

of

walls

and

partitions,

excluding

supporting members, but including stacking

BuildCOST

03 05

03 05 13

CONCRETE

Common Work Results For Concrete

Basic Concrete Materials

BARE COST

UNIT

Material

20

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Admixture, Concrete

10005

Providing and mixing admixtures, conforming to

IS:9103,

in

recommended

proportions,

in

concrete :

Accelerating admixtures

kg

43.85

5.00

48.85

56.18

51.54

59.27

10010

Retarding admixtures

kg

46.54

5.00

10015

Air entraining admixture

kg

43.18

5.00

48.18

55.40

10020

Water

reducing

(Plasticizer/Super Plasticizer)

admixtures

kg

64.08

5.00

69.08

79.45

Providing

and

mixing

water

proofing

compound, conforming to IS:2645, in cement

concrete/reinforced concrete works.

kg

60.45

5.00

65.45

75.27

21

Concrete Additives

10005

03 11

03 11 13

18

Concrete Forming

Structural Cast-in-place Concrete

Forming

BARE COST

UNIT

Material

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Forms In Place

10005

10010

10015

10020

10025

10030

10035

10040

10045

10050

10055

Providing and fixing centering and shuttering for

concrete work (plain and reinforced) in following

locations, including strutting, propping, bracing,

bolting tie bolt / spring coil / plastic cone ,

wedging, easing, striking, removal etc, complete.

Allow

for

forming

grooves,

drips,

throats ,

chamfers, cut-outs, openings etc. where called

for and for dressing with approved shuttering oil

to prevent adhesion. The works are at all levels .

The floor height is up to 4.00 m :

Sides of footings of columns and walls and

sides of base slabs.

Foundation beams, floor channels,

kerb

stones and drain walls.

Sides of columns, piers and pedestals of any

shape, size and profile.

Sides of walls, retaining walls, attached

columns, pilasters.

Soffits and sides of beams, plinth beams,

lintels, ties, ribs, pergolas and such other,

string courses, cornices, corbels.

Sides of facias, parapets, railings, planting

boxes and such other vertical elements.

Soffits and sides of suspended slabs, floor

and

roof

projections,

landing

slabs ,

canopies, chajjas, slabs of planting boxes

and such other horizontal elements, coffer

ribs and slabs.

Soffits and sides of waist slabs of stairs ,

sides of risers and stepped waist slabs ,

spiral staircases, etc.

Sides of mullions, suspenders, struts, ties,

slings including flarings or taperings of any

shape and profile.

Soffits of inclined slabs and ramps, folded

plates. ( slopes more than 15o and upto 45o)

Arches, archribs, domes, shells, vaults, etc.

10060

Well Steinings

10065

Vertical and horizontal

forming boxes

Chimney shafts

10070

fins

individually

or

sqm

68.20

63.00

131.20

150.88

sqm

68.20

63.00

131.20

150.88

sqm

82.92

199.98

282.90

325.34

sqm

66.93

180.72

247.65

284.79

sqm

70.41

144.00

214.41

246.57

sqm

63.50

252.09

315.59

362.93

sqm

70.12

199.98

270.10

310.62

sqm

54.26

218.97

273.23

314.22

sqm

74.07

413.82

487.89

561.07

sqm

72.24

252.09

324.33

372.98

sqm

321.38

437.90

759.27

873.16

sqm

68.61

968.34

1,036.95

1,192.49

sqm

63.50

252.09

315.59

362.93

sqm

66.93

180.72

247.65

284.79

13

BuildCOST

04 21

04 21 13

MASONRY

Clay Unit Masonry

Brick Masonry

BARE COST

UNIT

Material

46

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Brick Work, Conventional Bricks

10005

10010

10015

10020

10025

10030

10035

10040

10045

10050

10055

10060

10065

10070

10075

10080

10085

10090

10095

Providing brick work with bricks of class 75,

joints finished flush/raked to 12 mm depth, cured

including

necessary

scaffolding

complete

in

cement mortar 1:6 with coarse sand, in :

Foundations and plinths (1.5 m below and

cum

upto 1.2 m above GL)

Superstructures upto 20.0 m above plinth

cum

level.

Basement, under ground water tank and the

cum

like, upto 7.0 m below GL

Arches,

vaults,

domes,

etc.,

in

super

cum

structures/basements and the like in cement

mortar 1:3 with coarse sand including

centering,

shuttering,

struting,

proping ,

wedging,

bolting

and

removal,

etc. ,

complete.

