Professional Documents

Culture Documents

Wwkzii: Jan. 10, 1933. R. H. Farwell

Uploaded by

monem2014Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wwkzii: Jan. 10, 1933. R. H. Farwell

Uploaded by

monem2014Copyright:

Available Formats

Jan. 10, 1933.

R. H. FARWELL.

1,894,033

ENGINE

Filed July 31, 1950

wwkzii

1,894,033

Patented Jan. 10, 1933

ITED STATES

PATENT OFFICE

RAYMOND HILL FARWELL, OF GROTON, CONNECTICUT, .ASSIGNOR 'I'O MICHELL

CBANKLESS ENGINES CORPORATION, OF NEW YORK, N. Y., A CORPORATION OF NEW

YORK

ENGINE

Application ?led July 31, 1930. Serial _N'0. 471K985

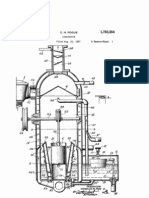

This invention relates to engines and par 21, 22, 23, 24, and 25 being shown. It will

ticularly to internal combustion engines and be understood, however, that any desired

number of cylinders may be used.

to scavenging means therefor.

' The invention has for its salient object to

The cylinders may be formed in any desired

manner and in the embodiment of the inven

provide an engine with scavenging means in

cluding a pump and conduits connecting the tion shown in Fig. 1 each cylinder has formed

10

15

pump to the engine cylinders and so con thereon, at each end, a ?ange 28 which is se

structed and arranged as to be disposed with cured to a ?ange 29 formed on an extension 30

in the engine casing, thereby reducing the di of the cylinder. Each cylinder, furthermore, 69

mensions of the engine and strengthening has a plurality of ports 31 through which the

intake gas and the scavenging charge are ad

the casing.

Further objects of the invention will ap_ mitted.

pear from the following speci?cation taken The end sections of the casing may be

in connection with the drawing, which forms formed in one section or, as shown in Fig. 1, 65.

in two sections, 32 and 33, which are connect

a part of this application, and in which

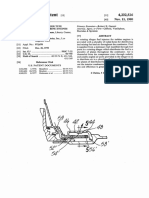

Fig. 1 is a longitudinal elevation, partly in ed together.

Each cylinder has mounted therein a pair

of

oppositely acting pistons 35 and 36, each

ance with the invention; and

section, of an engine constructed in accord

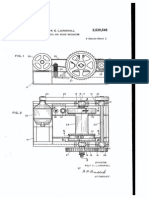

Fig. 2 is a transverse sectional elevation piston having secured thereto a rod 37 hav

20

25

ing a yoke 38. The yokes straddle the swash

The invention brie?y described consists of plate and each yoke has a pair of slipper pads

an engine comprising a plurality of cylin 39 a'nd40 which communicate the reciprocat

ders, a scavenging pump disposed preferably ing motion of the piston to the swash plate

at one end of the engine and conduits connect and have bearing surfaces engaging the op

ing the pump casingwith the cylinders. The posite faces of the swash plate. Une or more

conduits are formed within the engine cas of the yokes 38 has secured thereto and ex

ing and extend longitudinally thereof. At tending'therebeyond in axial alinement with

their outlet ends, the conduits communicate the piston rod an extension rod 45 on the end

with an annular chamber which in turn is of which is mounted a piston 46. The piston

adapted to communicate through suitable 46 is disposed in a pump cylinders? formed

ports with the cylinders, the communication in the outer end of the section C of the en

taken substantially on line 2-2 of Fig. 1.

75

80

through the ports being controlled by the gine casing. The pump cylinder 47 cominuni~

cates with a valve chamber 48 in which is

working pistons in the cylinders.

mounted a rotary valve 49.

The valve chamber 48 has suitable intake

pear from the following description.

