Professional Documents

Culture Documents

US 20130092673A1 - Wire Feed Motor Speed Control System and Method

Uploaded by

Ian McNairOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

US 20130092673A1 - Wire Feed Motor Speed Control System and Method

Uploaded by

Ian McNairCopyright:

Available Formats

US 20130092673A1

(19) United States

(12) Patent Application Publication (10) Pub. No.: US 2013/0092673 A1

(43) Pub. Date:

Lambert et al.

(54)

WIRE FEED MOTOR SPEED CONTROL

Publication Classi?cation

(71) ApplicantszRoger H. Lambert, West Lebanon, NH

(51)

Int. Cl.

323K 9/10

(52) U.S. Cl.

(US); Geoffrey H. Putnam, Topsham,

VT (US); Kevin Horner-Richardson,

Cornish, NH (US)

(72)

USPC

Inventors: Roger H. Lambert, West Lebanon, NH

VT (US); Kevin Horner-Richardson,

(21) App1.No.: 13/650,575

Oct. 12, 2012

Related U.S. Application Data

(60)

................................................... ..

Provisional application No. 61/547,672, ?led on Oct.

14, 2011.

ABSTRACT

/100

System

Input

/154

156 Power 158

Power + Circutt

lEMl

'

AC

225:?

112

Input /

.

"w

PFC

M Drive

'

|

114

Fans

176/

__________ _j

welding Output

/128

Spool Gun

Push/Pull

CPU \184

130

Gun

186

Motor

166

168

192

10 Pin COnnector

/32

.

_134

LW 0 M'9 /

Smart Gun W #136

_ _ _ _ _ _ _ _ _ _ _ _ _ _ __!

'_

Interface

162

Pleaete

/126

Sol.

174/

ower

0'

'

PWM

Cable

(PWM) \164

F

\ Acsoefs'

124

\ Control

Ribbon

H mm

172

Controls /190

switch

Sinks

170/

188

I /1

erma

TMMFLI

160\

110

/

150

Th

219/137.71

A system and a method are provided for improved run-in

control during a start of a Welding process. A poWer circuit

generates Welding output poWer. A control circuit in commu

nication With the poWer circuit controls the output poWer. The

control circuit receives a selection of a Wire feed speed setting

representing a Wire feed speed. The control circuit receives a

selection of a run-in setting representing a run-in percentage

of the Wire feed speed. The control circuit determines an

effective run-in percentage that is equal to the run-in percent

age plus an extra percentage.

Cornish, NH (US)

Filed:

(2006.01)

(57)

(US); Geoffrey H. Putnam, Topsham,

(22)

Apr. 18, 2013

8 Pin Connector

Foot Pedim/"4 38

Pendant

122

/__1 40

Ti, Gun /~142

Remote Trigger /"144

"-1 Stick L

Patent Application Publication

o:

Apr. 18, 2013 Sheet 1 0f 6

US 2013/0092673 A1

Patent Application Publication

Apr. 18, 2013 Sheet 2 0f 6

US 2013/0092673 A1

/200

202

EI

uJ!:

uJ!:

d'\|

J!

J!

III

FIG. 2A

Patent Application Publication

Apr. 18, 2013 Sheet 3 0f 6

US 2013/0092673 A1

/

230

210

232

27

\ \

212 / /24 /242

244

POWER

VRD ON 0

202

FAULT

O VRD OFF

_ _ _ _

m m m WI

Le Knob

Right Knob

WIRESPEED

ARC CONTROL

ADVANCED

FEATURES

280

250 260

252, 254

262, 264, 266, 268

FIG. 2B

Patent Application Publication

Apr. 18, 2013 Sheet 4 0f 6

US 2013/0092673 A1

/ 300

Receiving welding parameter inputs, including a wire

feed speed setting and a run-in setting

Determining an initial run-in speed

ll

Begin feeding wire at the determined run-in speed,

increasing wire rate to wire set point over a

constant period

FIG. 3

/310

Patent Application Publication

Apr. 18, 2013 Sheet 6 0f 6

US 2013/0092673 A1

1000

1010

PROCESSOR

1012

1016

1018

MEMORY

\ DISPLAY CONTROLLER

1014

W

/1020

NETWORK

DISPLAY DEVICE

CONTROLLER

FIG. 5

Apr. 18, 2013

US 2013/0092673 A1

WIRE FEED MOTOR SPEED CONTROL

[0012]

FIG. 4 is a graph illustrating effective run-in speed

as a function of selected Wire feed speed setting and selected

CROSS REFERENCE TO RELATED

APPLICATIONS

[0001] This application claims the bene?t of US. Provi

sional Patent Application No. 61/547,672 ?led Oct. 14,2011,

the content of Which is hereby incorporated by reference in its

entirety.

run-in setting; and

[0013]

FIG. 5 is a schematic vieW of a processing system

for implementing the methods described herein.

[0014] It should be understood that throughout the draW

ings, corresponding reference numerals indicate like or cor

responding parts and features.

BACKGROUND

DETAILED DESCRIPTION

[0002] The present application generally relates to improv

[0015] The term substantially or about used herein

With reference to a quantity or mathematical relationship

ing run-in control in a Welder.

SUMMARY

[0003] The present disclosure provides a system and a

method for improved run-in control during a start of a Weld

ing process. In some implementations, the system may

include a poWer circuit for generating Welding output poWer

and a control circuit in communication With the poWer circuit

to control the output poWer. The control circuit may receive a

selection of a Wire feed speed setting representing a Wire feed

speed. The control circuit may further receive a selection of a

run-in setting representing a run-in percentage of the Wire

feed speed. The control circuit may further determine an

effective run-in percentage that is equal to the run-in percent

age plus an extra percentage.

[0004] In some implementations, the method may include

generating, by the poWer circuit, Welding output poWer. The

method may further include receiving, by the control circuit,

a selection of a Wire feed speed setting representing a Wire

feed speed. The method may further include receiving, by the

control circuit, a selection of a run-in setting representing a

run-in percentage of the Wire feed speed. The method may

further include determining, by the control circuit, an effec

tive run-in percentage that is equal to the run-in percentage

plus an extra percentage.

[0005] In some implementations, the system may include a

poWer circuit for generating Welding output poWer and a

control circuit in communication With the poWer circuit to

control the output poWer. The control circuit may receive a

selection of a Wire feed speed setting representing a Wire feed

speed. The control circuit may further receive a selection of a

run-in setting representing a run-in speed that is a run-in

percentage of the Wire feed speed. The control circuit may

further determine an effective run-in speed that is equal to the

run-in speed plus an extra speed.

includes (1) a variation in the recited quantity or relationship

of an amount that is insubstantially different from a recited

quantity or relationship for an intended purpose or function,

or (2) a variation in the recited quantity or relationship of an

amount that produces the same quality.

