Professional Documents

Culture Documents

HRW Selection

Uploaded by

GohdsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HRW Selection

Uploaded by

GohdsCopyright:

Available Formats

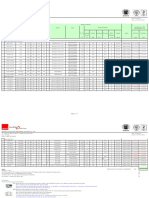

ECOFRESH Heat Recovery Wheels

Performance and Savings Analysis

15-Dec-15

PROJECT :

AREA :

Skypark Cyberjaya Hotel

HRW-1

HEAT RECOVERY WHEEL

Monsoon

Operation

MODEL HRW - 1900

25,163 CMH (incl. Purge Air )

35.0 C DBT

28.0 C WBT

20.7 Gm/Kg

FRESH AIR

24,313 CMH

30.1 C DBT

24.1 C WBT

16.2 Gm/Kg

SUPPLY AIR

24,313 CMH

30.1 C DBT

16.2 Gm/Kg

Cooling Coil

( A.H.U. )

SUPPLY

AIR

0 CMH

26.0 C DBT

12.4 Gm/Kg

EXHAUST AIR

17,509 CMH (incl. Purge Air )

33.2 C DBT

19.0 Gm/Kg

RETURN AIR

16,659 CMH

26.0 C DBT

60.0 %R.H.

12.4 Gm/Kg

REDUCTION IN AIRCON PLANT SIZE

Required AirCon Plant Capacity

Without

Heat Wheel

With

Heat Wheel

Btu/Hr

KW

Btu/Hr

KW

% Capacity Reduction

with Heat Wheel

24,313

12.8

12.2

8.5

RETURN

AIR

PROJECTED SAVINGS IN OPER. COST

Energy Consumption Ratio KW / TON :

Electricity Cost : RM. 0.365 / KWh

0.7

Latent

Total

850,444 122.4 TR

249.3

430.4 KWr

KWH Saved in Aircon Operation / year

481,880

141.2

536,011 84.8 TR

157.1

298.3 KWr

KWH spent /yr.on Wheel Oper.+ Pr.Drop

Nett Electricity saving KWH / year

37%

31%

C DBT

C WBT

Gm/Kg

CONDITIONED SPACE

Sensible

618,192

181.2

22%

CMH

Working Hrs./Day : 24

Working Days/ year : 365

Projected Saving per Year

114,567

RM.

34,287

80,280

29,302

SPECIFICATIONS

MODEL :

HRW - 1900 ( 2.0 MS )

SUPPLY SIDE

Air Flow

24,313 CMH

RECOVERY EFFICIENCY

Sensible

Latent

Pr. Drop

Purge Air =

54.4%

54.4%

0.78 "W.G.

199 Pascals

EXHAUST SIDE

16,659 CMH

79.5%

79.5%

0.49 "W.G.

124 Pascals

850 CMH

ENERGY RECOVERY

Sensible

Latent

Total

BTUH

136,312

314,433

450,745

KW

40.0

92.2

132.1

Moisture Transfer

128.4

Kg/Hr

Tons

37.56

Drive Motor : 415 V / 3 Ph./ 50 Hz ; 0.5 HP

Equipment Dimensions - mm

Width : 2030

Weight

Height : 2030

Depth : 325

: 329 Kgs

WHEEL MEDIA : Wheel Media shall be made of alternating layers of flat and corrugated Aluminium Foil, which will be coated with Molecular

Sieve 3** (Ecosorb 300),which limits the cross contamination to absolute minimum and ensure exclusion of contaminants in the air streams,

while transferring water vapour molecules i.e. selective adsorption.

Wheel shall not be made of Oxidised / etched / silica gel coated Media.

Dust particles upto 800 micron shall pass through media without causing choking of pores

PERFORMANCE : Both Sensible and Latent Recovery Efficiency shall not be less than specification.

Seals : Labyrinth Type seals shall be provided which do not touch media. Wheel shall not have Rubber / Brush type of Seals that rub against

the delicate media.

Drive : Constant Speed Belt Drive shall be provided.

Purge : Field Adjustable Purge Sector shall be provided.