Add for every additional 4.0 m height or part

cum

thereof for brick work/exposed brick work

beyond 7.0 m below GL

Add for every additional 20.0 m height or

cum

part thereof for brick work/exposed brick

work beyond 20.0 m above plinth level

Add for brick work in cement mortar 1:4 in

cum

place of 1:6

Add for brick work in cement mortar 1:3 in

cum

place of 1:6

Deduct for brick work in cement mortar with

cum

fine sand in place of coarse sand

Add for brick work/exposed brick work in

cum

square or rectangular pillars

Add for brick work, curved in plan/elevation,

cum

upto mean radius not exceeding 6.0 m

Add for cutting or chamfering the bricks to

m

required shape in masonry work

Deduct for using bricks of class 50 in place

cum

of class 75

Providing 70 mm thick and 57 mm projected

m

string course/ band with bricks of class 75 in

cement mortar 1:4 with coarse sand

Providing and making mouldings, cornices & 100 mm/m

corbels with bricks of class 75 in cement

mortar 1:4 with coarse sand (girth to be

measured in mm and length in running

metres)

Providing brick work with bricks of class 75 in

half brick thick walls in any shape and profile

including curvilinear, laid in cement mortar 1:4

with coarse sand, joints finished flush/raked to 12

mm depth, cured, including scaffolding and flat

reinforcement (25 x 3 mm) at every fourth course

and

embedding

the

same

in

adjoining

masonry/columns by drilling holes etc complete :

Super structure upto 20.0 m above plinth

sqm

level.

Basements, and the like, upto 7.0 m below

sqm

GL

Arches, domes, vaults at all levels in cement

sqm

mortar 1:3 with coarse sand including

centring and shuttering strutting, propping,

bolting and removal complete. (Flat iron

reinforcement 25 x 3 mm not to be provided)

Add for every 4.0 m height or part thereof for

sqm

27

2,629.27

699.25

22.50

3,351.02

3,853.68

2,629.27

1,339.85

70.20

4,039.32

4,645.22

2,629.27

983.53

38.18

3,650.98

4,198.62

3,713.71

2,037.04

58.32

5,809.07

6,680.43

187.98

187.98

216.17

373.13

373.13

429.09

182.00

182.00

209.30

364.00

364.00

418.60

99.33

99.33

114.23

256.75

256.75

295.26

144.18

223.70

367.88

423.06

10.45

10.45

12.02

172.28

172.28

198.12

11.36

6.59

0.29

18.24

20.97

10.56

7.41

0.28

18.25

20.98

397.39

158.23

5.04

560.65

644.75

397.39

129.39

5.58

532.35

612.21

653.54

607.37

5.58

1,266.48

1,456.45

21.55

21.55

24.78

BuildCOST

05 05

05 05 23

METALS

Common Work Results For Metals

Metal Fastenings

BARE COST

UNIT

Material

10

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Bolts & Hex Nuts

10005

88

Providing and fixing MS bolts upto 300 mm

in length including nuts and washers,

complete.

kg

47.72

22.80

70.52

81.10

236.00

236.00

271.40

3.00

3.00

3.45

178.00

178.00

204.70

2.50

2.50

2.88

Welding

10005

10010

10015

10020

05 12

05 12 23

Gas welding including mobilization at site , 10 mm/m

complete, (for designed structural welding).

Gas welding including mobilization at site , 10 mm

complete, (for non structural welding).

Electric arc welding including mobilization at 10 mm/m

site,

complete

(for

designed

structural

welding).

Electric arc welding including mobilization at 10 mm

site, complete (for non structural welding).

Structural Steel Framing

Structural Steel For Buildings

BARE COST

UNIT

Material

23

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Structural Steel Built Up Section

Providing, fabricating and erecting built up steel

tubular trusses, welded and bolted including

special shaped washers, etc. and applying a

primer coat of zinc chromate on duly prepared

surfaces, complete :

Hot finished, welded tubes

kg

85.74

19.19

104.92

120.66

10010

Hot finished, seamless tubes

kg

110.23

19.19

129.42

148.83

10015

Electric resistance or induction welded tubes

kg

102.44

19.19

121.62

139.87

10020

Providing, fabricating and erecting bolted

structural steel built up sections, trusses and

frames and applying a primer coat of zinc

chromate

on

duly

prepared

surfaces ,

complete.

Providing, fabricating and erecting welded

structural steel built up sections in trusses

and frames and applying a primer coat of

zinc chromate on duly prepared surfaces ,

complete.

Providing and applying three finish coats of

synthetic enamel paint on steel surfaces ,

complete.

kg

51.29

13.49

64.77

74.49

kg

53.73

9.10

62.83

72.26

2,457.53

47.45

2,504.98

2,880.72

kg

58.16

7.57

65.73

75.58

kg

48.78

6.50

55.28

63.58

10005

10025

10030

81

sqm

Structural Steel Single Section

10005

10010

05 51

05 51 16

Providing, fabricating and erecting structural

steel, single sections, and applying a primer

coat of zinc chromate on duly prepared

surfaces, complete.

Providing and fixing wind ties of MS section

Metal Stairs

Metal Floor Plate Stairs

BARE COST

UNIT

Material

13

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Steel Stairs

10005

Providing, fabricating and erecting MS welded

built up sections/ frames and applying a primer

coat of zinc chromate on duly prepared surfaces ,

complete :

In stringers,

treads,

landings,

etc.

of

staircases

including

chequered

plates

wherever required, all complete.

kg

41

69.92

3.83

73.75

84.81

BuildCOST

05 51

05 51 16

METALS

Metal Stairs

Metal Floor Plate Stairs

BARE COST

UNIT

Material

10010

In guard bars, ladders, railings, and similar

works.