[0016] NoW referring to FIG. 1, a poWer supply for a Weld

ing system 100 is provided. The poWer supply 110 receives

input poWer 112 Which may be an alternating current poWer

line, for example a 220 volt AC poWer line. HoWever, it is

understood that the poWer supply 110 may be adaptable to

receive a range of voltages, for example betWeen 187 to 276

volts AC. In addition, it may also be possible to con?gure the

poWer supply for other voltage ranges depending on the appli

cation and required Welding output poWer. The poWer supply

110 provides a direct current poWer output voltage 114 that

may be used as a Welding output poWer 116. In some imple

mentations, the poWer supply 110 may be used for stick

Welding (also knoWn as Shielded Metal Arc Welding or

SMAW) or various other Welding applications such as MIG

(Metal Inert Gas, also knoWn as gas metal arc Welding or

GMAW), ?ux core arc Welding, TIG (tungsten inert gas Weld

ing, also knoWn as Gas Tungsten Arc Welding or GTAW),

plasma arc, or other Welding processes. Therefore, in one

example the current return lead of the Welding output poWer

116 may be provided to a part 118 that is to be Welded, and the

supply voltage may be provided to an electrode, for example

a stick 120 or Wire 122. Therefore, as the stick 120 comes in

contact With the part 118 an arc may be formed that melts both

the base metal and electrode and cooperates to form a Weld. In

other implementations, the output voltage may be provided

through a Wire 122 Which may be continuously fed to the part

to form a continuous Weld. In TIG mode the electrode is not

melted, and generally only the base metal is melted.

[0017] The poWer supply 110 may control the output volt

age and the output current, as Well as the feeding of the Wire

[0006] Further objects, features and advantages of this

application Will become readily apparent to persons skilled in

to optimiZe the Welding process. In addition, the poWer sup

the art after a revieW of the folloWing description, With refer

ence to the draWings and claims that are appended to and form

a part of this speci?cation.

including for example a remote Wire feeder 126, a spool gun

128, or a push/pull gun 130. Further, the poWer supply 110

may be connected to other groups of accessories 132, for

example through an 8-pin connector. The second group of

BRIEF DESCRIPTION OF THE DRAWINGS

[0007]

The draWings described herein are for illustration

ply 110 may be connected to one group of accessories 124

accessories 132 may include a MIG gun 134, a smart gun 136,

a foot pedal 138, a pendant 140, a TIG gun 142, and/or a

purposes only and are not intended to limit the scope of the

remote control/trigger 144.

present disclosure in any Way.

[0008] FIG. 1 is a schematic vieW of a Welding system;

[0009] FIG. 2a is a perspective vieW of a housing Which

may be provided to a circuit breaker or sWitch 154. PoWer

may be provided from the circuit breaker 154 to a poWer

contains the Welding system of FIG. 1;

[0010]

FIG. 2b is a front vieW of an interface on the housing

of FIG. 2a;

[0011]

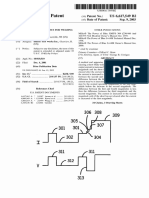

FIG. 3 is a How chart illustrating a method for

improved run-in speed control;

[0018]

Within the poWer supply 110, the input poWer 112

circuit 150. The poWer circuit 150 may condition the input

poWer to provide a Welding output poWer 116, as Well as, for

poWering various additional accessories to support the Weld

ing process. The poWer circuit 150 may also be in communi

cation With the control circuit 152. The control circuit 152

Apr. 18, 2013

US 2013/0092673 A1

may allow the user to control various Welding parameters, as

supply 110 is receiving the input poWer 112. A fault light 220

Well as, providing various control signals to the poWer circuit

150 to control various aspects of the Welding process. The

may indicate When the Welding process has entered a fault

condition. A VRD on indicator 230 may indicate When the

poWer from the circuit breaker 154 may be provided to an

EMI ?lter 156 of the poWer circuit 150. PoWer is provided

from the EMI ?lter 156 to an input bridge 158. PoWer may be

VRD is on, and aVRD off indicator 232 may indicate When

provided from the input bridge 158 to a conditioning circuit

162. The conditioning circuit 162 may include a boost circuit,

a transformer, as Well as a poWer factor correction circuit.

PoWer is provided from the conditioning circuit 162 to the

inverter 160 Where the poWer is converted to a DC signal 114

thereby providing Welding output poWer 11 6. PoWer may also

be provided to a bias circuit 170 to poWer a number of acces

sories internal or external to the poWer supply 110 that facili

tate operation of the poWer supply and Welding process. For

example, the bias circuit 170 may provide poWer to gas sole

noid valves 172, fans 174, as Well as, other accessory devices.

In addition, poWer is provided to a motor drive circuit 164 that

is in communication With a motor 166. The motor 166 may be

in communication With a feed mechanism 168 con?gured to

feed Wire 122 to a Weld gun for use in creation of the Weld.

The control circuit 152 may provide control signals to any of

the previously mentioned circuits in the poWer circuit 150 to

optimiZe the Weld process and performance of the poWer

supply 110. The control circuit 152 may include a pulse Width

modulator 182 and a processor 184 for analyZing various

Weld characteristics and calculating various Weld parameters

the VRD is off.

[0022] A mode selection input 240 may alloW the user to

select a desired Welding process. The mode selection input

240 may be a button Which When pressed causes the poWer

supply 100 to cycle through and select a Welding process.

Three Welding process indicators 242, 244, 246 may respec

tively light upon selection of, for example, MIG, TIG, or stick

Welding. The MIG selection provides a suitable con?guration

for both gas metal arc Welding and ?ux core arc Welding.

[0023] A trigger interlock input 270 may alloW a user to

select betWeen 2T and 4T modes for MIG, TIG and stick

Welds that are activated via an electric sWitch. The 2T mode

alloWs the user to push and hold the sWitch to activate and

release the sWitch to deactivate. The 4T mode alloWs the user

to push and release the sWitch to activate, then push and

release the sWitch again to deactivate. An indicator 272 may

light When the 2T mode is selected, and an indicator 274 may

light When the 4T mode is selected.

[0024]

An amperage input 252 may alloW a user to select a

desired output current. A Wire feed speed input 254 may alloW

a user to select a desired Wire feed speed of the Wire 122. The

desired Wire feed speed may be a desired steady-state Wire

feed speed. In some implementations, the inputs 252 and 254

according to user settings, as Well as, various feedback sig

nals. In addition, an interface circuit 186 may be provided to

control a display 188 that may provide information to the user

of the Welding system. The display 188 may include an LED

display, a LCD display, or various other knoWn display tech

nology. The display may provide various menu choices to the

user, as Well as, providing various feedback on the Welding

may be combined into an adjustable knob. A user may press

process including the values of various parameters or graphs

of previous Welding characteristics. The controls 190 may

desired output voltage of the Welding signal. An inductance

also be in communication With the interface circuit 186 to

alloW the user to provide input such as various Welding

Which, for example, may optimiZe Weld bead characteristics.

parameters to control the operation of the Welding process.

