Professional Documents

Culture Documents

Inspection & Test Plan

Uploaded by

ShivarajJadhavOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection & Test Plan

Uploaded by

ShivarajJadhavCopyright:

Available Formats

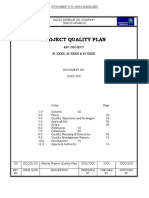

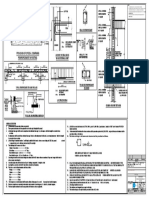

Hasan Juma Backer Trading & Contracting Co. LLC.

Doc No. :

Rev No. :

Date :

Page :

Inspection & Test Plan for Concrete Works

Total 1+3 pages

Inspection & Test Plan for Concrete Works

Client Approval

Revision

Date

Name /Designation

18.10.2014

First Issue

Revision

Date

Name /Designation

Signature

QA Engineer

Author

Quality Manager

Checked by

Contract Manager

Authorized by

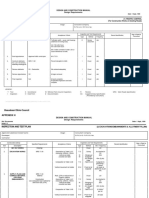

Hasan Juma Backer Trading & Contracting Co. LLC.

Inspection & Test Plan for Concreting

Sl No.

ACTIVITY

Varified by

REFERENCE

DOCUMENT

ACCEPTANCE CRITERIA

Doc No. :

Rev No. :

Date :

Page :

Varifying Document

H

HJB

W R

Total 1+3 pages

Client

M H W R

Remarks

M

CONCRETE WORKS

1

Review of drawings

2.0

Material approval

3.0

Material Storage

3.1

Cement

3.2

3.3

Aggregates

Admixture

Reinforcement bars

Civil Supervisor/ Drawing control

QA Engineer

index & AFC

drawing

Material

SP1279 part

Engineer

D,Sec. 2.3

AFC drawings/Standard drawings

Store

Keeper/Civil

Supervisor/ Civil

QC Inspector

Store

Keeper/Civil

Supervisor / Civil

QC Inspector

Stack Height =< 1500mm Cover with Visual

Polythene/Tarpaulin Store on 150mm high

raised platform. -Weather proof shed for

storage.

-Base of storage area: polythene or Lean Visual

concrete -Provide dividers for separation

from mix-up -Under shade -Storage and

use as per manufacturer's instructions.

SP1279 part

D,Sec. 2.3.1.2

SP1279 part

D,Sec. 2.3.2.2

SP1279 part

D,Sec. 2.3.7

Source approved by Client

Store

SP1279 part

Keeper/Civil

D,Sec. 2.3.3.1

Supervisor/ Civil HJB/Qsp.cvl.wi .4

QC Inspector

Stacking in groups, clear off ground and

labeled

Civil Qc

Inspector/Civil

Supervisor

SP1279

PartD.Sec2.5

SP1279

PartD.Sec2.3. 2

BSEN197 or

ASTM C150

SP1279

PartD.Sec2.5. 2

SP1279

PartD.Sec2.5. 2

SP1279

PartD.Sec2.5. 1

SP1279

PartD.Sec2.5. 1

Min grade C-35, BS5328 Parti Table9

Other Grades as per BS1881

20mm RCC, 40mm for mass concrete

BS8110

SP1279 Part Dsec2.5.2

AFC drawings /Standard

drawings

Material approval sheet

HJB/Qsp.cvl.CI.4

Mix Design Approval

Grade

Maximum size of

aggregate

Permitted Type of

Cement Minimum

Cement content

Target Slump

Chloride content in

concrete Sulphates in

concrete

Aggregate/Cement

ratio

Civil QC

inspector

OPC, min 375 kg/m3 for grade35.max.size of aggregate 20 OPC, min

300 kg/m3 for grade-35.max.size of

aggregate 40mm mm

75mm hevy reinforcement foundation

50mm min-other concreting works

SP1279 Part D Table D5 All cases 4.0,

including the sulphate ion in the cement

Page 1 of 3

Design Mix Test Report

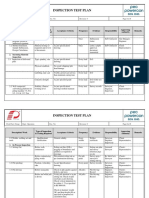

Hasan Juma Backer Trading & Contracting Co. LLC.

