Professional Documents

Culture Documents

Comparison of Various Standards For Timber PDF

Uploaded by

Mirela EnacheOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comparison of Various Standards For Timber PDF

Uploaded by

Mirela EnacheCopyright:

Available Formats

COMPARISON OF VARIOUS STANDARDS FOR THE CHARACTERISTIC

STRENGTH AND STIFFNESS OF STRUCTURAL TIMBER

G B Walford

Forest Research, Rotorua

SUMMARY

Comparing published design stresses for radiata pine with those for both visual and machine grades from Australia

USA, UK and ISO, in the nominal 150x50 mm dimension, it was found that:

Radiata pine has a relatively high assigned strength compared to other visual grades.

For US visual grades radiata pine No. 1 Framing is closest to the Ponderosa #1 grade, Redwood #2 grade and

Douglas fir south #1 grade.

For US machine stress rated (MSR) timbers, No. 1 Framing radiata equates closest to 1200/1.2 grade while

Engineering grade radiata equates closest to 1950/1.5 grade.

The MGP system tracks very closely with the ISO system for softwoods, with MGP8 grade equating to the ISO

S14 grade.

The Australian F-grade system clearly does not suit softwoods.

No. 1 Framing radiata is closest to C16 grade in the EN 338 (Eurocode) system.

INTRODUCTION

The stresses assigned to grades of structural timber can have an important influence of their international

competitiveness. The assigned stresses must represent their properties as accurately as possible yet some form of

grouping is necessary, simply to make their use in design manageable. There are well-established strength grouping

systems in use in Australia and the UK. There are strength class systems set up under ISO standards and Eurocodes.

There are sets of stresses assigned to species/grade combinations in use in USA/Canada and in spite of efforts to

rationalise these into a strength grouping system, the industry there has resisted all efforts, probably due to the belief it

would lose them a market niche, or there would be legal liability issues to face if they changed anything. There are also

the effects of grading method machine grading sorts for stiffness very effectively while visual grading is usually more

efficient at sorting for strength. This means that machine-graded timber will generally have a higher stiffness for a

given strength than will visually graded timber of the same species. In practice, it is the stiffness property (Modulus of

Elasticity or MoE or Youngs Modulus), that is limiting in the design of most timber structures for everyday use.

Hence machine grading is the more relevant grading method. Data from published design standards have been

converted to the same basis and are compared. Because of the size effects on timber stresses, particularly for visually

graded timber, the ISO standard of nominal 150x50 mm size has been used.

As a species group, Japanese standards consider radiata pine to be equivalent to the WWPA Spruce-Pine-Fir (SPF)

group. For machining and general non-structural uses, radiata pine has been considered to be equivalent to Ponderosa

pine.

DATA

Sources of data are:

New Zealand Standard 3603:1993. This lists characteristic stresses for visually graded radiata pine in Engineering

and No. 1 Framing graded to NZS 3631.

National Design Specification for Wood Construction: 1997, American Forest and Paper Association. This lists

allowable design stresses (psi, normal load duration) for visually graded lumber of species groups within the USA.

Within each group up to 30 grade/size combinations are listed.

British Standard BS 5268:Part 2: 1984, Structural Use of Timber. This lists grade stresses (i.e. long term load

duration) for a set of strength classes and for various species/grade combinations, both machine and visually

graded.

ISO TC 165 working document N269, Structural timber structural classes. This lists a set of 14 strength

classes for softwoods and 7 for hardwoods.

Australian standard AS 1720.1-1997. This lists F-grades which are for either visually or machine graded timber,

ISSUE 2 VOLUME 11

13

NZ TIMBER DESIGN JOURNAL

and MGP grades which are for machine graded pines only. The two MGP grades (MGP6 and MGP*) proposed by

Forest Research are added.

South African Standard SABS 0162-2:1994 lists stresses for South African Pine grades 5, 7 10 and 14.

Some conversion factors have been applied to bring the data to a common basis which is that of the NZ and Australian

data, i.e. MoE is the mean value and bending strength is the lower 5 percentile value determined with 75% confidence.

