Professional Documents

Culture Documents

Pressure Electrolyser

Uploaded by

JaviTron74Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Electrolyser

Uploaded by

JaviTron74Copyright:

Available Formats

http://elektrolyse.de/wordpress/?

page_id=38

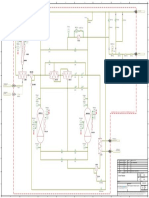

Pressure Electrolyser

Based on the LURGI System

Overview

Pressure electrolysis is a established process for the production of

high-purity hydrogen and oxygen from water. This Process has

compared to atmospheric electrolysis the advantage that the

product gases are available at a pressure of 30 bar as generated.

As a result the hydrogen and oxygen are directly usable for most

applications an do not require any separate compression.

The design of the Lurgi System pressure electrolyser Systems is

distinguished by advance engineering, high reliability, convenient

operation and a long life span. They are backed by decades of

experience in the construction an commissioning of pressure

electrolysis plants.

Bipolar Cells in filter-press type assembly

Electrodes made of steel with new galvanic protection activation and

increase of the geometric and active electrode surface

Improved construction of the cell block parts like cell-frame, cellplate and pre-electrodes. Designed for lower current resistance and

http://elektrolyse.de/wordpress/?page_id=38

increased active surface area. Produced without thermal and forming

process related tension

Pressure process results in very compact equipment design. A large

number of cells can be arranged in line and large quantities of

hydrogen can generated in a single unit of low space requirements

Electrolyte used is 25% potassium hydroxide solution

Forced circulation of electrolyte provides for optimum heat

dissipation an uniform electrolyte concentration in all cells

Separation of gas and electrolyte takes place in horizontal separators

fitted with special internals to reduce aerosol level in product gases

Advantages

The pressure electrolyser have many advantages that ensure a

sophisticated and trouble-free hydrogen & oxygen production.

The major advantages are:

Pressure operation results in low specific energy consumption

Very low level of aerosols in product gases. Scrubbing of gases to

clean them of KOH is not required

Hydrogen and oxygen are available at 30 bar pressure. No

compressor required for storage and use of the product gases at this

pressure, saving approx. 0,2 kWh/Nm3 H2 energy for compression

Capacities up to 1400 Nm3/h H2 accommodated in a single

electrolyser, resulting in very small space requirements, low building

construction costs and reduced maintenance expenditure

Easy and secure operation due to extensive automation

High availability of equipment together with extensive flexibility and

long life

Convenient installation of factory-assembled cell blocks

Very high environmental compatibility. The only operating

consumables required are water and electricity

Range of Supply

The pressure electrolysers are built in unit capacities of 200 to

1400 Nm3/h hydrogen output and 100 to 700 Nm3/h oxygen

output. Larger capacities are readily obtained by operating a

multiple number of units in parallel.

The capacity of the pressure electrolysers is matched to the given

gas demand by just modifying the number of cells. These cells are

factory-assembled as blocks of the required size.

http://elektrolyse.de/wordpress/?page_id=38

ELB supplies the engineering and equipment for complete

pressure electrolysis plants and undertakes on-site installation and

commissioning. In addition to the electrolyser, The overall plant

comprises:

Modern signaling and monitoring system

Transformer/Rectifier

Feed water system

Electrolyte station

Gas and electrolyte coolers

Auxiliary equipment to suit the intended use of the product

hydrogen and oxygen is also available, including:

Catalytic gas purifiers for the production of highest purity H 2 and

O2 (residual impurities < 1 ppm)

Gas dryers to reduce residual moisture to dew points as low as -70C

Gas compressors, for instance to deliver gas at bottling pressure

(200 bar)

Gas bottling units and/or storage tanks

Operating Data

http://elektrolyse.de/wordpress/?page_id=38

Hydrogen and oxygen are generated at a pressure of 30 bar.

Gas purities

Hydrogen:

Oxygen:

99,8 99,9 vol%

99,3 99,6 vol%

Residual impurities in product gases:

O2 in H2:

0,1 0,2 vol%

H2 in O2:

0,4 0,7 vol%

H2O:

approx. 1 2 g/Nm3

KOH:

< 10 mg/Nm3 H2

The product gases are free from CO, CO2, CH4 and sulphur or

chlorine components.