Providing, fabricating and erecting hand rails by

welding to steel ladders/railings, balcony railings,

and staircase railings including primer coat of

zinc chromate on

duly

prepared

surfaces ,

complete :

MS black tubes

Labour

Equipment

TOTAL

TOTAL INCL

OHP

kg

55.14

22.47

77.61

89.25

kg

190.77

20.09

210.86

242.49

10020

ERW tubes

kg

207.48

20.09

227.56

261.70

10025

Galvanised steel pipes

kg

183.33

20.09

203.42

233.93

10030

Structural

steel

channels, etc.

kg

68.45

18.90

87.35

100.45

10015

05 55

05 55 13

sections,

flats,

angles ,

Metal Stair Treads And Nosings

Metal Stair Treads

BARE COST

UNIT

Material

51

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Stair Treads And Nosing

10005

10010

10015

10020

05 73

05 73 23

Providing and fixing MS angles 50 x 50 x 5

mm nosing with lugs of MS flats 10 x 5 mm,

100 mm long and forked at ends, 600 mm

apart (minimum three lugs to be provided)

including necessary welding and applying a

primer coat on exposed surfaces etc.,

complete.

Providing and fixing aluminium angles 35 x

35 x 3 mm nosing with lugs of flats 10 x 3

mm, 100 mm long and forked at ends, 600

mm apart (minimum three lugs to be

provided) including necessary welding, etc.,

complete.

Providing and fixing aluminum strip edge to

staircases including fixing with rawl plugs and

stainless steel screws, with under layer of

cement mortar 1:3 with coarse sand, of strip

edging of size :

57 x 12 x 3 mm

38 x 12 x 3 mm

kg

63.52

16.67

80.19

92.22

kg

307.08

111.83

418.91

481.75

186.09

64.48

250.57

250.57

174.96

64.48

239.43

275.35

Decorative Metal Railings

Ornamental Railings

BARE COST

UNIT

Material

50

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Railings, Ornamental

10005

10010

Providing, fabricating and erecting MS balusters

in stair flight slabs, landing balconies and similar

other railings,

anchored to steps, landings etc .,

all fixing accessories including providing pockets

in concrete/brick works and grouting with ironite

or other equivalent, applying three coats of

synthetic enamel paint over a primer coat of zinc

chromate on duly prepared surfaces, complete.

Solid sections

Hollow sections

kg

172.73

66.45

239.18

275.06

kg

178.03

66.45

244.48

281.16

42

BuildCOST

06 11

06 11 10

WOOD, PLASTICS, AND COMPOSITES

Wood Framing

Wood Framing

BARE COST

UNIT

Material

12

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Ceiling Framing

Providing, fabricating and fixing in position

selected quality seasoned and chemically treat

ed wood work in frames of false ceilings,

partitions, etc., complete :

Ist class Deodar wood.

cum

47,709.24

3,750.00

51,459.24

10010

2nd class Deodar wood.

cum

46,516.19

3,750.00

50,266.19

57,806.11

10015

Sal wood

cum

27,546.49

3,750.00

31,296.49

35,990.96

10020

2nd class Kail wood

cum

20,984.64

3,750.00

24,734.64

28,444.83

10025

Hollock wood

cum

29,336.09

3,750.00

33,086.09

38,049.00

sqm

327.58

121.74

449.32

516.71

sqm

609.93

121.74

731.67

841.43

sqm

455.49

177.17

632.66

727.56

sqm

879.03

177.17

1,056.19

1,214.62

10005

40

59,178.12

Wall Framing

10005

10010

10015

10020

06 17

06 17 53

Providing and fixing wooden frame with 50 mm x

50 mm battens, fixed at 600 mm centre to centre

(both ways). Allow for solignum treatment to the

timber framework :

Sal wood

2nd class CP teak Wood

Providing and fixing wooden framework with 50

mm x 75 mm battens, fixed at 600 mm centre to

centre(both ways). Allow for solignum treatment

to the timber framework :

Sal wood

2nd class CP Teak Wood

Shop-fabricated Structural Wood

Shop-fabricated Wood Trusses

BARE COST

UNIT

Material

10

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Roof Trusses

Providing, fabricating and fixing in position

selected quality seasoned & chemically treated

wrought wood work in trusses, rafters, runners

posts, struts, walls plates etc. of size and profile

in inclind roofs including anchoring to concrete

members

with

holding

down

bolts,

fixing

accessories & all incidental works (Flat, angles,

other steel sections and holding down bolts used

in connections will be paid separately), complete

:

2nd class CP teak wood

cum

59,339.52

5,172.45

64,511.97

74,188.77

10010

Ist class Deodar wood

cum

44,620.53

5,172.45

49,792.98

57,261.93

10015

2nd class Deodar wood

cum

43,229.76

5,172.45

48,402.21

55,662.54

10020

Sal wood

cum

26,424.63

5,172.45

31,597.08

36,336.64

10025

Hollock wood

cum

27,235.92

5,172.45

32,408.37

37,269.62

10005

06 22

06 22 13

Millwork

Standard Pattern Wood Trim

BARE COST

UNIT

Material

12

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Mouldings

Providing and fixing select quality seasoned and

chemically treated wooden moulded beadings to

door and window frames with mild steel

screws/headless nails and a primer coat on

unexposed surface, etc. complete, of beading

sizes :