To convert from allowable stress to limit state design, the strength values in the case of the US data have been divided

by factor used in their derivation according to ASTM D 2915, (bending or tensile strength 0.475, compressive strength

parallel to grain 0.526, shear strength 0.244, compressive strength perpendicular to the grain 0.667). In the case of the

UK data the values from Eurocode EN338 were used. For US visual grades a size factor of 1.3 has been applied to the

bending stress. The conversion psi to MPa is 1 MPa = 145 psi. Table 1 lists the data from these sources and used for

comparison.

DISCUSSION

The UK and ISO strength class systems are not specific as to whether they refer to visually-graded or to machinegraded timber. The Australian F-grade system was initially developed for visually graded hardwoods and was used for

all timbers until the MGP system was introduced. Figure 1 compares visually graded radiata and MGP radiata with the

US visual grades.

Figure 1 shows:

Radiata pine has a relatively high strength compared to the others.

Douglas fir larch has a high stiffness for its strength.

Southern pine has exceptionally high strength and stiffness in the top grades.

The timbers closest to No. 1 Framing radiata are Redwood No. 2 grade Ponderosa No. 1 grade, and Douglas fir

south No. 1 grade.

Bending strength, MPa

40

30

20

Radiata

D fir - larch

D fir - south

Hem-fir

Southern pine

SPF

10

0

10

12

Redwood

Ponderosa*

MGP

AustFgrade

Sth Africa

14

16

MoE, GPa

Figure 1. Comparison of visually graded radiata and MGP grades with other visually graded timbers.

Figure 2 compares visually graded radiata and MGP with the stresses assigned to the US machine stress rated (MSR)

series.

ISSUE 2 VOLUME 11

14

NZ TIMBER DESIGN JOURNAL

Bending strength, MPa

40

30

20

10

0

Radiata

MGP

MSR

Sth Africa

10

12

14

16

MoE, GPa

Figure 2. Comparison of radiata pine with the US machine rating system.

Figure 2 shows:

The MGP system tracks the MSR series reasonably closely but with lower strengths for the same stiffnesses.

No. 1 Framing radiata equates closest to MSR 1200/1.2. grade..

Engineering grade radiata equates closest to MSR 1950/1.5 grade.

Figure 3. compares visually graded radiata and the MGP system with the various strength grade systems.

Bending strength, MPa

40

30

20

Radiata

EN385

AustFgrade

ISO soft

ISO hard

MGP

Sth Africa

10

10

12

14

16

MoE, GPa

Figure 3. Comparison of radiata pine with various strength class systems.

Figure 3 shows that:

The Australian F-grade system has a much higher strength-for-stiffness ratio than all the others. This will be due to

the fact that it is based on hardwood data.

The MGP system tracks very closely with the ISO system.

No. 1 Framing radiata is closest to C16 in the EN 338 system.

ISSUE 2 VOLUME 11

15

NZ TIMBER DESIGN JOURNAL

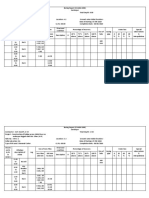

Table 1. List of characteristic stresses for various softwoods.