In the form of the invention illustrated in and discharge ports which communicate with

the drawing, there is shown an engine com~ a plurality of ducts or conduits 50 which, as

prising three sections, A, B and C. The en shown in Fig. 2, are disposed alternately with

gine shaft 10 is mounted in suitable hearings relation to the cylinders of the engine. The

in the sections A and C and extends through conduits 50 are formed on the inside of the

casing and in Fig. 2 are shown as angular in

the central section B.

rThe engine particularly illustrated in the cross section. The disposition of the conduits

drawings transmits the reciprocating motion within the casing has two important advan

of the pistons to the shaft 10 by means of a tages, namely, reducing the outside dimen

pair of swash plates or slants 11 and 12 which sions of the engine and strengthening the en

are ?xed to the'shatt, and are disposed re gine casing. The valve i9 and the outlet

spectively in the sections A and C of the en~ ports between the valve casing and the con

Further details of the invention will ap

35

gine casing. The cylinders are disposed par

duits are so relatively constructed and ar

allel to the shaft and are concentrically ar ranged that, as the valve is rotated by the

50

90

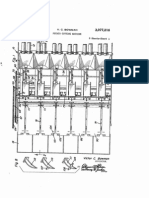

ranged, as shown in Fig. 2, six cylinders, 20, shaft, the valve casing having a compressed

100

1,894,038

charge of air therein will communicate suc

cessively with the ducts or conduits 50. The

conduits 5O discharge into an annular cham

ber 55 which is in communication with the

and having an axis parallel to the cylinder

axes, said chamber communicating with said

ports, an air pump at one end of the casin ,

and conduits connecting said pump with said

5 ports 31 and cylinders 20 to 25 inclusive. As chamber.

70

the pistons uncover the ports 31 the scaveng

4:. An internal combustion engine compris

\ ing charge of air enters the cylinders and ef ing an engine casing, a plurality of cylin

fectively discharges the burnt gases there

from and scavenges the cylinders. The ex

10 haust ports are shown at 41.

Although the reciprocating type of scav

ders having ports therein, working pistons in

said cylinders controlling said ports, a cham

ber surrounding said cylinders and commu 75

nicating with said ports, an air pump at one

enge pump is illustrated, it will be under

end of the casing, and conduits within the

stood that any desired form of pump may be

?asing connecting said pump with said cham

utilized to discharge the compressed air into

r.

5. An internal combustion engine compris

passes into the cylinders.

ing an engine casing, an engine shaft, a plu

In the form of the invention illustrated in rality of cylinders having their axes paral

Fig. 1,_the cylinders are bolted to the end sec lel to said shaft and having ports therein,

15 the ducts or conduits from which the air

80

tions A and C and these sections are also con working pistons in said cylinders controlling

20 nected by a central sleeve 60 which is secured said ports, a chamber surrounding said cyl 85

to the end sections by bolts 61.

It will be obvious from the foregoing de

'

inders and communicating with said ports,

an air pump at one end of the casing, said

scription that the engine constructed in the chamber being spaced from said pump, and

manner set forth will be compact and that conduits connecting said pump with said

25 the provision of the air ducts or conduits

within the casing of the engine will cut down

the dimensions of the engine and effectively

chamber.

'

'

90

RAYMOND HILL FARWELL.

strengthen the casing structure.

30

Although one speci?c embodiment of the

invention has been particularly shown and

95

described, it will be understood that the in

vention is capable of modi?cation and that

changes in the construction and in the ar

rangement of the various cooperating parts

35

may be made without departing from the

spirit or scope of the invention, as expressed

100

in the following claims.

What I claim is:

40

1. An internal combustion engine com

prising an engine casing, a shaft therein, a

105

tons in said cylinders, operative connections

between said pistons and said shaft, a pump

disposed at one end of the casing and driven

110

plurality of cylinders arranged parallel to

and circumferentially around the shaft, pis

45

by the engine, and conduits formed integrally

in said casing connecting the pump to the

cylinders said conduits being located circum-v

ferentially around the shaft and each con

50

duit being disposed between two cylinders.

115

52. An internal combustion ' engine com

prising an engine casing, a shaft therein, a

plurality of cylinders arranged parallel to

the shaft, pistons in said cylinders, operative

55

connections between said pistons and said

120

shaft, a pump disposed at one end of the cas

60

ing and driven by the engine, and conduits

disposed within said casing connecting the

pump to the cylinders, said conduits being

disposed alternately with said cylinders.

125

3. An internal combustion engine com

prising an engine casing, a. plurality of cyl

inders having ports therein, working pistons

in said cylinders controlling said ports, an

annular chamber surrounding said cylinders

130

..