[0019] The poWer supply 110 may further include a voltage

reducing device (VRD) circuit 192, a loW-poWer circuit that

detects contact betWeen the part 118 to be Welded and the

electrode. When an open circuit condition is detected

betWeen the electrode and the Work piece, the VRD circuit

192 may reduce the maximum open circuit voltage to safe

levels. When contact is made and/or the load is beloW a

threshold resistance, the VRD circuit 192 may no longer

reduce the voltage and thus may alloW the Welding system

100 to operate at full poWer. The VRD circuit 192 may be in

communication With a timer 194. The timer 194 may be

implemented as softWare as part of the control circuit 152, or

may be comprised of an electronic circuit.

the adjustment knob to cycle betWeen the inputs 252 and 254,

and then turn the adjustment knob to select a desired value of

the current or Wire feed speed. The selected desired value may

be displayed on a display 250, Which may be a super bright

red LED display.

[0025]

A voltage input 262 may alloW a user to select a

input 264 may alloW a user to select a desired inductance

An arc force input 266 may alloW a user to select desired

properties of arc force. A doWn slope input 268 may alloW a

user to select a doWn slope time, Which is a function of the

doWn ramp rate of the output current. In some implementa

tions, the inputs 262,264, 266, and 268 may be combined into

an adjustable knob. A user may press the adjustment knob to

cycle betWeen the inputs 262, 264, 266, and 268, and then turn

the adjustment knob to select a desired value of the voltage,

inductance, arc force, or doWn slope. The selected desired

value may be displayed on a display 260, Which may be a

super bright red LED display.

[0026]

An advanced features input 280 may alloW a user to

select menus and toggle through various further inputs, Which

are displayed on the displays 250 and 260. A MIG Welding

main menu may provide inputs for operation control, pre

[0020] NoW referring to FIG. 2a, a housing 200 is provided

that may be implemented With the Welding system 100. The

housing 200 may contain the poWer supply 110, and may

?oW, spot on/off, spot time, stitch on/off, stitch time, dWell

time, run-in setting, post-?oW, burn back time, Wire sharp,

further include a user interface 202 and a front connection

panel 204. The front connection panel 204 may, for example,

be used for connecting the poWer supply 110 to the ?rst and

inputs for Wire feed units, amperage calibration, voltage cali

bration, Wire speed calibration, arc hour display, VRD (on, off

or triggered), total Weld energy (for heat input computation),

second groups of accessories 124 and 132, as discussed

above.

provide inputs for operation control, hot start on/ off, hot start

[0021]

time, hot start amperage, and/or a setup submenu. The setup

NoW referring to FIG. 2b, a particular implementa

and/or a setup submenu. The setup submenu may provide

and/or factory defaults. A stick Welding main menu may

tion of a user interface 202 is provided that may include

various inputs selectable by a user and various indicators and

submenu may provide inputs for arc hour display, VRD dis

able, and factory defaults. The TIG main menu may provide

displays. A poWer indicator 21 0 may indicate When the poWer

inputs for operation control, pre-?oW, post-?oW, and a setup

Apr. 18, 2013

US 2013/0092673 A1

submenu. The setup submenu may provide inputs for arc hour

display, VRD disable, and factory defaults.

[0027] Burn back time may refer to an adjustable period of

time that the poWer supply 110 may provide poWer for the

Welding process after the Wire feed stops in order to burn back

the Wire and prevent it from sticking in the Weld puddle. Wire

sharp refers to the application of prede?ned current outputs

applied to the Wire, for example, a rapid series of poWerful

current pulses after the motor 166 is de-energiZed. This pre

another implementation, from a user-selectable value of 3 to

1 5 Wherein the values refer to percentages of the Welding Wire

feed speed. For example, 3, 8, 10, 12, and 15 respectively

refer to 30% (or 0.3), 80% (or 0.8), 100% (or 1), 120% (or

1.2), and 150% (or 1.5). In some implementations, the control

circuit 152 may also receive additional parameters such as the

voltage, Wire feed speed, inductance, burn-back time, and/or

Wire sharp setting from their respective inputs. In these imple

mentations, the percentage may be adjusted as a function of

vents a ball of molten metal from freezing on the end of the

one or more of these additional parameters. The method 300

Welding Wire, and tapers the end of the Weld Wire to a sharp

point, promoting a cleaner start When Welding resumes. The

may proceed from block 310 to block 320.

Most modern GMAW Welding machines provide a

[0032] In block 320, the control circuit 152 may determine

and store an effective run-in speed. The effective run-in speed

may be based on both the run-in setting and the Welding Wire

feed speed. As discussed, the run-in setting may be a select

means of user selectable run-in speed, a rate of Wire feed that

able percentage of the Welding Wire feed speed. Further, the

differs from the user selected steady-state Wire feed speed. It

alloWs an alternate, usually sloWer, motor speed at the begin

ning of a Weld procedure to expedite formation of a stable

molten Weld pool. A menu in the advanced features input 280

may alloW a user to select the run-in speed by choosing a

run-in setting. The run-in setting may be implemented in a

number of Ways. First, for example, the run-in setting may be

a selectable ratio or percentage of the Welding Wire feed

effective run-in speed may be a function of the run-in setting

as Well as other parameters. For example, the effective run-in

current outputs terminate When an open-circuit is detected or

after a prede?ned time or condition is reached.

[0028]

speed, Wherein the run-in speed is equal to the selectable

percentage multiplied by the Welding Wire feed speed setting.

Run-in percentage refers to a percent of Wire feed speed. The

percentage may range, for example, from about 25 percent to

about 150 percent of the Wire feed speed. Second, for

example, the run-in setting may be a selectable run-in speed.

The run-in setting may, for example, alloW a user to tempo

rarily alter the selected Wire feed speed to optimiZe MIG Weld

start characteristics.

[0029]

The control circuit 152 may receive each of the

quantities respectively associated With each of the inputs.

Further, although the above inputs are shoWn in particular

implementations, each of the inputs may be con?gured as a

dial, adjustment knob, button, or sWitch, for example. Addi

tionally, in some implementations, some of the inputs may be

automatically selected by the control circuit 152. Which

inputs are automatically selected and Which inputs are user

selectable may depend on Which Welding process is selected.

In some implementations, some parameters, for example Wire

diameter, material, gas, and joint design, may not be pro

grammed into the control circuit 152.

[0030] NoW referring to FIG. 3, a method 300 for improved

run-in speed control is provided. The method may be imple

speed may be a function the run-in setting, the Wire feed speed

setting (inches/minute), the maximum selectable Wire feed

speed or any combination of these parameters.

[0033]

In some implementations, the effective run-in speed

and effective run-in percentage may be calculated as folloWs.