Burma teak wood :

10005

30 x 12 mm

45

33.10

43.70

76.80

88.32

BuildCOST

06 22

06 22 13

WOOD, PLASTICS, AND COMPOSITES

Millwork

Standard Pattern Wood Trim

BARE COST

UNIT

Material

Labour

Equipment

TOTAL

TOTAL INCL

OHP

10010

40 x 12 mm

46.04

43.70

89.74

103.20

10015

40 x 20 mm

73.07

43.70

116.77

134.28

10020

50 x 12 mm

56.29

43.70

99.99

114.99

10025

50 x 20 mm

89.97

43.70

133.67

153.72

80.84

2nd class CP teak wood :

10030

30 x 12 mm

26.60

43.70

70.30

10035

40 x 12 mm

36.50

43.70

80.20

92.23

10040

40 x 20 mm

57.17

43.70

100.87

116.00

10045

50 x 12 mm

44.37

43.70

88.07

101.28

10050

50 x 20 mm

79.94

43.70

123.64

142.19

77.12

Ghana teak wood :

10055

30 x 12 mm

23.36

43.70

67.06

10060

40 x 12 mm

31.76

43.70

75.46

86.78

10065

40 x 20 mm

57.96

43.70

101.66

116.90

10070

50 x 12 mm

38.45

43.70

82.15

94.47

10075

50 x 20 mm

60.22

43.70

103.92

119.51

21.48

43.70

65.18

74.96

79.65

91.59

88.32

101.57

2nd class Deodar wood :

10080

30 x 12 mm

10085

40 x 12 mm

35.95

43.70

10090

40 x 20 mm

44.62

43.70

10095

50 x 12 mm

35.75

43.70

79.45

91.36

64.32

43.70

108.02

124.22

10100

50 x 20 mm

Rubber wood :

10105

30 x 12 mm

15.39

43.70

59.09

67.95

10110

40 x 12 mm

20.06

43.70

63.76

73.32

10115

40 x 20 mm

29.77

43.70

73.47

84.49

10120

50 x 12 mm

23.82

43.70

67.52

77.65

10125

50 x 20 mm

35.85

43.70

79.55

91.48

06 26

Board Paneling

06 26 13

Profile Board Paneling

BARE COST

UNIT

Material

10

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Paneling, Boards

10005

10010

11

Providing and fixing in wall lining flat pressed

three layer & graded (medium density) particle

boards,

prelaminated,

one

side

decorative

lamination

and

on

other

side

balancing

lamination, grade I, Type II, conforming to

IS:12823, with necessary fixing arrangements

and screws etc. complete, of thicknesses :

12 mm

18 mm

sqm

1,788.85

96.33

1,885.18

2,167.96

sqm

2,294.13

96.33

2,390.46

2,749.03

sqm

2,166.69

141.59

1.80

2,310.08

2,656.59

Pre-finished Paneling

10005

06 42

06 42 10

Providing and fixing 9 mm thick laminated

wall

panelling

made

of

melamine

impregnated MDF board having tonge and

groove

jointing

system,

complete

with

accessories like wall base skirting and other

profiles complete.

Wood Paneling

Wood Paneling

BARE COST

UNIT

Material

46

Labour

Equipment

TOTAL

TOTAL INCL

OHP

BuildCOST

07 11

07 11 17

THERMAL AND MOISTURE PROTECTION

Dampproofing

Damp-proof Course

BARE COST

UNIT

Material

10

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Damp-proof Course

10005

Providing and laying damp-proof course with

cement

concrete

1:2:4

with

graded

stone

aggregate 12.5 mm nominal size, including side

shuttering, compacting etc., complete.

40 mm thick

10010

50 mm thick

10015

Providing and mixing waterproofing material

in cement concrete work @ 1.0 kg per 50 kg

bag of cement used in the mix.

Applying a cost of residual petroleium

bitumen of penetration 80/100 @ 1.70 kg/sq.

on damp-proof course.

10020

07 13

07 13 13

sqm

155.50

78.62

9.90

244.02

280.62

sqm

192.82

87.08

10.98

290.88

334.51

kg/50kg

60.45

5.00

65.45

75.27

sqm

67.35

12.68

80.02

92.03

Sheet Waterproofing

Bituminous Sheet Waterproofing

BARE COST

UNIT

Material

13

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Built-Up Sheet Waterproofing

10005

10010

Providing and laying vapour barrier of low density

polythene film (700 microns), laid in blown grade

bitumen at 1 kg. per. sqm, over a coat of primer

at 400 gms per sqm and finished with a coat of

bitumen at 1 kg per sqm as per specifications ,

complete :

Over RCC roof surfaces.

On external wall surfaces.