You might also like

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Bob Neal Overunity Compression Unit - US2030759Document5 pagesBob Neal Overunity Compression Unit - US2030759John CarterNo ratings yet

- Dec. 15, 1942. - R. Lang:1 Al Diesel Engine With Charging PancaDocument3 pagesDec. 15, 1942. - R. Lang:1 Al Diesel Engine With Charging Pancamonem2014No ratings yet

- Charles Nelson Pouge (US Pat. 1750354)Document5 pagesCharles Nelson Pouge (US Pat. 1750354)GaleriaTechniki.PLNo ratings yet

- V-shaped engine cylinder block designDocument8 pagesV-shaped engine cylinder block designLalit KumarNo ratings yet

- Us 2397941Document3 pagesUs 2397941monem2014No ratings yet

- No. 648,153. - Patented Apr. 24, I900. J. P. Serve. : Means For Lubrigating Engine Fylinbers, 61.0Document3 pagesNo. 648,153. - Patented Apr. 24, I900. J. P. Serve. : Means For Lubrigating Engine Fylinbers, 61.0monem2014No ratings yet

- ??J.Wima: Patented JanDocument3 pages??J.Wima: Patented JanzgregzNo ratings yet

- Charles Nelson Pogue - US Patent - 1759354Document18 pagesCharles Nelson Pogue - US Patent - 1759354PM100% (1)

- CarburettorsDocument3 pagesCarburettorsAlejandro GonzalezNo ratings yet

- A. E. Jones: Filed March 20, 1924 2 Sheets-SheetDocument5 pagesA. E. Jones: Filed March 20, 1924 2 Sheets-SheetRinnoNo ratings yet

- May 12, 1942-, 'J. D Spaldlng 2,282,615: Brake For DrawworksDocument10 pagesMay 12, 1942-, 'J. D Spaldlng 2,282,615: Brake For DrawworkslfilippiniNo ratings yet

- Us 1001260Document5 pagesUs 1001260mehdi parsNo ratings yet

- Us2960824 PDFDocument5 pagesUs2960824 PDFgrigNo ratings yet

- Sept. 24, 1929. W. Siders: Filed Nov. 5. 1925Document3 pagesSept. 24, 1929. W. Siders: Filed Nov. 5. 1925monem2014No ratings yet

- LLL Billion" .Vizíaßllllla: July 14, 1959 F.V F. EhrlchDocument6 pagesLLL Billion" .Vizíaßllllla: July 14, 1959 F.V F. EhrlchDouglas SanchezNo ratings yet

- Thrust Reverser System with Translating-Rotating Blocker DoorsDocument14 pagesThrust Reverser System with Translating-Rotating Blocker DoorsMarco Raneo PezzanoNo ratings yet

- Us 3460614Document7 pagesUs 3460614scibduser001No ratings yet

- NOV-9, 1943. A. Ca. Schneider: Planetary Turbine TransmissionDocument6 pagesNOV-9, 1943. A. Ca. Schneider: Planetary Turbine Transmissionbelchior alvaroNo ratings yet

- H. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Document4 pagesH. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Josh FullerNo ratings yet

- US2128620 - Bending MachineDocument5 pagesUS2128620 - Bending MachinedevheadbotNo ratings yet

- Rotor Rim-Ventilated Generator with Turning Vanes for Rotor Inlet Coolant Gas FlowDocument4 pagesRotor Rim-Ventilated Generator with Turning Vanes for Rotor Inlet Coolant Gas FlowHamedJamshidiNo ratings yet

- United States Patent (191: McguganDocument6 pagesUnited States Patent (191: McguganJamesStenhouseNo ratings yet

- Variable displacement compressor hinge mechanismDocument13 pagesVariable displacement compressor hinge mechanismSelvaraji MuthuNo ratings yet

- Berthier Us1366863Document9 pagesBerthier Us1366863cll1968No ratings yet

- June 7, 1949. M. Covlns 2,472,647: Filed May 9, 1945Document4 pagesJune 7, 1949. M. Covlns 2,472,647: Filed May 9, 1945jemanuelvNo ratings yet

- 2,418,540 April 8, 1947.: R. E. BresslerDocument5 pages2,418,540 April 8, 1947.: R. E. Bresslerricva_rjNo ratings yet

- Gas Turbine Star Gear Train Coupling SystemDocument11 pagesGas Turbine Star Gear Train Coupling SystemKrozeNo ratings yet

- Rig-E???': Gill!Document6 pagesRig-E???': Gill!luiscremaschiNo ratings yet

- BY (Zém $7406: C. A. FranklinDocument5 pagesBY (Zém $7406: C. A. FranklinHasitha AmarasekaraNo ratings yet