The variables WS, PS, S S, M, P+, S+, PE, and SE, in the

folloWing formulas are de?ned as folloWs: (1) WS represents

user-selectable Wire feed speed. The Welding Wire feed speed

may be expressed in inches per minute (ipm) or meters per

minute, and de?nes the steady state Wire feed speed during

the Welding process; (2) PS represents the user-selectable

run-in percentage, Which may be a percent of the of the

selected Wire feed speed during run-in, and may range

betWeen 30% and 150%, as discussed above; (3) SS is the

run-in speed based on the user-selectable run-in percentage,

or may rather be a user-selected run-in speed; (4) M repre

sents the maximum selectable Wire feed speed Which may be

a prede?ned constant and is often is near the maximum motor

speed. In many systems, the maximum selectable Wire feed

speed is a value betWeen about 600 and 800 inches per

minute, and more speci?cally may be about 700 inches per

minute; (5) P+ represents extra run-in percentage, (6) S+

represents extra run-in speed, (7) PE represents effective run

in percentage, and (8) SE represents effective run-in speed.

[0034]

Normally, during run-in at the start of the Welding

process, the feed mechanism 168 may feed the Wire 122 at the

run-in speed S S:

SS: WsPs

mented in a Welding process, for example gas metal arc Weld

ing, Which is implemented When the MIG Welding setting is

[0035]

selected. The method alloWs a user to temporarily alter the

an additional extra run-in speed 8+:

selected Wire feed speed to optimiZe MIG Weld start charac

teristics. The ordering of the steps presented herein is merely

one implementation of the method 300. Those skilled in the

art Will recogniZe that the ordering may be varied, that some

steps may occur simultaneously, that some steps may be

omitted, and that further steps may be added. Moreover, each

step involving the controller may be implemented by con?g

uring (e.g. programming) the controller to perform the step.

[0031] The method 300 starts in block 310. In block 310,

the control circuit 152 may receive the run-in setting from the

run-in setting input and the Welding Wire feed speed setting

from the Wire feed speed input. In one implementation, the

run-in setting is a user-selectable percentage ranging from 30

percent to 150 percent of the Welding Wire feed speed, or in

HoWever, the feed mechanism 168 may also provide

5+: WSP+

[0036] Thus, the feed mechanism 168 may feed the Wire

122 at the effective run-in speed SE:

[0037] The extra run-in percentage P+ may be de?ned as

folloWs:

Apr. 18, 2013

US 2013/0092673 A1

[0038]

[0039]

Thus, the effective run-in percentage PE is:

And the effective run-in speed SE is:

drive. Although the feedback scheme performs satisfactorily

across the range of Wire speeds typically used in Gas Metal

Arc Welding, it is prone to fail at extreme loW speeds. The

motor may not turn using the feedback scheme because the

feedback signals are too feeble to compensate for excessive

friction. Additionally, When a sloW setting for Wire feed speed

is multiplied by a run in factor that is, for example, less than

1.0 (or 100%), some Welders might compute a motor speed

and produce a command signal that is too loW for reliable

operation. Attempts to limit or cap the minimum adjusted

motor speed computation could make Wire speed and run-in

settings seem unresponsive. Small changes in either still pro

duce values beloW the threshold, so they have no effect on

[0040] In some circumstances, an additional adjustment to

SE may be implemented. For example, the determined run-in

speed SE may be higher than a ?rst prede?ned speed, for

example the maximum motor speed (Which may, for example,

be the same as the maximum selectable Wire feed speed M).

This may occur, for example, When the selected run-in per

centage PS is higher than 1 (or 100%, or about 1, or about

100%) and the selected Wire feed speed WS is near its select

able maximum. To solve this problem, SE may be set to the

?rst prede?ned speed (or about the ?rst prede?ned speed), for

example the maximum motor speed (or the maximum select

able Wire feed speed M), to ensure that the motor does not run

beyond maximum capacity. In another example, the deter

mined run-in speed SE may be loWer than a second prede?ned

speed (that is loWer than the ?rst prede?ned speed), for

example a minimum motor speed (Which may, for example,

be the same as a minimum selectable Wire feed speed). This

may occur, for example, When the selected run-in percentage

PS is beloW 1 (or 100%, or about 1, or about 100%) and the

selected Wire feed speed WS is near its selectable minimum.

To solve this problem, SE may be set to the second prede?ned

speed (or about the second prede?ned speed), for example the

minimum motor speed (or the minimum selectable Wire feed

speed).

[0041]

Because of the absolute value term | 1PS|, When the

selected run-in percentage PS is 1 (representing 100%), the

extra run-in percentage P+ and the extra run-in speed S+ are

both Zero. But as the selected run-in percentage diverges from

1 (increases above 1 or decreases beloW 1), P+ and S+ both

increase.

[0042] Additionally, because of the term [(MWS)/M]2,

both P+ and S+ are Zero (or at their minima) When the selected

Wire feed WS is set to its maximum M. As the selected Wire

feed WS decreases from its maximum M to its minimum, the

extra run-in percentage P+ and thus the effective run-in per

centage PE increase. This increase ensures that the motor

command signals are not reduced to levels that produce unre

liable speed control. The method 300 may proceed from

block 320 to block 330.

[0043]

Inblock 330, the control circuit 152 may provide the

performance. The minimum reliable motor control speed of

such Welders may be near the desired minimum for steady

state operation, so reliable operation had to be attained at the

expense of an apparent Wide dead band of combined Wire

speed and run-in. The alternate choice, alloWing small prod

ucts of run-in and Wire speed, risked causing the motor to fail

to turn if feed friction Were unusually high or motor magnets

Were especially Weak.

[0045]

The method 300 solves all of these problems. First,

since effective run-in speed SE may be determined by Way of

a prede?ned formula, feedback is not required and thus feeble

feedback does not affect the effective run-in speed SE. Sec

ond, the method 300 eliminates the cost of a tachometer that

is mechanically coupled to the motor 166 or Wire drive, sub

stituting a feW relatively inexpensive electronic components,

such as operational ampli?ers, resistors, capacitors and

diodes, to govern Wire speed. Third, the method 3 00 improves

continuity of run-in adjustment When operators select com

binations of Wire speed and run-in that approach limit of

reliable motor drive operation. The method 300 decreases the

likelihood that the Wire drive system Will stall and appear

defective. By reducing the extra run-in percentage P+ as

selected run-in percentage PS approaches 100%, the compen

sation is nulli?ed, alloWing any arbitrary Wire speed to be

veri?ed by timed Wire feed measurements. Finally, since P+

becomes almost imperceptible at higher speeds, users per

ceive the settings intuitively as a simple percentage instead of

a complicated, nonlinear computation.