Providing and laying vapour barrier of aluminium

foil 0.075 mm thick, laid in blown grade bitumen

at 2 kg per sqm over a coat of primer at 400 gms

per sqm and finished with a coat of bitumen at 1

kg per sqm as per specifications, complete :

Over RCC roof surfaces

sqm

312.92

19.50

332.42

382.28

sqm

312.92

22.75

335.67

386.02

sqm

379.67

26.00

405.67

466.52

10020

On external wall surfaces

sqm

379.67

26.00

405.67

466.52

10025

Add for aluminum foil of thickness 0.1 mm

instead of 0.075 mm

Painting top of roof surface with 80 / 100

penetration bitumen @ 1.7 kg per sqm

impregnated with coarse sand, 6 mm thick,

including cleaning of slab surface with brush

and finally with a cloth soaked in kerosene

oil.

Providing

and

laying

damp-proofing

treatment comprising a primer coat, one

layer of aluminium foil 0.1 mm thick and two

layers of bitumen at the rate of 2 kg per sqm

per layer to ground floor/paving, complete.

Providing and laying waterproofing treatment

to roof slabs comprising of Primer coat, one

layer of fibre glass RP tissue, one layer of

aluminium foil 0.10 mm thickness, three

layers of bitumen at the rate of 2 Kg per sqm

per layer, sealing of edges and corners as

called for, complete.

Providing

and

laying

damp-proofing

treatment comprising a primer coat, one

layer of fibre-glass RP tissue and two layers

of bitumen at the rate 2 kg per sqm per layer

in toilets and other areas including side and

end laps, etc., complete.

Add for additional layer of aluminium foil,

(0.10 mm thick) and additional layer of

sqm

25.84

25.84

29.72

sqm

73.95

24.70

98.65

113.45

sqm

487.08

26.00

513.08

590.04

sqm

683.90

39.00

722.90

831.34

sqm

406.26

39.00

445.26

512.04

sqm

276.58

13.00

289.58

333.02

10015

10030

10035

10040

10045

10050

51

BuildCOST

07 13

07 13 13

THERMAL AND MOISTURE PROTECTION

Sheet Waterproofing

Bituminous Sheet Waterproofing

BARE COST

UNIT

Material

10055

10060

10065

10070

10075

10080

07 16

07 16 16

bitumen at the rate of 2 kg per sqm in roof

surface treatment.

Providing and laying at roof ridges and other

locations, where called for, waterproofing

treatment consisting of one layer of blown

grade bitumen at 1 kg per sqm followed by

one layer of fibreglass tissue laid and

finished with one layer of bitumen at 1 kg per

sqm.

Add for finishing the waterproofing treatment

with 6 mm pea-size gravel at the rate of 1

cum per 100 sqm (bitumen layer for laying

gravel included in waterproofing item).

Add for providing polymeric polythene felt

membrane instead of fibre-glass RP tissue.

Deduct for providing hessian based self

finish bitumen felt instead of fibre-glass RP

tissue.

Add for every additional coat of blown /

residual bitumen applied hot @ 2 kg per

sqm.

Add for every additional layer of fibre -glass

RP tissue and bitumen @ 2 kg per sqm.

Equipment

TOTAL

TOTAL INCL

OHP

sqm

237.68

26.00

263.68

303.24

sqm

6.68

1.70

8.38

9.63

sqm

49.62

49.62

57.06

sqm

-105.06

-105.06

-120.82

sqm

171.29

13.00

184.29

211.93

sqm

196.28

19.50

215.78

248.14

Cementitious And Reactive Waterproofing

Crystalline Waterproofing

BARE COST

UNIT

Material

20

Labour

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Cementitious Waterproofing

10005

Brick bat coba waterproofing treatment to

terraces, terrace gardens, roof surfaces and

such other locations where called for, by

providing an even base layer of minimum 20

mm thick cement mortar 1:4 with coarse

sand admixed with acrylic waterproofing

compound, brick bats of size ranging from

40 mm to 100 mm, laid with gaps of 10 to 15

mm between them and grouted with cement

mortar 1:4 with coarse sand and admixed

with acrylic waterproofing compound, laid to

slope of 1:120 or as specified and a

protective coat of 20 mm thick cement

mortar 1:4 with coarse sand admixed with

acrylic waterproofing compound, fixing of

rough Kotah stone of 18-20 mm thickness

over a bed of cement mortar 1:4 with coarse

sand admixed with acrylic waterproofing

compound and joints grouted to full depth of

stone with cement slurry admixed with

acrylic

waterproofing

compound.

Kotah

stone shall be fixed within 48 hours of

completing and laying the protective coat to

brick coba treatment. Treatment to vertical

faces of parapets, walls, beams, etc. will

comprise 20 mm thick cement plaster 1:4

with coarse sand admixed with acrylic

waterproofing compound and finished neet

upto a height of 300 mm (only horizontal

treatment area shall be measured for

payment). The average thickness, excluding

the Kotah stone and its bedding mortar, shall

be 120 mm.