Species

Grade

MoE

Radiata

Radiata

D fir - larch

D fir - larch

D fir - larch

D fir - larch

D fir - larch

D fir - south

D fir - south

D fir - south

D fir - south

Hem-fir

Hem-fir

Hem-fir

Hem-fir

Hem-fir

So. pine

So. pine

So. pine

So. pine

So. pine

So. pine

So. pine

So. pine

So. pine

So. pine

SPF

SPF

SPF

Redwood

Redwood

Redwood

Redwood

Redwood

Redwood

Redwood

Redwood

Redwood

Ponderosa*

Ponderosa*

Ponderosa*

# 1F

Eng

SS

#1+

#1

#2

#3

SS

#1

#2

#3

SS

#1+

#1

#2

#3

HD SS

SS

HD #1

LD SS

#1

HD #2

LD #1

#2

LD #2

#3

SS

# 1&2

#3

Clear

SS

#1

#2

SS fast

#1 fast

#3

#2 fast

#3 fast

SS

#1

#2

GPa

8.00

10.50

13.10

12.41

11.72

11.03

9.66

9.66

8.97

8.28

7.59

11.03

10.34

10.34

8.97

8.28

13.10

12.41

12.41

11.72

11.72

11.72

11.03

11.03

9.66

9.66

10.34

9.66

8.28

9.66

9.66

8.97

8.28

7.59

7.59

7.59

6.90

6.21

7.59

7.59

6.21

ISSUE 2 VOLUME 11

5%ile

MoR

MPa

17.7

27.7

28.10

22.65

18.87

16.99

9.91

25.48

17.46

16.04

9.44

26.42

20.76

18.40

16.04

9.44

39.20

37.02

25.41

34.12

23.96

21.05

21.78

18.15

16.70

10.89

23.59

16.52

9.44

33.03

25.48

18.40

17.46

20.76

14.63

9.91

13.68

8.02

20.76

17.46

11.32

Comp.

parl.

MPa

20.9

25.7

24.52

22.35

21.63

19.47

11.18

23.08

20.91

19.47

11.18

21.63

19.47

19.47

18.75

10.46

28.19

26.22

24.91

24.26

22.94

22.94

20.98

20.98

19.67

12.13

20.19

16.59

9.37

26.68

14.42

17.31

13.7

15.86

12.98

7.93

10.1

5.77

10.82

9.01

5.77

Tension

parl.

MPa

10.6

16.5

18.87

15.1

12.74

10.85

6.13

19.99

11.32

9.91

5.66

17.45

13.68

11.8

9.91

5.66

28.24

26.36

22.6

17.89

16.94

15.06

14.59

13.65

12.71

8

13.21

8.49

4.72

18.87

15.1

10.85

9.91

11.8

8.49

5.66

8.02

4.72

13.68

9.44

5.66

16

Shear in

beams

MPa

3.8

3.8

2.69

2.69

2.69

2.69

2.69

2.54

2.54

2.54

2.54

2.11

2.11

2.11

2.11

2.11

2.54

2.54

2.54

2.54

2.54

2.54

2.54

2.54

2.54

2.54

1.98

1.98

1.98

4.1

2.26

2.26

2.26

2.26

2.26

2.26

2.26

2.26

1.84

1.84

1.84

Compr.

perp.

MPa

8.9

8.9

6.46

6.46

6.46

6.46

6.46

5.37

5.37

5.37

5.37

4.19

4.19

4.19

4.19

4.19

6.82

5.84

6.82

4.96

5.84

6.82

4.96

5.84

4.96

5.84

4.39

4.39

4.39

6.72

6.72

6.72

6.72

4.39

4.39

6.72

4.39

4.39

5.53

5.53

5.53

Factor

ASD/

size

LSD

Fb

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

metric/

imperial

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

NZ TIMBER DESIGN JOURNAL

Table 1 (cont). List of characteristic stresses for various softwoods.