- L'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545Document12 pagesL'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545lfilippiniNo ratings yet

- Turboexpander-Generator Speed Control SystemDocument6 pagesTurboexpander-Generator Speed Control SystemNicandroGonzalesNo ratings yet

- TEPZZ 6 - Z A T: European Patent ApplicationDocument11 pagesTEPZZ 6 - Z A T: European Patent ApplicationtecreativNo ratings yet

- Us 2109297Document6 pagesUs 2109297lfilippiniNo ratings yet

- 1972.10.10 EN Patent DragPump EnergyThic US3697190 Truncated Conical Drag PumpDocument7 pages1972.10.10 EN Patent DragPump EnergyThic US3697190 Truncated Conical Drag PumpRenier SnymanNo ratings yet

- CarburettorsDocument4 pagesCarburettorsAlejandro GonzalezNo ratings yet

- US2736306 Ice PatentDocument4 pagesUS2736306 Ice PatentJosh KertoNo ratings yet

- Guide to Vaporizing Liquid Fuel for EnginesDocument8 pagesGuide to Vaporizing Liquid Fuel for EnginesXavi Granados ContrerasNo ratings yet

- Tree Climbing Motor Patent from 1903Document4 pagesTree Climbing Motor Patent from 1903monem2014No ratings yet

- Us2351483 PDFDocument7 pagesUs2351483 PDFbelchior alvaroNo ratings yet

- European Patent Specification: Turbine Engine With An Abradable SealDocument10 pagesEuropean Patent Specification: Turbine Engine With An Abradable SealshamsNo ratings yet

- Cumblned Muffle and Mud Guard For Mgtor Ve'Rhbles.: Patented July 22, 2%2Document3 pagesCumblned Muffle and Mud Guard For Mgtor Ve'Rhbles.: Patented July 22, 2%2monem2014No ratings yet

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDocument6 pagesWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaNo ratings yet

- Us4232526 PDFDocument5 pagesUs4232526 PDFFernando TaleroNo ratings yet

- Nemesgáz Motor Patent US20110113772 PDFDocument12 pagesNemesgáz Motor Patent US20110113772 PDFGergely HollóNo ratings yet

- SSntanv Engine.,: No. 630,648. - Pamnfed Aug.-A, - 899Document7 pagesSSntanv Engine.,: No. 630,648. - Pamnfed Aug.-A, - 899monem2014100% (1)

- Compressed Air MotorDocument10 pagesCompressed Air Motorjahson362No ratings yet

- Us2291241 PDFDocument5 pagesUs2291241 PDFbelchior alvaroNo ratings yet

- Chapter8-Kaplon Turbine10Document10 pagesChapter8-Kaplon Turbine10fazarbadhushaNo ratings yet

- Brevetto Harley DavidsonDocument3 pagesBrevetto Harley DavidsonAnonymous Wyb8Y1No ratings yet

- Apron MechanismDocument7 pagesApron Mechanismgopalpaul0% (2)

- Illlllllllllilllllllllilllllllllli: United States Patent (191Document3 pagesIlllllllllllilllllllllilllllllllli: United States Patent (191dgfsduuwioNo ratings yet

- United States Patent: Perlo Et Al. (45) Date of Patent: Dec. 20, 2005Document10 pagesUnited States Patent: Perlo Et Al. (45) Date of Patent: Dec. 20, 2005tristanNo ratings yet

- Hydraulic engine mount with variable movement absorptionDocument17 pagesHydraulic engine mount with variable movement absorptionmarcglebNo ratings yet

- Us3771455 PDFDocument3 pagesUs3771455 PDFdgfsduuwioNo ratings yet

- April 2, 1946-C. F. Voytech - 2,397,634: Filed Oc'C. 19, 1945 2 Sheets-Sheet 1Document8 pagesApril 2, 1946-C. F. Voytech - 2,397,634: Filed Oc'C. 19, 1945 2 Sheets-Sheet 1belchior alvaroNo ratings yet

- Reciprocating EngineDocument4 pagesReciprocating EnginePaulFerryNo ratings yet

- Modular Hydraulic System ComponentsDocument12 pagesModular Hydraulic System ComponentsharisupayNo ratings yet

- CCW Two Cylinder ModelsDocument6 pagesCCW Two Cylinder ModelsPaul MartinNo ratings yet