Inspection & Test Plan for Concreting

Sl No.

ACTIVITY

Varified by

REFERENCE

DOCUMENT

ACCEPTANCE CRITERIA

Design

Doc

No.Mix

: Test Report

Rev No. :

Date :

Page :

Varifying Document

X

0

18.10.2014

Total 1+3 pages

HJB

Client

W R M H W R

Remarks

M

CONCRETE WORKS

Admixture addition

5

6.0

7.0

8.0

9.0

Site Trail Mix (First

Civil

batch shall be

supervisor/Civil

discarded and

QC inspector

9cubes of 150mm,

shall be made from

each of the three

consecutive

batches=27 cubes Mix details for mixing Testing of cubes

Form work

SP1279

PartD.Sec2.3. 7

SP1279Part

DSec2.5.3,

Secl.4.2

Civil Supervisor/ SP 1279 Part D

Civil QC

Sec.2.4

Inspector

HJB/Qsp.cvl.wi .5

Prior Client approval required to use

3 from each set shall be tested at an age

of 7days,3 at 14 days,3 at 28 days(No

concreting shall commences on the

contract until the test results at 14 days

have been achieved

Trail Mix report

Concrete contact faces free from adherent HJB/Qsp.cvl.cl.5

grout, projecting nails, splits & other

defects Joints sufficiently tight to prevent

leakage 25 mm chamfer on exposed

corners (if not specified otherwise)

Deflection: < 3 mm on surfaces. Minimum

concrete cover -As per SP 1275

Fixing Reinforcement Civil Supervisor

Civil Foreman/

Civil QC

Inspector

SP

1279

Part As per approved drawing. All tying wire

HJB/Qsp.cvl.cl.4

"D"Sec.2.3.3. 3 BS knots within cage and shall not be located

4449, BS 6744 & towards the surface.

BS

4483

HJB/Qsp.cvl.wi .4

Spacing of spacer

blocks Cement

mortar blocks

Concrete Mixing Mix

concrete as per the

design mix

SP1279 Part D

Sec2.3.5

Civil foreman/

Civil QC

Inspector

Civil supervisor/

Civil QC

Inspector

Concrete grade ,max spacing -1 meter

SP1279 Part D

Design mix Ambient temp-max 46"c

Sec2.5.4,Sec2 .5.5 Concrete temp-max 30"c Weight Batch :

As per design mix Volume batch:

concreting<10m3 with Client approved

procedure. Admixture addition: as per

design mix Minimum mixing time:2

minutes

Page 2 of 3

Visual

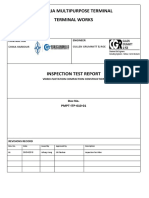

Hasan Juma Backer Trading & Contracting Co. LLC.

Inspection & Test Plan for Concreting

Sl No.

ACTIVITY

Varified by

REFERENCE

DOCUMENT

ACCEPTANCE CRITERIA

Doc No. :

Rev No. :

Date :

Page :

Varifying Document

H

0

18.10.2014

Total 1+3 pages

HJB

Client

W R M H W R

Remarks

CONCRETE WORKS

10

11.

12

13

14.

Placing, Compacting, Civil supervisor/ SP1279 Part D

Layer Depth: Max 300mm Placing time:

&curing

Civil QC

Sec2.5.5,Sec2 .5.6 within 30min of mixing For lift more than

Inspector

HJB/Qsp.cvl.wi .18 1.5mt use chutes.

Placement min area: Up to joints No

segregation during discharging concrete

Pumping not allowed without client

approval Shrinkage as per SP1279D Sec

2.5.9

Compacting

SP1279 Part D

Immersion Vibrator, Lateral dragging of

Sec2.5.5

concrete using vibrator not allowed No

HJB/Qsp.cvl.wi .18 excess or insufficient compaction

Curing

SP1279 Part

D.Sec2.5.6

Form work removal

SP 1279 Part D -Removal of Form work as per SP1279 D

Sec.2.4.2

table D4

Civil Supervisor

Civil QC

Inspector

Concrete Protection - Civil Supervisor

Surface Finish

Civil QC

Inspector

Testing Concrete

Lab. Techn.

