Professional Documents

Culture Documents

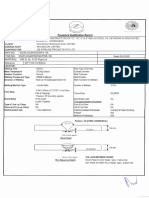

Polyolefinpeandpp Comparison For Sheath U Bolt

Uploaded by

dirgoramboOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polyolefinpeandpp Comparison For Sheath U Bolt

Uploaded by

dirgoramboCopyright:

Available Formats

POLYOLEFIN (PE AND PP)

Physical and mechanical properties: Polyolefins are milky white in appearance and waxy to the touch (except for

transparent PMP as it is uncrystallized). Polyolefins are opaque when thick and transparent when in the form of

film. Although often used as a container or as packing, polyolefins are not completely impervious to water, air or

hydrocarbons, but this implies the notion of time and amount of loss tolerated.

At ambient temperature (23C), PE and PP, partially crystalline, are above their vitreous transition temperature,

thus their uncrystallized phase is rubbery. The vitreous transition temperature of PP is very close to ambient

temperature. PEbd is, at ambient temperature, more sensitive to creep than PEhd and PP (more crystalline).

Polyolefins are more sensitive to orientation, i.e. the mechanical properties are improved if the macromolecules

are oriented in the direction of the stress.

For these crystalline polymers, cuts reducing shock resistance should be avoided.

The paraffinic nature of polyethylene (especially PEhd), makes it a material with good frictional properties.

Chemical properties: Polyolefins have very good chemical stability. At temperatures below 60C, they are

practically insoluble. They are attacked neither by acids (except for oxidants), nor bases, nor salt solutions. They

are insoluble in water and even have little affinity for water. They are recognized as being usable for food

applications. Polypropylenes are sensitive to hydrocarbons. Polyolefins are, in their natural state, very sensitive to

the action of ultraviolet rays (UV) in the presence of oxygen (air), but there are effective photo-stabilizers, as for

example black carbon, the ultimate use of a black dye.

Electrical properties: Polyolefins are excellent electrical insulators for various ambient conditions. This explains

their tendency to be electrostatic. They have a very high resistivity and a high dielectric strength. The low dielectric

loss factor (tan ) that represents the energy lost, converted to heat in the dielectric, prohibits high-frequency

welding.

Thermal properties: PE and PP burn, even when the igniting flame is no longer present, with a bluish flame and

they "drip". In incomplete combustion (fire), carbon monoxide and small quantities of hydrocarbon are formed.

Polyolefins are, in general, rated HB by UL94, but some flame-retardant grades of PP can be V0 or V2.

The vitreous transition temperature crossover is all the less sensitive when the polymer is more crystalline, as

PEhd and PP.

Dimensional properties: Stability is independent of the ingress of humidity (low < 0.2 %) (little affinity for water).

These highly-crystalline polymers thus undergo extensive retraction when molded.

Printing and marking properties: In a general way, polyolefins have a surface on which adhesion is difficult.

However, each manufacturer provides solutions and a surface preparation for printing, painting, marking, and

even vacuum-system metallization. Polyolefins are pleasant to the touch. Certain grades of copolymer are

specially provided for "pleasant contact" applications (handles, grips, etc...).

Implementation properties: Polyolefins are very difficult to glue together. It is necessary to carry out a flame-type

surface preparation (light oxidation) or chemical attack.

Infrared, contact, ultrasonic or hot-air welding is no problem. Induction welding (high frequency) is not applicable

directly as the energy spreading through the material is insufficient for heating it. This drawback can be corrected

by embedding a metal insert in the material. Heating of this metal in the plane of the joint will melt the polyolefin

to be welded.

Summary by GAGGIONE SAS

Information taken from MATIERE PLASTIQUE NATHAN SEPTEMBER 2007

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- ANSYS For Designers - ExtractDocument74 pagesANSYS For Designers - ExtractNono_geotecNo ratings yet

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Key Condenser Failure MechanismDocument8 pagesKey Condenser Failure MechanismdirgoramboNo ratings yet

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- ASME Pressure Vessels Basic CalculationsDocument23 pagesASME Pressure Vessels Basic Calculationsdhasdj100% (17)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Key Condenser Failure MechanismDocument8 pagesKey Condenser Failure MechanismdirgoramboNo ratings yet

- Key Condenser Failure MechanismDocument8 pagesKey Condenser Failure MechanismdirgoramboNo ratings yet

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- MIT18 03SCF11 s27 5textDocument2 pagesMIT18 03SCF11 s27 5textTushar GuptaNo ratings yet

- MIT18 03S10 c30 PDFDocument5 pagesMIT18 03S10 c30 PDFdirgoramboNo ratings yet

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- MIT18 03S10 c30 PDFDocument5 pagesMIT18 03S10 c30 PDFdirgoramboNo ratings yet

- Lecture 99Document5 pagesLecture 99dirgoramboNo ratings yet

- A Comparison of Selective Extraction Soil Geochemistry and Biogeochemistry in The Cobar AreaDocument17 pagesA Comparison of Selective Extraction Soil Geochemistry and Biogeochemistry in The Cobar AreaCharles XavierNo ratings yet