**Not available in select countries...Check with us for details

Ambient Conditions Considered for Energy

30.0 C DBT

63.7 % RH

Savings Analysis

24.4 C WBT

16.7 Gm/Kg

version : v : 010901

Type = 200 mm - MS

ECOFRESH Heat Recovery Wheels

Performance and Savings Analysis

15-Dec-15

PROJECT :

AREA :

Skypark Cyberjaya Hotel

HRW-2

HEAT RECOVERY WHEEL

Monsoon

Operation

MODEL HRW - 2000

27,480 CMH (incl. Purge Air )

35.0 C DBT

28.0 C WBT

20.7 Gm/Kg

FRESH AIR

26,538 CMH

29.4 C DBT

23.5 C WBT

15.5 Gm/Kg

SUPPLY AIR

26,538 CMH

29.4 C DBT

15.5 Gm/Kg

Cooling Coil

( A.H.U. )

SUPPLY

AIR

0 CMH

26.0 C DBT

12.4 Gm/Kg

EXHAUST AIR

23,734 CMH (incl. Purge Air )

32.6 C DBT

18.4 Gm/Kg

RETURN AIR

22,792 CMH

26.0 C DBT

60.0 %R.H.

12.4 Gm/Kg

REDUCTION IN AIRCON PLANT SIZE

Required AirCon Plant Capacity

Without

Heat Wheel

With

Heat Wheel

Btu/Hr

KW

Btu/Hr

KW

% Capacity Reduction

with Heat Wheel

26,538

12.8

12.2

8.5

RETURN

AIR

CMH

C DBT

C WBT

Gm/Kg

CONDITIONED SPACE

PROJECTED SAVINGS IN OPER. COST

Energy Consumption Ratio KW / TON :

Electricity Cost : RM. 0.365 / KWh

0.7

Sensible

674,784

197.8

Latent

Total

928,297 133.6 TR

272.1

469.8 KWr

KWH Saved in Aircon Operation / year

143,742

503,759

147.6

533,790 86.5 TR

156.4

304.1 KWr

KWH spent /yr.on Wheel Oper.+ Pr.Drop

Nett Electricity saving KWH / year

42,291

101,451

Projected Saving per Year

37,030

25%

42%

35%

Working Hrs./Day : 24

Working Days/ year : 365

RM.

SPECIFICATIONS

MODEL :

HRW - 2000 ( 2.0 MS )

SUPPLY SIDE

Air Flow

26,538 CMH

RECOVERY EFFICIENCY

Sensible

Latent

Pr. Drop

Purge Air =

62.6%

62.6%

0.77 "W.G.

195 Pascals

EXHAUST SIDE

22,792 CMH

72.9%

72.9%

0.63 "W.G.

161 Pascals

941 CMH

ENERGY RECOVERY

Sensible

Latent

Total

BTUH

171,025

394,507

565,532

KW

50.1

115.6

165.7

Moisture Transfer

161.2

Kg/Hr

Tons

47.13

Drive Motor : 415 V / 3 Ph./ 50 Hz ; 0.5 HP

Equipment Dimensions - mm

Width : 2130

Weight

Height : 2130

Depth : 325

: 345 Kgs

WHEEL MEDIA : Wheel Media shall be made of alternating layers of flat and corrugated Aluminium Foil, which will be coated with Molecular

Sieve 3** (Ecosorb 300),which limits the cross contamination to absolute minimum and ensure exclusion of contaminants in the air streams,

while transferring water vapour molecules i.e. selective adsorption.

Wheel shall not be made of Oxidised / etched / silica gel coated Media.

Dust particles upto 800 micron shall pass through media without causing choking of pores

PERFORMANCE : Both Sensible and Latent Recovery Efficiency shall not be less than specification.

Seals : Labyrinth Type seals shall be provided which do not touch media. Wheel shall not have Rubber / Brush type of Seals that rub against

the delicate media.

Drive : Constant Speed Belt Drive shall be provided.

Purge : Field Adjustable Purge Sector shall be provided.