Species

Grade

MoE

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

EN338

EN335

EN338

EN338

EN338

EN338

EN338

EN338

EN338

Aust Fgrade

Aust Fgrade

Aust Fgrade

Aust Fgrade

Aust Fgrade

Aust Fgrade

900/1.0

1200/1.2

1400/1.2

1350/1.3

1450/1.3

1500/1.3

1650/1.3

1250/1.4

1500/1.4

1600/1.4

1650/1.5

1800/1.5

1950/1.5

1650/1.6

1700/1.6

1800/1.6

2000/1.6

1950/1.7

2250/1.7

2100/1.8

2250/1.8

2400/1.8

2250/1.9

1750/2.0

2400/2.0

2700/2.0

2550/2.1

2500/2.2

2700/2.2

2850/2.3

3000/2.4

C14

C16

C18

C22

C24

C27

C30

C35

C40

F4

F5

F7

F8

F11

F14

GPa

6.90

8.28

8.28

8.97

8.97

8.97

8.97

8.97

9.66

9.66

10.34

10.34

10.34

11.03

11.03

11.03

11.03

11.72

11.72

12.41

12.41

12.41

13.10

13.10

13.80

13.80

14.48

15.17

15.17

15.87

16.55

7

8

9

10

11

12

12

13

14

6.10

6.90

7.90

9.10

10.50

12.00

ISSUE 2 VOLUME 11

5%ile

MoR

MPa

13.07

17.42

20.33

19.60

21.05

21.78

23.96

18.15

21.78

23.23

23.96

26.13

28.31

23.96

24.68

26.13

29.04

28.31

32.67

30.49

32.67

34.85

32.67

25.41

34.85

39.20

37.02

36.30

39.20

41.38

43.56

14

16

18

22

24

27

30

35

40

13

16

20

25

34

40

Comp.

parl.

MPa

13.77

18.36

20.98

20.98

21.31

21.63

22.29

19.34

21.63

21.96

22.29

22.94

23.6

22.29

22.62

22.94

23.93

23.6

25.24

24.58

25.24

25.89

25.24

22.62

25.89

27.53

29.5

26.22

27.53

28.19

28.84

4.3

4.6

4.8

5.1

5.3

5.6

5.7

6.0

6.3

9.7

12

15

20

25

30

Tensio

n parl.

MPa

5.08

8.71

11.62

10.89

11.62

13.07

14.81

11.62

13.07

13.79

14.81

18.87

19.96

17.06

17.06

17.06

18.87

19.96

25.41

22.87

25.41

27.95

25.41

16.33

27.95

26.13

29.76

25.41

31.22

33.39

34.85

8

10

11

13

14

16

18

21

24

6.5

8.2

10

13

17

21

17

Shear in

beams

MPa

Compr

. perp.

MPa

same

same

as

as

those

those

for

for

#2

#2

visual

visual

grade

grade

timber

timber

of

of

the

the

spp

spp

1.7

1.8

2.0

2.4

2.5

2.8

3.0

3.4

3.8

1.5

1.8

2.1

2.5

3.1

3.7

4.3

4.6

4.8

5.1

5.3

5.6

5.7

6.0

6.3

7.7

7.7

9.7

9.7

12

12

Factor

ASD/

size

LSD

Fb

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

0.475

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

metric/

imperial

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

1/145

NZ TIMBER DESIGN JOURNAL

Table 1 (cont). List of characteristic stresses for various softwoods.

Species

Grade

5%ile

MoR

GPa

MPa

ISO soft

S10

6.20

10

ISO soft

S12

7.00

12

ISO soft

S14

7.80

14

ISO soft

S16

8.60

16

ISO soft

S18

9.30

18

ISO soft

S20

10.00

20

ISO soft

S22

10.70

22

ISO soft

S24

11.40

24

ISO soft

S27

12.40

27

ISO soft

S30

13.30

30

ISO soft

S35

14.90

35

ISO soft

S40

16.30

40

ISO soft

S45

17.70

45

ISO soft

S50

19.10

50

ISO hard

H30

13.30

30

ISO hard

H35

14.20

35

ISO hard

H40

15.00

40

ISO hard

H50

16.70

50

ISO hard

H60

18.40

60

ISO hard

H70

20.10

70

ISO hard

H80

21.80

80

MGP

6

6.00

10

MGP

8

8.00

14

MGP

10

10.00

19

MGP

12

12.70

28

MGP

15

15.20

41

Sth African

5

11.50

7.80

Sth African

7

15.80

9.60

Sth African

10

23.30

12.00

Sth African

14

32.40

16.00

* Ponderosa only in 5 x 5 and larger sizes

ISSUE 2 VOLUME 11

MoE

Comp.

parl.

MPa

18

19

20

20

21

22

23

24

26

27

30

32

34

37

24

28

32

40

48

56

64

16

20

24

29

35

16.4

20.7

23.8

23.1

Tensio

n parl.