[0046] NoW referring to FIG. 4 and Table 1 beloW, a graph

400 and a chart are provided shoWing effective run-in per

centage PE, as de?ned above, as a function of selected Wire

feed speed WS and selected run-in percentage PS When 700

inches per minute is the maximum selectable Wire feed speed

M and is the maximum rate at Which the motor 166 can feed

Wire 122. The selected Wire feed speed WS varies betWeen 50

inches per minute and 700 inches per minute. The selected

run-in percentage PS varies betWeen 30% and 150% (or 0.3 to

1.5). The relationships betWeen effective run-in percentage

PE and selected Wire feed speed WS for selected run-in per

centages PS of 30%, 50%, 75%, 100%, 125%, and 150% are

respectively designated by reference numerals 410, 420, 430,

determined effective run-in speed SE to the motor drive circuit

164 Which causes the motor 166 and feed mechanism 168 to

feed the Wire 122 to the Weld gun at the determined effective

440, 450, and 460. In Table 1, the ?ve single-starred effective

run-in percentages PE in the loWer-right quadrant and their

run-in speed SE during the start of the Welding process. The

extra run-in speed SE improves continuity of run-in adjust

ment When operators select combinations of Wire feed speed

ensure that the effective run-in speeds SE do not exceed the

maximum rate at Which the motor 166 can feed the Wire 122.

corresponding effective run-in speeds SE are adjusted to

settings and run-in settings that approach the limits of reliable

motor drive operation. Providing the extra run-in speed S+

Additionally, the ?ve double- starred effective run-in percent

also decreases the chance that the motor 166 Will stall and

appear defective.

[0044] Some control schemes use voltage and current feed

back from the motor drive to compensate for varying torques

needed to overcome disparate degrees of friction in the Wire

effective run-in speeds SE are adjusted to ensure that the

effective run-in speeds SE do not fall beloW a minimum speed,

shoWn in Table 1 as 51 inches per minute. All other effective

run-in percentages PE in Table 1 are not adjusted, and instead

ages PE in the upper-left quadrant and their corresponding

folloW the formula.

Apr. 18, 2013

US 2013/0092673 A1

TABLE 1

Wire feed speed W (ipm)

50

Runin PS

(%)

30%

50%

75%

100%

125%

150%

100

102%** 51%**

102%** 59%

102%** 80%

102%** 100%

130%

130%

161%

159%

150

200

250

300

400

41% 39% 37% 36% 33%

58% 56% 55% 54% 52%

79% 78% 78% 77% 76%

100% 100% 100% 100% 100%

129% 128% 128% 127% 126%

158% 156% 155% 154% 152%

500

600

700

31%

51%

76%

100%

126%

140%*

30%

50%

75%

100%

30%

50%

75%

100%

117%*

117%*

100%*

100%*

[0047] Any of the controllers, control circuits, modules,

encoding or carrying a set of instructions for execution by a

servers, or engines described may be implemented in one or

more computer systems or integrated controllers. One exem

processor or that cause a computer system to perform any one

or more of the methods or operations disclosed herein.

plary system is provided in FIG. 5. The computer system

[0051] As a person skilled in the art will readily appreciate,

the above description is meant as an illustration of the prin

1000 includes a processor 1010 for executing instructions

such as those described in the methods discussed above. The

instructions may be stored in a computer readable medium

such as memory 1012 or storage devices 1014, for example a

disk drive, CD, or DVD, or in some form of nonvolatile

ciples of this invention. This description is not intended to

limit the scope or application of this invention in that the

memory, internal or external to the processor, such as

EPROM or ?ash. The computer may include a display con

invention is susceptible to modi?cation, variation and

change, without departing from spirit of this invention, as

de?ned in the following claims.

1. A system for providing improved run-in control in a

troller 1016 responsive to instructions to generate a textual or

welding process, the system comprising:

graphical display on a display device 1018, for example a

computer monitor. In addition, the processor 1010 may com

a power circuit for generating welding output power for a

municate with a network controller 1020 to communicate

a control circuit in communication with the power circuit to

data or instructions to other systems, for example other gen

eral computer systems. The network controller 1020 may

control the welding process, the control circuit being

con?gured to:

communicate over Ethernet or other known protocols to dis

tribute processing or provide remote access to information

over a variety of network topologies, including local area

networks, wide area networks, the Internet, or other com

receive a selection of a wire feed speed setting repre

monly used network topologies.

[0048] In other embodiments, dedicated hardware imple

mentations, such as application speci?c integrated circuits,

programmable logic arrays and other hardware devices, can

be constructed to implement one or more of the methods

described herein. Applications that may include the apparatus

and systems of various embodiments can broadly include a

variety of electronic and computer systems. One or more

embodiments described herein may implement functions

using two or more speci?c interconnected hardware modules

or devices with related control and data signals that can be

communicated between and through the modules, or as por

tions of an application-speci?c integrated circuit. Accord

ingly, the present system encompasses software, ?rmware,

and hardware implementations.

[0049] In accordance with various embodiments of the

present disclosure, the methods described herein may be

welding process; and

senting a wire feed speed;

receive a selection of a run-in setting representing a

run-in percentage of the wire feed speed; and

determine an effective run-in percentage that is equal to

the run-in percentage plus an extra percentage.

2. The system of claim 1 wherein the extra percentage is

Zero when the percentage is 100%.

3. The system of claim 1 wherein the extra percentage

increases as the run-in percentage increases above 100%.

4. The system of claim 1 wherein the extra percentage

increases as the run-in percentage decreases below 100%.

5. The system of claim 1 wherein the extra percentage

decreases as the wire feed speed setting approaches its maxi

mum selectable setting.

6. The system of claim 1 wherein the extra percentage is

Zero when the wire feed speed setting is set to its maximum

selectable setting.

7. The system of claim 1 wherein the extra percentage

increases as the wire feed speed setting approaches its mini

system or processor. Further, in an exemplary, non-limited

embodiment, implementations can include distributed pro

mum selectable setting.

8. The system of claim 1 further comprising a feed mecha

nism con?gured to feed wire at a start of the welding process

at an effective run in speed that is equal to the determined

cessing, component/object distributed processing, and paral

effective run-in percentage multiplied by the wire feed speed.

implemented by software programs executable by a computer

lel processing. Alternatively, virtual computer system pro

cessing can be constructed to implement one or more of the

methods or functionality as described herein.

[0050]

Further, the methods described herein may be

embodied in a computer-readable medium. The term com

puter-readable medium includes a single medium or mul

tiple media, such as a centralized or distributed database,

and/or associated caches and servers that store one or more

sets of instructions. The term computer-readable medium

shall also include any medium that is capable of storing,

9. A method for providing improved run-in control in a

welding process, the method comprising:

by a power circuit:

generating welding output power;

by a control circuit in communication with the power cir

cuit to control the welding process:

receiving a selection of a wire feed speed setting repre

senting a wire feed speed;

receiving a selection of a run-in setting representing a

run-in percentage of the wire feed speed; and

Apr. 18, 2013

US 2013/0092673 A1

determining an effective run-in percentage that is equal

receive a selection of a run-in setting representing a

to the run-in percentage plus an extra percentage.