**Not available in select countries...Check with us for details

Ambient Conditions Considered for Energy

30.0 C DBT

63.7 % RH

Savings Analysis

24.4 C WBT

16.7 Gm/Kg

version : v : 010901

Type = 200 mm - MS

You might also like

- Innovation for Energy Efficiency: Proceedings of the European Conference, Newcastle upon Tyne, UK, 15–17 September 1987From EverandInnovation for Energy Efficiency: Proceedings of the European Conference, Newcastle upon Tyne, UK, 15–17 September 1987D A ReayNo ratings yet

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideFrom EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideNo ratings yet

- Bry-Air Heat Recovery Wheel PDFDocument4 pagesBry-Air Heat Recovery Wheel PDFDak SerikNo ratings yet

- Heat Wheel: Mohammad Yusuf 13PKB380Document10 pagesHeat Wheel: Mohammad Yusuf 13PKB380Haider Ali100% (1)

- ORC Working Fluids Comparison ECOS PresentationDocument16 pagesORC Working Fluids Comparison ECOS Presentationoverlord5555No ratings yet

- Carrier E20-II Design Software Hourly Analysis Program v4.60 Release SheetDocument2 pagesCarrier E20-II Design Software Hourly Analysis Program v4.60 Release SheetZeeshan HasanNo ratings yet

- Heat TransferDocument1 pageHeat TransferhuangjlNo ratings yet

- HVAC Design For Sustainable Lab: by Gregory R. Johnson, P.E., Member ASHRAEDocument11 pagesHVAC Design For Sustainable Lab: by Gregory R. Johnson, P.E., Member ASHRAEAu NguyenNo ratings yet

- PRICE - Air Distribution GuideDocument5 pagesPRICE - Air Distribution Guidenvenkat.narayan100% (1)

- Zoning Reference GuideDocument20 pagesZoning Reference GuideqwincyNo ratings yet

- Geothermal HVAC: Shifting Performance Risk From Buyer To SellerDocument5 pagesGeothermal HVAC: Shifting Performance Risk From Buyer To SellerKagitha TirumalaNo ratings yet

- Air-Conditioning Load EstimationDocument23 pagesAir-Conditioning Load Estimationtkm2004No ratings yet

- 02 Cooling Load Calculation - HAPDocument2 pages02 Cooling Load Calculation - HAPU DEEPAKNo ratings yet

- Simultaneous Heating & Cooling With ChillersDocument23 pagesSimultaneous Heating & Cooling With ChillersashishtanjeaaNo ratings yet

- BSE 3712 HVAC System Design for Commercial BuildingDocument19 pagesBSE 3712 HVAC System Design for Commercial BuildingChan Tsz HimNo ratings yet

- HVAC ReportDocument5 pagesHVAC ReportrazahNo ratings yet

- Guide To Build Steam RoomDocument2 pagesGuide To Build Steam RoomsidNo ratings yet

- Oxycom IntrCool Brochure (2019) enDocument20 pagesOxycom IntrCool Brochure (2019) enAnkit JainNo ratings yet

- Ventilation Design for Small WorkshopDocument4 pagesVentilation Design for Small WorkshoplaichmailNo ratings yet

- HPT Optimizing Outside Air With HPTDocument11 pagesHPT Optimizing Outside Air With HPTNGUYEN QUANGNo ratings yet

- Design of Ventilation SystemsDocument5 pagesDesign of Ventilation SystemsSimon LaurentNo ratings yet

- 1Document3 pages1ntt_121987No ratings yet

- Ventilation Design Sample For Locker Rooms and HACCPDocument10 pagesVentilation Design Sample For Locker Rooms and HACCPerickquinto100% (1)

- PIBCV-40Document2 pagesPIBCV-40James ChanNo ratings yet

- AHU Heat Gain Due To Supply Fan Motor - HVAC - R Engineering - Eng-TipsDocument8 pagesAHU Heat Gain Due To Supply Fan Motor - HVAC - R Engineering - Eng-TipsNatarajNo ratings yet

- Saiver AHUDocument12 pagesSaiver AHUNorsyafiqah RoziNo ratings yet

- CIBSE Heat Loss & Heat Gain Calculation MethodsDocument9 pagesCIBSE Heat Loss & Heat Gain Calculation Methodsวรศิษฐ์ อ๋องNo ratings yet

- E20 Heat Load Estimation Form: DT Is Too High, Determine Supply CFM For Desired Difference by SupplyDocument1 pageE20 Heat Load Estimation Form: DT Is Too High, Determine Supply CFM For Desired Difference by Supplypsn_kylmNo ratings yet