Utilities consumption

Energy:

4,3 4,65 kWh/Nm3 H2

(gas at 0C, 1013 mbar, dry)

Feed water:

Cooling water:

0,85 l/Nm3 H2

80 l/Nm3 H2

Gas production rate is variable between 25% and 100% of the

nominal capacity on every electrolyser.

Maintenance

The pressure electrolysers are designed for many years of

uninterrupted operation and are essentially free from maintenance

requirements.

Plants now in service have been operating for more than 20 years

without the cells having to be opened during the time.

ELB can offer you full after-sales services from inspections,

maintenance support, qualified advices if any problems arise to

optimisation of operating parameters.

You might also like

- Solutions To Irodov's Problems - Volume IIDocument442 pagesSolutions To Irodov's Problems - Volume IIZequinha de Abreu100% (2)

- Hydrogen TechDocument57 pagesHydrogen Techruk1921No ratings yet

- Hydrogen Production in ProgerssDocument21 pagesHydrogen Production in ProgerssAnonymous Tepy8LZzGW100% (1)

- Electrolyser Case Studies: Key Players and TechnologiesDocument26 pagesElectrolyser Case Studies: Key Players and TechnologiesRaulNo ratings yet

- Dynamic model of manipulatorsDocument20 pagesDynamic model of manipulatorsbalkyderNo ratings yet

- Heuristic Design of Pressure Swing AdsorptionDocument19 pagesHeuristic Design of Pressure Swing AdsorptionGenoa SweatersNo ratings yet

- HydrogenDocument38 pagesHydrogenClaudio Ibarra Casanova0% (2)

- NREL Novel Electrolyzer Applications Providing More Than Just Hydrogen PDFDocument35 pagesNREL Novel Electrolyzer Applications Providing More Than Just Hydrogen PDFJosePPMolinaNo ratings yet

- Max Born, Albert Einstein-The Born-Einstein Letters-Macmillan (1971)Document132 pagesMax Born, Albert Einstein-The Born-Einstein Letters-Macmillan (1971)Brian O'SullivanNo ratings yet

- PEM Water Electrolyzers: Modeling, Simulation and Experimental AnalysisDocument64 pagesPEM Water Electrolyzers: Modeling, Simulation and Experimental Analysisabhijay1987100% (1)

- Pre ElectrDocument195 pagesPre ElectrIndra MaulanaNo ratings yet

- Cummins Hystat 70 SpecsheetDocument2 pagesCummins Hystat 70 SpecsheetamsukdNo ratings yet

- Top 2018-03-02 FC Expo Nel FinalDocument37 pagesTop 2018-03-02 FC Expo Nel Finalmsantosu000No ratings yet

- Corrosion Intergranular ASTM A262Document4 pagesCorrosion Intergranular ASTM A262JaviTron74100% (1)

- Annex 1 - Hystat-10 IndoorDocument15 pagesAnnex 1 - Hystat-10 Indoorc108No ratings yet

- Report On Hydrogen ProductionDocument237 pagesReport On Hydrogen ProductionAnura Bandara100% (2)

- Bellin, E. H. (1984) - The Psychoanalytic Narrative On The Transformational Axis Between Writing and SpeechDocument15 pagesBellin, E. H. (1984) - The Psychoanalytic Narrative On The Transformational Axis Between Writing and SpeechofanimenochNo ratings yet

- Recent Progress in Alkaline Water Electrolysis For Hydrogen Production and Applications.Document20 pagesRecent Progress in Alkaline Water Electrolysis For Hydrogen Production and Applications.Salvador Leon GomezNo ratings yet

- Advances in Alkaline Water Electrolyzers: A Review: A, B, C, C A, BDocument54 pagesAdvances in Alkaline Water Electrolyzers: A Review: A, B, C, C A, BJoshua Mitchell100% (1)

- 2 2 2 Hydrogen FuelingDocument16 pages2 2 2 Hydrogen Fuelingsbr4No ratings yet

- AC-DC Converters For Electrolyzer Applications StaDocument30 pagesAC-DC Converters For Electrolyzer Applications StaAudaNo ratings yet

- 3 - Li2016 Article PressureSwingAdsorptionMembranDocument10 pages3 - Li2016 Article PressureSwingAdsorptionMembranMohammadAsifNo ratings yet