Cube Testing for 7

/Civil QC

days curing and 28

Inspector

days curing Slump

Test

Repair of Concrete

HJB/Qsp.cvl.cl.18

Cover with polythene for not more than 24

hours or concrete stiffened sufficiently.

Remove polythene sheet after hardening

and cover with wet Hessian cloth. Hessian

shall be kept thoroughly & permanently

wet for not less than 7 days Curing period:

depends on item.

SP 1279 Part D Dense smooth finish, free from honey

HJB/Qsp.cvl.cl.18

Sec.2.5.6

combing, form marks ,fins and other

Irregularities.

SP 1279 Part "D" BS 1881 & BS EN 12350 SP 1279 Part

Test Reports

Sec.2.9

"D" Table D6 7 days test - 2 cubes 28 days

test - 2 cubes Spare -1 cube (keep till end

of contract) One slump test shall be

carried out on the first batch of concrete

mixed on the worksite on each day to set

the standard for the day.

Civil Foreman

SP 1279 Part D Client approved methods of statement for HJB/Qsp.cvl.cl.18

Civil Supervisor/ Sec.2.5.10

repair of concrete. Air holes filled with

Civil QC

mortar sand (1 part) + cement (1.5 parts).If

required approved binding agent shall be

used.

Page 3 of 3

You might also like

- Itp For Construction of Precast FoundationDocument7 pagesItp For Construction of Precast Foundationreachpunnya5538100% (2)

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFDocument53 pagesA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFMOST PASONNo ratings yet

- 03 Rebar InspectionDocument1 page03 Rebar InspectionDawit SolomonNo ratings yet

- Field Civil Inspection & Test PlanDocument9 pagesField Civil Inspection & Test PlanChristian Albert Sinaga RumajarNo ratings yet

- SITE-SPECIFIC QC PLANDocument3 pagesSITE-SPECIFIC QC PLANloveanbu24100% (1)

- Field Engineering Change Control FormDocument1 pageField Engineering Change Control Formmoytabura96No ratings yet

- Concrete Work: (Please Provide Detail of Repair Activities E.G)Document2 pagesConcrete Work: (Please Provide Detail of Repair Activities E.G)Eze NonsoNo ratings yet

- 023-Itp Concrete Works PDFDocument32 pages023-Itp Concrete Works PDFKöksal Patan100% (5)

- Saudi Oger Ltd. (Project Name) : PlasteringDocument1 pageSaudi Oger Ltd. (Project Name) : PlasteringAnthony AngelesNo ratings yet

- QA/QC Plan Ensures Project ComplianceDocument18 pagesQA/QC Plan Ensures Project ComplianceSen IMO67% (3)

- 027 ITP For Pre Cast Concrete PDFDocument27 pages027 ITP For Pre Cast Concrete PDFlinga2014No ratings yet

- Inspection & Test Plan for Civil and Structural SteelDocument33 pagesInspection & Test Plan for Civil and Structural SteelAhmed Mohsin100% (1)

- Quality Plan 2 PDF FreeDocument21 pagesQuality Plan 2 PDF FreeEng.arifNo ratings yet

- ITP-00010 Pavement Road WorksDocument3 pagesITP-00010 Pavement Road WorksIsmail MydeenNo ratings yet

- General Guide To Activities and Documentation Flow From Mechanical Completion To Final HandoverDocument4 pagesGeneral Guide To Activities and Documentation Flow From Mechanical Completion To Final HandoverMahmoud ZeirNo ratings yet

- ITP CIVIL WORK-Rev-1Document6 pagesITP CIVIL WORK-Rev-1Ateeq Rahman100% (1)

- Inspection Test Plan: When Required Depth Is Achieved When Bearing Layer Is IdentifiedDocument16 pagesInspection Test Plan: When Required Depth Is Achieved When Bearing Layer Is IdentifiedAziz Fathiry RahmanNo ratings yet

- Renovation Works at Al Forsan Sports ResortDocument7 pagesRenovation Works at Al Forsan Sports ResortAshimolowo BabatundeNo ratings yet