The minimum thickness at

khurra, excluding the Kotah stone and its

bedding mortar, shall be 80 mm.

sqm

52

921.23

684.79

11.70

1,617.71

1,860.37

BuildCOST

08 09

08 09 16

10

OPENINGS

Metal Doors, Windows And Frames

Aluminum Doors, Windows And

Frames

Aluminum

Frames

10005

10010

08 09 21

Doors,

Windows

BARE COST

UNIT

Material

Equipment

TOTAL

TOTAL INCL

OHP

And

Providing, fabricating and fixing aluminium doors ,

windows and ventilators with sections (IS 733

and IS 1825), 60 microns pure polyster coated,

25 microns colour nutred anodised (IS 1868), of

grade AC 25, fixed with rawl plugs and screws /

fixing clips / expansion hold fasteners and filling

gaps with PVC / Neoprene felt along with

aluminium snap beadings, CP brass/stainless

steel screws for glazing / panelling complete

(cost of glazing / panelling not included )

(payment will be made for weight of aluminium

used in the work).

Fixed portion

Shutters of doors, windows and ventilators

including providing and fixing hinges /pivots

and making provision for fixing of fittings

including

PVC/neoprene

gasket,

complete

(cost of fitting not included).

Steel Doors, Windows And Frames

kg

kg

343.31

15.00

358.31

412.06

362.21

20.00

382.21

439.54

BARE COST

UNIT

Material

10

Labour

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Steel Doors, Windows And Frames

10005

Providing and fixing MS glazed doors, windows

and ventilators of standard heavy rolled steel

sections, conforming to IS 7452-1990, joints

mitred and welded with 15 x 3 mm lugs, 100 mm

long, embedded in cement concrete blocks 150 x

100 x 100 mm of 1:3:6 with coarse sand or with

wooden plugs and screws or rawl plugs and

screws/ with fixing clips/ with bolts and nuts as

required, incluing providing and fixing of 4 mm

thick glass panes with glazing clips and special

metal sash putty including three coats of

synthetic enamel paint over a primer coat of zinc

chromate on duly prepared surfaces excluding

the cost of metal beading and other fittings

except necessary hinges or pivot as required ,

complete :

Doors

sqm

4,934.06

260.44

0.90

5,195.40

5,974.71

260.44

0.90

4,771.20

5,486.88

10010

Windows fixed

sqm

4,509.86

10015

Windows-side hung

sqm

4,934.06

260.44

0.90

5,195.40

5,974.71

10020

Ventilators-top hung

sqm

4,934.06

260.44

0.90

5,195.40

5,974.71

10025

Ventilators-centre hung

sqm

4,934.06

260.44

0.90

5,195.40

5,974.71

sqm

4,509.86

260.44

0.90

4,771.20

5,486.88

10030

In composite units of doors, windows

ventilator :

(For overall portion treated as fixed)

and

Add for side hung portion :

10035

Doors

sqm

424.20

424.20

487.83

10040

Windows

sqm

424.20

424.20

487.83

10045

Add for top hung portion.

sqm

424.20

424.20

487.83

10050

Add for centre hung portion.

sqm

424.20

424.20

487.83

10055

Add for providing vertical coupling, mullion

bar, or horizontal coupling mullion bar (when

openable windows are to be coupled above

fixed ones or between two fixed windows) or

horizontal

coupling

mullion

bar

(where

windows are not exposed to weather).

Extra

for

providing

horizontal

coupling

mullion bar or weather bar (especially used

99.26

10.08

109.34

125.74

126.84

12.88

139.72

160.67

10060

63

BuildCOST

08 09

08 09 21

OPENINGS

Metal Doors, Windows And Frames

Steel Doors, Windows And Frames

BARE COST

UNIT

Material

10065

08 11

08 11 13

when the coupled unit is exposed to rain).

Add for providing and fixing stainless steel /

aluminium beading of approved shape and

section with SS screws instead of glazing

clips and metal sash putty in steel doors ,

windows, ventilators and composite units.

62.73

Equipment

6.30

TOTAL

69.03

TOTAL INCL

OHP

79.38

Metal Doors And Frames

Hollow Metal Doors And Frames

BARE COST

UNIT

Material

11

Labour

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Hollow Metal Doors and Frames

10005

10010

10015

10020

08 12

08 12 21

Providing, fabricating and fixing 1 mm thick

MS sheet door with hollow MS section frame

of 40 x 40 x 3 mm and 3 mm gussets at the

junctions and corners with necessary fittings

and three coats of synthetic enamel paint

over a primer coat of zinc chromate on duly

prepared surfaces, complete.

Providing, fabricating and fixing 1 mm thick

MS sheet door with MS angle 40 x 40 x 6

mm frame, and 3 mm gussets at the

junctions and corners with necessary fittings ,

three coats of synthetic enamel paint over a

primer coat of zinc chromate on duly

prepared surfaces, complete.

Add for MS angles 40 x 40 x 6 mm for

diagonal braces.

Add for MS flats 30 x 6 mm for diagonal

braces and central cross piece.

sqm

7,183.00

803.09

7,986.09

9,184.00

sqm

7,184.11

803.09

7,987.19

9,185.27

sqm

1,053.02

182.22

1,235.24

1,420.53

sqm

505.20

175.39

680.58

782.67

Metal Frames

Steel Frames

BARE COST

UNIT

Material

13

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Steel Frames

10005

10010

Providing and fixing MS frames for doors,

windows

and

ventilators

with

Tee/angle/fabricated-sections,

joints

mitred

and welded with 15 x 3 mm lugs 100 mm

long embedded in cement concrete blocks

150 x 100 x 100 mm 1:3:6 with coarse sand

or with wooden plugs and screws or rawls

plugs and screws/with fixing clips/with bolts

and nuts as required including fixing of butt

hinges and screws and applying three coats

of synthetic enamel paint over a primer coat

of zinc chromate on duly prepared surfaces ,

complete.