- Hydrogen Liquefaction ReportDocument33 pagesHydrogen Liquefaction ReportDilla WahabNo ratings yet

- Renewable Hydrogen Technologies: Production, Purification, Storage, Applications and SafetyFrom EverandRenewable Hydrogen Technologies: Production, Purification, Storage, Applications and SafetyLuis M GandiaRating: 3 out of 5 stars3/5 (2)

- Hydrogen IcsDocument16 pagesHydrogen IcsVũ PhươngNo ratings yet

- Compressed HydrogenDocument12 pagesCompressed Hydrogenkmrosario100% (1)

- Hydrogen Purification by Pressure Swing Adsorption Uni - 2Document2 pagesHydrogen Purification by Pressure Swing Adsorption Uni - 2asamad54No ratings yet

- Design Considerations For Industrial Water Electrolyzer PlantsDocument17 pagesDesign Considerations For Industrial Water Electrolyzer PlantsMorteza MahdaviNo ratings yet

- Green Hydrogen: Opportunities in The Energy SystemDocument11 pagesGreen Hydrogen: Opportunities in The Energy SystemAdhi ErlanggaNo ratings yet

- CCS in Hydrogen ProductionDocument36 pagesCCS in Hydrogen ProductionAkshay PatelNo ratings yet

- Dynamic Modelling of a Proton Exchange Membrane (PEM) ElectrolyzerDocument10 pagesDynamic Modelling of a Proton Exchange Membrane (PEM) Electrolyzer1balamanianNo ratings yet

- Ammonia Hydrogen ProductionDocument23 pagesAmmonia Hydrogen ProductionTony Morrow100% (1)

- Hydrogenics - Electrolyzer TechnologyDocument39 pagesHydrogenics - Electrolyzer TechnologyAyahKenzieNo ratings yet

- Cummins Hylyzer 1000 SpecsheetDocument2 pagesCummins Hylyzer 1000 SpecsheetamsukdNo ratings yet

- Renewable Hydrogen - Nikolaos LYMPEROPOULOS (ID 13339910)Document9 pagesRenewable Hydrogen - Nikolaos LYMPEROPOULOS (ID 13339910)valentino alaiaNo ratings yet

- Presentation - HydrogenicsDocument40 pagesPresentation - HydrogenicsAnh NguyenNo ratings yet

- Electrolyzer Modules A) Unipolar and B) Bipolar Cell ConfigurationsDocument8 pagesElectrolyzer Modules A) Unipolar and B) Bipolar Cell ConfigurationsAnuj ShahiNo ratings yet

- API Plans PosterDocument1 pageAPI Plans Posterskdalalsin100% (1)

- P165338A-HPS-1 Rev05Document1 pageP165338A-HPS-1 Rev05Shahzad AhmedNo ratings yet

- Manual HidrigeneradoraDocument170 pagesManual HidrigeneradoraLividodj NirvanakcobainNo ratings yet

- Hydrogen storage methods for a sustainable futureDocument9 pagesHydrogen storage methods for a sustainable futureCevdet AyazNo ratings yet

- WP 17Document34 pagesWP 17Tyndall Centre for Climate Change Research100% (2)

- Episode 3: Production of Synthesis Gas by Steam Methane ReformingDocument31 pagesEpisode 3: Production of Synthesis Gas by Steam Methane ReformingSAJJAD KHUDHUR ABBASNo ratings yet

- NREL Hydrogen Fuel Station CostsDocument46 pagesNREL Hydrogen Fuel Station CostsJim HindsonNo ratings yet

- Hydrogen ProductionDocument6 pagesHydrogen Productionsekhar_jvjNo ratings yet

- 017 Hydrogen Generation PlantDocument4 pages017 Hydrogen Generation PlantSubhasish mukherjeeNo ratings yet

- Modeling, Control, and Optimization of Natural Gas Processing PlantsFrom EverandModeling, Control, and Optimization of Natural Gas Processing PlantsRating: 5 out of 5 stars5/5 (1)

- Weld Defect Wall ChartDocument6 pagesWeld Defect Wall ChartMuhammad Attaulla KhanNo ratings yet