- Quality PlanDocument21 pagesQuality PlanQianlei ZhuNo ratings yet

- ENCOCORP QUALITY MANUAL ISO 9001-2015 - Updated On 5-Mar-2016 Webiste With ITP REV1Document29 pagesENCOCORP QUALITY MANUAL ISO 9001-2015 - Updated On 5-Mar-2016 Webiste With ITP REV1Sofia RegaladoNo ratings yet

- Mumbai Trans Harbour Link Project Non-Conforming Item ProcedureDocument15 pagesMumbai Trans Harbour Link Project Non-Conforming Item ProcedureDeepak UpadhayayNo ratings yet

- Inspection and Test PlanDocument6 pagesInspection and Test PlanMadison ChanNo ratings yet

- Appendix H: Design and Construction Manual Design RequirementsDocument17 pagesAppendix H: Design and Construction Manual Design RequirementsPageduesca RouelNo ratings yet

- PQP EpldtDocument8 pagesPQP Epldtmartin leeNo ratings yet

- QA/QC Guidelines Objectives & ScopeDocument20 pagesQA/QC Guidelines Objectives & ScopeFurqanam196100% (2)

- Project Logo Inspection Test Plan for Plastering WorksDocument5 pagesProject Logo Inspection Test Plan for Plastering WorksMohasin KhanNo ratings yet

- Project Quality Template (Att. IV)Document16 pagesProject Quality Template (Att. IV)aslam.ambNo ratings yet

- Civil Quality Control Plan-EarthworksDocument3 pagesCivil Quality Control Plan-Earthworksengsam777100% (2)

- Quality Plan AuditDocument5 pagesQuality Plan AuditRajan100% (1)

- Project Earthwork ProcedureDocument6 pagesProject Earthwork ProcedureJitesh SahiNo ratings yet

- INSPECTION AND TEST PLAN (ITP) FOR TEST TANK PDM T-1001 A Rev B PDFDocument7 pagesINSPECTION AND TEST PLAN (ITP) FOR TEST TANK PDM T-1001 A Rev B PDFgst ajah100% (4)

- QES PEVC-ENG237 - Checklist For PSS Fencing DetailsDocument2 pagesQES PEVC-ENG237 - Checklist For PSS Fencing DetailsRupesh Khandekar100% (1)

- 044 ITP For Installation of Gypsum Board Buildings PDFDocument10 pages044 ITP For Installation of Gypsum Board Buildings PDFHarshvardhan PathakNo ratings yet

- Site Quality Observation Report #3 Tabuk-J&PDocument15 pagesSite Quality Observation Report #3 Tabuk-J&PmasahinNo ratings yet

- Internal QMS Audit Schedule: - Audit Area Department Auditor Auditee Audit Date RemaksDocument3 pagesInternal QMS Audit Schedule: - Audit Area Department Auditor Auditee Audit Date RemaksBihanChathurangaNo ratings yet

- Cb2 Q Zen 05 60211 Itp For Earth Work - Rev.bDocument6 pagesCb2 Q Zen 05 60211 Itp For Earth Work - Rev.bAnonymous wIPMQ5rhNo ratings yet

- Lesson 10 Project Quality PlanningDocument51 pagesLesson 10 Project Quality PlanningDevjit MandalNo ratings yet

- ITP-01 - BackfillingDocument1 pageITP-01 - BackfillingMaddala Srinivasa Rao50% (2)

- Inspection Test Plan Piling WorkDocument4 pagesInspection Test Plan Piling WorkAhmad AfeeqNo ratings yet

- Method Statement Trial TrenchDocument6 pagesMethod Statement Trial TrenchSasi KumarNo ratings yet

- ET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Document2 pagesET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Sagar Aliasjackey100% (1)

- Inspection and Test Plan For Earthworks NSCR-PSC-N05-CRKDPT-PRO-QA-000000Document7 pagesInspection and Test Plan For Earthworks NSCR-PSC-N05-CRKDPT-PRO-QA-000000ResearcherNo ratings yet

- ER288-Rebar Test PlanDocument4 pagesER288-Rebar Test PlanalfieNo ratings yet

- Project Quality Plan ChecklistDocument3 pagesProject Quality Plan ChecklistMylean Monterola100% (3)