- Biddle - VRVDocument31 pagesBiddle - VRVutzu_yooNo ratings yet

- Glass Unit V Air-Conditioning Load CalculationDocument26 pagesGlass Unit V Air-Conditioning Load CalculationASWIN KUMAR N SNo ratings yet

- Buffer Tank Hydraulic SeparatorDocument4 pagesBuffer Tank Hydraulic SeparatorJohn MoreNo ratings yet

- ADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.Document8 pagesADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.John EvansNo ratings yet

- CO2 Sensor RoomDocument8 pagesCO2 Sensor RoomTrần Khắc ĐộNo ratings yet

- Small Absorption Chillers Process ApplicationsDocument2 pagesSmall Absorption Chillers Process ApplicationsAdil AbdoNo ratings yet

- Nicotra (Backward Curve)Document95 pagesNicotra (Backward Curve)Archityrema Surya100% (1)

- Technical Handbook Air CurtainsDocument13 pagesTechnical Handbook Air Curtainsaca111111No ratings yet

- Closed Expansion TankDocument4 pagesClosed Expansion Tanka_salehiNo ratings yet

- AC V For Fast Food RestaurantsDocument4 pagesAC V For Fast Food Restaurantselijah namomoNo ratings yet

- Living Room Heat Loss Calculation in BudapestDocument5 pagesLiving Room Heat Loss Calculation in BudapestJoshua RanjithNo ratings yet

- Central Air Conditioning Systems ReviewDocument23 pagesCentral Air Conditioning Systems ReviewlalaNo ratings yet

- Fan Coil Unit Selection Program User ManualDocument18 pagesFan Coil Unit Selection Program User ManualkirmaniNo ratings yet

- Free Cooling Types and ControlsDocument2 pagesFree Cooling Types and ControlsHnin PwintNo ratings yet

- KRANTZ ProductsDocument38 pagesKRANTZ Productsduuk73No ratings yet

- Heat Pumps - Technology GuideDocument44 pagesHeat Pumps - Technology Guideilieoniciuc100% (1)

- Heat Gain From Electrical and Control Equipment in Industrial Plants, Part II, ASHRAE Research Project RP-1395Document4 pagesHeat Gain From Electrical and Control Equipment in Industrial Plants, Part II, ASHRAE Research Project RP-1395Michael LagundinoNo ratings yet

- Sizing calculations for BFW pumps, FD, SA and ID fans for 50,000 kg/hr boilerDocument5 pagesSizing calculations for BFW pumps, FD, SA and ID fans for 50,000 kg/hr boilerMati Dalam Penantian CintamuNo ratings yet

- KRUGER - S - Q - KVN20-AL-123G - R01 - CC H9BC Binh Duong - KANDENKODocument4 pagesKRUGER - S - Q - KVN20-AL-123G - R01 - CC H9BC Binh Duong - KANDENKODo MinhNo ratings yet

- RLT 01 GuidelineDocument24 pagesRLT 01 GuidelineBruno GuedesNo ratings yet

- District Cooling Guide Second Edition - Unlocked-2Document2 pagesDistrict Cooling Guide Second Edition - Unlocked-2Ahmed LabibNo ratings yet

- 10 Induction in Chilled Beams and DiffusersDocument2 pages10 Induction in Chilled Beams and DiffusersPerunding Kotrek Sdn BhdNo ratings yet

- Improving Air Quality of Indoor Swimming Pools: Ir. J.G. MiddendorfDocument18 pagesImproving Air Quality of Indoor Swimming Pools: Ir. J.G. MiddendorftasabajcNo ratings yet

- Fire Size Calculation for Smoke Spill SystemsDocument1 pageFire Size Calculation for Smoke Spill SystemsLee SienNo ratings yet

- Machinery Room Ventilation Analysis ToolDocument48 pagesMachinery Room Ventilation Analysis ToolDon Quijote de la ManchaNo ratings yet

- FAHU-01 equipment efficiency and air parametersDocument2 pagesFAHU-01 equipment efficiency and air parametersRawan Alwan ZarifNo ratings yet

- APN069 ParkingGarage WEB 1 8 15Document8 pagesAPN069 ParkingGarage WEB 1 8 15Rafael Leonardo GomezNo ratings yet

- Why Enthalpy Economizers Don't WorkDocument11 pagesWhy Enthalpy Economizers Don't WorkDGGNo ratings yet