- NMDC-WABAG-54-05-15-BE-1153-R2 - Process Design Basis - APPDocument31 pagesNMDC-WABAG-54-05-15-BE-1153-R2 - Process Design Basis - APPneeraj1mishraNo ratings yet

- Design and Analysis of Go Kart Chasis PDFDocument6 pagesDesign and Analysis of Go Kart Chasis PDFPushparaj MariaNo ratings yet

- PlasticsDocument21 pagesPlasticsJaypee MontealegreNo ratings yet

- Overall Schedule - 29 OctDocument4 pagesOverall Schedule - 29 OctQamar Hassan IqbalNo ratings yet

- Rotary EvaporatorDocument4 pagesRotary EvaporatorArif FerdianNo ratings yet

- Design Project Title: 100,000 Mta of Soda Ash Production PlantDocument439 pagesDesign Project Title: 100,000 Mta of Soda Ash Production PlantSliman Al Taya100% (4)

- Bitumen Phenomenal Hau KauDocument5 pagesBitumen Phenomenal Hau Kautariq wazedNo ratings yet

- CR Mm3.Ot Mammo: Plates & CassettesDocument4 pagesCR Mm3.Ot Mammo: Plates & CassettesMahdi Saleh AishanNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- IEEE STD C37.41 Ciclo TermicoDocument9 pagesIEEE STD C37.41 Ciclo Termicofelipe sanchezNo ratings yet

- Extra Item Rates AnalysisDocument18 pagesExtra Item Rates AnalysisAnish DhillonNo ratings yet

- 6 Dyeing With Reactive DyeDocument19 pages6 Dyeing With Reactive DyeLuk Ming YinNo ratings yet

- Din 580-Lifting Eye Bolts PDFDocument1 pageDin 580-Lifting Eye Bolts PDFAntohi CatalinNo ratings yet

- Chemistry 17 (Second Long Sample Exam)Document2 pagesChemistry 17 (Second Long Sample Exam)Nyka C.No ratings yet

- AB EPDM BlendsDocument6 pagesAB EPDM BlendsSurej RajanNo ratings yet

- PQR 3Document2 pagesPQR 3Mecon HyderabadNo ratings yet

- Solid Mechanics - Unit 1 NotesDocument34 pagesSolid Mechanics - Unit 1 NotesBONI TARUNNo ratings yet

- Finite Element Analysis Project ReportDocument11 pagesFinite Element Analysis Project ReportNuraini Sulong100% (3)

- Fatigue Process in Beams of Reinforced Concrete Bridges - A Literature ReviewDocument8 pagesFatigue Process in Beams of Reinforced Concrete Bridges - A Literature ReviewFernandoNo ratings yet

- EEMUA 159 Corrigendum Imprint 04 2015 PDFDocument22 pagesEEMUA 159 Corrigendum Imprint 04 2015 PDFAlfian Ibnu Pratama100% (1)

- Air Quality Meter Gasman-H2S Hydrogen Sulfide - PCE InstrumentsDocument3 pagesAir Quality Meter Gasman-H2S Hydrogen Sulfide - PCE InstrumentsSalman HaroonNo ratings yet

- Olivine Thin Section GuideDocument16 pagesOlivine Thin Section Guideishotthesherifswife100% (1)

- Spaghetti Challenge - 2022-0Document2 pagesSpaghetti Challenge - 2022-0diegoNo ratings yet

- Chemical Waste Log Book 2011 PDFDocument15 pagesChemical Waste Log Book 2011 PDFVictor AniekanNo ratings yet

- Fixed Base Anchor Bolt DesignDocument3 pagesFixed Base Anchor Bolt Designkhan84mind50% (2)

- Assignment 8 SolutionDocument6 pagesAssignment 8 SolutionBrishen Hawkins100% (1)

- AXIS INDIA Earthing-and-Lightning-Protection-SystemDocument68 pagesAXIS INDIA Earthing-and-Lightning-Protection-Systemaminchhipa6892No ratings yet

- Pengajuan Penamaan InfusDocument1 pagePengajuan Penamaan InfusNur AzlinNo ratings yet

- Mukesh Paper I JR Arjun e 2019Document18 pagesMukesh Paper I JR Arjun e 2019lisbeth suasacaNo ratings yet

- Cambridge International AS & A Level: CHEMISTRY 9701/42Document24 pagesCambridge International AS & A Level: CHEMISTRY 9701/42YasminNo ratings yet

- Sully: The Untold Story Behind the Miracle on the HudsonFrom EverandSully: The Untold Story Behind the Miracle on the HudsonRating: 4 out of 5 stars4/5 (103)

- The Fabric of Civilization: How Textiles Made the WorldFrom EverandThe Fabric of Civilization: How Textiles Made the WorldRating: 4.5 out of 5 stars4.5/5 (58)

- Hero Found: The Greatest POW Escape of the Vietnam WarFrom EverandHero Found: The Greatest POW Escape of the Vietnam WarRating: 4 out of 5 stars4/5 (19)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaFrom EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNo ratings yet

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)