- CREC Construction Inspection Equipment ProcedureDocument3 pagesCREC Construction Inspection Equipment ProcedureStephen David GozunNo ratings yet

- Method Statement & Itp For Waterproofing WorkDocument7 pagesMethod Statement & Itp For Waterproofing WorkRumi ZamNo ratings yet

- Qatar Petrolum Qsp-Qac-09Document40 pagesQatar Petrolum Qsp-Qac-09Victor SimionNo ratings yet

- QAP Plan For Biratnagar AirportDocument20 pagesQAP Plan For Biratnagar AirportNirmal bhandariNo ratings yet

- Monthly QA/QC Report SummaryDocument2 pagesMonthly QA/QC Report Summarymahdi_gNo ratings yet

- Method Statement For HospitalDocument3 pagesMethod Statement For HospitalsandipNo ratings yet

- Contractor Quality Control Plan For Electrical Equipment InstallationDocument7 pagesContractor Quality Control Plan For Electrical Equipment Installationhasan_676489616No ratings yet

- ITP Fencing Rev - 00 PDFDocument3 pagesITP Fencing Rev - 00 PDFanon_987276020No ratings yet

- ITP For Civil WorksDocument15 pagesITP For Civil WorksNoor A Qasim100% (7)

- Check List For Backfilling WorksDocument2 pagesCheck List For Backfilling WorksYash SharmaNo ratings yet

- ITP 001 Fencing, CurbingDocument19 pagesITP 001 Fencing, CurbingMikiRoniWijaya50% (2)

- Project: EXPO 2020 - OV016 - USA PAVILION Inspection and Test Plan (Itp)Document5 pagesProject: EXPO 2020 - OV016 - USA PAVILION Inspection and Test Plan (Itp)qc_531040655No ratings yet

- PMPT Itp 010Document3 pagesPMPT Itp 010hz135874No ratings yet

- QCF113 Structural Steel Pre-Fabrication CertificateDocument1 pageQCF113 Structural Steel Pre-Fabrication CertificateminhnnNo ratings yet

- F4281-GEDI-M-SS-ITP-1039-3 ITP For Equipment and Pipe Installation in - Compressed Air System PDFDocument19 pagesF4281-GEDI-M-SS-ITP-1039-3 ITP For Equipment and Pipe Installation in - Compressed Air System PDFDang Hieu NguyenNo ratings yet

- NRI QuestionnaireDocument2 pagesNRI QuestionnaireShivarajJadhavNo ratings yet

- Mep Rooms Handover Tracker: Project: Parsons Regional HeadquartersDocument1 pageMep Rooms Handover Tracker: Project: Parsons Regional HeadquartersShivarajJadhavNo ratings yet

- Mep Rooms Handover Tracker: Project: Parsons Regional HeadquartersDocument1 pageMep Rooms Handover Tracker: Project: Parsons Regional HeadquartersShivarajJadhavNo ratings yet

- Mep Rooms Handover Tracker: Project: Parsons Regional HeadquartersDocument1 pageMep Rooms Handover Tracker: Project: Parsons Regional HeadquartersShivarajJadhavNo ratings yet

- 175 PMP Sample Questions PDFDocument109 pages175 PMP Sample Questions PDFKamlakar MohiteNo ratings yet

- Mep Rooms Handover Tracker: Project: Parsons Regional HeadquartersDocument1 pageMep Rooms Handover Tracker: Project: Parsons Regional HeadquartersShivarajJadhavNo ratings yet

- Topic 5: Rigid Pavements: CSE29357 Highway EngineeringDocument45 pagesTopic 5: Rigid Pavements: CSE29357 Highway EngineeringTszwun CheungNo ratings yet

- Manual Design of MSBDocument77 pagesManual Design of MSBPriya100% (1)

- Superstructure Slab BeamDocument33 pagesSuperstructure Slab BeamVenkata MayurNo ratings yet

- Basics of post-installed rebar connectionsDocument33 pagesBasics of post-installed rebar connectionsHaitham KayyaliNo ratings yet

- Composition Book: Edificio Polifunzionale. Studio Passarelli.Document29 pagesComposition Book: Edificio Polifunzionale. Studio Passarelli.Maria Camila Rodriguez0% (1)