Providing and fixing pressed steel door frames ,

manufactured from commercial mild steel sheet

of 1.25 mm thickness, including hinges jamb,

lock jamb, bead, and required threshold of mild

steel flat of section 30 x 3 mm/8 mm round or

square bar welded or rigidly fixed together by

mechanical means, adjustable lugs with split end

tail to each jamb including steel butt hinges 2.5

mm thick with mortar guards, lock strike - plate

and shock absorbers and applying three coats of

synthetic enamel paint over a primer coat of zinc

chromate on duly prepared surfaces i /c filling

hollows of the frame with CC 1:3:6, complete :

Profile A

kg

194.71

11.46

0.00

206.16

237.09

1,262.65

44.20

0.72

1,307.57

1,503.70

64

BuildCOST

09 21

09 21 13

FINISHES

Plaster And Gypsum Board Assemblies

Plaster Assemblies

BARE COST

UNIT

Material

13

Expansion

Mesh

10005

09 22

09 22 26

Control

With

Equipment

TOTAL

TOTAL INCL

OHP

Chicken

Providing and fixing galvanized chicken wire

mesh (24 gauge 12 mm size) to junctions of

concrete and masonry work and other

locations including cutting to required sizes ,

side laps of minimum 75 mm and fixing in

position with galvanized iron wire nails,

complete.

sqm

117.36

120.00

2.00

239.36

275.26

Supports For Plaster And Gypsum Board

Suspension Systems

BARE COST

UNIT

Material

14

Labour

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Aluminium Frame Work

Providing and fixing frame work for suspended

ceiling with anodised aluminium 15 microns

coating/Polyester pre-coated (50 microns), main

runner T-sections 35 x 35 x 1.5 mm thick

suspended from ceiling with 6 mm dia MS

adjustable hangers, fixed to ceiling with MS cleat

25 x 25 x 5 mm and 50 mm long, fixed to RCC

surface with expandable fasteners 12.5 x 40 mm,

intermediate T-section 23.5 x 19 x 1.5 mm thick

fixed to main runner and perimeter angle 35 x 15

x 1.5 mm thick fixed to wall/beam with cadmium

plated steel screws with rawl plug @ 450 mm

etc., all complete, for panel sizes (cost of

hangers with cleat to be paid for separately) :

1220 x 610 mm

sqm

486.05

146.38

632.43

727.30

10010

610 x 610 mm

sqm

549.62

146.38

696.00

800.40

10015

Add for providing and making arrangement

for fixing light, fixture grills and diffusers in

the frame work.

sqm

437.59

146.25

583.84

671.42

10005

15

Ms Frame Work

Providing and fixing frame work for suspended

ceiling, made from 0.55 mm thick GS sheet

section consisting of GS channel main runner

suspended from ceiling with 6 mm dia MS

adjustable hanger fixed to ceiling with MS angle

of 25 x 25 x 5 mm thick and 50 mm long with

expandable fastners 12.5 x 40 mm, intermediate

T - sections fixed to main runner, and perimeter

channel section fixed to wall with cadmium

plated steel screw with rawl plug @ 450 mm

centre to centre, complete, for panel size (cost of

hangers with cleat to be paid for separately).

1220 x 610 mm

sqm

502.23

146.38

648.61

745.91

10010

610 x 610 mm

sqm

594.31

146.38

740.69

851.79

10015

Add for providing and making arrangement

for fixing light fixture grills and diffusers in the

frame work.

sqm

594.31

146.25

740.56

851.64

Each

57.26

9.65

66.91

76.95

10005

16

Ceiling Supports, Suspension

10005

Providing and fixing level adjusting hangers

of 6 mm dia. MS Rods fixed to roof slabs by

means of MSangle ceiling cleats 40 x 40 x 5

mm size, 40 mm long and expansion hold

fastners 12.5 mm dia. 40 mm long including

applying a primer coat of zinc chromate ,

complete.

79

BuildCOST

SPECIALTIES

10 14

Signage

10 14 53

Traffic Signage

BARE COST

UNIT

Material

20

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Traffic Signs

10005

10 28

10 28 16

Providing and fixing Cats Eye (Glow studs),

heavy

duty

integral

stem,

reflective ,

aluminium dia cast with elegant finish, of

size 100 x 100 mm and 20 mm high, having

a stem of 50 mm screwed / nailed with 12

mm dia 90 mm long nail to fix into the road

surface or at the nosing of the central verge .

The road studs should have reflectors fitted

on one side of the studs, complete.