10. The method of claim 9 Wherein the extra percentage is

Zero When the percentage is 100%.

11. The method of claim 9 Wherein the extra percentage

increases as the run-in percentage increases above 100%.

12. The method of claim 9 Wherein the extra percentage

increases as the run-in percentage decreases beloW 100%.

13. The method of claim 9 Wherein the extra percentage

run-in speed that is a run-in percentage of the Wire

decreases as the Wire feed speed setting approaches its maxi

mum selectable setting.

14. The method of claim 9 Wherein the extra percentage is

Zero When the Wire feed speed setting is set to its maximum

selectable setting.

15. The method of claim 9 Wherein the extra percentage

increases as the Wire feed speed setting approaches its mini

mum selectable setting.

16. The method of claim 9 further comprising feeding Wire

feed speed; and

determine an effective run-in speed that is equal to the

run-in speed plus an extra speed.

18. The system of claim 17 Wherein the extra speed is Zero

When the run-in speed is equal to the Wire feed speed.

19. The system of claim 17 Wherein the extra speed

increases as the run-in speed increases above the Wire feed

speed.

20. The system of claim 17 Wherein the extra speed

increases as the run-in speed decreases beloW the Wire feed

speed.

21. The system of claim 17 Wherein the extra speed

decreases as the Wire feed speed setting approaches its maxi

mum selectable setting.

22. The system of claim 17 Wherein the extra speed is Zero

When the Wire feed speed setting is set to its maximum select

able setting.

at a start of the Welding process at an effective run in speed

23. The system of claim 17 Wherein the effective run-in

that is equal to the determined effective run-in percentage

speed is equal to an effective run-in percentage multiplied by

the Wire feed speed, Wherein the effective run-in percentage is

multiplied by the Wire feed speed.

17. A system for providing improved run-in control in a

Welding process, the system comprising:

a poWer circuit for generating Welding output poWer for a

Welding process; and

a control circuit con?gured to:

receive a selection of a Wire feed speed setting repre

senting a Wire feed speed;

equal to the run-in percentage plus an extra percentage,

Wherein the extra percentage increases as the Wire feed speed

setting approaches its minimum selectable setting.

24. The system of claim 17 further comprising a feed

mechanism con?gured to feed Wire at a start of the Welding

process at the effective run in speed.

*

You might also like

- Ulllted States Patent (19) (11) Patent Number: 6,075,224: de Coster (45) Date of Patent: Jun. 13, 2000Document9 pagesUlllted States Patent (19) (11) Patent Number: 6,075,224: de Coster (45) Date of Patent: Jun. 13, 2000KrozeNo ratings yet

- United States Patent (191Document15 pagesUnited States Patent (191pradip panthaNo ratings yet

- Aircraft Starter/Generator Digital Control System Optimizes Power and EfficiencyDocument15 pagesAircraft Starter/Generator Digital Control System Optimizes Power and EfficiencychodekiranNo ratings yet

- United States Mar. 28, 2013: (12) Patent Application Publication (10) Pub. No.: US 2013/0076154 A1Document20 pagesUnited States Mar. 28, 2013: (12) Patent Application Publication (10) Pub. No.: US 2013/0076154 A1aspen89No ratings yet

- @ - Control - : United States Patent (19) (11) Patent Number: 6,103,994Document10 pages@ - Control - : United States Patent (19) (11) Patent Number: 6,103,994KrozeNo ratings yet

- WO SpecClaimsAbstractDocument30 pagesWO SpecClaimsAbstractRaphael Novos RumosNo ratings yet

- United States Patent (19) (11) Patent Number: 6,111,215: Lilly (45) Date of Patent: Aug. 29, 2000Document14 pagesUnited States Patent (19) (11) Patent Number: 6,111,215: Lilly (45) Date of Patent: Aug. 29, 2000Ian McNairNo ratings yet

- Us 20140210278Document12 pagesUs 20140210278Harjinder SinghNo ratings yet

- Development of An Automatic Arc Welding System Using Smaw ProcessDocument7 pagesDevelopment of An Automatic Arc Welding System Using Smaw ProcessapoiNo ratings yet

- Sensorless step recognition for stepping motorsDocument8 pagesSensorless step recognition for stepping motorsMamoun Slamah AlzyoudNo ratings yet

- To Microcomputer: Unlted States Patent (19) (11) Patent Number: 4,712,050Document11 pagesTo Microcomputer: Unlted States Patent (19) (11) Patent Number: 4,712,050Donz RahmandaniNo ratings yet

- Winch system with emergency braking and controlled loweringDocument13 pagesWinch system with emergency braking and controlled loweringAli ViraniNo ratings yet

- SynopsisDocument8 pagesSynopsispradeepagrahari100% (2)

- 0730CT9801R108Document40 pages0730CT9801R108Ursula JohnsonNo ratings yet

- 345KV Autotransformer Spec (08.29.2012)Document56 pages345KV Autotransformer Spec (08.29.2012)Dante FilhoNo ratings yet

- Observation Sheet: DC S S S S R S S SDocument13 pagesObservation Sheet: DC S S S S R S S SSameera MadhushankaNo ratings yet

- Ep 15275056 Nwa 1Document53 pagesEp 15275056 Nwa 1Stephane Brehaut PhD Ceng SMIEEENo ratings yet

- Doubly Fed Induction Generator Using Back To Back PWM Converters and Its Application To Variable-Speed Wind-Energy GenerationDocument11 pagesDoubly Fed Induction Generator Using Back To Back PWM Converters and Its Application To Variable-Speed Wind-Energy GenerationVally ZazaNo ratings yet

- Gtaw and Gmaw Equipment and Supplies: 7.2 Arc Welding Power Sources For GTAWDocument19 pagesGtaw and Gmaw Equipment and Supplies: 7.2 Arc Welding Power Sources For GTAWNachiket MujumdarNo ratings yet

- A Comparison of Techniques For Measurement of Shaft Currents in Rotating MachinesDocument5 pagesA Comparison of Techniques For Measurement of Shaft Currents in Rotating MachinesJavier MaldonadoNo ratings yet

- Reduce CMV in VFDs with Dead-Time CancellationDocument17 pagesReduce CMV in VFDs with Dead-Time CancellationLava KumarNo ratings yet

- T 34Document14 pagesT 34kaliappan45490No ratings yet

- United States Patent (10) Patent No.: US 8,520,412 B2Document25 pagesUnited States Patent (10) Patent No.: US 8,520,412 B2david19775891No ratings yet

- GTP (66 20 6.6KV)Document99 pagesGTP (66 20 6.6KV)ms_kazmi100% (1)