- Repair and RehabilitationDocument115 pagesRepair and RehabilitationBala Subramanian0% (1)

- Causes of Distress and Deterioration of Concrete, EM 1110-2-2002 1995-06-30Document14 pagesCauses of Distress and Deterioration of Concrete, EM 1110-2-2002 1995-06-30RONALD MUELLERNo ratings yet

- Structural Analysis ExamDocument3 pagesStructural Analysis ExamJessie Radaza TutorNo ratings yet

- Bending MomentDocument4 pagesBending MomentNicholas TedjasukmanaNo ratings yet

- Class 13 - Design of Compression Members - Bucking 2022Document9 pagesClass 13 - Design of Compression Members - Bucking 2022Engr. Waqas AhmedNo ratings yet

- Estimation of ShedDocument2 pagesEstimation of Shedpage oneNo ratings yet

- Henscha Phils. Inc.: Concrete Pouring ChecklistDocument4 pagesHenscha Phils. Inc.: Concrete Pouring Checklistchester carpioNo ratings yet

- Seismic RC BuildingDocument33 pagesSeismic RC BuildingDario Manrique GamarraNo ratings yet

- FiCEB Spreadsheet V01Document49 pagesFiCEB Spreadsheet V01Kutty MansoorNo ratings yet

- Notes8 Shear 2mnbduwDocument16 pagesNotes8 Shear 2mnbduwAdji SutamaNo ratings yet

- (18044824 - Transactions of The VŠB - Technical University of Ostrava, Civil Engineering Series.) NUMERICAL ANALYSIS OF CASTELLATED BEAMDocument7 pages(18044824 - Transactions of The VŠB - Technical University of Ostrava, Civil Engineering Series.) NUMERICAL ANALYSIS OF CASTELLATED BEAMShinichi KudoNo ratings yet

- Structural Loads & Analysis MethodsDocument3 pagesStructural Loads & Analysis MethodsCharlotte Frias BenitoNo ratings yet

- Summary of Master Programme - 30.05Document9 pagesSummary of Master Programme - 30.05hmdineshNo ratings yet

- CSSBI 58 04 Lightweight Steel Framing Wall Stud and Floor Joist Load TablesDocument48 pagesCSSBI 58 04 Lightweight Steel Framing Wall Stud and Floor Joist Load Tablescons2engNo ratings yet

- Internship Report: Vasuki Vocational CentreDocument83 pagesInternship Report: Vasuki Vocational CentreManoj ReddyNo ratings yet

- Lot - 1 Weekly Progress ReportDocument14 pagesLot - 1 Weekly Progress ReportMesfin DerbewNo ratings yet

- QLD TMR Design Criteria For Bridges and Other StructuresDocument215 pagesQLD TMR Design Criteria For Bridges and Other Structuresyyanan1118No ratings yet

- Provision of Special Confining Reinforcement in FootingDocument1 pageProvision of Special Confining Reinforcement in FootingSS INFRAZONENo ratings yet

- Week 5 Reinforced Concrete Floor SystemsDocument11 pagesWeek 5 Reinforced Concrete Floor SystemsjoanneNo ratings yet

- Fosroc Catalogue 2011Document112 pagesFosroc Catalogue 2011Bahtiar AntanaNo ratings yet

- Effect of Shear Wall Location in Buildings Subjected To Seismic LoadsDocument11 pagesEffect of Shear Wall Location in Buildings Subjected To Seismic LoadsSujtth MathewNo ratings yet

- Module 1 Introduction To Prestressed ConcreteDocument19 pagesModule 1 Introduction To Prestressed ConcreteDastardly HeelNo ratings yet

- Stainless Steel in Fire Final Summary Report March 08 PDFDocument121 pagesStainless Steel in Fire Final Summary Report March 08 PDFjovanaNo ratings yet

- Partition WallsDocument25 pagesPartition Wallssaransh yadavNo ratings yet

- Methodology-TG DECK-rev0 (4feb12)Document11 pagesMethodology-TG DECK-rev0 (4feb12)beshnu garanaik100% (1)