MPa

6

7

8

10

11

12

13

14

16

18

21

24

27

30

18

21

24

30

36

42

48

4

6.3

8.9

15

23

6.7

10.0

13.3

19.1

18

Shear in

beams

MPa

2.7

3

3.4

3.7

4

4.4

4.7

5

5.5

6

6.8

7.6

8.5

9.3

4.5

4.7

4.8

5.1

5.4

5.7

6.1

2.5

4

5

6.5

9.1

1.6

5.0

2.9

4.0

Compr

. perp.

MPa

5

5.2

5.4

5.5

5.7

5.9

6.1

6.3

6.5

6.8

7.3

7.7

8.2

8.6

8.6

9.6

10.6

12.5

14.5

16.4

18.4

8.9

8.9

12

12

12

4.7

6.7

9.1

12.9

Factor

ASD/

size

LSD

Fb

metric/

imperial

NZ TIMBER DESIGN JOURNAL

You might also like

- Color PsychologyDocument40 pagesColor PsychologyMirela EnacheNo ratings yet

- Street Art Passion For Urban RegenerationDocument31 pagesStreet Art Passion For Urban RegenerationMirela EnacheNo ratings yet

- IDStudentHandbook122612 r3Document26 pagesIDStudentHandbook122612 r3RajapandianNo ratings yet

- Interior Design InfoDocument2 pagesInterior Design InfoMirela EnacheNo ratings yet

- Home Design & DecorDocument68 pagesHome Design & DecorNeo Magasa100% (1)

- ch01 PDFDocument11 pagesch01 PDFMirela EnacheNo ratings yet

- FurnitureDocument9 pagesFurnitureDezyne EcoleNo ratings yet

- Interior Design and Interior Architecture: Extension - Berkeley.eduDocument5 pagesInterior Design and Interior Architecture: Extension - Berkeley.eduMirela EnacheNo ratings yet

- Interior Design Info PDFDocument36 pagesInterior Design Info PDFMirela EnacheNo ratings yet

- Indoor Air Quality: Wood As A Sustainable Building MaterialDocument8 pagesIndoor Air Quality: Wood As A Sustainable Building MaterialEmil JamesNo ratings yet

- Grinzi Cu ZabreleDocument1 pageGrinzi Cu ZabreleMirela EnacheNo ratings yet

- Fema 426Document420 pagesFema 426Mirela Enache100% (1)

- Glulam Handbook 02Document111 pagesGlulam Handbook 02Mirela Enache100% (1)

- EN1995 2 WinterDocument89 pagesEN1995 2 WinterMirela EnacheNo ratings yet

- Comparison of Various Standards For TimberDocument6 pagesComparison of Various Standards For TimberMirela EnacheNo ratings yet

- Eurocoduri NecesareDocument1 pageEurocoduri NecesareGeană MihaelaNo ratings yet

- Earthquake Resistant Steel StructuresDocument128 pagesEarthquake Resistant Steel StructuresQamar Uz Zaman100% (1)

- Lecture2013 02Document36 pagesLecture2013 02Mirela EnacheNo ratings yet

- Eurocode Handbook Explains Structural Design StandardsDocument155 pagesEurocode Handbook Explains Structural Design StandardscristinelbNo ratings yet

- Sustainability of The Building Envelope: Within This PageDocument11 pagesSustainability of The Building Envelope: Within This PageMirela EnacheNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Iqwq-Ce1092-Cpzzz-00-0003 - 0 - Civil Work Construction Procedure PDFDocument12 pagesIqwq-Ce1092-Cpzzz-00-0003 - 0 - Civil Work Construction Procedure PDFNassim SabriNo ratings yet

- 3) T-BeamsDocument4 pages3) T-BeamsVanessa Rosal PalerNo ratings yet

- CP220i Manual Standard Part Numbers Complete - MasterDocument67 pagesCP220i Manual Standard Part Numbers Complete - Masterjacklyn ade putra100% (1)