- Torque ControlDocument6 pagesTorque Controlochenapothik2012No ratings yet

- Thyrotronic GBDocument8 pagesThyrotronic GBjunpamsNo ratings yet

- 9 - 3RH, 3TH Contactor Realys PDFDocument6 pages9 - 3RH, 3TH Contactor Realys PDFsaina124796010No ratings yet

- Project Report For Completion OF B. Tech. in Electrical EngineeringDocument57 pagesProject Report For Completion OF B. Tech. in Electrical EngineeringetasureshNo ratings yet

- Us 20130292944Document11 pagesUs 20130292944Victor Von DoomNo ratings yet

- Prepared By: Luis Fernando Montoya Chun-Ju Huang Ashish K. SolankiDocument33 pagesPrepared By: Luis Fernando Montoya Chun-Ju Huang Ashish K. SolankigouravNo ratings yet

- 1Ph Motor 2010Document8 pages1Ph Motor 2010t_meierNo ratings yet

- 750V DC Traction SystemDocument26 pages750V DC Traction SystemShashi Bhusan Singh100% (2)

- Patent Application Publication (10) Pub. No.: US 2015/0278681 A1Document23 pagesPatent Application Publication (10) Pub. No.: US 2015/0278681 A1Greta GarboNo ratings yet

- Tuning A PID Controller For A Digital Excitation Control SystemDocument8 pagesTuning A PID Controller For A Digital Excitation Control SystemSharat Chandra KeswarNo ratings yet

- P&WC Propeller Governor Maintenance ManualDocument12 pagesP&WC Propeller Governor Maintenance ManualMiguel Condor100% (1)

- 13.8kV Bus Duct Sizing For Arar Dated 23.03.2005Document9 pages13.8kV Bus Duct Sizing For Arar Dated 23.03.2005srigirisetty208No ratings yet

- Study On Operational Tests For FACTS Thyristor ValvesDocument8 pagesStudy On Operational Tests For FACTS Thyristor ValvesMįhír PatelNo ratings yet

- Design and Implementation of Welding With Electromagnetic Trailing Peening Control CircuitDocument4 pagesDesign and Implementation of Welding With Electromagnetic Trailing Peening Control CircuitSamuel ChristyNo ratings yet

- 11 AC Induction Motor TestingDocument12 pages11 AC Induction Motor TestingrajNo ratings yet

- Speed Control of DC MotorDocument48 pagesSpeed Control of DC MotorVivek VickyNo ratings yet

- Design and Implementation of An Automatic Voltage Regulator With A Great Precision and Proper HysteresisDocument13 pagesDesign and Implementation of An Automatic Voltage Regulator With A Great Precision and Proper HysteresisDuy Cao GiaNo ratings yet

- New Approach For Modelling Doubly-Fed Induction Generator (DFIG) For Grid-Connection StudiesDocument13 pagesNew Approach For Modelling Doubly-Fed Induction Generator (DFIG) For Grid-Connection StudiesKhalid HarounNo ratings yet

- Nemesgáz Motor Patent US20110113772 PDFDocument12 pagesNemesgáz Motor Patent US20110113772 PDFGergely HollóNo ratings yet

- Development of An Automatic Arc Welding System Using SMAW ProcessDocument7 pagesDevelopment of An Automatic Arc Welding System Using SMAW ProcessAnonymous g80PbBY73No ratings yet

- Im Cordinate Csi CNTRLDocument11 pagesIm Cordinate Csi CNTRLsandeepbabu28No ratings yet

- AVR492: Brushless DC Motor Control Using AT90PWM3: Application NoteDocument26 pagesAVR492: Brushless DC Motor Control Using AT90PWM3: Application NotenicoletabytaxNo ratings yet

- SCR Drive System Technical Manual OverviewDocument30 pagesSCR Drive System Technical Manual OverviewDda Ddan100% (4)

- Drive Electronics For Moving Magnet Type Linear Motor CompressorDocument9 pagesDrive Electronics For Moving Magnet Type Linear Motor Compressorpad abtNo ratings yet

- Us 20130222183Document18 pagesUs 20130222183noneNo ratings yet

- Moog New Tb117Document24 pagesMoog New Tb117Hammad Ali Zaman100% (1)

- Fixed Frequency Sliding Mode Modulator For Current Mode PWM InvertersDocument7 pagesFixed Frequency Sliding Mode Modulator For Current Mode PWM InvertersPaulo UchihaNo ratings yet

- Altivar Atv66 User ManualDocument52 pagesAltivar Atv66 User ManualNitin SutarNo ratings yet

- O & M Manual For Governor HMCDocument42 pagesO & M Manual For Governor HMCKrishna D91% (11)

- Wind Turbine Generator System Safety and Function Test ReportDocument0 pagesWind Turbine Generator System Safety and Function Test ReportPaul Ramos VegaNo ratings yet

- United States Patent: Lindoerfer Et A) - (10) Patent N0.: (45) Date of PatentDocument9 pagesUnited States Patent: Lindoerfer Et A) - (10) Patent N0.: (45) Date of PatentdollarrbillNo ratings yet

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Si5351A VFO/Signal Generator: 2.1 Modes of OperationDocument9 pagesSi5351A VFO/Signal Generator: 2.1 Modes of OperationIan McNairNo ratings yet

- Main Combi 24 HE User ManualDocument12 pagesMain Combi 24 HE User ManualsleepyninjitsuNo ratings yet

- ESAB Puls Mig Welding Hand BookDocument20 pagesESAB Puls Mig Welding Hand BookLeonardo De La HudiNo ratings yet

- G3RJV Harmonic - Filters Calculation PDFDocument3 pagesG3RJV Harmonic - Filters Calculation PDFIan McNairNo ratings yet

- IXGN200N60ADocument4 pagesIXGN200N60AIan McNairNo ratings yet

- High Performance Drive StructureDocument7 pagesHigh Performance Drive StructureIan McNairNo ratings yet

- Making Inverter Welder - IRFDocument18 pagesMaking Inverter Welder - IRFShaun Dwyer Van Heerden0% (1)

- SUR2x100 06Document3 pagesSUR2x100 06Ian McNairNo ratings yet

- IXGN320N60A3Document5 pagesIXGN320N60A3Ian McNairNo ratings yet

- Controlled Waveform Welding Wire Feeder US20130327753Document27 pagesControlled Waveform Welding Wire Feeder US20130327753Ian McNairNo ratings yet

- Method and Apparatus For Welding With RestrikeDocument9 pagesMethod and Apparatus For Welding With RestrikeIan McNairNo ratings yet

- Consumable Electrode Type D.C. Arc WelderDocument7 pagesConsumable Electrode Type D.C. Arc WelderIan McNairNo ratings yet

- DC Fastmig MF MSF MXF MXP enDocument1 pageDC Fastmig MF MSF MXF MXP enIan McNairNo ratings yet