- 9 571 WaterCooledChillerPlantWithEconomizerVP PDFDocument10 pages9 571 WaterCooledChillerPlantWithEconomizerVP PDFFirasNo ratings yet

- Ficha Tecnica 320D3 GCDocument12 pagesFicha Tecnica 320D3 GCanahdezj88No ratings yet

- Kamatsu PC220 - 220LC-8Document7 pagesKamatsu PC220 - 220LC-8Piotr Gabryś Hi-this100% (1)

- ROL - Chiller Eff.Document3 pagesROL - Chiller Eff.GohdsNo ratings yet

- CONQUAS 8th Edition Manual PDFDocument68 pagesCONQUAS 8th Edition Manual PDFladhytiaputraNo ratings yet

- Hrol - 19DVG41G43 700RTDocument5 pagesHrol - 19DVG41G43 700RTGohds100% (1)

- HROL Chiller Part Load ComparisonDocument1 pageHROL Chiller Part Load ComparisonGohdsNo ratings yet

- Mont Kiara Water Heater Explosion PreventableDocument2 pagesMont Kiara Water Heater Explosion PreventableGohdsNo ratings yet

- CKAPS - Specialist ClinicsDocument11 pagesCKAPS - Specialist ClinicsGohdsNo ratings yet

- SLLS Linear Ceiling Diffuser: Materials Surface Finish Standard SizeDocument7 pagesSLLS Linear Ceiling Diffuser: Materials Surface Finish Standard SizeRafi Vica RaficaNo ratings yet

- 03 RyDocument2 pages03 RyGohdsNo ratings yet

- Comparison of Water Cooled and Air CooledDocument3 pagesComparison of Water Cooled and Air CooledGohdsNo ratings yet

- Fan Installation GuideDocument50 pagesFan Installation GuideGohds100% (1)

- Optimize supply air grille performance dataDocument7 pagesOptimize supply air grille performance dataGohdsNo ratings yet

- Phcfasc2006 PDFDocument81 pagesPhcfasc2006 PDFGohdsNo ratings yet

- Optimize supply air grille performance dataDocument7 pagesOptimize supply air grille performance dataGohdsNo ratings yet

- CKAPS - Rehab Facilities and ServicesDocument7 pagesCKAPS - Rehab Facilities and ServicesGohdsNo ratings yet

- Testing & Commissioning Procedure (Electrical)Document100 pagesTesting & Commissioning Procedure (Electrical)Roland Nicolas100% (1)

- Standard Construction ContractsDocument17 pagesStandard Construction ContractsGnabBang75% (4)

- Water Filter CatalogueDocument5 pagesWater Filter CatalogueGohdsNo ratings yet

- Malaysia Construction Law GuideDocument17 pagesMalaysia Construction Law GuideCC OoiNo ratings yet

- Phcfasc2006 PDFDocument81 pagesPhcfasc2006 PDFGohdsNo ratings yet

- Plate Heat ExchangersDocument1 pagePlate Heat ExchangersGohdsNo ratings yet

- 8470-1 Mechanical Car Park & Electric ChargerDocument9 pages8470-1 Mechanical Car Park & Electric ChargerGohdsNo ratings yet

- Nebb T&CDocument118 pagesNebb T&Cbabmech6007100% (3)

- ASHRAE Journal - Primary-Only Vs Primary-Secondary Variable Flow SystemsDocument5 pagesASHRAE Journal - Primary-Only Vs Primary-Secondary Variable Flow SystemsQaz Zaq100% (1)

- True-I Brochure 2017Document2 pagesTrue-I Brochure 2017GohdsNo ratings yet

- BSEEP Active Design GuidebookDocument218 pagesBSEEP Active Design GuidebookArvensisdesignNo ratings yet

- PM&C Asia Operations Manual Project Execution PlanDocument18 pagesPM&C Asia Operations Manual Project Execution PlanGohdsNo ratings yet

- Sewage ComparisonDocument1 pageSewage ComparisonGohdsNo ratings yet

- Summary Average Prices M Jan 09Document16 pagesSummary Average Prices M Jan 09Nyu123456No ratings yet

- m4 Pending DrawingsDocument2 pagesm4 Pending DrawingsGohdsNo ratings yet

- Testing & Commissioning Procedure (Electrical)Document100 pagesTesting & Commissioning Procedure (Electrical)Roland Nicolas100% (1)