- PEM Water Electrolysis-Fundamentals Prof. TsiplakidesDocument37 pagesPEM Water Electrolysis-Fundamentals Prof. TsiplakidesfernandinhogmzNo ratings yet

- Status of Large Scale Hydrogen Production PlantsDocument15 pagesStatus of Large Scale Hydrogen Production PlantsRohan Lalwani100% (1)

- Unesco - Eolss Sample Chapters: Alkaline Water ElectrolysisDocument6 pagesUnesco - Eolss Sample Chapters: Alkaline Water Electrolysisjorge bustosNo ratings yet

- A One Gigawatt Green PlantDocument45 pagesA One Gigawatt Green PlantIsabelMaríaGarcíaNo ratings yet

- Italy Hydrogen Production SteamDocument10 pagesItaly Hydrogen Production Steamsorincarmen88No ratings yet

- 9013 Energy Requirements For Hydrogen Gas CompressionDocument6 pages9013 Energy Requirements For Hydrogen Gas CompressionPedro JuanNo ratings yet

- Ammonia Based ESSDocument158 pagesAmmonia Based ESSlsaishankarNo ratings yet

- Nel Electrolysers Brochure 2018 PD 0600 0125 Web - 18041145Document9 pagesNel Electrolysers Brochure 2018 PD 0600 0125 Web - 18041145Chaeeon LimNo ratings yet

- Hydrogen Flare Stack Diffusion Flames ReportDocument38 pagesHydrogen Flare Stack Diffusion Flames ReportcottomohrNo ratings yet

- Producing Technology of HydrogenDocument21 pagesProducing Technology of HydrogenOmer Utku Ozdemir100% (1)

- Thermochemical Hydrogen Production: Past and Present ProcessesDocument6 pagesThermochemical Hydrogen Production: Past and Present ProcessesamoNo ratings yet

- 005 Hydrogenics Denis Thomas - Electrolyzer Technology of BioCat ProjectDocument26 pages005 Hydrogenics Denis Thomas - Electrolyzer Technology of BioCat ProjectgmolguinpNo ratings yet

- Hydrogen For TransportationDocument5 pagesHydrogen For Transportationrussell_hodgesNo ratings yet

- Hydrogen NIST DataDocument4 pagesHydrogen NIST DataDevansh MehtaNo ratings yet

- Energy Efficiency of Hydrogen As A Fuel (2016)Document17 pagesEnergy Efficiency of Hydrogen As A Fuel (2016)Marie StorvikNo ratings yet

- Hydrogenics - Power-To-GasDocument19 pagesHydrogenics - Power-To-GasGreenEnergyFuturesNo ratings yet

- Cryogenic Air Separation Unit, Oxy-CombustionDocument15 pagesCryogenic Air Separation Unit, Oxy-CombustionHWANG INBUMNo ratings yet

- Hydrogen Production With PSADocument20 pagesHydrogen Production With PSAghasem_726990287No ratings yet

- Welding DocumentDocument31 pagesWelding DocumentCak NhassNo ratings yet

- Ficha Awwa C-207 Tab5cle Steel RingDocument1 pageFicha Awwa C-207 Tab5cle Steel RingCesar Antonio Vera MazzoNo ratings yet

- Dimension Ring T6 Class FDocument1 pageDimension Ring T6 Class FJaviTron74No ratings yet

- Ficha Awwa C-207 Tab5cle Steel RingDocument1 pageFicha Awwa C-207 Tab5cle Steel RingCesar Antonio Vera MazzoNo ratings yet

- AWWA Standard Steel-Hub Flange Dimensions and SpecificationsDocument1 pageAWWA Standard Steel-Hub Flange Dimensions and SpecificationsJaviTron74No ratings yet

- Flange CatalogDocument1 pageFlange Catalogisrar khanNo ratings yet

- Dimension Hub T3 Class DDocument1 pageDimension Hub T3 Class DJaviTron74No ratings yet

- Asme V - 2010 (A2011)Document4 pagesAsme V - 2010 (A2011)JaviTron74No ratings yet

- Ficha Awwa C-207 Tab5cle Steel RingDocument1 pageFicha Awwa C-207 Tab5cle Steel RingCesar Antonio Vera MazzoNo ratings yet