- Tree Climbing Motor Patent from 1903Document4 pagesTree Climbing Motor Patent from 1903monem2014No ratings yet

- No. 748,348. PATENTED DEC. 29, 1903. Rotary'Fluid Engine.: J. F. GooleyDocument4 pagesNo. 748,348. PATENTED DEC. 29, 1903. Rotary'Fluid Engine.: J. F. Gooleymonem2014No ratings yet

- Us 2844129Document3 pagesUs 2844129monem2014No ratings yet

- SSntanv Engine.,: No. 630,648. - Pamnfed Aug.-A, - 899Document7 pagesSSntanv Engine.,: No. 630,648. - Pamnfed Aug.-A, - 899monem2014100% (1)

- Combined Electric Starter, Battery Recharger and Engine Supercharger for Internal Combustion EnginesDocument4 pagesCombined Electric Starter, Battery Recharger and Engine Supercharger for Internal Combustion Enginesmonem2014No ratings yet

- No. 648,153. - Patented Apr. 24, I900. J. P. Serve. : Means For Lubrigating Engine Fylinbers, 61.0Document3 pagesNo. 648,153. - Patented Apr. 24, I900. J. P. Serve. : Means For Lubrigating Engine Fylinbers, 61.0monem2014No ratings yet

- Cumblned Muffle and Mud Guard For Mgtor Ve'Rhbles.: Patented July 22, 2%2Document3 pagesCumblned Muffle and Mud Guard For Mgtor Ve'Rhbles.: Patented July 22, 2%2monem2014No ratings yet

- March23, 1954 J. L, Dunnlgan Y 2,672,853: Sealed Cooling System For Internal-Combustion EnginésDocument3 pagesMarch23, 1954 J. L, Dunnlgan Y 2,672,853: Sealed Cooling System For Internal-Combustion Enginésmonem2014No ratings yet

- Us 2527424Document3 pagesUs 2527424monem2014No ratings yet

- May 15, l945-W. Kilchenmann: Reversible Supercharged Two-Stroke Internal-Combustion Engine IDocument3 pagesMay 15, l945-W. Kilchenmann: Reversible Supercharged Two-Stroke Internal-Combustion Engine Imonem2014No ratings yet

- Us 2668523Document4 pagesUs 2668523monem2014No ratings yet

- Sept. 24, 1929. W. Siders: Filed Nov. 5. 1925Document3 pagesSept. 24, 1929. W. Siders: Filed Nov. 5. 1925monem2014No ratings yet

- Nov. 12, 1935. W. D. Appel 2,020,597: Filed Aug. 13, 1934Document3 pagesNov. 12, 1935. W. D. Appel 2,020,597: Filed Aug. 13, 1934monem2014No ratings yet

- 46, Tazecfeafe Fue) : Filed Oct. 5, 195.1IDocument42 pages46, Tazecfeafe Fue) : Filed Oct. 5, 195.1Imonem2014No ratings yet

- Us 1301141Document4 pagesUs 1301141monem2014No ratings yet

- June 13, 1961 ' F. Wankel Etal 2,988,065: Rotary Internal Conbustion Engine Filed Nov. 17, 1958 2l Sheets-Sheet 1Document33 pagesJune 13, 1961 ' F. Wankel Etal 2,988,065: Rotary Internal Conbustion Engine Filed Nov. 17, 1958 2l Sheets-Sheet 1monem2014No ratings yet

- Oct. 24, 1944, C. K. Newcombe 7 2,360,969: Supercharger For Internal-Combustion EnginesDocument3 pagesOct. 24, 1944, C. K. Newcombe 7 2,360,969: Supercharger For Internal-Combustion Enginesmonem2014No ratings yet

- "A Framework For Assessing The Adequacy and Effectiveness of Software Development MethodologiesDocument47 pages"A Framework For Assessing The Adequacy and Effectiveness of Software Development Methodologiesmonem2014No ratings yet

- Device For Preventing High Voltage ArcingDocument4 pagesDevice For Preventing High Voltage Arcingmonem2014No ratings yet

- Medical Gas DesignDocument8 pagesMedical Gas Designwetchkrub100% (1)

- MD1-0-E-505!06!00001 Generator Transformer Sizing CalculationDocument19 pagesMD1-0-E-505!06!00001 Generator Transformer Sizing Calculationtvpham12350% (2)