- Duct Works ChecklistDocument1 pageDuct Works Checklistmd azmathNo ratings yet

- CIAP Document 102: General Conditions of ContractsDocument3 pagesCIAP Document 102: General Conditions of ContractsSheila Mary Delojero CamuloNo ratings yet

- Final Report - Bubble Deck - Hollow Core SlabDocument24 pagesFinal Report - Bubble Deck - Hollow Core SlabDaphne Tan 丽文No ratings yet

- Footing Design Calculations for ABS ProjectDocument8 pagesFooting Design Calculations for ABS Projectabhijeet sahuNo ratings yet

- Building Repair and Maintenance From CracksDocument3 pagesBuilding Repair and Maintenance From Cracksmayur1985febNo ratings yet

- Eccentrically Loaded ColumnsDocument2 pagesEccentrically Loaded ColumnsKing RickNo ratings yet

- Boring ReportDocument8 pagesBoring Reportsourabh_gupta_54No ratings yet

- High performance concrete admixtureDocument2 pagesHigh performance concrete admixturetuski24No ratings yet

- Shear Wall Modelling Techniques: A ReviewDocument9 pagesShear Wall Modelling Techniques: A ReviewAmanulla MullaNo ratings yet

- J - Transmission Design PDFDocument27 pagesJ - Transmission Design PDFosvald97No ratings yet

- Mini ProjectDocument42 pagesMini ProjectVamshi ChinthalaNo ratings yet

- Amims K 3105 - 2Document14 pagesAmims K 3105 - 2wangkai01.sneiNo ratings yet

- How To Select A Heat Shrink SleeveDocument2 pagesHow To Select A Heat Shrink SleeveLava SatNo ratings yet

- Material Takeoff For Clear ASH MezzanineDocument31 pagesMaterial Takeoff For Clear ASH MezzanineMoe Oo Htun - Pebsteel MyanamarNo ratings yet

- White Book C03 S03 Steel Encasements GypLyner ENCASEDocument20 pagesWhite Book C03 S03 Steel Encasements GypLyner ENCASEPavaloaie Marian ConstantinNo ratings yet

- Ecowall's Revolutionary ECA Panel Wall SolutionDocument8 pagesEcowall's Revolutionary ECA Panel Wall SolutionVibhuti Premjibhai KalavadiaNo ratings yet

- Example 3.3 - Simply Supported One Way Slab PDFDocument6 pagesExample 3.3 - Simply Supported One Way Slab PDFFarhana HussinNo ratings yet

- Bill No. 5 - Cluster B, D & FDocument204 pagesBill No. 5 - Cluster B, D & FmimrusfanNo ratings yet

- Church Renovation ProjectDocument11 pagesChurch Renovation Projectapi-689850659No ratings yet

- Product Range: Price ListDocument20 pagesProduct Range: Price ListSilviu PaduraruNo ratings yet

- Shear Wall Design PDFDocument9 pagesShear Wall Design PDFjk.dasgupta100% (2)

- TDS Renderoc SP40 IndiaDocument2 pagesTDS Renderoc SP40 IndiaAnonymous Gb9LeJcI100% (1)

- Structural Design of Movenpick Hotel: An-Najah National University Civil Engineering DepartmentDocument77 pagesStructural Design of Movenpick Hotel: An-Najah National University Civil Engineering Departmentlayaljamal2No ratings yet

- Romac 611 Pipe Restraining System GuideDocument2 pagesRomac 611 Pipe Restraining System GuideQubit SizedNo ratings yet

- 17FG0045 BoqDocument2 pages17FG0045 BoqrrpenolioNo ratings yet

- IGBC GREEN BUILDING RATING SYSTEM UPDATEDocument8 pagesIGBC GREEN BUILDING RATING SYSTEM UPDATEEHS HalolNo ratings yet

- Home Exploration Process: Understanding the StepsDocument3 pagesHome Exploration Process: Understanding the StepsMishra SanjayNo ratings yet