- Shipping TermsDocument4 pagesShipping TermsJaviTron74No ratings yet

- ContainersDocument2 pagesContainersJaviTron74No ratings yet

- UPS Fails Insulation Resistance Test - 5E67Document2 pagesUPS Fails Insulation Resistance Test - 5E67JaviTron74No ratings yet

- Welding Procedure DocumentationDocument5 pagesWelding Procedure DocumentationJaviTron74No ratings yet

- Shipping TermsDocument4 pagesShipping TermsJaviTron74No ratings yet

- Pumps - IntroductionDocument31 pagesPumps - IntroductionSuresh Thangarajan100% (1)

- IMChap 014 SDocument14 pagesIMChap 014 STroy WingerNo ratings yet

- Solution of Homework 4Document4 pagesSolution of Homework 4Kamalakar Reddy100% (2)

- SERVICE MANUAL CRAWLER EXCAVATOR R210LC-7Document1 pageSERVICE MANUAL CRAWLER EXCAVATOR R210LC-7DmitryNo ratings yet

- Manuale Fancoil - Eng 2012-Rev02Document19 pagesManuale Fancoil - Eng 2012-Rev02ricardo daccacheNo ratings yet

- Tutorial CorelDRAW-X8Document10 pagesTutorial CorelDRAW-X8Ajay BhargavaNo ratings yet

- Sem 2Document128 pagesSem 2Agustin A.No ratings yet

- Product Presentation Nova Blood Gas AnalyzerDocument38 pagesProduct Presentation Nova Blood Gas Analyzerlaboratorium rsdmadani100% (1)

- Tradesman Electronics PDFDocument13 pagesTradesman Electronics PDFsandeepxrNo ratings yet

- Example 1 LS Dyna - Bullet Model SimulationDocument6 pagesExample 1 LS Dyna - Bullet Model Simulationsunil_vrvNo ratings yet

- CBSE Class 5 Mathematics Sample Paper Set NDocument4 pagesCBSE Class 5 Mathematics Sample Paper Set NRamanjeet KaurNo ratings yet

- ICSE Mathematics X PapersDocument22 pagesICSE Mathematics X PapersImmortal TechNo ratings yet

- College of Information Technology Dmmmsu-Mluc City of San FernandoDocument9 pagesCollege of Information Technology Dmmmsu-Mluc City of San FernandoZoilo BagtangNo ratings yet

- Manual 1Document37 pagesManual 1Şahin GüngörNo ratings yet

- VCTDS 00543 enDocument62 pagesVCTDS 00543 enguido algaranazNo ratings yet

- DasibiOzoneMonitorManual 1008Document183 pagesDasibiOzoneMonitorManual 1008api-26966403100% (2)

- Home Automation Iot Bca Up (2ND SEMINAR PPT) RTDocument30 pagesHome Automation Iot Bca Up (2ND SEMINAR PPT) RTTejaswiniNo ratings yet

- Windows Mbox Viewer User Manual 1.0.3.4Document33 pagesWindows Mbox Viewer User Manual 1.0.3.4Billy NoelNo ratings yet

- Canalis KDP-KBA-KBB-KNA-KSA-20-1000A-2014Document324 pagesCanalis KDP-KBA-KBB-KNA-KSA-20-1000A-2014Rubén González CabreraNo ratings yet

- Leveling Limits For Stationary Reciprocating Compressors: Engineering ReferenceDocument2 pagesLeveling Limits For Stationary Reciprocating Compressors: Engineering ReferencealtruismNo ratings yet

- How To Publish A Package in RDocument14 pagesHow To Publish A Package in Rtoton1181No ratings yet

- Tech Note 14Document2 pagesTech Note 14meteohrNo ratings yet

- Microstation V8I Accudraw Basics: Bentley Institute Course GuideDocument80 pagesMicrostation V8I Accudraw Basics: Bentley Institute Course Guideh_eijy2743No ratings yet

- Tesla Regen, Brakes and Sudden AccelerationDocument66 pagesTesla Regen, Brakes and Sudden AccelerationmartinvvNo ratings yet

- 2017 Yr 9 Linear Relations Test A SolutionsDocument13 pages2017 Yr 9 Linear Relations Test A SolutionsSam JeffreyNo ratings yet

- Simultaneous EquationsDocument11 pagesSimultaneous EquationsSaleena AurangzaibNo ratings yet