- Plasma: Introduction To The Fourth State of MatterDocument10 pagesPlasma: Introduction To The Fourth State of MatterNobita NobiNo ratings yet

- ES 12 - Chapter 17 - Plane Motion of Rigid Bodies - Energy and Momentum MethodsDocument50 pagesES 12 - Chapter 17 - Plane Motion of Rigid Bodies - Energy and Momentum Methodscriscab12345No ratings yet

- Evaporative Cooler Design PDFDocument2 pagesEvaporative Cooler Design PDFJamesNo ratings yet

- 2010 H2 Physics Paper 9646/03 suggested solutionsDocument8 pages2010 H2 Physics Paper 9646/03 suggested solutionslaslover100% (1)

- APES Chapter 16 Energy Efficiency and Renewable EnergyDocument83 pagesAPES Chapter 16 Energy Efficiency and Renewable EnergyNWALLLNo ratings yet

- Pages From Chapter 17-16Document10 pagesPages From Chapter 17-16taNo ratings yet

- ECE 467 Solar Cells and Their Applications Midterm Exam I Due Feb. 27th, 2015 NameDocument4 pagesECE 467 Solar Cells and Their Applications Midterm Exam I Due Feb. 27th, 2015 NameRafael BarrosNo ratings yet

- Practice Test 2 - Nuclear ChemistryDocument5 pagesPractice Test 2 - Nuclear ChemistryRauMuống XàoTỏi VắtChanhNo ratings yet

- Modern Physics PDFDocument20 pagesModern Physics PDFkaushik247No ratings yet

- Notes 05Document77 pagesNotes 05Nazhan HaziqNo ratings yet

- Lithium - Properties and InteractionsDocument111 pagesLithium - Properties and Interactionscorey6No ratings yet

- 2 Tractebel RomaniaDocument7 pages2 Tractebel RomaniaJay Rameshbhai ParikhNo ratings yet

- Evans The Atomic Nucleus PDFDocument2 pagesEvans The Atomic Nucleus PDFKevinNo ratings yet

- Nuclei Properties and Nuclear Reactions QuizDocument172 pagesNuclei Properties and Nuclear Reactions QuizNeil Patrick CartajenasNo ratings yet

- Wind & Solar EnergyDocument8 pagesWind & Solar EnergyGayashan KulathungaNo ratings yet

- Solar Water PumpingDocument4 pagesSolar Water PumpingVaibhav Vithoba NaikNo ratings yet

- Electrical Interview Questions Part 14Document13 pagesElectrical Interview Questions Part 14Veera RagavanNo ratings yet

- CR65 & CR65 ICHP Renewable - 331039F - LowresDocument2 pagesCR65 & CR65 ICHP Renewable - 331039F - LowresacastromNo ratings yet

- Sample Energy Auditing For Electrical Appliances of A Residential HomeDocument9 pagesSample Energy Auditing For Electrical Appliances of A Residential Homedarshak444No ratings yet

- MIT Physics 8.01 Exam SolutionsDocument11 pagesMIT Physics 8.01 Exam SolutionsAli RostamiNo ratings yet

- Bal Bharati Public School Class VIII Science Summative Assessment Coal & PetroleumDocument3 pagesBal Bharati Public School Class VIII Science Summative Assessment Coal & Petroleumravilulla0% (1)

- NLCDocument51 pagesNLCPrasant Prasad100% (1)

- Playland Energy AssignmentDocument3 pagesPlayland Energy Assignmentapi-345090993No ratings yet

- Malaysia WordDocument3 pagesMalaysia WordFazrian EkaNo ratings yet

- Solar Panel Importance in 40 CharactersDocument12 pagesSolar Panel Importance in 40 CharactersDevdatt Dhakane50% (6)

- InfralinePlus June 2016Document76 pagesInfralinePlus June 2016SurendranathNo ratings yet

- Application of ASME Performance Test Codes To Geothermal Plant Performance TestingDocument18 pagesApplication of ASME Performance Test Codes To Geothermal Plant Performance Testingmrizalygani99No ratings yet

- Renewable Energy SourcesDocument3 pagesRenewable Energy SourcesApril ShowersNo ratings yet