Each

524.77

544.75

626.46

Toilet, Bath, And Laundry Accessories

Bath Accessories

BARE COST

UNIT

Material

10

19.98

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Bath Accessories

10005

10010

10015

10020

10025

10030

10035

10040

10045

Providing and fixing

stainless steel curtain rods

with stainless steel brackets, complete, of size :

25 mm outer dia

32 mm outer dia

Providing and fixing

CP brass curtain rod

with CP brass brackets 25 mm outer dia,

complete.

Providing and fixing CP brass brackets for

curtain rods 25 mm outer dia, complete.

Providing and fixing angular/bent grab bars

fabricated from 32 mm dia. seamless stainless

steel

tubes

with

peened

non-slip

gripping

surface, polished flanges firmly fixed, to be fully

safe, with heavy duty anchor fastener having

finish/capping similar to the grab bar, complete,

including

cutting

and

making

good

the

walls/floors for :

Wall-mounted /floor-mounted for European

type water closet - 830 mm high

Bath tub - 1320 mm long

Wash basin and shower - 610 mm long

Providing and fixing fully automatic "NO

TOUCH" hand driers of stainless steel body

suitable to operate on 230 V, single ph 50

Hz, AC power supply including brackets for

fixing on wall including cutting and making

good the walls, etc., complete.

Providing and fixing bevelled edge mirrors

5.5 mm thick of float glass, complete with 6

mm thick marine ply board backing, fixed

with

CP

brass

screws

and

washers,

complete, of size 450 x 600 mm.

Providing and fixing float glass mirror 5.5 mm

thick with plastic moulded frame and 6 mm thick

marine ply board backing, complete, of outer

dimensions :

Circular shape 450 mm dia

320.19

130.00

450.19

349.70

130.00

479.70

551.66

1,201.21

130.00

1,331.21

1,530.89

Set

523.28

97.44

620.72

713.83

Each

794.79

195.20

989.99

1,138.48

Each

958.31

195.20

1,153.50

1,326.53

Each

1,094.57

195.20

1,289.77

1,483.24

Each

12,092.10

195.20

12,287.30

14,130.39

Each

1,761.16

227.31

1,988.47

2,286.74

517.72

Each

455.33

227.31

682.64

785.03

10055

Rectangular shape 453 x 357 mm

Each

371.28

227.31

598.59

688.37

10060

Oval shape 450 x 350 mm

Each

371.89

227.31

599.19

689.07

10065

Rectangular shape 1500 x 450 mm

Each

894.13

292.83

1,186.96

1,365.00

10070

Providing and fixing rectangular float glass

mirror 5.5 mm thick of any size with 6 mm

thick marine ply board backing, supported on

clips fixed with CP brass screws and

washers, complete.

sqm

805.50

325.00

1,130.50

1,300.08

10050

107

BuildCOST

21 12

21 12 13

FIRE SUPPRESSION

Fire-suppression Standpipes

Fire-suppression Hoses And Nozzles

BARE COST

UNIT

Material

52

Labour

Equipment

TOTAL

TOTAL INCL

OHP

Fire Hose And Equipment

10005

10010

10015

10020

10025

10030

10035

10040

Providing and fixing stand post fire hydrants

Type A, conforming to IS:908, with 63 mm

dia.

outlet

fitted

with

gunmetal

instantaneous type coupling, 80 mm dia .

inlet, one number cast iron double flanged

sluice valve, CI duck foot bends and flanged

riser, painting with one coat of ready mixed

red oxide primer and two coats of synthetic

enamel paint of fire red colour, finished to an

even shade, complete, excluding the cost of

brick chamber.

Providing and fixing gun metal, under ground

type fire hydrants, conforming to IS-909, with

control valve and 63 mm dia single outlet

fitted

with

instantaneous

type

coupling ,

conforming to IS-901 for connection to hose

and 80 mm dia inlet and chained cap,

complete,

excluding

the

cost

of

brick

chamber.

Providing and fixing gunmetal, hand wheel

operated fire hydrant valves Type A, conforming

to IS:5290, with 63 mm dia outlet fitted with

instantaneous female coupling, conforming to

IS:901, and 80 mm dia inlet, complete, with

blank caps and chains with :

Single outlet

Double outlet

Providing and fixing first aid hose reels, of

heavy duty mild steel construction, with CI

brackets, wall mounted, swinging type, fitted

with 19 mm dia., 36.5 m long high pressure

hose, conforming to IS-5132, with 5 mm dia

outlet gunmetal nozzle and shut off valve ,

conforming to IS 884-1967, complete.

Providing and fixing 63 mm dia, 15 m long

reinforced rubber lined hoses, conforming to

IS:636, including gunmetal male and female

instantaneous type coupling, conforming to

IS: 903, machine wound with galvanised

steel wire, complete.

Providing and fixing standard short size

gunmetal

branch

pipes,

conforming

to

IS-903, with 16 mm dia. outlet gunmetal

nozzle,

suitable

to

fit

with

standard

instantaneous type 63 mm coupling along

with nozzle spanner, complete.

Providing and fixing standard firemans axes

with

heavy

insulated

rubber

handle ,

conforming to IS:926, complete.

Providing and fixing gunmetal fire brigade

connections, conforming to IS-905, with 63 mm

dia. instantaneous type inlet and 150 mm dia

flanged outlet with built in check valves for fire