- Catalog AmorDocument25 pagesCatalog AmorIan McNairNo ratings yet

- Current Transformer Circuits For Power ElectronicslDocument213 pagesCurrent Transformer Circuits For Power ElectronicslJason RobinsonNo ratings yet

- Design of Inductors and HF TransformersDocument6 pagesDesign of Inductors and HF TransformersIan McNairNo ratings yet

- Ss-40ht Assembly Manual v1.1fDocument30 pagesSs-40ht Assembly Manual v1.1fIan McNairNo ratings yet

- Sizing Your Power Converter's Magnetics (Part 1) : Inductor Power Rating With Fixed Input VoltageDocument5 pagesSizing Your Power Converter's Magnetics (Part 1) : Inductor Power Rating With Fixed Input VoltageIan McNairNo ratings yet

- Patent US20060226131-1Document18 pagesPatent US20060226131-1Ian McNairNo ratings yet

- Newcastle Metro MapDocument1 pageNewcastle Metro MapIan McNairNo ratings yet

- Isolated IGBT Gate-Drive Push-Pull Power Supply With 4 OutputsDocument41 pagesIsolated IGBT Gate-Drive Push-Pull Power Supply With 4 OutputsIan McNairNo ratings yet

- Newcastle Metro MapDocument1 pageNewcastle Metro MapIan McNairNo ratings yet

- Scale eDocument0 pagesScale eMallickarjunaNo ratings yet

- Newcastle Metro MapDocument1 pageNewcastle Metro MapIan McNairNo ratings yet

- LM5030 100V Push-Pull Current Mode PWM Controller: Features ApplicationsDocument19 pagesLM5030 100V Push-Pull Current Mode PWM Controller: Features ApplicationsIan McNairNo ratings yet

- Making Inverter Welder - IRFDocument18 pagesMaking Inverter Welder - IRFShaun Dwyer Van Heerden0% (1)

- Zxgd3004e6 8a 40v Gate DriverDocument8 pagesZxgd3004e6 8a 40v Gate DriverIan McNairNo ratings yet

- SMD Relay 60-1278Document6 pagesSMD Relay 60-1278Ian McNairNo ratings yet

- DDS RF Signal Generator Design GuideDocument9 pagesDDS RF Signal Generator Design GuideIan McNairNo ratings yet

- B2.1 8 025 2001PVDocument4 pagesB2.1 8 025 2001PVJaimeNo ratings yet

- Astm A847Document5 pagesAstm A847Mohamed FaroukNo ratings yet

- Aircraft Construction and Repair Chap.2Document8 pagesAircraft Construction and Repair Chap.2Yenoh SisoNo ratings yet

- Root Gap PDFDocument6 pagesRoot Gap PDFmetasoniko81No ratings yet

- Kiefner - Low Frequency ERW and Lap Welded Longitudinal Seam EvaluationDocument99 pagesKiefner - Low Frequency ERW and Lap Welded Longitudinal Seam EvaluationJames PhillipsNo ratings yet

- Lesson 9Document23 pagesLesson 9Huynh Thanh TamNo ratings yet

- AWS A5.6 Spec for Copper Arc Welding ElectrodesDocument6 pagesAWS A5.6 Spec for Copper Arc Welding Electrodesalok987No ratings yet

- GOST 6996-66 Welded Joints Methods For Determining Mechanical PropertiesDocument51 pagesGOST 6996-66 Welded Joints Methods For Determining Mechanical PropertiesSree SudhaNo ratings yet

- CutMaster 52 - Service Manual - 0-4962Document110 pagesCutMaster 52 - Service Manual - 0-4962vikrampatel1986100% (1)

- ASTM A403-A403M-07aDocument8 pagesASTM A403-A403M-07aNadhiraNo ratings yet

- Updated Resume 2016Document4 pagesUpdated Resume 2016Ralph ManuelNo ratings yet

- 2009-04-CEN-TC121 N1574 Working Programme CEN TC 121Document28 pages2009-04-CEN-TC121 N1574 Working Programme CEN TC 121Manuel ValenteNo ratings yet

- Std. QAP of Expension Joints (March 16)Document6 pagesStd. QAP of Expension Joints (March 16)ghaghra bridgeNo ratings yet

- Vocational Diploma Practical Time TbaleDocument5 pagesVocational Diploma Practical Time TbaleSundaramoorthy KaliappanNo ratings yet

- Feature Based Cost and Carbon Emission Modelling For WAAMDocument128 pagesFeature Based Cost and Carbon Emission Modelling For WAAMMark BacklerNo ratings yet

- 913.1183.1 SmartWelding V5 ENDocument78 pages913.1183.1 SmartWelding V5 ENVudayabhaskarNo ratings yet

- Komatsu Pc75uu 3 Shop ManualDocument20 pagesKomatsu Pc75uu 3 Shop ManualRaymond100% (58)

- General Specification of Offshore PlatformsDocument25 pagesGeneral Specification of Offshore Platformshalim_ka100% (1)

- Invertec V160-T: Stick, TIG, Pulsed TIG K1845-1 See Back For Complete SpecsDocument2 pagesInvertec V160-T: Stick, TIG, Pulsed TIG K1845-1 See Back For Complete Specsapi-237777038No ratings yet

- App 037Document19 pagesApp 037Hung Nguyen VanNo ratings yet

- Arc Welding Electrodes (Product Catalogue)Document28 pagesArc Welding Electrodes (Product Catalogue)ddprt123No ratings yet

- Sheet Metal Work BizHouse - UkDocument2 pagesSheet Metal Work BizHouse - UkAlex BekeNo ratings yet

- Tender9 Vol II o II Pig Launcher and Receiver by MeconDocument31 pagesTender9 Vol II o II Pig Launcher and Receiver by MeconVeena S VNo ratings yet

- Barangay Skills Need Survey Form 2-TADIAN MUNICIPALITYDocument230 pagesBarangay Skills Need Survey Form 2-TADIAN MUNICIPALITYshell liwagNo ratings yet

- Report 1 - Process 2Document8 pagesReport 1 - Process 2Jason DignosNo ratings yet

- CX14 Op's ManualDocument194 pagesCX14 Op's Manualap919976No ratings yet

- Fabrication Quality Dossier IndexDocument22 pagesFabrication Quality Dossier IndexAli KayaNo ratings yet

- List of Steel Conference ExhibitorsDocument18 pagesList of Steel Conference ExhibitorsJitendra100% (1)

- Welding Equipment Selection Chart: Manual Machines Hydraulic MachinesDocument2 pagesWelding Equipment Selection Chart: Manual Machines Hydraulic MachinesJOSE GABRIELNo ratings yet

- Identification of Mechanical Properties of Weld Joints of Almgsi07.F25 Aluminium AlloyDocument4 pagesIdentification of Mechanical Properties of Weld Joints of Almgsi07.F25 Aluminium AlloyVisuvaratnam SuseendranNo ratings yet