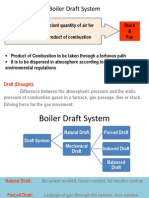

- Boiler Draft SystemDocument56 pagesBoiler Draft SystemAmit Chauhan78% (9)

- SME015 - 4PD0240I C Engine TerminologyDocument67 pagesSME015 - 4PD0240I C Engine TerminologyAshwin KudiNo ratings yet

- Flow SheetsDocument23 pagesFlow SheetsAmmar SaeedNo ratings yet

- DuctulatorDocument44 pagesDuctulatorgeorgeNo ratings yet

- Bomba de Agua CentrifugaDocument3 pagesBomba de Agua CentrifugaHermann DarioNo ratings yet

- Calorific Value Lecture 3, Fuel Tech-LlDocument12 pagesCalorific Value Lecture 3, Fuel Tech-LlShakeel AhmadNo ratings yet

- Trane xr80Document16 pagesTrane xr80Victor Hugo Castillo AguirreNo ratings yet

- SB MultiVIV HighStaticDucted ARNU543BRA4!8!15 20150904103919Document2 pagesSB MultiVIV HighStaticDucted ARNU543BRA4!8!15 20150904103919ags387No ratings yet

- Geothermal Power PointDocument69 pagesGeothermal Power PointArielle Jean BarcenasNo ratings yet

- Kokam SLPB100255255HR2Document3 pagesKokam SLPB100255255HR2Cristhian SalinasNo ratings yet

- Gas FlaringDocument14 pagesGas FlaringWaleed El-azabNo ratings yet

- MATLAB An Introduction With Applications by Amos Gilat (5th Edition)Document53 pagesMATLAB An Introduction With Applications by Amos Gilat (5th Edition)John TauloNo ratings yet

- Valero Blinding Guideline Provides Safety ProceduresDocument13 pagesValero Blinding Guideline Provides Safety ProcedureskishorsinghNo ratings yet

- Tedom Micro: Small Combined Heat & Power UnitDocument5 pagesTedom Micro: Small Combined Heat & Power UnitDan StroescuNo ratings yet

- Nash TC Data SheetDocument2 pagesNash TC Data SheetAnthonyNo ratings yet

- Present Scenario of Solar Energy in India and Scope in FutureDocument17 pagesPresent Scenario of Solar Energy in India and Scope in FutureAbhishek Ranjan100% (3)

- Lecture 3 - Improving Performance - RegenerationDocument5 pagesLecture 3 - Improving Performance - RegenerationMuhammad Alam Zaib KhanNo ratings yet

- Undra Undra Undra Undra: ChileDocument1 pageUndra Undra Undra Undra: ChileValentin Bustos MolinaNo ratings yet

- GEA 18714 Consolidated 1900-P Series Safety Relief Valve Fact SheetDocument2 pagesGEA 18714 Consolidated 1900-P Series Safety Relief Valve Fact SheetWormInchNo ratings yet

- Aft Tme Case StudyDocument2 pagesAft Tme Case Studypca97No ratings yet

- ASHRAE Results-Summary-Spreadsheet-2018Document29 pagesASHRAE Results-Summary-Spreadsheet-2018mech_sahilNo ratings yet

- Dynamic Programming Solution Yields Minimum CostDocument13 pagesDynamic Programming Solution Yields Minimum CostSarayu GowdaNo ratings yet

- Why heat with wood is economical, environmentally friendly and easyDocument20 pagesWhy heat with wood is economical, environmentally friendly and easygflores65100% (1)

- LNG Vaporisers Technologies Onshore LNG Terminals 1610376799Document11 pagesLNG Vaporisers Technologies Onshore LNG Terminals 1610376799lpczyfansNo ratings yet

- Risks of Operating Candu 6 Nuclear Power PlantsDocument66 pagesRisks of Operating Candu 6 Nuclear Power PlantsART'S PLACE100% (2)

- All GTs IntroDocument119 pagesAll GTs Introsppram100% (1)

- CV - Venkatesh Ramachandran - SWPCDocument14 pagesCV - Venkatesh Ramachandran - SWPChusam riadNo ratings yet

- ME321 Turbomachines 2020Document4 pagesME321 Turbomachines 2020Ashish DaundkarNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeFrom EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo ratings yet

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeFrom EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeRating: 4 out of 5 stars4/5 (130)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet